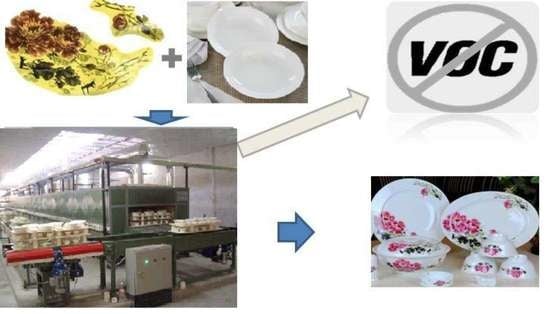

Investigation and Accounting Research of VOC in Daily and Specialty Ceramic Industry

Abstract

:1. Introduction

2. Experimental Section

2.1. Experimental Process

2.2. Data Processing

- m1: the weight of the flower paper before baking, g

- m2: the weight after baking, g

- m3: the weight of the loss, g

- m1: the weight of the special ceramic wax before the wax, g

- m2: the weight after waxing, g

- m3: loss of special ceramics, g

3. Results and Discussion

3.1. FT-IR Analysis

3.1.1. Low Temperature Paper

3.1.2. Water Transfer Paper and PVB Paper

3.1.3. Cover Oil and Varnish in Water Transfer Paper Components

3.1.4. Beeswax, Oleic Acid and Paraffin in Special Ceramics Group

3.2. DTA/TG Analysis

3.2.1. Low Temperature Flower Paper

3.2.2. Water Transfer Paper and PVB Paper

3.2.3. Water Transfer Paper Component Cover Oil and Varnish

3.2.4. Special Ceramic Organic Components Beeswax Oleic Acid and Paraffin

3.3. Effect of Temperature on the Loss of Paper Waste

3.3.1. Loss on Ignition of the Same Flower Paper at Different Temperatures

3.3.2. Loss on Ignition of Different Flower Papers at 850 °C

3.4. Effect of Temperature on the Loss of Wax in Special Ceramics

3.5. Accounting Analysis of VOC in Flue Gas of Roasted Flowers and Special Ceramics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Mang, L.; Guo, X.W.; Zhong, Z.Z.; You, M.S. Characterization and Inventory of PCDD/F Emissions from the Ceramic Industry in China, Environ. Sci. Technol. 2012, 46, 4159–4165. [Google Scholar]

- Qin, J.F. Ceramic glass flower paper Application of environmentally friendly pigments and decorative auxiliaries. Screen Print. Ind. 2018, 11, 15–20. [Google Scholar] [CrossRef]

- Cheng, W.M. Common Problems and Solutions for Daily Ceramic Small Film Flowers. Art Technol. 2018, 7, 113. [Google Scholar]

- Tan, Y.B.; Wu, C.S. Development status of new products in my country’s building ceramics industry. China Build. Mater. Sci. Technol. 2020, 29, 109–110. [Google Scholar]

- Lin, Y. Analysis of energy consumption in the production of sanitary ceramics. Ceramics 2019, 8, 46–49. [Google Scholar]

- Huang, H.C.; Chen, B.; Zhang, K.; Ao, M.; Xiao, J.X. Comparative analysis of domestic and foreign standards for daily-use ceramic products. China Ceram. 2019, 55, 85–89. [Google Scholar]

- An, X.H. Monitoring Method and Treatment Technology of Volatile Organic Compounds. Chem. Eng. Des. Commun. 2018, 44, 71. [Google Scholar] [CrossRef]

- Liu, Z.; Li, N.; Hou, L.; Lyu, B. Characteristics and source identification of VOCs pollution in ambient air in Jinan. China Environ. Monit. 2014, 6, 83–88. [Google Scholar] [CrossRef]

- Ci, B.S. Five decorative methods and development prospects of daily ceramic flower paper. Screen Print. Ind. 2019, 1, 49–51. [Google Scholar]

