Performance Evaluation of Sustainable Soil Stabilization Process Using Waste Materials

Abstract

:1. Introduction

2. Waste Materials and the Circular Economy Principle

3. Materials and Methods

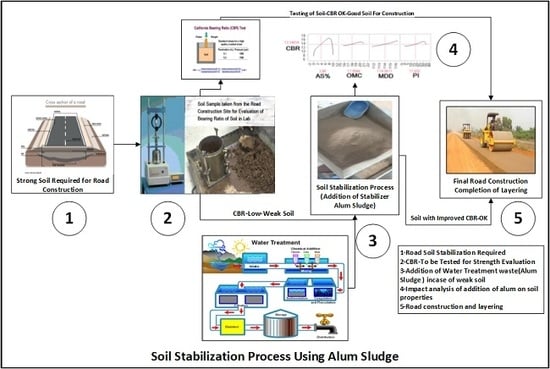

3.1. Experimental Framework

- Step 1: Site Selection and Soil Sample Collection;

- Step 2: Soil Stabilizer (Alum Sludge) Addition;

- Step 3: Particle Size Analysis;

- Step 4: Atterberg Limits Tests and Modified Proctor Test;

- Step 5: California Bearing Ratio (CBR) Test;

- Step 6: Statistical Analysis-Application of ANNs;

- Step 7: Profile Analysis of Soil and Decision Making.

3.2. Site Selection and Sample Collection

3.3. Soil Stabilizer (Alum Sludge) Addition

3.4. Particle Size Analysis

3.5. Atterberg Limits Tests and Modified Proctor Test

3.6. California Bearing Ratio (CBR)

4. Results and Discussion

4.1. Impact of Alum Sludge Addition on California Bearing Ratio (CBR)

4.2. Application of Artificial Neural Networks (ANNs)

4.3. Model Parameters

4.4. Impact Analysis of Variables

4.5. Interactional Profile Analysis

4.6. Variable Importance Analysis

5. Practical Implications of the Study

6. Conclusions and Future Recommendations

Author Contributions

Funding

Conflicts of Interest

Notation

| CBR | California bearing ratio |

| PI | Plasticity index |

| LL | Liquid Limit |

| MC | Moisture Content |

| MDD | Maximum dry density |

| OMC | Optimum moisture content |

| USCS | Unified soil classification system |

| AASHTO | American Association of State Highway and Transportation Officials |

References

- Ouyang, C.F.; Xu, Z.L.; Lan, W.Z. Study of the treatment and reuse of municipal sewage treatment plant sludge. In Proceedings of the 8th Annual Meeting Sanitary Engineering, Taipei, Taiwan, 1998. [Google Scholar]

- Tay, J.-H.; Show, K.-Y. The use of lime-blended sludge for production of cementitious material. Environ. Res. 1992, 64, 6–12. [Google Scholar] [CrossRef]

- Yang, C.P.; Hong, G.S. The soil properties of the estuary with mangrove habitat and its improvement. J. Chin. Agric. Eng. 2005, 51, 1–11. [Google Scholar]

- Lin, D.-F.; Luo, H.-L.; Hsiao, D.-H.; Yang, C.-C. The effects of sludge ash on the strength of soft subgrade soil. J. Chin. Inst. Environ. Eng. 2005, 15, 1–10. [Google Scholar]

- Lin, D.-F.; Lin, K.-L.; Hung, M.-J.; Luo, H.-L. Sludge ash/hydrated lime on the geotechnical properties of soft soil. J. Hazard. Mater. 2007, 145, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Lin, D.-F. Stabilization treatment of soft subgrade soil by sewage sludge ash and cement. J. Hazard. Mater. 2009, 162, 321–327. [Google Scholar] [CrossRef] [PubMed]

- Rajeswari, K.; Naidu, C.D.; Rao, K.B.; Kumari, G.H. Study of soil stabalization on subgrade using bagasse ash and phosphogypsum. Int. J. Technol. Res. Eng. 2018, 5, 3133–3142. [Google Scholar]

