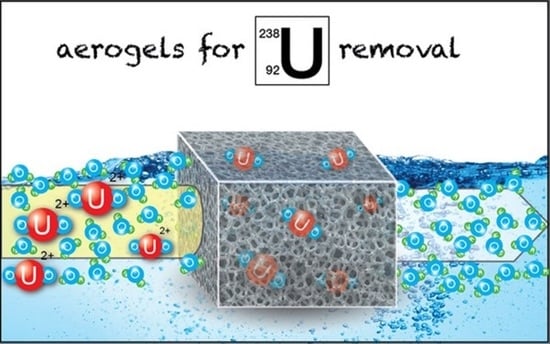

Uranium Removal from Aqueous Solutions by Aerogel-Based Adsorbents—A Critical Review

Abstract

:1. Introduction

1.1. Aerogels

1.2. Uranium

2. Uranium Sorption by Aerogels

2.1. pH Effect

2.2. Sorption Kinetics and Kinetic Modelling

2.3. Sorption Isotherms

2.4. Effect of Solution Composition and Competing Ions

2.5. Temperature Effect and Sorption Thermodynamics

2.6. Uranium Recovery and Material Recycling

2.7. Effect of the Adsorbent Mass and Ionic Strength

2.8. Spectroscopic Studies and Sorption Mechanism

2.9. Bulk Density of the Aerogel Material

3. Conclusions and Future Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Veglio, F.; Beolchini, F. Removal of Metals by Biosorption: A Review. Hydrometallurgy 1997, 44, 301–316. [Google Scholar] [CrossRef]

- Gazso, G.L. The Key Microbial Processes in the Removal of Toxic Metals and Radionuclides from the Environment. Cent. Eur. J. Occup. Environ. Med. Hung. 2001, 71-73, 178–185. [Google Scholar]

- Ishikawa, S.-I.; Suyama, K.; Arihara, K.; Itoh, M. Selective Recovery of Uranium and Thorium Ions from Dilute Aqueous Solutions by Animal Biopolymers. Biol. Trace Elem. Res. 2002, 86, 227–236. [Google Scholar] [CrossRef]

- Srinivasa Gowd, S.; Govil, P.K. Distribution of Heavy Metals in Surface Water of Ranipet Industrial Area in Tamil Nadu, India. Environ. Monit. Assess 2008, 136, 197–207. [Google Scholar] [CrossRef] [PubMed]

- Brugge, D.; deLemos, J.L.; Oldmixon, B. Exposure Pathways and Health Effects Associated with Chemical and Radiological Toxicity of Natural Uranium: A Review. Rev. Environ Health 2005, 20, 177–194. [Google Scholar] [CrossRef]

- Anastopoulos, I.; Massas, I.; Ehaliotis, C. Use of Residues and By-Products of the Olive-Oil Production Chain for the Removal of Pollutants from Environmental Media: A Review of Batch Biosorption Approaches. J. Environ. Sci. Health A 2015, 50, 677–718. [Google Scholar] [CrossRef] [PubMed]

- Raffa, C.M.; Chiampo, F.; Shanthakumar, S. Remediation of Metal/Metalloid-Polluted Soils: A Short Review. Appl. Sci. 2021, 11, 4134. [Google Scholar] [CrossRef]

- Bleise, A.; Danesi, P.R.; Burkart, W. Properties, Use and Health Effects of Depleted Uranium (DU): A General Overview. J. Environ. Radioact. 2003, 64, 93–112. [Google Scholar] [CrossRef]

- Markich, S.J. Uranium Speciation and Bioavailability in Aquatic Systems: An Overview. Sci. World J. 2002, 2, 707–729. [Google Scholar] [CrossRef] [Green Version]

- Mühr-Ebert, E.L.; Wagner, F.; Walther, C. Speciation of Uranium: Compilation of a Thermodynamic Database and Its Experimental Evaluation Using Different Analytical Techniques. Appl. Geochem. 2019, 100, 213–222. [Google Scholar] [CrossRef]

- Fanghänel, T.; Neck, V. Aquatic Chemistry and Solubility Phenomena of Actinide Oxides/Hydroxides. Pure Appl. Chem. 2002, 74, 1895–1907. [Google Scholar] [CrossRef]

- Philippou, K.; Savva, I.; Pashalidis, I. Uranium(VI) Binding by Pine Needles Prior and after Chemical Modification. J. Radioanal. Nucl. Chem. 2018, 318, 2205–2211. [Google Scholar] [CrossRef]

- Liatsou, I.; Michail, G.; Demetriou, M.; Pashalidis, I. Uranium Binding by Biochar Fibres Derived from Luffa Cylindrica after Controlled Surface Oxidation. J. Radioanal. Nucl. Chem. 2017, 311, 871–875. [Google Scholar] [CrossRef]

- Hadjittofi, L.; Pashalidis, I. Uranium Sorption from Aqueous Solutions by Activated Biochar Fibres Investigated by FTIR Spectroscopy and Batch Experiments. J. Radioanal. Nucl. Chem. 2015, 304, 897–904. [Google Scholar] [CrossRef]

- Stasi, C.; Georgiou, E.; Ioannidis, I.; Pashalidis, I. Uranium Removal from Laboratory and Environmental Waters by Oxidised Biochar Prepared from Palm Tree Fibres. J. Radioanal. Nucl. Chem. 2022, 331, 375–381. [Google Scholar] [CrossRef]

- Bhalara, P.D.; Punetha, D.; Balasubramanian, K. A Review of Potential Remediation Techniques for Uranium(VI) Ion Retrieval from Contaminated Aqueous Environment. J. Environ. Chem. Eng. 2014, 2, 1621–1634. [Google Scholar] [CrossRef]

- Gupta, R.; Ahuja, P.; Khan, S.; Saxena, R.K.; Mohapatra, H. Microbial Biosorbents: Meeting Challenges of Heavy Metal Pollution in Aqueous Solutions. Curr. Sci. 2000, 78, 967–973. [Google Scholar]

- Giannakoudakis, D.A.; Anastopoulos, I.; Barczak, M.; Antoniou, Ε.; Terpiłowski, K.; Mohammadi, E.; Shams, M.; Coy, E.; Bakandritsos, A.; Katsoyiannis, I.A.; et al. Enhanced Uranium Removal from Acidic Wastewater by Phosphonate-Functionalized Ordered Mesoporous Silica: Surface Chemistry Matters the Most. J. Hazard. Mater. 2021, 413, 125279. [Google Scholar] [CrossRef]

- Jjagwe, J.; Olupot, P.W.; Menya, E.; Kalibbala, H.M. Synthesis and Application of Granular Activated Carbon from Biomass Waste Materials for Water Treatment: A Review. J. Bioresour. Bioprod. 2021, 6, 292–322. [Google Scholar] [CrossRef]

- Ioannou, K.; Hadjiyiannis, P.; Liatsou, I.; Pashalidis, I. U(VI) Adsorption by Biochar Fiber–MnO2 Composites. J. Radioanal. Nucl. Chem. 2019, 320, 425–432. [Google Scholar] [CrossRef]

