Heat Unit Requirements of “Flame Seedless” Table Grape: A Tool to Predict Its Harvest Period in Protected Cultivation

Abstract

:1. Introduction

2. Results

2.1. Cardinal Temperatures for “Flame Seedless”

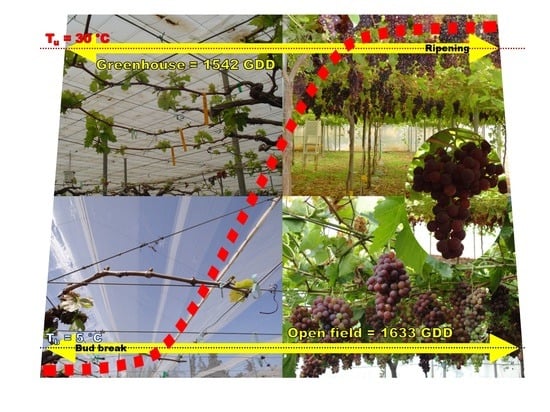

2.2. Determination of the Heat Requirements of “Flame Seedless” from Bud Break to Ripening—Accuracy and Robustness

2.3. Harvest Prediction in “Flame Seedless” Table Grape Cultivated under Greenhouse

3. Discussion

4. Materials and Methods

4.1. Site and Plant Management

4.2. Threshold Temperatures for “Flame Seedless”

4.3. Growing Degree Days Determination—Accuracy and Prediction Ability of the Procedure

4.4. Harvest Prediction in “Flame Seedless” Table Grape Cultivated under Greenhouse

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Britz, B.S. Environmental provisions for plants in Seventeenth-Century Northern Europe. J. Soc. Archit. Hist. 1974, 33, 133–144. [Google Scholar] [CrossRef]

- Novello, V.; Palma, L.; Tarricone, L.; Vox, G. Effects of different plastic sheet coverings on microclimate and berry ripening of table grape cv. ‘Matilde’. J. Int. Sci. Vigne Vin. 2000, 34, 49–55. [Google Scholar] [CrossRef] [Green Version]

- Novello, V.; Palma, L. Growing grapes under cover. Acta Hortic. 2008, 785, 353–362. [Google Scholar] [CrossRef]

- Vox, G.; Schettini, E.; Scarascia Mugnozza, G.; Tarricone, L.; Palma, L. Covering plastic films for vineyard protected cultivation. Acta Hortic. 2014, 1037, 897–904. [Google Scholar] [CrossRef]

- Alonso, F.; Hueso, J.J.; Cuevas, J. Efectos de la cobertura plástica sobre precocidad del cultivo de uva apirena. Rev. Hortic. 2004, 175, 40–42. [Google Scholar]

- Angot, A. Étude sur les vendanges en France. In Annales du Bureau Central Météorologique de France; Mascart, E., Ed.; Année 1883; Gauthier-Villars, Imprimeur-Libraire: Paris, France, 1885; Volume 1, pp. B29–B120. [Google Scholar]

- Bioletti, F.T. Elements of Grape Growing in California; The College of Agriculture, University of California: Berkeley, CA, USA, 1929. [Google Scholar]

- Winkler, A.J.; Williams, W.O. The heat required to bring Tokay grapes to maturity. Proc. Am. Soc. Hort. Sci. 1939, 37, 650–652. [Google Scholar]

- Amerine, M.A.; Winkler, A.J. Composition and quality of musts and wines of California grapes. Hilgardia 1944, 15, 493–675. [Google Scholar] [CrossRef] [Green Version]

- Labbé, T.; Pfister, C.; Brönnimann, S.; Rousseau, D.; Franke, J.; Bois, B. The longest homogeneous series of grape harvest dates, Beaune 1354–2018, and its significance for the understanding of past and present climate. Clim. Past 2019, 15, 1485–1501. [Google Scholar] [CrossRef] [Green Version]