- Yadav, A.K.; Gaurav, K.; Kishor, R.; Suman, S. Stabilization of alluvial soil for subgrade using rice husk ash, sugarcane bagasse ash and cow dung ash for rural roads. Int. J. Pavement Technol. 2017, 10, 254–261. [Google Scholar] [CrossRef]

- Seleiman, M.F.; Kheir, A.M. Saline soil properties, quality and productivity of wheat grown with bagasse ash and thiourea in different climatic zones. Chemosphere 2018, 193, 538–546. [Google Scholar] [CrossRef]

- Hasan, H.; Dang, L.; Khabbaz, H.; Fatahi, B.; Terzaghi, S. Remediation of Expansive Soils Using Agricultural Waste Bagasse Ash. Procedia Eng. 2016, 143, 1368–1375. [Google Scholar] [CrossRef] [Green Version]

- Jamsawang, P.; Poorahong, H.; Yoobanpot, N.; Songpiriyakij, S.; Jongpradist, P. Improvement of soft clay with cement and bagasse ash waste. Constr. Mater. 2017, 154, 61–71. [Google Scholar] [CrossRef]

- Muntohar, A.S. Utilization of uncontrolled burnt rice husk ash in soil improvement. Civ. Eng. Dimens. 2004, 4, 100–105. [Google Scholar]

- Okagbue, C.O.; Yakubu, J.A. Limestone ash waste as a substitute for lime in soil improvement for engineering construction. Eng. Geol. 2000, 58, 107–113. [Google Scholar] [CrossRef]

- Sezer, A.; Inan, G.; Yılmaz, H.R.; Ramyar, K. Utilization of a very high lime fly ash for improvement of Izmir clay. Build. Environ. 2006, 41, 150–155. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H.; Sabbar, A.S. Effect of flyash on liquefaction behaviour of sand-bentonite mixture. Soils Found. 2018, 58, 1288–1296. [Google Scholar] [CrossRef]

- Al-Malack, M.H.; Abdullah, G.M.; Al-Amoudi, O.S.B.; Bukhari, A.A. Stabilization of indigenous Saudi Arabian soils using fuel oil flyash. J. King Saud Univ. Eng. Sci. 2016, 28, 165–173. [Google Scholar] [CrossRef] [Green Version]

- Basha, E.; Hashim, R.; Mahmud, H.; Muntohar, A. Stabilization of residual soil with rice husk ash and cement. Constr. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef] [Green Version]

- Rifa’i, A.; Yasufuku, N.; Tsuji, K. Characterization and effective utilization of coal ash as soil stabilization on road application. In Proceedings of the International Symposium on Ground Improvement Technologies and Case Histories, ISGI’09, Singapore, 9–12 December 2009. [Google Scholar]

- Sharma, A.K.; Sivapullaiah, P. Improvement of strength of expansive soil with waste granulated blast furnace slag. In GeoCongress 2012: State of the Art and Practice in Geotechnical Engineering; American Society of Civil Engineers: Oakland, CA, USA, 2012; pp. 3920–3928. [Google Scholar]

- Sharma, A.K.; Sivapullaiah, P. Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils Found. 2016, 56, 205–212. [Google Scholar] [CrossRef]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.-L.; Chindaprasirt, P. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef]

- Türkmen, I. Influence of different curing conditions on the physical and mechanical properties of concretes with admixtures of silica fume and blast furnace slag. Mater. Lett. 2003, 57, 4560–4569. [Google Scholar] [CrossRef]

- Solanki, P.; Khoury, N.; Zaman, M. Engineering behavior and microstructure of soil stabilized with cement kiln dust. In In Soil Improvement; American Society of Civil Engineers: Denver, CO, USA, 2007; pp. 1–10. [Google Scholar]

- Al-Homidy, A.A.; Dahim, M.H.; El Aal, A.K.A. Improvement of geotechnical properties of sabkha soil utilizing cement kiln dust. J. Rock Mech. Geotech. Eng. 2017, 9, 749–760. [Google Scholar] [CrossRef]