- Christou, C.; Philippou, K.; Krasia-Christoforou, T.; Pashalidis, I. Uranium Adsorption by Polyvinylpyrrolidone/Chitosan Blended Nanofibers. Carbohydr. Polym. 2019, 219, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Philippou, K.; Anastopoulos, I.; Dosche, C.; Pashalidis, I. Synthesis and Characterization of a Novel Fe3O4-Loaded Oxidized Biochar from Pine Needles and Its Application for Uranium Removal. Kinetic, Thermodynamic, and Mechanistic Analysis. J. Environ. Manag. 2019, 252, 109677. [Google Scholar] [CrossRef] [PubMed]

- Philippou, K.; Christou, C.N.; Socoliuc, V.; Vekas, L.; Tanasă, E.; Miclau, M.; Pashalidis, I.; Krasia-Christoforou, T. Superparamagnetic Polyvinylpyrrolidone/Chitosan/Fe3O4 Electrospun Nanofibers as Effective U(VI) Adsorbents. J. Appl. Polym. Sci. 2021, 138, 50212. [Google Scholar] [CrossRef]

- Anastopoulos, I.; Milojković, J.V.; Tsigkou, K.; Zafiri, C.; Lopičić, Z.R.; Kornaros, M.; Pashalidis, I. A Nappies Management By-Product for the Treatment of Uranium-Contaminated Waters. J. Hazard. Mater. 2021, 404, 124147. [Google Scholar] [CrossRef] [PubMed]

- Ilia, R.; Liatsou, I.; Savva, I.; Vasile, E.; Vekas, L.; Marinica, O.; Mpekris, F.; Pashalidis, I.; Krasia-Christoforou, T. Magnetoresponsive Polymer Networks as Adsorbents for the Removal of U(VI) Ions from Aqueous Media. Eur. Polym. J. 2017, 97, 138–146. [Google Scholar] [CrossRef]

- Arkas, M.; Anastopoulos, I.; Giannakoudakis, D.A.; Pashalidis, I.; Katsika, T.; Nikoli, E.; Panagiotopoulos, R.; Fotopoulou, A.; Vardavoulias, M.; Douloudi, M. Catalytic Neutralization of Water Pollutants Mediated by Dendritic Polymers. Nanomaterials 2022, 12, 445. [Google Scholar] [CrossRef]

- Panagiotou, N.; Liatsou, I.; Pournara, A.; Angeli, G.K.; Giappa, R.M.; Tylianakis, E.; Manos, M.J.; Froudakis, G.E.; Trikalitis, P.N.; Pashalidis, I.; et al. Water-Stable 2-D Zr MOFs with Exceptional UO22+ Sorption Capability. J. Mater. Chem. A 2020, 8, 1849–1857. [Google Scholar] [CrossRef]

- Liu, H.; Fu, T.; Mao, Y. Metal–Organic Framework-Based Materials for Adsorption and Detection of Uranium(VI) from Aqueous Solution. ACS Omega 2022, 7, 14430–14456. [Google Scholar] [CrossRef] [PubMed]

- Koppula, S.; Manabolu Surya, S.; Katari, N.K.; Dhami, P.S.; Sivasankaran Nair, R.K. Mesoporous MOF Composite for Efficient Removal of Uranium, Methyl Orange, Methylene Blue, and Congo Red Dyes from Aqueous Solutions. Appl. Organomet. Chem. 2022, 36, e6554. [Google Scholar] [CrossRef]

- Guo, H.; Mei, P.; Xiao, J.; Huang, X.; Ishag, A.; Sun, Y. Carbon Materials for Extraction of Uranium from Seawater. Chemosphere 2021, 278, 130411. [Google Scholar] [CrossRef] [PubMed]

- Guo, D.; Song, X.; Zhang, L.; Chen, W.; Chu, D.; Tan, L. Recovery of Uranium (VI) from Aqueous Solutions by the Polyethyleneimine-Functionalized Reduced Graphene Oxide/Molybdenum Disulfide Composition Aerogels. J. Taiwan Inst. Chem. Eng. 2020, 106, 198–205. [Google Scholar] [CrossRef]

- Huang, Z.; Li, Z.; Zheng, L.; Zhou, L.; Chai, Z.; Wang, X.; Shi, W. Interaction Mechanism of Uranium(VI) with Three-Dimensional Graphene Oxide-Chitosan Composite: Insights from Batch Experiments, IR, XPS, and EXAFS Spectroscopy. Chem. Eng. J. 2017, 328, 1066–1074. [Google Scholar] [CrossRef]

- Coleman, S.J.; Coronado, P.R.; Maxwell, R.S.; Reynolds, J.G. Granulated Activated Carbon Modified with Hydrophobic Silica Aerogel-Potential Composite Materials for the Removal of Uranium from Aqueous Solutions. Environ. Sci. Technol. 2003, 37, 2286–2290. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Wang, H.; Hu, E.; Lei, Z.; Fan, B.; Wang, Q. Efficient Adsorption of Uranium from Aqueous Solutions by Microalgae Based Aerogel. Microporous Mesoporous Mater. 2020, 305, 110383. [Google Scholar] [CrossRef]

- Yin, J.; Yang, S.; He, W.; Zhao, T.; Li, C.; Hua, D. Biogene-Derived Aerogels for Simultaneously Selective Adsorption of Uranium(VI) and Strontium(II) by Co-Imprinting Method. Sep. Purif. Technol. 2021, 271, 118849. [Google Scholar] [CrossRef]

- Yu, J.; Wang, J.; Jiang, Y. Removal of Uranium from Aqueous Solution by Alginate Beads. Nucl. Eng. Technol. 2017, 49, 534–540. [Google Scholar] [CrossRef] [Green Version]

- Xiong, T.; Li, Q.; Liao, J.; Zhang, Y.; Zhu, W. Highly Enhanced Adsorption Performance to Uranium(VI) by Facile Synthesized Hydroxyapatite Aerogel. J. Hazard. Mater. 2022, 423, 127184. [Google Scholar] [CrossRef]

- Xiong, T.; Li, Q.; Liao, J.; Zhang, Y.; Zhu, W. Design of Hydroxyapatite Aerogel with Excellent Adsorption Performance to Uranium. J. Environ. Chem. Eng. 2021, 9, 106364. [Google Scholar] [CrossRef]

- Georgiou, E.; Raptopoulos, G.; Papastergiou, M.; Paraskevopoulou, P.; Pashalidis, I. Extremely Efficient Uranium Removal from Aqueous Environments with Polyurea-Cross-Linked Alginate Aerogel Beads. ACS Appl. Polym. Mater. 2022, 4, 920–928. [Google Scholar] [CrossRef]

- Zhao, M.; Tesfay Reda, A.; Zhang, D. Reduced Graphene Oxide/ZIF-67 Aerogel Composite Material for Uranium Adsorption in Aqueous Solutions. ACS Omega 2020, 5, 8012–8022. [Google Scholar] [CrossRef] [Green Version]

- Lei, Y.; Li, K.; Liao, J.; Zhang, Y.; Zhang, L.; Zhu, W. Design of 3D Alumina-Doped Magnesium Oxide Aerogels with a High Efficiency Removal of Uranium(VI) from Wastewater. Inorg. Chem. Front. 2021, 8, 2561–2574. [Google Scholar] [CrossRef]

- Chen, M.; Liu, T.; Zhang, X.; Zhang, R.; Tang, S.; Yuan, Y.; Xie, Z.; Liu, Y.; Wang, H.; Fedorovich, K.V.; et al. Photoinduced Enhancement of Uranium Extraction from Seawater by MOF/Black Phosphorus Quantum Dots Heterojunction Anchored on Cellulose Nanofiber Aerogel. Adv. Funct. Mater. 2021, 31, 2100106. [Google Scholar] [CrossRef]