- Fraga, H.; Santos, J.; Moutinho-Pereira, J.; Carlos, C.; Silvestre, J.; Eiras-Dias, J.; Mota, T.; Malheiro, A. Statistical modelling of grapevine phenology in Portuguese wine regions: Observed trends and climate change projections. J. Agric. Sci. 2016, 154, 795–811. [Google Scholar] [CrossRef] [Green Version]

- Parker, A.K.; García de Cortázar-Atauri, I.; Trought, M.C.; Destrac, A.; Agnew, R.; Sturman, A.; van Leeuwen, C. Adaptation to climate change by determining grapevine cultivar differences using temperature-based phenology models. OENO One 2020, 54, 955–974. [Google Scholar] [CrossRef]

- van Leeuwen, C.; Destrac-Irvine, A.; Dubernet, M.; Duchêne, E.; Gowdy, M.; Marguerit, E.; Pieri, P.; Parker, A.; de Rességuier, L.; Ollat, N. An update on the impact of climate change in viticulture and potential adaptations. Agronomy 2019, 9, 514. [Google Scholar] [CrossRef] [Green Version]

- Parker, A.K.; García de Cortázar-Atauri, I.; Gény, L.; Spring, J.L.; Destrac, A.; Schultz, H.; Molitor, D.; Lacombe, T.; Graça, A.; Monamy, C.; et al. Temperature-based grapevine sugar ripeness modelling for a wide range of Vitis vinifera L. cultivars. Agric. For. Meteorol. 2020, 285–286, 107902. [Google Scholar] [CrossRef]

- Verdugo-Vásquez, N.; Pañitrur-De la Fuente, C.; Ortega-Farías, S. Model development to predict phenological scale of table grapes (cvs. Thompson, Crimson and Superior Seedless and Red Globe) using growing degree days. OENO One 2017, 51, 277–288. [Google Scholar] [CrossRef]

- Bonhomme, R. Bases and limits using ‘degree days’ units. Eur. J. Agron. 2000, 13, 1–10. [Google Scholar] [CrossRef]

- Trudgill, D.L.; Honek, A.; Li, D.; Van Straalen, N.M. Thermal time—Concepts and utility. Ann. Appl. Biol. 2005, 146, 1–14. [Google Scholar] [CrossRef]

- Wilson, L.T.; Barnett, W.W. Degree-days: An aid in crop and pest management. Calif. Agric. 1983, 37, 4–7. [Google Scholar]

- Luo, Q. Temperature thresholds and crop production: A review. Clim. Chang. 2011, 109, 583–598. [Google Scholar] [CrossRef]

- Arnold, C.Y. The determination and significance of the base temperature in a linear heat unit system. Proc. Am. Soc. Hort. Sci. 1959, 74, 430–445. [Google Scholar]

- Perry, K.B.; Wehner, T.C.; Johnson, G.L. Comparison of 14 methods to determine heat unit requirements for cucumber harvest. HortScience 1986, 21, 419–423. [Google Scholar]

- Moncur, M.W.; Rattigan, K.; Mackenzie, D.H.; Mc Intyre, G.N. Base temperatures for budbreak and leaf appearance of grapevines. Am. J. Enol. Vitic. 1989, 40, 21–26. [Google Scholar]

- Swanepoel, J.J.; Villiers, F.S.; Pouget, R. Predicting the date of bud burst in grapevines. S. Afr. J. Enol. Vitic. 1990, 11, 46–49. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, M. Calculation of budbreak and flowering base temperatures for Vitis vinifera cv. Touriga Francesa in the Douro Region of Portugal. Am. J. Enol. Vitic. 1998, 49, 74–78. [Google Scholar]

- Lebon, E.; Pellegrino, A.; Tardieu, F.; Lecoeur, J. Shoot development in grapevine (Vitis vinifera) is affected by the modular branching pattern of the stem and intra- and inter-shoot trophic competition. Ann. Bot. 2004, 93, 263–274. [Google Scholar] [CrossRef] [Green Version]

