Design and Optimization of a Process for the Production of Methyl Methacrylate via Direct Methylation

Abstract

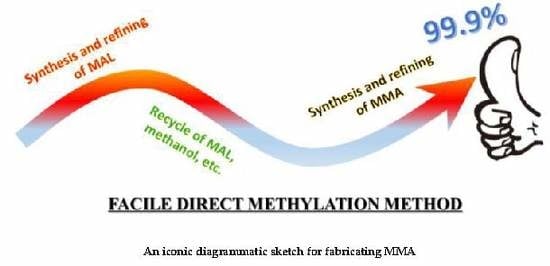

:1. Introduction

2. Simulation and Experimental Methods

2.1. Main Reaction Equation

2.2. Whole Process Design

2.3. Process Simulation

2.3.1. Thermodynamic Method Determination

2.3.2. Process Design

2.3.3. Data Acquisition

3. Results and Discussion

3.1. Process Recycle Design

3.2. Design of a Highly Efficient MAL Absorption Column

3.2.1. MAL Absorber Column Stage

3.2.2. Methanol Absorbent Flow Rate

3.3. Controllable Design for MMA with High Purity

3.3.1. Double-Effect Distillation Design

3.3.2. Design of a Promising Chloroform Recovery Process

3.4. Energy-Saving Optimization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bai, H.; Walsh, F.; Gludovatz, B.; Delettre, B.; Huang, C.L.; Chen, Y.; Tomsic, A.P.; Ritchie, R.O. Bioinspired hydroxyapatite/poly(methyl methacrylate) composite with nacre-mimetic architecture by a bidirectional freezing method. Adv. Mater. 2016, 28, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Engelis, N.G.; Anastasaki, A.; Nurumbetov, G.; Truong, N.P.; Nikolaou, V.; Shegiwal, A.; Whittaker, M.R.; Davis, D.P.; Haddleton, D.M. Sequence-controlled methacrylic multiblock copolymers via sulfur-free raft emulsion polymerization. Nat. Chem. 2016, 9, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Ogura, Y.; Terashima, T.; Sawamoto, M. Terminal-selective transesterification of chlorine-capped poly(methyl methacrylate)s: A modular approach to telechelic and pinpoint-functionalized polymers. J. Am. Chem. Soc. 2016, 138, 5012–5015. [Google Scholar] [CrossRef] [PubMed]

- Bendic, V.; Dobrotă, D.; Dobrescu, T.; Enciu, G.; Pascu, N.E. Rheological issues of phase change materials obtained by the complex coacervation of butyl stearate in poly methyl methacrylate membranes. Energies 2019, 12, 917. [Google Scholar] [CrossRef]

- Wang, X.Y.; Sun, X.L.; Wang, F.; Tang, Y. SaBOX/copper catalysts for highly syndio-specific atom transfer radical polymerization of methyl methacrylate. ACS Catal. 2017, 7, 4692–4696. [Google Scholar] [CrossRef]

- Singh, M.K.; Shokuhfar, T.; Gracio, J.J.A.; Sousa, A.C.M.; Fereira, J.M.D.F.; Garmestani, H.; Ahzi, S. Hydroxyapatite modified with carbon-nanotube-reinforced poly(methyl methacrylate): A nanocomposite material for biomedical applications. Adv. Funct. Mater. 2008, 18, 694–700. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Hirao, M.; Ookubo, T.; Sasaki, A. Design of recycling system for poly (methyl methacrylate) (PMMA). Part 1: Recycling scenario analysis. Int. J. Life Cycle Assess. 2014, 19, 120–129. [Google Scholar] [CrossRef]

- Yannicelli, S. Nutrition therapy of organic acidaemias with amino acid-based formulas: Emphasis on methylmalonic and propionic acidaemia. J. Inherit. Met. Dis. 2006, 29, 281–287. [Google Scholar] [CrossRef]

- Luda, M.P.; Zanetti, M. Cyclodextrins and cyclodextrin derivatives as green char promoters in flame retardants formulations for polymeric materials. A review. Ploymers 2019, 11, 664. [Google Scholar] [CrossRef]

- Patil, R.R.; Turgman-Cohen, S.; Šrogl, J.; Kiserow, D.; Genzer, J. On-demand degrafting and the study of molecular weight and grafting density of poly(methyl methacrylate) brushes on flat silica substrates. Langmuir 2015, 31, 2372–2381. [Google Scholar] [CrossRef]

- Spivey, J.J.; Gogate, M.R.; Zoeller, J.R.; Colberg, R.D. Novel catalysts for the environmentally friendly synthesis of methyl methacrylate. Ind. Eng. Chem. Res. 1997, 36, 4600–4608. [Google Scholar] [CrossRef]

- Nagai, K. New developments in the production of methyl methacrylate. Appl. Catal. A Gen. 2001, 221, 367–377. [Google Scholar] [CrossRef]

- Lei, L.; Tao, R.; Shi, J.; Jing, X.; Ma, H.H. Rapid and continuous synthesis of methacrolein with high selectivity by condensation of propanal with formaldehyde in laboratory. Can. J. Chem. Eng. 2017, 95, 1985–1992. [Google Scholar] [CrossRef]

- Yan, R.Y.; Li, Z.X.; Diao, Y.Y.; Fu, C.; Wang, H.; Li, C.S.; Chen, Q.; Zhang, X.P.; Zhang, S.J. Green process for methacrolein separation with ionic liquids in the production of methyl methacrylate. AIChE J. 2011, 9, 2388–2396. [Google Scholar] [CrossRef]