- Liao, J.; Liu, P.; Xie, Y.; Zhang, Y. Metal Oxide Aerogels: Preparation and Application for the Uranium Removal from Aqueous Solution. Sci. Total Environ. 2021, 768, 144212. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Liao, J.; Zhang, Y. Adsorption Performance and Mechanism of Al2O3 Aerogels towards Aqueous U(VI) Using Template Synthesis Technology. Colloids Surf. A Physicochem. Eng. 2021, 612, 125980. [Google Scholar] [CrossRef]

- Liao, J.; Zhang, Y.; Zhang, L. Improved Catalytic Activity on the Thermal Decomposition of Ammonium Perchlorate and Efficient Adsorption of Uranium Using a Novel Ultra-Low Density Al2O3-Based Aerogels. J. Hazard. Mater. 2020, 387, 122015. [Google Scholar] [CrossRef]

- Li, N.; Yang, L.; Wang, D.; Tang, C.; Deng, W.; Wang, Z. High-Capacity Amidoxime-Functionalized β-Cyclodextrin/Graphene Aerogel for Selective Uranium Capture. Environ. Sci. Technol. 2021, 55, 9181–9188. [Google Scholar] [CrossRef]

- Liao, J.; Zhang, Y.; He, X.; Zhang, L.; He, Z. The Synthesis of a Novel Titanium Oxide Aerogel with Highly Enhanced Removal of Uranium and Evaluation of the Adsorption Mechanism. Dalton Trans. 2021, 50, 3616–3628. [Google Scholar] [CrossRef]

- Dang, Z.; Jia, M.; Liao, J.; Zhang, Y.; Zhu, W. Fabrication of the Al2O3 Aerogels by in Situ Water Formation Method for the Highly Efficient Removal of Uranium(VI). Microporous Mesoporous Mater. 2021, 316, 110952. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, X.; Liu, Y.; Li, Y.; Lan, T.; Wang, C.; Liu, Y.; Yuan, D.; Cao, X.; He, H.; et al. Assembly of Three-Dimensional Ultralight Poly(Amidoxime)/Graphene Oxide Nanoribbons Aerogel for Efficient Removal of Uranium(VI) from Water Samples. Sci. Total Environ. 2021, 765, 142686. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, J.; Jin, B.; Chu, S.; Peng, R. Modification of ZIF-8 on Bacterial Cellulose for an Efficient Selective Capture of U(VI). Cellulose 2021, 28, 5241–5256. [Google Scholar] [CrossRef]

- Hu, Y.; Pan, C.; Liu, S.; Wang, X.; Zheng, X.; Hu, F.; Xu, L.; Xu, G.; Jian, Y.; Peng, X. Ultra-Fast Adsorption of Radioactive-U(VI) and Cs(I) with High Adsorption Capacity towards CAA@MgAlFe Spongy-like Aerogel: Mechanism and Application Feasibility Study. J. Nucl. Mater. 2022, 559, 153463. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Zhang, Y.; Zhang, Z.; Li, Y.; Li, W. Nanocellulose Aerogel for Highly Efficient Adsorption of Uranium (VI) from Aqueous Solution. Carbohydr. Polym. 2021, 267, 118233. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Zhang, L.; Chen, F.; Wang, H.; Wang, Q.; Liang, K. Efficiency and Mechanism of Adsorption of Low-Concentration Uranium from Water by a New Chitosan/Aluminum Sludge Composite Aerogel. Dalton Trans. 2020, 49, 3209–3221. [Google Scholar] [CrossRef]

- Li, Y.; He, H.; Liu, Z.; Lai, Z.; Wang, Y. A Facile Method for Preparing Three-Dimensional Graphene Nanoribbons Aerogel for Uranium(VI) and Thorium(IV) Adsorption. J. Radioanal. Nucl. Chem. 2021, 328, 289–298. [Google Scholar] [CrossRef]

- Chen, L.; Feng, S.; Zhao, D.; Chen, S.; Li, F.; Chen, C. Efficient Sorption and Reduction of U(VI) on Zero-Valent Iron-Polyaniline-Graphene Aerogel Ternary Composite. J. Colloid Interface Sci. 2017, 490, 197–206. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Zhou, L.; Le, Z.; Wang, Y.; Liu, Z.; Huang, G.; Adesina, A.A. Preparation of Porous Chitosan/Carboxylated Carbon Nanotube Composite Aerogels for the Efficient Removal of Uranium(VI) from Aqueous Solution. Int. J. Biol. Macromol. 2020, 160, 1000–1008. [Google Scholar] [CrossRef]

- Wu, F.; Liu, D.; Li, G.; Li, L.; Yan, L.; Hong, G.; Zhang, X. Bayberry Tannin Directed Assembly of a Bifunctional Graphene Aerogel for Simultaneous Solar Steam Generation and Marine Uranium Extraction. Nanoscale 2021, 13, 5419–5428. [Google Scholar] [CrossRef]

- Zhou, Q.; Jin, B.; Zhao, P.; Chu, S.; Peng, R. RGO/CNQDs/ZIF-67 Composite Aerogel for Efficient Extraction of Uranium in Wastewater. Chem. Eng. J. 2021, 419, 129622. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Chen, T.; Duan, T.; Yao, W.; Zheng, K.; Dai, L.; Zhu, W. Bioassembly of Fungal Hypha/Graphene Oxide Aerogel as High Performance Adsorbents for U(VI) Removal. Chem. Eng. J. 2018, 347, 407–414. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.; Wang, W.; Zhang, X. Symbiotic Aerogel Fibers Made via In-Situ Gelation of Aramid Nanofibers with Polyamidoxime for Uranium Extraction. Molecules 2019, 24, 1821. [Google Scholar] [CrossRef] [Green Version]

- Liao, J.; Li, K.; Zhang, Y.; Zhang, L. Facile Synthesis of a Novel Ultra-Low Density Praseodymium Oxide Aerogel for Catalyst and Adsorbent. Mater. Lett. 2019, 254, 364–366. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, Y.; Zhao, S.; Wakeel, M.; Wang, Z.; Shaikh, R.S.; Hayat, T.; Chen, C. A Simple Method for Preparing Ultra-Light Graphene Aerogel for Rapid Removal of U(VI) from Aqueous Solution. Environ. Pollut. 2019, 251, 547–554. [Google Scholar] [CrossRef] [PubMed]

- Yin, N.; Ai, Y.; Xu, Y.; Ouyang, Y.; Yang, P. Preparation of Magnetic Biomass-Carbon Aerogel and Its Application for Adsorption of Uranium(VI). J. Radioanal. Nucl. Chem. 2020, 326, 1307–1321. [Google Scholar] [CrossRef]

- He, Y.-R.; Li, X.-L.; Li, X.-L.; Tan, Z.-Y.; Zhang, D.; Chen, H.-B. Aerogel Based on Melamine-Formaldehyde and Alginate: Simply Removing of Uranium from Aqueous Solutions. J. Mol. Liq. 2019, 289, 111154. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, M.; Chen, D. Production of Three-Dimensional Porous Polydopamine-Functionalized Attapulgite/Chitosan Aerogel for Uranium(VI) Adsorption. J Radioanal Nucl Chem 2018, 316, 635–647. [Google Scholar] [CrossRef]