- Menora, N.D.; Joshi, V.; Kumar, V.; Vijaya, D.; Debnath, M.K.; Pattanashetty, S.; Padmavathamma, A.S.; Variath, M.T.; Biradar, S.; Khadakabhavi, S. Influence of rootstock on bud break, period of anthesis, fruit set, fruit ripening, heat unit requirement and berry yield of commercial grape varieties. Int. J. Plant Breed. Genet. 2015, 9, 126–135. [Google Scholar] [CrossRef] [Green Version]

- Van Den Brink, C. Predicting harvest date of the ‘Concord’ grape crop in Southwest Michigan. HortScience 1974, 9, 206–208. [Google Scholar]

- Williams, D.W.; Andris, H.L.; Beede, R.H.; Luvisi, D.A.; Norton, M.V.K.; Williams, L.E. Validation of a model for the growth and development of the Thompson Seedless grapevine. II. Phenology. Am. J. Enol. Vitic. 1985, 36, 283–289. [Google Scholar]

- Zhou, G.; Wang, Q. A new nonlinear method for calculating growing degree days. Sci. Rep. 2018, 8, 10149. [Google Scholar] [CrossRef]

- Pedro Júnior, M.J.; Sentelhas, P.C.; Pommer, C.V.; Martins, F.P. Determinação da temperatura-base, graus-dia e índice biometeorológico para a videira ‘Niagara Rosada’. Rev. Bras. Agrometeorol. 1994, 2, 51–56. [Google Scholar]

- Ferreira, E.A.; Regina, M.A.; Chalfun, N.N.J.; Antunes, L.E.C. Antecipação de safra para videira ‘Niagara Rosada’ na região sul do Estado de Minas Gerais. Cienc. Agrotec. 2004, 28, 1221–1227. [Google Scholar] [CrossRef]

- Scarpare, F.V.; Scarpare Filho, J.A.; Rodrigues, A.; Reichardt, K.; Angelocci, L.R. Growing degree-days for the ‘Niagara Rosada’ grapevine pruned in different seasons. Int. J. Biometeorol. 2012, 56, 823–830. [Google Scholar] [CrossRef]

- Jones, G.V.; Davis, R.E. Climate influences on grapevine phenology, grape composition, and wine production and quality for Bordeaux, France. Am. J. Enol. Vitic. 2000, 51, 249–261. [Google Scholar]

- Winkler, A.J. Maturity test for table grapes. The relation of heat summation to time of maturing and palatability. J. Am. Soc. Hortic. Sci. 1948, 51, 295–298. [Google Scholar]

- Mc Intyre, G.N.; Kliewer, W.M.; Lider, L.A. Some limitations of the degree day system as used in viticulture in California. Am. J. Enol. Vitic. 1987, 39, 128–132. [Google Scholar]

- Nendel, C. Grapevine bud break prediction for cool winter climates. Int. J. Biometeorol. 2010, 54, 231–241. [Google Scholar] [CrossRef] [PubMed]

- Molitor, D.; Junk, J.; Evers, D.; Hoffmann, L.; Beyer, M. A high-resolution cumulative degree day-based model to simulate phenological development of grapevine. Am. J. Enol. Vitic. 2014, 65, 72–80. [Google Scholar] [CrossRef]

- García de Cortázar-Atauri, I.; Brisson, N.; Gaudillere, J.P. Performance of several models for predicting budburst date of grapevine (Vitis vinifera L.). Int. J. Biometeorol. 2009, 53, 317–326. [Google Scholar] [CrossRef]

- Schrader, J.A.; Cochran, D.R.; Domoto, P.A.; Nonnecke, G.R. Phenology and winter hardiness of cold-climate grape cultivars and advanced selections in Iowa climate. HortTechnology 2019, 29, 906–922. [Google Scholar] [CrossRef] [Green Version]