- Wu, Y.C.; Hsu, C.S.; Huang, H.P.; Chien, I.L. Design and control of a methyl methacrylate separation process with a middle decanter. Ind. Eng. Chem. Res. 2011, 50, 4595–4607. [Google Scholar] [CrossRef]

- Chang, W.L.; Chien, I.L. Energy-saving design and control of a methyl methacrylate separation process. Ind. Eng. Chem. Res. 2016, 55, 3064–3074. [Google Scholar] [CrossRef]

- Mizuno, N.; Han, W.; Kudo, T.; Iwamoto, M. Direct oxidation of isobutane into methacrylic acid over Cs, Ni, and v-substituted H3PMo12O40 heteropoly compounds. Stud. Surf. Sci. Catal. 1996, 101, 1001–1010. [Google Scholar]

- Yamamatsu, S.; Yamaguchi, T.; Yokota, K.; Nagano, O.; Chono, M.; Aoshima, A. Development of catalyst technology for producing methyl methacrylate (MMA) by direct methyl esterification. Catal. Surv. Asia 2010, 14, 124–131. [Google Scholar] [CrossRef]

- Diao, Y.Y.; He, H.Y.; Yang, P.; Wang, L.; Zhang, S.J. Optimizing the structure of supported Pd catalyst for direct oxidative esterification of methacrolein with methanol. Chem. Eng. Sci. 2015, 135, 128–136. [Google Scholar] [CrossRef]

- Delikonstantis, E.; Scapinello, M.; Stefanidis, G.D. Process modeling and evaluation of Plasma-assisted ethylene production from methane. Processes 2019, 7, 68. [Google Scholar] [CrossRef]

- Yu, N.; Li, L.M.; Chen, M.Q.; Wang, J.X.; Liu, D.; Sun, L.Y. Novel reactive distillation process with two side streams for dimethyl adipate production. Chem. Eng. Process. 2017, 118, 9–18. [Google Scholar] [CrossRef]

- Delikonstantis, E.; Scapinello, M.; Stefanidis, G.D. Investigating the plasma-assisted and thermal catalytic dry methane reforming for syngas production: Process design, simulation and evaluation. Energies 2017, 10, 1429. [Google Scholar] [CrossRef]

- Vikse, M.; Watson, H.A.J.; Gundersen, T.; Barton, P.I. Simulation of dual mixed refrigerant natural gas liquefaction processes using a nonsmooth framework. Processes 2018, 6, 193. [Google Scholar] [CrossRef]

- Zhai, R.R.; Liu, H.T.; Wu, H.; Yu, H.; Yang, Y.P. Analysis of Integration of mea-based CO2 capture and solar energy system for coal-based power plants based on thermo-economic structural theory. Energies 2018, 11, 1284. [Google Scholar] [CrossRef]

- Sarda, P.; Hedrick, E.; Reynolds, K.; Bhattacharyya, D.; Zitney, S.E.; Omell, B. Development of a dynamic model and control system for load-following studies of supercritical pulverized coal power plants. Processes 2018, 6, 226. [Google Scholar] [CrossRef]

- Tian, W. Study on Catalysts for Selective Oxidation of Isobutylene to Methacrolein; Jiangnan University: Wuxi, China, 2008. [Google Scholar]

- Li, G.H.; Zhang, S.J.; Li, Z.X.; Li, M.X.; Zhao, W. Preparation of methyl methacrylate by one-step oxidative esterification of methacrolein. Chin. J. Process Eng. 2004, 4, 508–512. [Google Scholar]

- Jin, L.L.; Zhang, C.Y.; Fei, X.J. Realizing energy savings in integrated process planning and scheduling. Processes 2019, 7, 120. [Google Scholar] [CrossRef]

- Guo, X.G.; Li, X.M.; Lai, C.; Jiang, X.; Li, X.L.; Shu, Y.J. Facile approach to the green synthesis of novel ternary composites with excellent superhydrophobic and thermal stability property: An expanding horizon. Chem. Eng. J. 2017, 309, 240–248. [Google Scholar] [CrossRef]

- Yang, H.C.; Xie, Y.S.; Hou, J.W.; Cheetham, A.K.; Chen, V.; Darling, S.B. Janus membranes: Creating asymmetry for energy efficiency. Adv. Mater. 2018, 30, 1801495–1801506. [Google Scholar] [CrossRef]

- Guo, X.G.; Lai, C.; Jiang, X.; Mi, W.H.; Yin, Y.J.; Li, X.M.; Shu, Y.J. Remarkably facile fabrication of extremely superhydrophobic high-energy binary composite with ultralong lifespan. Chem. Eng. J. 2018, 335, 843–854. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, T.; Guo, X.; Giwa, A.S.; Shi, J.; Li, Y.; Wei, Y.; Wang, X.; Cao, X.; Tang, X.; Du, J. Design and Optimization of a Process for the Production of Methyl Methacrylate via Direct Methylation. Processes 2019, 7, 377. https://doi.org/10.3390/pr7060377

Liang T, Guo X, Giwa AS, Shi J, Li Y, Wei Y, Wang X, Cao X, Tang X, Du J. Design and Optimization of a Process for the Production of Methyl Methacrylate via Direct Methylation. Processes. 2019; 7(6):377. https://doi.org/10.3390/pr7060377

Chicago/Turabian StyleLiang, Taotao, Xiaogang Guo, Abdulmoseen Segun Giwa, Jianwei Shi, Yujin Li, Yan Wei, Xiaojuan Wang, Xuansong Cao, Xiaofeng Tang, and Jialun Du. 2019. "Design and Optimization of a Process for the Production of Methyl Methacrylate via Direct Methylation" Processes 7, no. 6: 377. https://doi.org/10.3390/pr7060377