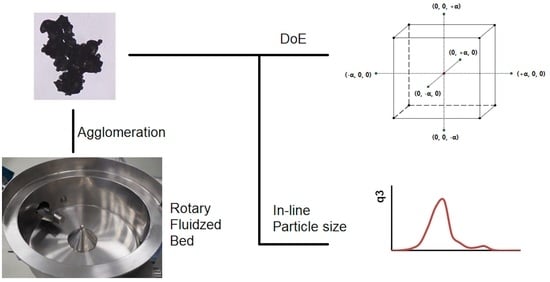

Statistical Investigation of Rotary Fluidized Bed Agglomeration Process with Tangential Spray and In-Line Particle Size Measurement for PAT Process Control

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Rotary Fluidized Bed Process

2.3. Central Composite Design

2.4. Particle Size Measurement

3. Results and Discussion

3.1. Statistical Evaluation of CCD

3.1.1. Statistical Evaluation of Median (x50.3)

3.1.2. Statistical Evaluation of CoV (x50.3)

3.2. Comparison of Particle Size Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| API | active pharmaceutical ingredient |

| CCD | central composite design |

| CLD | chord length distribution |

| CoV (x50.3) | coefficient of variation of median |

| DIA | dynamic image analysis |

| GPCG | Glatt pelletization, coating, and granulating apparatus |

| MCC | microcrystalline cellulose |

| PAT | process analytical technology |

| SD SFV | standard deviation spatial filter velocimetry |

| x50.3 | median of particle size distribution |

References

- Parikh, D.M. Handbook of Pharmaceutical Granulation Technology, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar]

- Priese, F.; Wolf, B. Development of high drug loaded pellets by Design of Experiment and population balance model calculation. Powder Technol. 2013, 241, 149–157. [Google Scholar] [CrossRef]

- Uhlemann, H.; Mörl, L. Wirbelschicht—Sprühgranulation, 1st ed.; Springer: Berlin, Germany, 2014. [Google Scholar]

- Priese, F.; Frisch, T.; Wolf, B. Comparison of film—Coated retarded release pellets manufactured by layering technique or by bed rotor pelletization. Pharm. Dev. Technol. 2015, 20, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Serno, P.; Kleinebudde, P.; Knop, K. Granulieren: Grundlagen, Verfahren, Formulierungen, 2nd ed.; ECV Editio Cantor Verlag: Aulendorf, Germany, 2016. [Google Scholar]

- Parikh, D.M. How to Optimize Fluid Bed Processing Technology: Part of the Expertise in Pharmaceutical Process Technology Series; Elsevier Academic Press: London, UK; San Diego, CA, USA; Cambridge, MA, USA; Oxford, UK, 2017. [Google Scholar]

- Gajdos, B. Rotorgranulatoren—Verfahrenstechnische Bewertung der Pelletherstellung mit Hilfe der faktoriellen Versuchsplanung. Pharm. Ind. 1983, 45, 722–728. [Google Scholar]

- Vertommen, J.; Kinget, R. The Influence of Five Selected Processing and Formulation Variables on the Particle Size, Particle Size Distribution and Friability of Pellets Produced in a Rotary Processor. Drug Dev. Ind. Pharm. 1997, 23, 39–46. [Google Scholar] [CrossRef]

- Kristensen, J.; Schæfer, T.; Kleinebudde, P. Direct Pelletization in a Rotary Processor Controlled by Torque Measurements. I. Influence of Process Variables. Pharm. Dev. Technol. 2000, 5, 247–256. [Google Scholar] [CrossRef] [PubMed]

- Pisek, R.; Planinsek, O.; Tus, M.; Srcic, S. Influence of Rotational Speed and Surface of Rotating Disc on Pellets Produced by Direct Rotor Pelletization. Pharm. Ind. 2000, 62, 312–319. [Google Scholar]

- Bouffard, J.; Dumont, H.; Bertrand, F.; Legros, L. Optimization and scale-up of a fluid bed tangential spray rotorgranulation process. Int. J. Pharm. 2006, 335, 54–62. [Google Scholar] [CrossRef] [PubMed]

- Pašić, M.; Betz, G.; Hadžidedić, Š.; Kocova El-Arini, S.; Leuenberger, H. Investigation and development of robust process for direct pelletization of lansoprazole in fluidized bed rotary processor using experimental design. J. Drug Deliv. Sci. Technol. 2010, 20, 367–376. [Google Scholar] [CrossRef]

- Neuwirth, J.; Antonyuk, S.; Heinrich, S.; Jacob, M. CFD-DEM study and direct measurement of the granular flow in a rotor granulator. Chem. Eng. Sci. 2013, 86, 151–163. [Google Scholar] [CrossRef]

- Food and Drug Administration, Guidance for Industry: PAT—A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance Guidance for Industry. Rockville, October 2004. Available online: https://www.fda.gov/media/71012/download (accessed on 30 March 2023).