- Mosa, A.M.; Taher, A.H.; Al-Jaberi, L.A. Improvement of poor subgrade soils using cement kiln dust. Case Stud. Constr. Mater. 2017, 7, 138–143. [Google Scholar] [CrossRef]

- Owaid, H.M.; Hamid, R.; Taha, M. Influence of thermally activated alum sludge ash on the engineering properties of multiple-blended binders concretes. Constr. Mater. 2014, 61, 216–229. [Google Scholar] [CrossRef]

- USGS. Bauxite and Alumina Statistics and Information; USGS Mineral Industry Surveys: Reston, VA, USA, 2009.

- AZoM. Alumina (Aluminium Oxide)—The Different Types of Commercially Available Grades. 2002. Available online: https://www.azom.com/article.aspx?ArticleID=1389 (accessed on 10 January 2019).

- Eddy, M. Wastewater Engineering-Treatment, Disposal, Reuse; INC.: New York, NY, USA, 1979; p. 473. [Google Scholar]

- Reed, S.C.; Crites, R.W.; Middlebrooks, E.J. Natural Systems for Waste Management and Treatment; McGraw-Hill, Inc.: New York, NY, USA, 1995. [Google Scholar]

- Millar, N.; McLaughlin, E.; Börger, T. The Circular Economy: Swings and Roundabouts? Ecol. Econ. 2019, 158, 11–19. [Google Scholar] [CrossRef]

- Falcone, P.; Imbert, E. Social Life Cycle Approach as a Tool for Promoting the Market Uptake of Bio-Based Products from a Consumer Perspective. Sustainability 2018, 10, 1031. [Google Scholar] [CrossRef]

- Stahel, W.R. The circular economy. Nat. News 2016, 531, 435. [Google Scholar] [CrossRef] [PubMed]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Bartolacci, F.; Paolini, A.; Quaranta, A.G.; Soverchia, M. Assessing factors that influence waste management financial sustainability. Waste Manag. 2018, 79, 571–579. [Google Scholar] [CrossRef]

- Falcone, P.M.; Sica, E. Assessing the Opportunities and Challenges of Green Finance in Italy: An Analysis of the Biomass Production Sector. Sustainability 2019, 11, 517. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Müller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the circular economy: evidence from the european union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Falcone, P.M.; Morone, P.; Sica, E. Greening of the financial system and fuelling a sustainability transition: A discursive approach to assess landscape pressures on the Italian financial system. Technol. Forecast. Soc. Chang. 2018, 127, 23–37. [Google Scholar] [CrossRef]

- Mazzucato, M.; Semieniuk, G. Financing renewable energy: Who is financing what and why it matters. Technol. For. Soc. Chang. 2018, 127, 8–22. [Google Scholar] [CrossRef]

- Burmister, D.M. Principles and techniques of soil identification. In Proceedings of the Highway Research Board, Washington, DC, USA, 13–16 December 1949. [Google Scholar]

- Semen, P.M. A Generalized Approach to Soil Strength Prediction with Machine Learning Methods; Technical Report ERDC/CRREL TR-06-15; Engineer Research and Development Center, Cold Regions Research and Engineering Laboratory: Hanover, Germany, 2006. [Google Scholar]

- Black, W.P.M. A method of estimating the california bearing ratio of cohesive soils from plasticity data. Géotechnique 1962, 12, 271–282. [Google Scholar] [CrossRef]

- De Graft-Johnson, J.; Bhatia, H.; Gidigasu, D. The engineering characteristics of the laterite gravels of Ghana. In Proceedings of the 7th international conference on soil mechanics and foundation engineering, San Fandila, Mexico, 21 July 1969. [Google Scholar]

- Agarwal, K.; Ghanekar, K. Prediction of CBR from plasticity characteristics of soil. In Proceeding of the 2nd south-east Asian conference on soil engineering, Singapore, 11–15 June 1970. [Google Scholar]