- Yang, L.; Huang, C.; Luo, X.; Zhang, L.; Ye, Y.; Jun, H.; Wang, Y. Chitosan-Based Aerogel with Anti-Swelling for U(VI) Adsorption from Aqueous Solution. Colloids Surf. A Physicochem. Eng. 2021, 630, 127527. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, Z.; Wang, X.; Dai, Y.; Cao, X.; Wang, Y.; Hua, R.; Feng, H.; Chen, J.; Liu, Y.; et al. Synthesis of Ultralight Phosphorylated Carbon Aerogel for Efficient Removal of U(VI): Batch and Fixed-Bed Column Studies. Chem. Eng. J. 2019, 370, 1376–1387. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, J.; Dong, Z.; Luo, B.; Liu, Y.; Dai, Y.; Cao, X.; Wang, Y.; Hua, R.; Liu, Y. Ultralight Sulfonated Graphene Aerogel for Efficient Adsorption of Uranium from Aqueous Solutions. J. Radioanal. Nucl. Chem. 2019, 321, 1045–1055. [Google Scholar] [CrossRef]

- Gu, Z.; Wang, Y.; Tang, J.; Yang, J.; Liao, J.; Yang, Y.; Liu, N. The Removal of Uranium(VI) from Aqueous Solution by Graphene Oxide–Carbon Nanotubes Hybrid Aerogels. J. Radioanal. Nucl. Chem. 2015, 303, 1835–1842. [Google Scholar] [CrossRef]

- Dubey, S.P.; Dwivedi, A.D.; Kim, I.-C.; Sillanpaa, M.; Kwon, Y.-N.; Lee, C. Synthesis of Graphene–Carbon Sphere Hybrid Aerogel with Silver Nanoparticles and Its Catalytic and Adsorption Applications. Chem. Eng. J. 2014, 244, 160–167. [Google Scholar] [CrossRef]

- Riley, B.J.; Chun, J.; Um, W.; Lepry, W.C.; Matyas, J.; Olszta, M.J.; Li, X.; Polychronopoulou, K.; Kanatzidis, M.G. Chalcogen-Based Aerogels As Sorbents for Radionuclide Remediation. Environ. Sci. Technol. 2013, 47, 7540–7547. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liu, H.; Lei, Z.; Huang, L.; Wu, T.; Liu, S.; Ye, G.; Lu, Y.; Wang, X. Graphene Aerogel for Photocatalysis-Assist Uranium Elimination under Visible Light and Air Atmosphere. Chem. Eng. J. 2020, 402, 126256. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Huang, L.; Lin, F.; Liu, S.; Wu, T.; Alharbi, N.S.; Rabah, S.O.; Lu, Y.; Wang, X. Graphene Aerogel Capsulated Precipitants for High Efficiency and Rapid Elimination of Uranium from Water. Chem. Eng. J. 2020, 396, 125272. [Google Scholar] [CrossRef]

- Leventis, N.; Sadekar, A.; Chandrasekaran, N.; Sotiriou-Leventis, C. Click Synthesis of Monolithic Silicon Carbide Aerogels from Polyacrylonitrile-Coated 3D Silica Networks. Chem. Mater. 2010, 22, 2790–2803. [Google Scholar] [CrossRef]

- Vareda, J.P.; Lamy-Mendes, A.; Durães, L. A Reconsideration on the Definition of the Term Aerogel Based on Current Drying Trends. Microporous Mesoporous Mater 2018, 258, 211–216. [Google Scholar] [CrossRef]

- Aegerter, M.A.; Leventis, N.; Koebel, M.M. Aerogels Handbook; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011; ISBN 978-1-4419-7589-8. [Google Scholar]

- Kistler, S.S. Coherent Expanded Aerogels and Jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Kistler, S.S. The Relation between Heat Conductivity and Structure in Silica Aerogel. J. Phys. Chem. 1934, 39, 79–86. [Google Scholar] [CrossRef]

- Kistler, S.S. Coherent Expanded-Aerogels. J. Phys. Chem. 1931, 36, 52–64. [Google Scholar] [CrossRef]

- Kistler, S.S.; Swann, S.; Appel, E.G. Aerogel Catalysts—Thoria: Preparation of Catalyst and Conversions of Organic Acids to Ketones. Ind. Eng. Chem. 1934, 26, 388–391. [Google Scholar] [CrossRef]

- Kistler, S.S. Method of Making Aerogels. U.S. Patent 2249767A, 22 July 1941. [Google Scholar]

- Peri, J.B. Infrared Study of OH and NH2 Groups on the Surface of a Dry Silica Aerogel. J. Phys. Chem. 1966, 70, 2937–2945. [Google Scholar] [CrossRef]

- Arenillas, A.; Menéndez, J.A.; Reichenauer, G.; Celzard, A.; Fierro, V.; Hodar, F.J.M.; Bailόn-Garcia, E.; Job, N. Organic and Carbon Gels: From Laboratory Synthesis to Applications; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-030-13897-4. [Google Scholar]

- Ratke, L.; Gurikov, P. The Chemistry and Physics of Aerogels: Synthesis, Processing, and Properties; Cambridge University Press: Cambridge, UK, 2021; ISBN 978-1-108-80540-7. [Google Scholar]

- Du, A.; Zhou, B.; Zhang, Z.; Shen, J. A Special Material or a New State of Matter: A Review and Reconsideration of the Aerogel. Materials 2013, 6, 941–968. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stepanian, C. Highly Flexible Aerogel Insulated Textile-like Blankets. U.S. Patent 20070154698A1, 5 July 2007. [Google Scholar]

- Tafreshi, O.A.; Mosanenzadeh, S.G.; Karamikamkar, S.; Saadatnia, Z.; Park, C.B.; Naguib, H.E. A Review on Multifunctional Aerogel Fibers: Processing, Fabrication, Functionalization, and Applications. Mater. Today Chem. 2022, 23, 100736. [Google Scholar] [CrossRef]

- Cashman, J.L.; Nguyen, B.N.; Dosa, B.; Meador, M.A.B. Flexible Polyimide Aerogels Derived from the Use of a Neopentyl Spacer in the Backbone. ACS Appl. Polym. Mater. 2020, 2, 2179–2189. [Google Scholar] [CrossRef]

- Meador, M.A.B.; Alemán, C.R.; Hanson, K.; Ramirez, N.; Vivod, S.L.; Wilmoth, N.; McCorkle, L. Polyimide Aerogels with Amide Cross-Links: A Low Cost Alternative for Mechanically Strong Polymer Aerogels. ACS Appl. Mater. Interfaces 2015, 7, 1240–1249. [Google Scholar] [CrossRef] [Green Version]

- Ganesan, K.; Budtova, T.; Ratke, L.; Gurikov, P.; Baudron, V.; Preibisch, I.; Niemeyer, P.; Smirnova, I.; Milow, B. Review on the Production of Polysaccharide Aerogel Particles. Materials 2018, 11, 2144. [Google Scholar] [CrossRef] [Green Version]

- Paraskevopoulou, P.; Chriti, D.; Raptopoulos, G.; Anyfantis, G.C. Synthetic Polymer Aerogels in Particulate Form. Materials 2019, 12, 1543. [Google Scholar] [CrossRef] [Green Version]