- Bundesministerium für Forschung und Bildung. Industrie 4.0, Innovationen im Zeitalter Der Digitalisierung; Bundesministerium für Forschung und Bildung: Berlin, Germany, 2020; Available online: https://www.bmbf.de/SharedDocs/Publikationen/de (accessed on 30 March 2023).

- Aizu, Y.; Asakura, T. Spatial Filtering Velocimetry: Fundamentals and Applications; Springer: Berlin, Germany, 2006. [Google Scholar]

- Fischer, C.; Peglow, M.; Tsotsas, E. Restoration of particle size distributions from fiber-optical in-line measurements in fluidized bed processes. Chem. Eng. Sci. 2011, 66, 2842–2852. [Google Scholar] [CrossRef]

- Petrak, D.; Dietrich, S.; Eckardt, G.; Köhler, M. In-line particle sizing for real-time process control by fibre-optical spatial filtering technique (SFT). Adv. Powder Technol. 2011, 22, 203–208. [Google Scholar]

- Silva, A.F.T.; Burggraeve, A.; Denon, Q.; van der Meeren, P.; Sandler, N.; van den Kerkhof, T.; Hellings, M.; Vervaet, C.; Remon, J.P.; Lopes, J.A.; et al. Particle sizing measurements in pharmaceutical applications: Comparison of in-process methods versus off-line methods. Eur. J. Pharm. Biopharm. 2013, 85, 1006–1018. [Google Scholar] [CrossRef] [PubMed]

- Kukec, S.; Hudovornik, G.; Dreu, R.; Vrečer, F. Study of granule growth kinetics during in situ fluid bed melt granulation using in-line FBRM and SFT probes. Drug Dev. Ind. Pharm. 2014, 40, 952–959. [Google Scholar] [CrossRef] [PubMed]

- Wiegel, D.; Eckardt, G.; Priese, F.; Wolf, B. In-line particle size measurement and agglomeration detection of pellet fluidized bed coating by Spatial Filter Velocimetry. Powder Technol. 2016, 301, 261–267. [Google Scholar] [CrossRef]

- Schaeper, M.; Damaschke, N. Fourier-based layout for grating function structure in spatial filtering velocimetry. Meas. Sci. Technol. 2017, 28, 55008. [Google Scholar] [CrossRef]

- Petrak, D.; Eckardt, G.; Dietrich, S.; Köhler, M.; Wiegel, D.; Wolf, B.; Priese, F.; Jacob, M. Inline-Messung von Schicht-dicke, Agglomeratanteil und Sprühtrocknung beim Pelletcoating in der Wirbelschicht. Einsatz einer In-line-Partikelsonde als PAT-Instrument zur Echtzeit-Überwachung. Pharm. Ind. 2018, 80, 262–270. [Google Scholar]

- Langner, L.; Kitzmann, I.; Ruppert, A.-L.; Wittich, I.; Wolf, B. In-line particle size measurement and process influences on rotary fluidized bed agglomeration. Powder Technol. 2020, 364, 673–679. [Google Scholar] [CrossRef]

- Langner, M. Inline-Partikelgrößenbestimmung auf Basis der Ortsfilteranemometrie im Rotor-Wirbelschichtprozess. Ph.D. Thesis, Otto-von-Guericke-Universität, Magdeburg, Germany, 25 April 2022. [Google Scholar]

- Dietrich, S.; Köhler, M. Personal Communication; Parsum GmbH.: Chemnitz, Germany, 2017. [Google Scholar]

- Grundwerk, Bundesinstitut für Arzneimittel und Medizinprodukte. Europäisches Arzneibuch. Amtliche Deutsche Ausgabe, 9th ed.; Deutscher Apotheker Verlag: Stuttgart, Germany, 2019. [Google Scholar]

- Rasch, B. Quantitative Methoden 1: Einführung in Die Statistik; Springer Medizin Verlag Heidelberg: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