- Doshi, S.; Mesdary, M.; Guirguis, H. A statistical study of laboratory CBR for Kuwaiti soils. In Proceedings of the 4th Conference on Road Engineering Association of Asia and Australasia, Jakarta, Indonesia, 22–26 August 1983. [Google Scholar]

- Stephens, D. The prediction of the California bearing ratio. J. South Afr. Inst. Civ. Eng. 1990, 32, 523–528. [Google Scholar]

- NCHRP. Guide for Mechanistic–Empirical Design of New and Rehabilitated Pavement Structures. In In Appendix CC-1: Correlation of CBR Values with Soil Index Properties, Final Report, NCHRP Project 1-37A; ERES Consultants Division, West University Avenue, ARA, Inc.: Champaign, IL, USA, 2001. [Google Scholar]

- Mansoor, J.; Shah, S.A.R.; Khan, M.M.; Sadiq, A.N.; Anwar, M.K.; Siddiq, M.U.; Ahmad, H. Analysis of Mechanical Properties of Self Compacted Concrete by Partial Replacement of Cement with Industrial Wastes under Elevated Temperature. Appl. Sci. 2018, 8, 364. [Google Scholar] [CrossRef]

- Shah, S.; Brijs, T.; Ahmad, N.; Pirdavani, A.; Shen, Y.; Basheer, M. Road Safety Risk Evaluation Using GIS-Based Data Envelopment Analysis—Artificial Neural Networks Approach. Appl. Sci. 2017, 7, 886. [Google Scholar] [CrossRef]

| Components | Percentage |

|---|---|

| Al2O3 | 37.85% |

| Fe2O3 | 14.97% |

| CaO | 1.20% |

| MgO | 0.60% |

| Na2O | 0.86% |

| K2O | 1.73% |

| SiO2 | 28.91% |

| TiO2 | 0.92% |

| SO3 | 0.78% |

| Rb2O | 0.04% |

| P2O5 | 0.42% |

| Others | 0.95% |

| Loss on ignition | 10.77% |

| Sample | Alum Sludge (%) | USCS Symbol | OMC (%) | MDD (lb/ft³) | MDD (KN/m3) | LL (%) | PL (%) | PI (%) |

|---|---|---|---|---|---|---|---|---|

| S 1 | 0 | CH | 21 | 111.7 | 17.55 | 56 | 21 | 35 |

| S 2 | 0 | CH | 20 | 112.5 | 17.67 | 54 | 20 | 34 |

| S 3 | 0 | CH | 20.5 | 112.1 | 17.61 | 55 | 22.2 | 32.8 |

| Sample | Sample Detail | Moisture Content (%) | Sample | Sample Detail | Moisture Content (%) |

