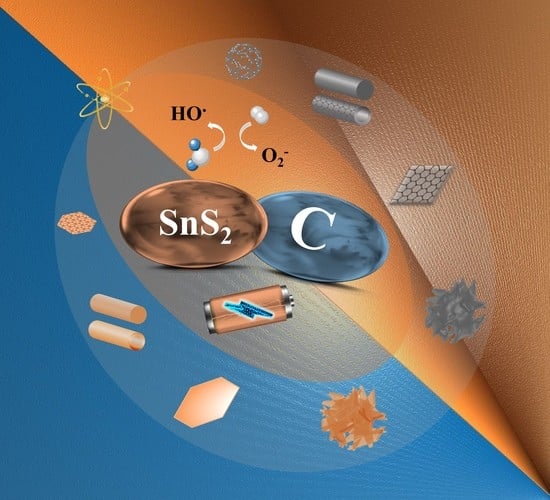

Synthesis and Applications of Dimensional SnS2 and SnS2/Carbon Nanomaterials

Abstract

:1. Introduction

2. Synthesis Methods

2.1. Wet Chemical Synthesis of SnS2 and SnS2/Carbon Nanomaterials

2.1.1. Wet Chemical Synthesis of SnS2 Nanomaterials

2.1.2. Wet Chemical Synthesis of SnS2/Carbon Nanomaterials

2.2. Solid-Phase Synthesis of SnS2 and SnS2/Carbon Nanomaterials

2.2.1. Solid-Phase Synthesis of SnS2 Nanomaterials

2.2.2. Solid-Phase Synthesis of SnS2/Carbon Nanomaterials

3. Dimensional Characteristics of SnS2 and SnS2/Carbon Nanomaterials

3.1. Dimensional Characteristics of SnS2 Nanomaterials

3.1.1. Zero-Dimensional (0D Nanodots) SnS2 Nanomaterials

3.1.2. One-Dimensional (1D) SnS2 Nanomaterials

3.1.3. Two-Dimensional (2D) SnS2/Flake Nanomaterials

3.1.4. Three-Dimensional (3D) Self-Supporting SnS2 Nanoflowers

3.2. Dimensional Characteristics of SnS2/Carbon Composite Nanomaterials

3.2.1. Zero-Dimensional (0D) SnS2/Carbon Composite Nanodots

| Dimension | SnS2 Structures | Carbon Structures | Published Composite Nanomaterials | Ref. |

|---|---|---|---|---|

| 0D |  |  |  | [91] |

| 1D |  |  |  | [58,92,95,135,136,137,138] |

| 2D |  |  |  | [89,139,140,141,142,143] |

| 3D |  |  |  | [111,136,144,145,146,147,148,149,150] |

| Potential structures of SnS2/Carbon composite nanomaterials | ||||

| ||||

3.2.2. One-Dimensional (1D) SnS2/Carbon Composite Nanomaterials

3.2.3. Two-Dimensional (2D) SnS2/Carbon Composite Nanomaterials

3.2.4. Three-Dimensional (3D) Self-Supporting SnS2/Carbon Nanomaterials

4. Applications of Synthesized SnS2 and SnS2/Carbon Nanomaterials in Environmental Remediation, Electrochemical Energy Conversion, and Storage

4.1. Photocatalyst in Pollutant Degradation

4.1.1. SnS2 Nanomaterials in Photocatalysis

4.1.2. SnS2/Carbon Nanomaterials in Photocatalysis

4.2. Electrochemical Conversion and Energy Storage Applications of SnS2 and SnS2/Carbon Nanomaterials

4.2.1. SnS2 Nanomaterials in Electrochemical Conversion and Energy Storage

4.2.2. SnS2/Carbon Nanomaterials in Electrochemical Conversion and Energy Storage

| Dimension | Materials | High Reversible Capacity (mAh g−1) | Cycle | Capacity Retention | Applications | Ref. |

|---|---|---|---|---|---|---|

| 1D | SnS2 | - | - | - | - | - |

| SnS2/Carbon Nanotubes | 940 & 605 | 200 | 91.2% & 87.6% @100 mA/g | LIB/SIB | [55] | |