| Content [w/w] | |

|---|---|

| Sodium benzoate | 56.4 |

| Microcrystalline cellulose | 28.6 |

| Polyvinylpyrrolidone | 5.0 |

| Polyethylene glycol 6000 | 10.0 |

| 100.0 |

| Process Parameter | Setting |

|---|---|

| Spray rate (g/min) | 11.5–21.5 |

| Spray pressure (bar) | 1.4–2.2 |

| Rotor speed (rpm) | 300–1000 |

| Process air temperature (°C) | 70–90 |

| Process air volumetric flow (m3/h) | 35–60 |

| Difference pressure above rotor disk (Pa) | 450 |

| Spray nozzle diameter (mm) | 1.0 |

| Position of spray nozzle cap (scales) | 2 |

| Distance of spray nozzle (cm) | 3 |

| Batch size (g) | 350 |

| Factor | Level Adjustment | ||||

|---|---|---|---|---|---|

| −α | Low (−) | Central Point | High (+) | +α | |

| Level distance | −2 | −1 | 0 | +1 | +2 |

| Spray rate (g/min) | 11.5 | 14.0 | 16.5 | 19.0 | 21.5 |

| Spray pressure (bar) | 1.4 | 1.6 | 1.8 | 2.0 | 2.2 |

| Rotor speed (rpm) | 300 | 475 | 650 | 825 | 1000 |

| Process air temperature (°C) | 70 | 75 | 80 | 85 | 90 |

| Median (x50.3) | CoV (x50.3) | Sphericity | |

|---|---|---|---|

| SD | 14.7 | 0.01 | 0.04 |

| Mean | 172.4 | 0.45 | 0.78 |

| CoV % | 8.5 | 2.84 | 4.99 |

| R2 | 0.92 | 0.94 | 0.34 |

| Median (x50.3) | CoV (x50.3) | |||||||

|---|---|---|---|---|---|---|---|---|

| p-Value | St. Reg. Par. | 95% CI Low | 95% CI High | p-Value | St. Reg. Par. | 95% CI Low | 95% CI High | |

| Model | <0.001 | - | - | - | <0.001 | - | - | - |

| Constant | - | 160.0 | 147.2 | 172.7 | - | 0.445 | 0.434 | 0.456 |

| A Spray pressure | <0.001 | −26.2 | −32.6 | −19.8 | <0.001 | −0.021 | −0.027 | −0.016 |

| B Proc. air temp. | 0.744 | −1.0 | −7.4 | 5.4 | 0.113 | −0.004 | −0.010 | 0.001 |

| C Rotor speed | 0.565 | −1.8 | −8.1 | 4.6 | 0.002 | −0.010 | −0.015 | −0.004 |

| D Spray rate | <0.001 | 23.4 | 17.0 | 29.7 | <0.001 | 0.025 | 0.020 | 0.030 |

| AB | 0.829 | −0.8 | −8.6 | 7.0 | 0.921 | −0.000 | −0.007 | 0.006 |

| AC | 0.123 | −6.0 | −13.8 | 1.8 | 0.022 | −0.008 | −0.015 | −0.001 |

| AD | 0.003 | −13.3 | −21.1 | −5.5 | 0.011 | −0.009 | −0.016 | −0.002 |

| BC | 0.498 | 2.5 | −5.3 | 10.4 | 0.836 | −0.001 | −0.007 | 0.006 |

| BD | 0.287 | 4.0 | −3.8 | 11.9 | 0.036 | 0.007 | 0.001 | 0.014 |

| CD | 0.035 | 8.5 | 0.7 | 16.3 | 0.001 | 0.013 | 0.006 | 0.019 |

| A2 | 0.032 | 6.6 | 0.7 | 12.6 | 0.117 | 0.004 | −0.001 | 0.009 |

| B2 | 0.001 | 11.0 | 5.0 | 16.9 | 0.007 | 0.008 | 0.002 | 0.013 |

| C2 | 0.222 | −3.6 | −9.5 | 2.4 | 0.002 | −0.009 | −0.014 | −0.004 |

| D2 | 0.603 | 1.5 | −4.5 | 7.5 | 0.430 | 0.002 | −0.003 | 0.007 |

| Residual | - | - | - | - | - | - | - | - |

| Lack of Fit | 0.150 | - | - | - | 0.211 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Langner, M.; Zhou, B.; Priese, F.; Wolf, B. Statistical Investigation of Rotary Fluidized Bed Agglomeration Process with Tangential Spray and In-Line Particle Size Measurement for PAT Process Control. Processes 2023, 11, 1066. https://doi.org/10.3390/pr11041066

Langner M, Zhou B, Priese F, Wolf B. Statistical Investigation of Rotary Fluidized Bed Agglomeration Process with Tangential Spray and In-Line Particle Size Measurement for PAT Process Control. Processes. 2023; 11(4):1066. https://doi.org/10.3390/pr11041066

Chicago/Turabian StyleLangner, Marcel, Biwen Zhou, Florian Priese, and Bertram Wolf. 2023. "Statistical Investigation of Rotary Fluidized Bed Agglomeration Process with Tangential Spray and In-Line Particle Size Measurement for PAT Process Control" Processes 11, no. 4: 1066. https://doi.org/10.3390/pr11041066