- Chriti, D.; Raptopoulos, G.; Papastergiou, M.; Paraskevopoulou, P. Millimeter-Size Spherical Polyurea Aerogel Beads with Narrow Size Distribution. Gels 2018, 4, 66. [Google Scholar] [CrossRef] [Green Version]

- Leventis, N.; Trifu, R.; Begag, R.; Gould, G.L.; Zafiropoulos, N.A.; Miller, H.R. Aqueous Polyimide Processes. U.S. Patent 20220185970A1, 16 June 2022. [Google Scholar]

- Bang, A.; Buback, C.; Sotiriou-Leventis, C.; Leventis, N. Flexible Aerogels from Hyperbranched Polyurethanes: Probing the Role of Molecular Rigidity with Poly(Urethane Acrylates) Versus Poly(Urethane Norbornenes). Chem. Mater. 2014, 26, 6979–6993. [Google Scholar] [CrossRef]

- Paraskevopoulou, P.; Raptopoulos, G.; Len, A.; Dudás, Z.; Fábián, I.; Kalmár, J. Fundamental Skeletal Nanostructure of Nanoporous Polymer-Cross-Linked Alginate Aerogels and Its Relevance To Environmental Remediation. ACS Appl. Nano Mater. 2021, 4, 10575–10583. [Google Scholar] [CrossRef]

- Kanellou, A.; Anyfantis, G.C.; Chriti, D.; Raptopoulos, G.; Pitsikalis, M.; Paraskevopoulou, P. Poly(Urethane-Norbornene) Aerogels via Ring Opening Metathesis Polymerization of Dendritic Urethane-Norbornene Monomers: Structure-Property Relationships as a Function of an Aliphatic Versus an Aromatic Core and the Number of Peripheral Norbornene Moieties. Molecules 2018, 23, 1007. [Google Scholar] [CrossRef] [Green Version]

- Papastergiou, M.; Kanellou, A.; Chriti, D.; Raptopoulos, G.; Paraskevopoulou, P. Poly(Urethane-Acrylate) Aerogels via Radical Polymerization of Dendritic Urethane-Acrylate Monomers. Materials 2018, 11, 2249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Papastergiou, M.; Chriti, D.; Damalas, D.E.; Raptopoulos, G.; Paraskevopoulou, P. Poly(Urethane-Acrylate) Aerogels from the Isocyanurate Trimer of Isophorone Diisocyanate. J. Supercrit. Fluids 2019, 148, 42–54. [Google Scholar] [CrossRef]

- Taghvaee, T.; Donthula, S.; Rewatkar, P.M.; Majedi Far, H.; Sotiriou-Leventis, C.; Leventis, N. K-Index: A Descriptor, Predictor, and Correlator of Complex Nanomorphology to Other Material Properties. ACS Nano 2019, 13, 3677–3690. [Google Scholar] [CrossRef] [PubMed]

- Antonietti, M.; Fechler, N.; Fellinger, T.-P. Carbon Aerogels and Monoliths: Control of Porosity and Nanoarchitecture via Sol–Gel Routes. Chem. Mater. 2014, 26, 196–210. [Google Scholar] [CrossRef]

- Leventis, N. Polyurea Aerogels: Synthesis, Material Properties, and Applications. Polymers 2022, 14, 969. [Google Scholar] [CrossRef]

- Chidambareswarapattar, C.; Larimore, Z.; Sotiriou-Leventis, C.; Mang, J.T.; Leventis, N. One-Step Room-Temperature Synthesis of Fibrous Polyimide Aerogels from Anhydrides and Isocyanates and Conversion to Isomorphic Carbons. J. Mater. Chem. 2010, 20, 9666–9678. [Google Scholar] [CrossRef]

- Leventis, N.; Sotiriou-Leventis, C.; Chandrasekaran, N.; Mulik, S.; Larimore, Z.J.; Lu, H.; Churu, G.; Mang, J.T. Multifunctional Polyurea Aerogels from Isocyanates and Water. A Structure−Property Case Study. Chem. Mater. 2010, 22, 6692–6710. [Google Scholar] [CrossRef]

- Chidambareswarapattar, C.; McCarver, P.M.; Luo, H.; Lu, H.; Sotiriou-Leventis, C.; Leventis, N. Fractal Multiscale Nanoporous Polyurethanes: Flexible to Extremely Rigid Aerogels from Multifunctional Small Molecules. Chem. Mater. 2013, 25, 3205–3224. [Google Scholar] [CrossRef]

- Leventis, N.; Chidambareswarapattar, C.; Bang, A.; Sotiriou-Leventis, C. Cocoon-in-Web-Like Superhydrophobic Aerogels from Hydrophilic Polyurea and Use in Environmental Remediation. ACS Appl. Mater. Interfaces 2014, 6, 6872–6882. [Google Scholar] [CrossRef]

- Bang, A.; Mohite, D.; Saeed, A.M.; Leventis, N.; Sotiriou-Leventis, C. Polydicyclopentadiene Aerogels from First- versus Second-Generation Grubbs’ Catalysts: A Molecular versus a Nanoscopic Perspective. J. Sol-Gel Sci. Technol. 2015, 75, 460–474. [Google Scholar] [CrossRef]

- Meyers, F. IUPAC Announces the 2022 Top Ten Emerging Technologies in Chemistry. Available online: https://iupac.org/iupac-2022-top-ten/ (accessed on 13 November 2022).

- Lavoine, N.; Bergström, L. Nanocellulose-Based Foams and Aerogels: Processing, Properties, and Applications. J. Mater. Chem. A 2017, 5, 16105–16117. [Google Scholar] [CrossRef] [Green Version]

- Akimov, Y.K. Fields of Application of Aerogels (Review). Instrum. Exp. Tech. 2003, 46, 287–299. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel Insulation for Building Applications: A State-of-the-Art Review. Energy Build 2011, 43, 761–769. [Google Scholar] [CrossRef] [Green Version]

- Koebel, M.; Rigacci, A.; Achard, P. Aerogel-Based Thermal Superinsulation: An Overview. J. Sol-Gel Sci. Technol. 2012, 63, 315–339. [Google Scholar] [CrossRef] [Green Version]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward Aerogel Based Thermal Superinsulation in Buildings: A Comprehensive Review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Zhao, S.; Malfait, W.J.; Guerrero-Alburquerque, N.; Koebel, M.M.; Nyström, G. Biopolymer Aerogels and Foams: Chemistry, Properties, and Applications. Angew. Chem. Int. Ed. 2018, 57, 7580–7608. [Google Scholar] [CrossRef] [PubMed]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A Review and Evaluation of Thermal Insulation Materials and Methods for Thermal Energy Storage Systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Linhares, T.; de Amorim, M.T.P.; Durães, L. Silica Aerogel Composites with Embedded Fibres: A Review on Their Preparation, Properties and Applications. J. Mater. Chem. A 2019, 7, 22768–22802. [Google Scholar] [CrossRef]

- Jones, S.M. Aerogel: Space Exploration Applications. J. Sol-Gel Sci. Technol. 2006, 40, 351–357. [Google Scholar] [CrossRef]

- Economopoulos, E.; Ioannides, T. Synthesis of Transparent Silica Aerogels Using Tetraalkylammonium Fluoride Catalysts. J. Sol-Gel Sci. Technol. 2009, 49, 347–354. [Google Scholar] [CrossRef]