- Hendrickson, L.; Förster, B.; Furbank, R.T.; Chow, W.S. Processes contributing to photoprotection of grapevine leaves illuminated at low temperature. Physiol. Plant. 2004, 121, 272–281. [Google Scholar] [CrossRef] [PubMed]

- Bertamini, M.; Muthuchelian, K.; Rubinigg, M.; Zorer, R.; Nedunchezhian, N. Low-night temperature (LNT) induced changes of photosynthesis in grapevine (Vitis vinifera L.) plants. Plant Physiol. Biochem. 2005, 43, 693–699. [Google Scholar] [CrossRef] [PubMed]

- Alonso, F.; Hueso, J.J.; González, M.; Baeza, E.; Sacot, P.; Cuevas, J. Physiological response of ‘Flame Seedless’ table grape to three natural ventilation levels in a parral greenhouse. Acta Hortic. 2006, 719, 181–188. [Google Scholar] [CrossRef]

- Greer, D.H. Modelling leaf photosynthetic and transpiration temperature-dependent responses in Vitis vinifera cv. Semillon grapevines growing in hot, irrigated vineyard conditions. AoB Plants 2012, 2012, pls009. [Google Scholar] [CrossRef] [PubMed]

- Kriedemann, P.E.; Smart, R.E. Effects of irradiance, temperature, and leaf water potential on photosynthesis of vine leaves. Photosynthetica 1971, 5, 6–15. [Google Scholar]

- Kriedemann, P.E. Photosynthesis in vine leaves as a function of light intensity, temperature, and leaf age. Vitis 1968, 7, 213–220. [Google Scholar] [CrossRef]

- Ferrini, F.; Mattii, G.B.; Nicese, F.P. Effect of temperature on key physiological responses of grapevine leaf. Am. J. Enol. Vitic. 1995, 46, 375–379. [Google Scholar]

- Buttrose, M.S.; Hale, C.R. Effect of temperature on development of grapevine inflorescence after bud burst. Am. J. Enol. Vitic. 1973, 24, 14–16. [Google Scholar]

- Kadir, S. Thermostability of photosynthesis of Vitis aestivalis and Vitis vinifera. J. Am. Soc. Hortic. Sci. 2006, 131, 476–483. [Google Scholar] [CrossRef] [Green Version]

- Mauromicale, G.; Cosentino, S.; Copani, V. Validity of thermal unit summations for purposes of prediction in Phaseolus vulgaris L. cropped in mediterranean environment. Acta Hortic. 1988, 229, 321–332. [Google Scholar] [CrossRef]

- Perry, K.B.; Wehner, T.C. Prediction of cucumber harvest date using a heat unit model. HortScience 1990, 25, 405–406. [Google Scholar] [CrossRef] [Green Version]

- Morris, J.R.; Cawthon, D.L.; Spayd, S.E.; May, R.D.; Bryan, D.R. Prediction of ‘Concord’ grape maturation and sources of error. J. Am. Soc. Hortic. Sci. 1980, 105, 313–318. [Google Scholar]

- Faruqi, N.A.; Bin-Taher, A.; Abukanesha, F.F.; Wali, T.; Baruni, A. Heat units and number of days required to mature certain cultivars of peach in Tarhuna region, Libya. Acta Hortic. 1988, 218, 83–90. [Google Scholar] [CrossRef]

- Hueso, J.J.; Pérez, M.; Alonso, F.; Cuevas, J. Harvest prediction in ‘Algerie’ loquat. Int. J. Biometeorol. 2007, 51, 449–455. [Google Scholar] [CrossRef] [PubMed]

- Calò, A.; Tomasi, D.; Costacurta, A.; Boscaro, S.; Aldighieri, R. The effect of temperature thresholds on grapevine (Vitis sp.) bloom: An interpretive model. Riv. Vitic. Enol. 1994, 1, 3–14. [Google Scholar]