| SnS2/Carbon Nanotubes | 513.8 | 10 | 82% @100 mA/g | LIBs | [58] | |

| Polypyrrole/SnS2/Carbon | 1009 | 100 | 97.7% @100 mA/g | LIBs | [93] | |

| SnS2/Graphene Nanorods | 335 | 350 | 92% @100 mA/g | LIBs | [135] | |

| SnS2/HCNF 1 | 675 | 500 | 92.3% @ 100 mA/g | LSBs | [239] | |

| SnS2/Carbon (MWNTs) 2 | 768 | 100 | 78% @ 100 mA/g | SIBs | [250] | |

| SnS2/Carbon Nanofibers | 457 | ~1000@2 A/g | 89.5% @ 50 mA/g | PIBs 5 | [251] | |

| 2D | SnS2 Nanosheets | 733 | 50 | 100 mA/g | SIB | [125] |

| SnS2 Nanoplates | 521 | 50 | 90% @ 100 mA/g | LIBs | [218] | |

| SnS2/PCN 3 | 816 | 100 | - | LSBs | [237] | |

| SnS2/EPC 4 | 443 | 450 | 89.4% @100 mA/g | SIBs | [252] | |

| SnS2/Graphene | 911 | 200 | 89% @ 100 mA/g | LIBs | [253] | |

| SnS2/rGO | 738 | 60 | 76.5% @ 0.2 C | LIBs | [254] | |

| 3D | SnS2 Nanoflowers | 557 | 50 | 65% @ 0.1 C | LIBs | [53] |

| SnS2 Nanoflowers | 549.5 | 10 | 73% @ 100 mA/g | LIBs | [129] | |

| SnS2 Nanoflowers | 502 | 50 | 84% @ 0.3 C | LIBs | [255] | |

| SnS2/Carbon | 960 | 300 | 95% @ 100 mA/g | LIBs | [256] | |

| SnS2/Carbon-rGO | 953 | 90 | 100 mA/g | LIBs | [257] | |

| SnS2/Carbon Nanoflowers | 551 | 50 | 97% @ 100 mA/g | LIBs | [148] | |

| SnS2/Carbon Nanocubes | 1080.1 | 200 | 84.1% @ 100 mA/g | LIBs | [109] | |

| SnS2/Carbon Nanospheres | 690 | 150 @ 1 A/g | 87% @ 100 mA/g | SIBS | [110] |

5. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, J.; Müller, A.H.E. One-Dimensional Organic-Inorganic Hybrid Nanomaterials. Polymer 2010, 51, 4015–4036. [Google Scholar] [CrossRef] [Green Version]

- Moon, D.S.; Lee, J.K. Tunable Synthesis of Hierarchical Mesoporous Silica Nanoparticles with Radial Wrinkle Structure. Langmuir 2012, 28, 12341–12347. [Google Scholar] [CrossRef] [PubMed]

- Cai, H.; Qiao, X.; Chen, M.; Feng, D.; Alghamdi, A.A.; Alharthi, F.A.; Pan, Y.; Zhao, Y.; Zhu, Y.; Deng, Y. Hydrothermal Synthesis of Hierarchical SnO2 Nanomaterials for High-Efficiency Detection of Pesticide Residue. Chin. Chem. Lett. 2020, 32, 1502–1506. [Google Scholar] [CrossRef]

- Liu, N.; Prall, B.S.; Klimov, V.I. Hybrid Gold/Silica/Nanocrystal-Quantum-Dot Superstructures: Synthesis and Analysis of Semiconductor-Metal Interactions. J. Am. Chem. Soc. 2006, 128, 15362–15363. [Google Scholar] [CrossRef]

- Xiong, J.; Du, X.; Cheng, G.; Yang, H.; Chen, J.; Dou, S.; Li, Z. One Dimensional Hierarchical Nanostructures Composed of CdS Nanosheets/Nanoparticles and Ag Nanowires with Promoted Photocatalytic Performance. Inorg. Chem. Front. 2018, 5, 903–915. [Google Scholar] [CrossRef] [Green Version]