- Mandal, C.; Donthula, S.; Soni, R.; Bertino, M.; Sotiriou-Leventis, C.; Leventis, N. Light Scattering and Haze in TMOS-Co-APTES Silica Aerogels. J. Sol-Gel Sci. Technol. 2019, 90, 127–139. [Google Scholar] [CrossRef]

- Mandal, C.; Donthula, S.; Far, H.M.; Saeed, A.M.; Sotiriou-Leventis, C.; Leventis, N. Transparent, Mechanically Strong, Thermally Insulating Cross-Linked Silica Aerogels for Energy-Efficient Windows. J. Sol-Gel Sci. Technol. 2019, 92, 84–100. [Google Scholar] [CrossRef]

- Biener, J.; Stadermann, M.; Suss, M.; Worsley, M.A.; Biener, M.M.; Rose, K.A.; Baumann, T.F. Advanced Carbon Aerogels for Energy Applications. Energy Environ. Sci. 2011, 4, 656–667. [Google Scholar] [CrossRef]

- Li, F.; Xie, L.; Sun, G.; Kong, Q.; Su, F.; Cao, Y.; Wei, J.; Ahmad, A.; Guo, X.; Chen, C.-M. Resorcinol-Formaldehyde Based Carbon Aerogel: Preparation, Structure and Applications in Energy Storage Devices. Microporous Mesoporous Mater. 2019, 279, 293–315. [Google Scholar] [CrossRef]

- Amonette, J.E.; Matyáš, J. Functionalized Silica Aerogels for Gas-Phase Purification, Sensing, and Catalysis: A Review. Microporous Mesoporous Mater. 2017, 250, 100–119. [Google Scholar] [CrossRef]

- Keshavarz, L.; Ghaani, M.R.; MacElroy, J.M.D.; English, N.J. A Comprehensive Review on the Application of Aerogels in CO2-Adsorption: Materials and Characterisation. Chem. Eng. J. 2021, 412, 128604. [Google Scholar] [CrossRef]

- Karami, D. A Review of Aerogel Applications in Adsorption and Catalysis. J. Pet. Technol. 2018, 8, 3–15. [Google Scholar] [CrossRef]

- Saeed, A.M.; Rewatkar, P.M.; Majedi Far, H.; Taghvaee, T.; Donthula, S.; Mandal, C.; Sotiriou-Leventis, C.; Leventis, N. Selective CO2 Sequestration with Monolithic Bimodal Micro/Macroporous Carbon Aerogels Derived from Stepwise Pyrolytic Decomposition of Polyamide-Polyimide-Polyurea Random Copolymers. ACS Appl. Mater. Interfaces 2017, 9, 13520–13536. [Google Scholar] [CrossRef]

- Donthula, S.; Mandal, C.; Leventis, T.; Schisler, J.; Saeed, A.M.; Sotiriou-Leventis, C.; Leventis, N. Shape Memory Superelastic Poly(Isocyanurate-Urethane) Aerogels (PIR-PUR) for Deployable Panels and Biomimetic Applications. Chem. Mater. 2017, 29, 4461–4477. [Google Scholar] [CrossRef]

- Donthula, S.; Mandal, C.; Schisler, J.; Leventis, T.; Meador, M.A.B.; Sotiriou-Leventis, C.; Leventis, N. Nanostructure-Dependent Marcus-Type Correlation of the Shape Recovery Rate and the Young’s Modulus in Shape Memory Polymer Aerogels. ACS Appl. Mater. Interfaces 2018, 10, 23321–23334. [Google Scholar] [CrossRef]

- Chriti, D.; Raptopoulos, G.; Brandenburg, B.; Paraskevopoulou, P. Large, Rapid Swelling of High-Cis Polydicyclopentadiene Aerogels Suitable for Solvent-Responsive Actuators. Polymers 2020, 12, 1033. [Google Scholar] [CrossRef] [PubMed]

- Pierre, A.C.; Pajonk, G.M. Chemistry of Aerogels and Their Applications. Chem. Rev. 2002, 102, 4243–4266. [Google Scholar] [CrossRef]

- Moreno-Castilla, C.; Maldonado-Hódar, F.J. Carbon Aerogels for Catalysis Applications: An Overview. Carbon 2005, 43, 455–465. [Google Scholar] [CrossRef]

- Wan, W.; Zhang, R.; Ma, M.; Zhou, Y. Monolithic Aerogel Photocatalysts: A Review. J. Mater. Chem. A 2018, 6, 754–775. [Google Scholar] [CrossRef]

- Maleki, H.; Hüsing, N. Current Status, Opportunities and Challenges in Catalytic and Photocatalytic Applications of Aerogels: Environmental Protection Aspects. Appl. Catal. B Environ. 2018, 221, 530–555. [Google Scholar] [CrossRef]

- Saeed, A.M.; Wisner, C.A.; Donthula, S.; Majedi Far, H.; Sotiriou-Leventis, C.; Leventis, N. Reuseable Monolithic Nanoporous Graphite-Supported Nanocatalysts (Fe, Au, Pt, Pd, Ni, and Rh) from Pyrolysis and Galvanic Transmetalation of Ferrocene-Based Polyamide Aerogels. Chem. Mater. 2016, 28, 4867–4877. [Google Scholar] [CrossRef]

- García-González, C.A.; Budtova, T.; Durães, L.; Erkey, C.; Del Gaudio, P.; Gurikov, P.; Koebel, M.; Liebner, F.; Neagu, M.; Smirnova, I. An Opinion Paper on Aerogels for Biomedical and Environmental Applications. Molecules 2019, 24, 1815. [Google Scholar] [CrossRef] [Green Version]

- Kaya, G.G.; Aznar, E.; Deveci, H.; Martínez-Máñez, R. Aerogels as Promising Materials for Antibacterial Applications: A Mini-Review. Biomater. Sci. 2021, 9, 7034–7048. [Google Scholar] [CrossRef]

- Mikkonen, K.S.; Parikka, K.; Ghafar, A.; Tenkanen, M. Prospects of Polysaccharide Aerogels as Modern Advanced Food Materials. Trends Food Sci. Technol. 2013, 34, 124–136. [Google Scholar] [CrossRef]

- Maleki, H. Recent Advances in Aerogels for Environmental Remediation Applications: A Review. Chem. Eng. J. 2016, 300, 98–118. [Google Scholar] [CrossRef]

- Kumar, A.; Rana, A.; Sharma, G.; Sharma, S.; Naushad, M.; Mola, G.T.; Dhiman, P.; Stadler, F.J. Aerogels and Metal–Organic Frameworks for Environmental Remediation and Energy Production. Environ. Chem. Lett. 2018, 16, 797–820. [Google Scholar] [CrossRef]

- AERoGELS COST Action. Available online: https://cost-aerogels.eu/ (accessed on 13 November 2022).