|---|---|---|---|---|---|

| S-1 | S-1-Optimum | 21 | S-10 | S-10-Optimum | 16.2 |

| S-1-Dry | 16.1 | S-10-Dry | 11.7 | ||

| S-1-Wet | 27.4 | S-10-Wet | 21.8 | ||

| S-2 | S-2-Optimum | 20 | S-11 | S-11-Optimum | 16.5 |

| S-2-Dry | 15.3 | S-11-Dry | 12 | ||

| S-2-Wet | 26.5 | S-11-Wet | 20.6 | ||

| S-3 | S-3-Optimum | 20.5 | S-12 | S-12-Optimum | 16.6 |

| S-3-Dry | 15.8 | S-12-Dry | 12.4 | ||

| S-3-Wet | 27 | S-12-Wet | 21.6 | ||

| S-4 | S-4-Optimum | 19 | S-13 | S-13-Optimum | 15.8 |

| S-4-Dry | 13.7 | S-13-Dry | 11.6 | ||

| S-4-Wet | 21.5 | S-13-Wet | 20.7 | ||

| S-5 | S-5-Optimum | 18 | S-14 | S-14-Optimum | 16 |

| S-5-Dry | 12.6 | S-14-Dry | 12.5 | ||

| S-5-Wet | 21.2 | S-14-Wet | 21 | ||

| S-6 | S-6-Optimum | 18.6 | S-15 | S-15-Optimum | 16.1 |

| S-6-Dry | 13.4 | S-15-Dry | 12.8 | ||

| S-6-Wet | 20.9 | S-15-Wet | 20.2 | ||

| S-7 | S-7-Optimum | 17.4 | S-16 | S-16-Optimum | 19.5 |

| S-7-Dry | 13.8 | S-16-Dry | 12.9 | ||

| S-7-Wet | 21.3 | S-16-Wet | 22.1 | ||

| S-8 | S-8-Optimum | 17 | S-17 | S-17-Optimum | 19 |

| S-8-Dry | 12.1 | S-17-Dry | 10.4 | ||

| S-8-Wet | 22.8 | S-17-Wet | 21 | ||

| S-9 | S-9-Optimum | 17.5 | S-18 | S-18-Optimum | 19.2 |

| S-9-Dry | 12.9 | S-18-Dry | 13.6 | ||

| S-9-Wet | 22.5 | S-18-Wet | 22.8 |

| Variable | Description | Mean | SD | Min. | Med. | Max. |

|---|---|---|---|---|---|---|

| CBR | California Bearing Ratio | 12.19 | 3.801 | 6.53 | 13 | 16.86 |

| AS (%) | Alum Sludge | 5 | 3.515 | 0 | 5 | 10 |

| PI | Plasticity Index | 17.6 | 11.72 | 0 | 16.84 | 35 |

| OMC | Optimum Moisture Content | 17.994 | 1.659 | 15.8 | 17.75 | 21 |

| MDD | Max. Dry Density | 114.06 | 1.63 | 111.7 | 114.4 | 116.4 |

| Parameter | H1_1 | H1_2 | H1_3 | H1_4 |

|---|---|---|---|---|

| AS (%) | 0.778894 | 0.586618 | 0.034067 | −0.36091 |

| OMC | −0.67213 | −0.02785 | 0.14313 | −0.10689 |

| MDD | −0.45533 | 0.020422 | −1.21731 | −0.01654 |

| PI | −0.654 | 0.001748 | −0.74646 | 0.076513 |

| Intercept | 1.451715 | −0.92283 | −1.35736 | -0.05674 |

| CBR | 2.342307 | 8.766582 | −0.16405 | 2.38735 |

| Estimates | Training | Validation | Remarks |

|---|---|---|---|

| R2 | 0.9997552 | 1.0000000000 | V. Good |

| RMSE | 0.0582346 | 0.0000000007 | V. Good |

| Sum Freq | 15 | 3 | As per standard |

| Variables | Main Effect | Total Effect | Visuals |

|---|---|---|---|

| AS (%) | 0.918 | 0.977 |  |

| PI | 0.02 | 0.058 |  |

| OMC | 0.011 | 0.039 |  |

| MDD | 0.012 | 0.034 |  |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aamir, M.; Mahmood, Z.; Nisar, A.; Farid, A.; Ahmed Khan, T.; Abbas, M.; Ismaeel, M.; Shah, S.A.R.; Waseem, M. Performance Evaluation of Sustainable Soil Stabilization Process Using Waste Materials. Processes 2019, 7, 378. https://doi.org/10.3390/pr7060378

Aamir M, Mahmood Z, Nisar A, Farid A, Ahmed Khan T, Abbas M, Ismaeel M, Shah SAR, Waseem M. Performance Evaluation of Sustainable Soil Stabilization Process Using Waste Materials. Processes. 2019; 7(6):378. https://doi.org/10.3390/pr7060378

Chicago/Turabian StyleAamir, Muhammad, Zarnish Mahmood, Aqsa Nisar, Amjad Farid, Tanveer Ahmed Khan, Mudassir Abbas, Muhammad Ismaeel, Syyed Adnan Raheel Shah, and Muhammad Waseem. 2019. "Performance Evaluation of Sustainable Soil Stabilization Process Using Waste Materials" Processes 7, no. 6: 378. https://doi.org/10.3390/pr7060378