- Zhong, W.; Lei, Y.J. Analysis and research on hot die casting process of typical structural ceramic parts. China Ceram. 2015, 10, 29–33. [Google Scholar] [CrossRef]

- Feng, J.T. Ceramic Die Casting Technology and Its New Development. China Ceram. 2003, 39, 34–38. [Google Scholar]

- Jin, B.; Peng, R.F.; Shen, J.; Tan, B.S.; Chu, S.J.; Dong, H.S. Study on the synthesis and thermal properties of polyvinyl benzal. Funct. Mater. 2011, 7, 1269–1272. [Google Scholar]

- Li, A.H. Analysis and detection of Volatile Organic Compounds in the air. Chem. Eng. Des. Commun. 2018, 44, 153. Available online: https://wenku.baidu.com/view/823bcfbef11dc281e53a580216fc700aba685280.html (accessed on 10 January 2022).

- Baer, T.; Cote, R.O.; Grillet, A.M.; Yang, P.; Hopkins, M.M.; Noble, D.R.; Notz, P.K.; Rao, R.R.; Halbleib, L.L.; Castaneda, J.N.; et al. Modeling Injection Molding of Net-Shape Active Ceramic Components; Sandia National Laboratories (SNL): Albuquerque, NM, USA; Livermore, CA, USA, 2006. [CrossRef] [Green Version]

- Matsumur, M.; Antonia, R.A. Momentum and heat transport in the turbulent intermediate wake of a circular cylinder. J. Fluid Mech. 1993, 250, 651–669. [Google Scholar] [CrossRef]

- Mohammad, A.S.; David, C.; David, S.; Will, W.; Bamber, R.K.B.; John, P.D.; Paul, A.H. On the bonding between glass and PVB in laminated glass. Eng. Fract. Mech. 2019, 214, 504–519. [Google Scholar]

- Jun, Z.H.; Meng, Q.L.A. One-dimensional VOC emission model of moisture-dominated cure adhesives, Department of Building Science. Build. Environ. 2019, 156, 171–177. [Google Scholar]

| No. | Name | Types | Physical Photo | Main Ingredient | Baking Temperature (°C) | Sampling Conditions | ||

|---|---|---|---|---|---|---|---|---|

| T (°C) | P (hpa) | V (m3) | ||||||

| 1 | 95 ceramics | Special ceramics |  | 95%Al2O3 + Paraffin wax + peak wax + oleic acid | 800 | 22–24 | 1000 | 95 |

| 2 | Side flower | water transfer paper |  | Cover oil + varnish + ceramic pigment | 800 | |||

| 3 | Fen wine | Low temperature flower paper |  | (Cover oil + varnish + ceramic pigment) | 200 | |||

| 4 | Tartar oil | / |  | Vegetable oil or synthetic resin | 500 | |||

| 5 | Cover oil | / |  | Acrylic resin | 500 | |||

| 6 | Social pig | PVB Paper |  | ((polyvinyl butyral)) + pigment + varnish | 800 | |||