- Konstantinou, M.; Pashalidis, I. Speciation and Spectrophotometric Determination of Uranium in Seawater. Mediterr. Mar. Sci. 2004, 5, 55–60. [Google Scholar] [CrossRef]

- Paraskevopoulou, P.; Smirnova, I.; Athamneh, T.; Papastergiou, M.; Chriti, D.; Mali, G.; Čendak, T.; Chatzichristidi, M.; Raptopoulos, G.; Gurikov, P. Mechanically Strong Polyurea/Polyurethane-Cross-Linked Alginate Aerogels. ACS Appl. Polym. Mater. 2020, 2, 1974–1988. [Google Scholar] [CrossRef]

- Paraskevopoulou, P.; Smirnova, I.; Athamneh, T.; Papastergiou, M.; Chriti, D.; Mali, G.; Čendak, T.; Raptopoulos, G.; Gurikov, P. Polyurea-Crosslinked Biopolymer Aerogel Beads. RSC Adv. 2020, 10, 40843. [Google Scholar] [CrossRef]

- Fricke, M.; Paraskevopoulou, P.; Gurikov, P.; Chriti, D.; Papastergiou, M.; Raptopoulos, G.; Athamneh, T.; Smirnova, I.; Movahed, S.; Weinrich, D.; et al. Polyurea/Polyurethane-Crosslinked Alginate Aerogels. EP3848409A1, 14 July 2021. [Google Scholar]

- Raptopoulos, G.; Papastergiou, M.; Chriti, D.; Effraimopoulou, E.; Čendak, T.; Samartzis, N.; Mali, G.; Ioannides, T.; Gurikov, P.; Smirnova, I.; et al. Metal-Doped Carbons from Polyurea-Crosslinked Alginate Aerogel Beads. Mater. Adv. 2021, 2, 2684–2699. [Google Scholar] [CrossRef]

- Paraskevopoulou, P.; Raptopoulos, G.; Leontaridou, F.; Papastergiou, M.; Sakellari, A.; Karavoltsos, S. Evaluation of Polyurea-Crosslinked Alginate Aerogels for Seawater Decontamination. Gels 2021, 7, 27. [Google Scholar] [CrossRef]

- Georgiou, E.; Pashalidis, I.; Raptopoulos, G.; Paraskevopoulou, P. Efficient Removal of Polyvalent Metal Ions (Eu(III) and Th(IV)) from Aqueous Solutions by Polyurea-Crosslinked Alginate Aerogels. Gels 2022, 8, 478. [Google Scholar] [CrossRef]

- Zoi, A.; Karanika, E.A. Heavy Metals Uptake from Water Using Polyurea-Crosslinked Alginate Aerogels. Diploma Thesis, Department of Chemistry, National and Kapodistrian University of Athens, Athens, Greece, 2021. [Google Scholar]

- Pashalidis, I.; Czerwinski, K.R.; Fanghänel, T.; Kim, J.I. Solid-Liquid Phase Equilibria of Pu(VI) and U(VI) in Aqueous Carbonate Systems. Determination of Stability Constants. Radiochim. Acta 1997, 76, 55–62. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Azizian, S.; Douven, S. Implications of Apparent Pseudo-Second-Order Adsorption Kinetics onto Cellulosic Materials: A Review. BioResources 2019, 14, 7582–7626. [Google Scholar] [CrossRef]

- Lima, E.C.; Sher, F.; Guleria, A.; Saeb, M.R.; Anastopoulos, I.; Tran, H.N.; Hosseini-Bandegharaei, A. Is One Performing the Treatment Data of Adsorption Kinetics Correctly? J. Environ. Chem. Eng. 2021, 9, 104813. [Google Scholar] [CrossRef]

- Liakos, E.V.; Lazaridou, M.; Michailidou, G.; Koumentakou, I.; Lambropoulou, D.A.; Bikiaris, D.N.; Kyzas, G.Z. Chitosan Adsorbent Derivatives for Pharmaceuticals Removal from Effluents: A Review. Macromol 2021, 1, 130–154. [Google Scholar] [CrossRef]

- Payne, T.E.; Brendler, V.; Ochs, M.; Baeyens, B.; Brown, P.L.; Davis, J.A.; Ekberg, C.; Kulik, D.A.; Lutzenkirchen, J.; Missana, T.; et al. Guidelines for Thermodynamic Sorption Modelling in the Context of Radioactive Waste Disposal. Environ. Model. Softw. 2013, 42, 143–156. [Google Scholar] [CrossRef]

- Liatsou, I.; Pashalidis, I.; Nicolaides, A. Triggering Selective Uranium Separation from Aqueous Solutions by Using Salophen-Modified Biochar Fibers. J. Radioanal. Nucl. Chem. 2018, 318, 2199–2203. [Google Scholar] [CrossRef]

- Konstantinou, M.; Kasseta, G.; Pashalidis, I. Boron Adsorption on Alumina (Al2O3) and Magnesia (MgO) in Aqueous Solutions: A Comparative Study. Int. J. Environ. Technol. Manag. 2006, 6, 466–479. [Google Scholar] [CrossRef]

- Chriti, D.; Raptopoulos, G.; Anyfantis, G.C.; Paraskevopoulou, P. An Extreme Case of Swelling of Mostly Cis-Polydicyclopentadiene by Selective Solvent Absorption—Application in Decontamination and Environmental Remediation. ACS Appl. Polym. Mater. 2019, 1, 1648–1659. [Google Scholar] [CrossRef]

| Aerogel Material | pH | Temp. (K) | [U(VI)]o/max (mol L–1) | Best-Fitted Isotherm/Kinetic Model | qmax (g kg–1) | Competition/Recycling/Recovery | Data Related to U(VI) Adsorption | Ref. |

|---|---|---|---|---|---|---|---|---|

| Hydroxyapatite (templated with konjac gum) | 4 | 298 | 4.2 × 10–4 | Langmuir, PSO | 2088 | anion/cation competition reuse for five cycles | FTIR, XPS, and mechanistic studies | [37,38] |

| Polyurea-crosslinked alginate (X-alginate) | 3 | 298 | 4.2 × 10–5 | Langmuir | 2023 | natural waters, seawater, modelling, wastewater, and recycling | FTIR and EDS | [39] |

| Reduced graphene oxide/ZIF-67 a | 4 | 298 | 1.05 × 10–3 | Langmuir, PSO | 1888 | cation competition, reuse for five cycles | FTIR and XPS | [40] |

| Al2O3/MgO | 6 | 298 | 4.2 × 10–5 | Langmuir, PSO | 1047 | cation competition, reuse for five cycles | XPS and mechanistic studies | [41] |

| MOF/black phosphorus quantum dots on cellulose b | 7 | 303 | Langmuir, PSO | 858 | seawater and recycling | XPS and mechanistic studies | [42] | |

| Pr2O3 | 7 | 298 | 4.2 × 10–5 | Langmuir, PSO | 841 | cation competition and reuse for five cycles | FTIR and XPS | [43] |

| Al2O3 (templated with chitosan) | 7 | 298 | 4.2 × 10–5 | Langmuir, PSO | 814 | anion/cation competition and reuse for five cycles | FTIR, XPS, and mechanistic studies | [44,45] |

| Al2O3 (templated with polyethylene glycol) | 7 | 298 | 4.2 × 10–5 | Langmuir, PSO | 737 | anion/cation competition and reuse for five cycles | FTIR, XPS, and mechanistic studies | [44] |

| Amidoxime-functionalized β-cyclodextrin/graphene | 6 | 298 | 8.4 × 10–4 | Langmuir | 654 | cation competition and reuse for ten cycles | FTIR and XPS | [46] |

| TiO2 | 5 | 298 | 4.2 × 10–5 | Langmuir, PSO | 638 | cation competition and reuse for five cycles | FTIR and XPS | [47] |

| Al2O3 (prepared with thiourea) | 7 | 298 | 4.2 × 10–5 | Langmuir, PSO | 634 | seawater | FTIR and XPS | [48] |