- Tomasi, D.; Calò, A.; Costacurta, A.; Biscaro, S.; Sansone, L. Studio della dinamica delle fenofasi nella Vitis vinifera L.: Interazione genotipo x condizioni termiche. Italus Hortus 1994, 5, 62–70. [Google Scholar]

- Caffarra, A.; Eccel, E. Increasing the robustness of phenological models for Vitis vinifera cv. Chardonnay. Int. J. Biometeorol. 2010, 54, 255–267. [Google Scholar] [CrossRef]

- Ortega-Farias, S.; Riveros-Burgos, C. Modeling phenology of four grapevine cultivars (Vitis vinifera L.) in Mediterranean climate conditions. Sci. Hortic. 2019, 250, 38–44. [Google Scholar] [CrossRef]

- Papadakis, J. Climates of the World and Their Agricultural Potentialities; J. Papadakis: Buenos Aires, Argentina, 1966. [Google Scholar]

- Richardson, E.A.; Seeley, S.D.; Walker, D.R. A model for estimating the completion of rest for ‘Redhaven’ and ‘Elberta’ peach trees. HortScience 1974, 9, 331–332. [Google Scholar]

- Colapietra, M. L’uva da Tavola: La Coltura, il Mercato, il Consumo; Edagricole: Bologna, Italy, 2004. [Google Scholar]

- Lancashire, P.D.; Bleiholder, H.; Boom, T.V.D.; Langelüddeke, P.; Stauss, R.; Weber, E.; Witzenberger, A. A uniform decimal code for growth stages of crops and weeds. Ann. Appl. Biol. 1991, 119, 561–601. [Google Scholar] [CrossRef]

- Galet, P. Précis de Viticulture, 3rd ed.; Dehan: Montpellier, France, 1976. [Google Scholar]

- Vidaud, J.; Charmont, S.; Wagner, R. Le Raisin de Table; Centre Technique Interprofessionnel des Fruits et Légumes (CTIFL): Paris, France, 1993. [Google Scholar]

- Yang, S.; Logan, J.; Coffey, D.L. Mathematical formulae for calculating the base temperature for growing degree days. Agric. For. Meteorol. 1995, 74, 61–74. [Google Scholar] [CrossRef]

- Ometto, J.C. Bioclimatologia Vegetal, 1st ed.; Agronômica Ceres: São Paulo, Brazil, 1981. [Google Scholar]

- Fernández, M.D.; López, J.C.; Baeza, E.; Céspedes, A.; Meca, D.E.; Bailey, B. Generation and evaluation of typical meteorological year datasets for greenhouse and external conditions on the Mediterranean coast. Int. J. Biometeorol. 2015, 59, 1067–1081. [Google Scholar] [CrossRef] [PubMed]

- Argiriou, A.; Lykoudis, S.; Kontoyiannidis, S.; Balaras, C.A.; Asimakopoulos, D.; Petrakis, M.; Kassomenos, P. Comparison of methodologies for tmy generation using 20 years data for Athens, Greece. Sol. Energy 1999, 66, 33–45. [Google Scholar] [CrossRef]

| Data Sets | SD 1GDD 2 | SDDAYS | CV 3GDD | RE 4 | X-Intercept |

|---|---|---|---|---|---|

| Five seasons | 15.82 | 15.53 | 5.94 | 7.10 | 6.86 |

| Three seasons (excluding 2005 and 2006) | 28.54 | 357.50 | 338.73 | 347.32 | 105.00 |