| No. | Roasted Flower Temperature (°C) | Loss on Ignition (%) |

|---|---|---|

| 1 | 50 | 1.79 |

| 2 | 100 | 2.06 |

| 3 | 150 | 12.4 |

| 4 | 200 | 53.82 |

| 5 | 250 | 60.6 |

| 6 | 300 | 60.8 |

| 7 | 450 | 61.3 |

| 8 | 550 | 61.5 |

| 9 | 850 | 61.5 |

| Name | Loss of Burning Content (%) |

|---|---|

| Social man (PVB) | 79.1962 |

| Social pig (PVB) | 80.3771 |

| Fu (word) | 75.8784 |

| Birds and flower | 74.3708 |

| Lion + child (side) | 73.8013 |

| Fujian Garden House | 86.2327 |

| Lion + child (up and down) | 67.8336 |

| Where the Yellow River meets the Yangtze River | 62.3425 |

| Fine pottery (small pieces) | 65.2784 |

| Peaceful and wealthy | 96.3303 |

| National color | 67.5095 |

| Side flower (water transfer paper sample) | 60.9921 |

| Name | Loss of Burning Content (%) |

|---|---|

| Talc porcelain 1 | 15.53 |

| Talc porcelain 2 | 14.24 |

| 95 porcelain 1 | 10.8 |

| 95 porcelain 2 | 11.25 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| VOC Name | 95 Special Ceramics | Water Transfer Paper | Low Temperature Flower Paper | Tartar Oil | Cover Oil | PVB Paper (Social Pig) |

| Acetone | 0.02 | 0.02 | 0.01 | 0.01 | 0.01 L | 0.01 L |

| Isopropanol | 0.006 | / | 0.002 | 0.002 | / | 0.002 |

| Hexane | 0.047 | 0.005 | 0.053 | 0.004 | 0.004 L | 0.018 |

| Ethyl acetate | / | / | / | / | / | / |

| Benzene | 0.263 | / | / | 0.013 | 0.005 | 0.007 |

| 3-pentanone | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.003 |

| N-heptane | 0.009 | / | / | / | 0.006 | / |

| Toluene | / | / | 0.018 | 0.006 | / | / |

| Ethyl lactate | / | / | / | / | 0.0277 | / |

| Butyl acetate | 0.005 | 0.005 | 0.007 | / | 0.005 | 0.006 |

| Ethylbenzene | / | / | 0.034 | / | / | / |

| Para-/m-xylene | / | / | 0.062 | 0.091 | / | / |

| O-xylene | / | / | 0.062 | / | / | / |

| Styrene | / | 0.004 | 0.005 | / | 0.004 | 0.011 |

| Anisole | / | 0.004 | 0.004 | 0.005 | / | / |

| Benzaldehyde | 0.007 | 0.013 | 0.027 | 0.009 | 0.013 | 0.026 |

| 1-decene | 0.003 | 0.003 | 0.006 | 0.003 | 0.006 | 0.003 |

| 1-dodecene | / | / | 0.008 L | / | / | 0.008 L |

| 2-heptanone | / | / | 0.062 | / | / | 0.003 |

| 2-nonanon | 0.003 | 0.003 | 0.015 | 0.004 | 0.008 | 0.003 |

| Propylene glycol monomethyl ether acetate | 0.005 | 0.005 | 0.007 | / | 0.005 | 0.006 |

| TVOC | 0.370 | 0.064 | 0.280 | 0.252 | 0.082 | 0.088 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Name | 95 Ceramics | Water Transfer Paper | Low Temperature Flower Paper | Tartar Oil | Cover Oil | PVB Paper |

| VOC in loss on ignition (%) | 0.42 | 0.73 | 3.96 | 3.2 | 0.97 | 1.15 |

| VOC in sample weight (%) | 0.046 | 0.45 | 3.17 | 3.2 | 0.97 | 0.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Jiang, J.; Xia, L.; Xu, H.; Ye, C.; Sun, J.; Gu, R. Investigation and Accounting Research of VOC in Daily and Specialty Ceramic Industry. Coatings 2022, 12, 279. https://doi.org/10.3390/coatings12020279

Cheng Y, Jiang J, Xia L, Xu H, Ye C, Sun J, Gu R. Investigation and Accounting Research of VOC in Daily and Specialty Ceramic Industry. Coatings. 2022; 12(2):279. https://doi.org/10.3390/coatings12020279

Chicago/Turabian StyleCheng, Yue, Jiaxiang Jiang, Lei Xia, Hongxia Xu, Changlin Ye, Juan Sun, and Rui Gu. 2022. "Investigation and Accounting Research of VOC in Daily and Specialty Ceramic Industry" Coatings 12, no. 2: 279. https://doi.org/10.3390/coatings12020279