| Al2O3 (templated with dopamine) | 7 | 298 | 4.2 × 10–5 | Langmuir, PSO | 592 | anion/cation competition and reuse for five cycles | FTIR, XPS, and mechanistic studies | [44] |

| Poly(amidoxime)/graphene oxide nanoribbons | 4.5 | 298 | 5.0 × 10–4 | Langmuir | 589 | cation competition and reuse for five cycles | XPS, mechanistic studies, and DFT modelling | [49] |

| Nd2O3 | 7 | - | 4.2 × 10–5 | Langmuir, PSO | 587 | cation competition and reuse for five cycles | FTIR and XPS | [43] |

| Bacterial cellulose@ZIF-8 carbon c | 3 | 308 | 8.4 × 10–5 | Langmuir, PSO | 535 | cation competition and reuse for five cycles | FTIR and XPS | [50] |

| Calcium alginate/MgAlFe layered double hydroxides | 5 | 298 | 8.4 × 10–5 | Langmuir, PSO | 532 | - | FTIR and XPS | [51] |

| CeO2 | 7 | 298 | 4.2 × 10–5 | Langmuir, PSO | 482 | cation competition and reuse for five cycles | FTIR and XPS | [43] |

| Nanocellulose | 5 | 298 | 4.2 × 10–5 | Langmuir, PSO | 441 | cation competition and reuse for five cycles | FTIR and XPS | [52] |

| Chitosan/aluminum sludge composite | 4 | 308 | 3 × 10–3 | Langmuir, PSO | 435 | cation competition and reuse for five cycles | XPS and mechanistic studies | [53] |

| Graphene oxide nanoribbon | 4.5 | 298 | 2.52 × 10–4 | Langmuir, PSO | 431 | - | [54] | |

| Calcium alginate | 3 | 298 | 4.2 × 10–5 | Langmuir | 388 | - | [39] | |

| Iron-polyaniline-graphene composite | 5.5 | 318 | 4.2 × 10–5 | Langmuir, PSO | 350 | reuse for five cycles | FTIR, XPS, EDS, and mechanistic studies | [55] |

| Chitosan/carboxylated carbon nanotube composite | 5 | 318 | 5.04 × 10–4 | Langmuir, PSO | 341 | cation competition | FTIR and XPS | [56] |

| Bayberry tannin/graphene composite | 5 | 298 | - | - | 330 | - | [57] | |

| Reduced graphene oxide/g-C3N4 quantum dots/ZIF-67 composite carbon a | 3 | 328 | 8.4 × 10–5 | Langmuir, PSO | 316 | cation competition and reuse for five cycles | FTIR and XPS | [58] |

| Aromatic polyurea derived from TIPM d | 3 | 298 | 4.2 × 10–5 | Langmuir | 305 | - | [39] | |

| Fungus hypha/graphene oxide | 5 | 293 | 5.04 × 10–4 | Langmuir | 288 | cation competition and reuse for six cycles | XPS | [59] |

| Aramid/polyamidoxime | 6 | 298 | 4.2 × 10–4 | Langmuir, PSO | 262 | cation competition and reuse for five cycles | [60] | |

| Pr2O3 | 8 | 298 | 4.2 × 10–5 | - | 252 | - | [61] | |

| Graphene | 4 | 298 | 1.02 × 10–4 | Langmuir, PSO | 239 | reuse for four cycles | XPS | [62] |

| Carbon/Fe3O4 | 6 | 303 | 2.1 × 10–4 | Langmuir, PSO | 230 | anion/cation competition and reuse for five cycles | FTIR and XPS | [63] |

| Melamine-formaldehyde/alginate | 4 | 298 | 4.2 × 10–4 | Langmuir | 211 | cation competition | [64] | |

| Polydopamine- functionalized attapulgite/chitosan | 6 | - | 2.1 × 10–4 | Langmuir, PSO | 175 | reuse for six cycles | FTIR and XPS | [65] |

| p-Phthalaldehyde/3,5-diaminobenzoic acid-crosslinked chitosan | 6 | 308 | 4.2 × 10–5 | Langmuir, PSO | 160 | - | XPS | [66] |

| Phosphorylated carbon | 5.5 | 298 | 4.2 × 10–5 | Langmuir, PSO | 150 | cation competition and reuse for five cycles | FTIR and XPS | [67] |

| Sulfonated graphene | 5 | 298 | 4.2 × 10–5 | Langmuir, PSO | 148 | cation competition and reuse for five cycles | FTIR and XPS | [68] |

| Graphene oxide/carbon nanotubes | 5 | 298 | 2.1 × 10–4 | Langmuir, PSO | 100 | - | [69] | |

| Graphene/Ag nanoparticles | 5–6 | 298 | 8.4 × 10–5 | Langmuir | 13 | - | [70] |

| Aerogel Material | ΔH0 (kJ mol–1) | ΔS0 (J K–1 mol–1) | Ref. |

|---|---|---|---|

| Reduced graphene oxide/ZIF-67 a | 11.7 | 120 | [40] |

| Bacterial cellulose@ZIF-8 carbon b | 113.73 | 382.4 | [50] |

| Nanocellulose | 10.80 | 71.33 | [52] |

| Chitosan/aluminum sludge composite | 6.5 | 77 | [53] |

| Iron-polyaniline-graphene composite | 60.74 | - | [55] |

| Chitosan/carboxylated carbon nanotube composite | 21.96 | 157.3 | [56] |

| Fungus hypha/graphene oxide | 9.31 | 51.55 | [59] |

| Graphene | −47.94 | −73.03 | [62] |

| Carbon/Fe3O4 | 141.4 | 500.2 | [63] |

| Polydopamine- functionalized attapulgite/chitosan | 5.45 | 50.24 | [65] |

| p-Phthalaldehyde/3,5-diaminobenzoic acid-crosslinked chitosan | 2.147 | 58.288 | [66] |

| Sulfonated graphene | 4.3 | 89.9 | [68] |

| Graphene oxide/carbon nanotubes | 8.146 | 91.43 | [69] |

| Polyurea-crosslinked alginate (X-alginate) | >0 | >0 | [39] |

| Reduced graphene oxide/g-C3N4 quantum dots/ZIF-67 composite carbon a | >0 | >0 | [58] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Georgiou, E.; Raptopoulos, G.; Anastopoulos, I.; Giannakoudakis, D.A.; Arkas, M.; Paraskevopoulou, P.; Pashalidis, I. Uranium Removal from Aqueous Solutions by Aerogel-Based Adsorbents—A Critical Review. Nanomaterials 2023, 13, 363. https://doi.org/10.3390/nano13020363

Georgiou E, Raptopoulos G, Anastopoulos I, Giannakoudakis DA, Arkas M, Paraskevopoulou P, Pashalidis I. Uranium Removal from Aqueous Solutions by Aerogel-Based Adsorbents—A Critical Review. Nanomaterials. 2023; 13(2):363. https://doi.org/10.3390/nano13020363

Chicago/Turabian StyleGeorgiou, Efthalia, Grigorios Raptopoulos, Ioannis Anastopoulos, Dimitrios A. Giannakoudakis, Michael Arkas, Patrina Paraskevopoulou, and Ioannis Pashalidis. 2023. "Uranium Removal from Aqueous Solutions by Aerogel-Based Adsorbents—A Critical Review" Nanomaterials 13, no. 2: 363. https://doi.org/10.3390/nano13020363