| Four seasons (excluding 2005) | 35.82 | 64.22 | 107.94 | 108.80 | 58.50 |

| Four seasons (excluding 2006) | 14.71 | 14.30 | 7.96 | 8.66 | 8.37 |

| Open Field | ||||||

|---|---|---|---|---|---|---|

| Season | Bud Break–Full Bloom | Full Bloom–Harvest | Total | |||

| GDD | Days | GDD | Days | GDD | Days | |

| 2003 | 679 | 62 | 974 | 59 | 1652 | 121 |

| 2005 | 628 | 52 | 862 | 52 | 1490 | 104 |

| 2006 | 620 | 54 | 1120 | 68 | 1740 | 122 |

| 2007 | 703 | 65 | 932 | 55 | 1634 | 120 |

| 2008 | 841 | 71 | 808 | 48 | 1650 | 119 |

| Mean | 694 | 61 | 939 | 56 | 1633 | 117 |

| Greenhouse | ||||||

| Season | Bud Break–Full Bloom | Full Bloom–Harvest | Total | |||

| GDD | Days | GDD | Days | GDD | Days | |

| 2005 | 574 | 64 | 924 | 69 | 1498 | 133 |

| 2006 | 641 | 64 | 984 | 68 | 1625 | 132 |

| 2007 | 613 | 58 | 929 | 70 | 1542 | 128 |

| 2008 | 590 | 58 | 913 | 70 | 1503 | 128 |

| Mean | 605 | 61 | 937 | 69 | 1542 | 130 |

| Open Field | |||||

|---|---|---|---|---|---|

| Season | GDD | Calendar Days | |||

| OHD 1 | PHD 2 | PHD − OHD | PHD | PHD − OHD | |

| 2003 | 11 July | 10 July | −1 | 7 July | −4 |

| 2005 | 3 July | 11 July | +8 | 16 July | +13 |

| 2006 | 10 July | 4 July | −6 | 5 July | −5 |

| 2007 | 9 July | 9 July | 0 | 6 July | −3 |

| 2008 | 14 July | 14 July | 0 | 12 July | −2 |

| Accuracy | 3 | 5 | |||

| Greenhouse | |||||

| Season | GDD | Calendar Days | |||

| OHD1 | PHD2 | PHD − OHD | PHD | PHD − OHD | |

| 2005 | 2 June | 12 June | +10 | 17 May | −16 |

| 2006 | 6 June | 7 June | +1 | 21 May | −16 |

| 2007 | 5 June | 11 June | +6 | 25 May | −11 |

| 2008 | 29 May | 6 June | +8 | 18 May | −11 |

| Accuracy | 6 | 14 | |||

| Season | OHD 1 | GDD Tb 5 °C and Tu 30 °C | PHD 2 | PHD − OHD | Calendar Days | PHD | PHD − OHD |

|---|---|---|---|---|---|---|---|

| 2005 | 2 June | 1498 | 5 June | +3 | 133 | 30 May | −3 |

| 2006 | 6 June | 1625 | 30 May | −7 | 132 | 4 June | −2 |

| 2007 | 5 June | 1542 | 5 June | 0 | 128 | 7 June | +2 |

| 2008 | 29 May | 1503 | 1 June | +3 | 128 | 31 May | +2 |

| Mean | 1542 | 130 | |||||

| Accuracy | 3 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alonso, F.; Chiamolera, F.M.; Hueso, J.J.; González, M.; Cuevas, J. Heat Unit Requirements of “Flame Seedless” Table Grape: A Tool to Predict Its Harvest Period in Protected Cultivation. Plants 2021, 10, 904. https://doi.org/10.3390/plants10050904

Alonso F, Chiamolera FM, Hueso JJ, González M, Cuevas J. Heat Unit Requirements of “Flame Seedless” Table Grape: A Tool to Predict Its Harvest Period in Protected Cultivation. Plants. 2021; 10(5):904. https://doi.org/10.3390/plants10050904

Chicago/Turabian StyleAlonso, Francisca, Fernando M. Chiamolera, Juan J. Hueso, Mónica González, and Julián Cuevas. 2021. "Heat Unit Requirements of “Flame Seedless” Table Grape: A Tool to Predict Its Harvest Period in Protected Cultivation" Plants 10, no. 5: 904. https://doi.org/10.3390/plants10050904