- Mikhaylov, A.A.; Medvedev, A.G.; Grishanov, D.A.; Edison, E.; Srinivasan, M.; Sladkevich, S.; Gun, J.; Prikhodchenko, P.V.; Lev, O. Green Synthesis of a Nanocrystalline Tin Disulfide-Reduced Graphene Oxide Anode from Ammonium Peroxostannate: A Highly Stable Sodium-Ion Battery Anode. ACS Sustain. Chem. Eng. 2020, 8, 5485–5494. [Google Scholar] [CrossRef]

- Jeghan, S.M.N.; Lee, G. One-Dimensional Hierarchical Nanostructures of NiCo2O4, NiCo2S4 and NiCo2Se4 with Superior Electrocatalytic Activities toward Efficient Oxygen Evolution Reaction. Nanotechnology 2020, 31, 295405. [Google Scholar] [CrossRef]

- Iqbal, J.; Jan, T.; Ul-Hassan, S.; Ahmed, I.; Mansoor, Q.; Umair Ali, M.; Abbas, F.; Ismail, M. Facile Synthesis of Zn Doped CuO Hierarchical Nanostructures: Structural, Optical and Antibacterial Properties. AIP Adv. 2015, 5, 127112. [Google Scholar] [CrossRef] [Green Version]

- Zheng, P.; Dai, Z.; Zhang, Y.; Dinh, K.N.; Zheng, Y.; Fan, H.; Yang, J.; Dangol, R.; Li, B.; Zong, Y.; et al. Scalable Synthesis of SnS2/S-Doped Graphene Composites for Superior Li/Na-Ion Batteries. Nanoscale 2017, 9, 14820–14825. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Shao, H.; Yang, C.; Feng, X.; Han, L.; Zhou, Y.; Du, W.; Sun, X.; Xu, Z.; Zhang, X.; et al. SnS2 Nanosheets with rGO Modification as High-Performance Anode Materials for Na-Ion and k-Ion Batteries. Nanomaterials 2021, 11, 1932. [Google Scholar] [CrossRef]

- Smith, A.T.; LaChance, A.M.; Zeng, S.; Liu, B.; Sun, L. Synthesis, Properties, and Applications of Graphene Oxide/Reduced Graphene Oxide and Their Nanocomposites. Nano Mater. Sci. 2019, 1, 31–47. [Google Scholar] [CrossRef]

- Tao, H.; Xiong, L.; Zhu, S.; Yang, X.; Zhang, L. Flexible Binder-Free Reduced Graphene Oxide Wrapped Si/Carbon Fibers Paper Anode for High-Performance Lithium Ion Batteries. Int. J. Hydrogen Energy 2016, 41, 21268–21277. [Google Scholar] [CrossRef]

- Li, H.; He, X.; Kang, Z.; Huang, H.; Liu, Y.; Liu, J.; Lian, S.; Tsang, C.H.A.; Yang, X.; Lee, S.T. Water-Soluble Fluorescent Carbon Quantum Dots and Photocatalyst Design. Angew. Chem. Int. Ed. 2010, 49, 4430–4434. [Google Scholar] [CrossRef]

- Xiong, Z.; Fuji, M.; Zhou, J. Ultrathin Carbon-Coated Fe7S8 Core/Shell Nanosheets towards Superb Na Storage in Both Ether and Ester Electrolyte Systems. Sustain. Energy Fuels 2019, 3, 2845–2858. [Google Scholar] [CrossRef]

- Mas, N.; Hueso, J.L.; Martinez, G.; Madrid, A.; Mallada, R.; Ortega-Liebana, M.C.; Bueno-Alejo, C.; Santamaria, J. Laser-Driven Direct Synthesis of Carbon Nanodots and Application as Sensitizers for Visible-Light Photocatalysis. Carbon. N. Y. 2020, 156, 453–462. [Google Scholar] [CrossRef]

- Yan, L.; Li, L.; Ru, X.; Wen, D.; Ding, L.; Zhang, X.; Diao, H.; Qin, Y. Core-Shell, Wire-in-Tube and Nanotube Structures: Carbon-Based Materials by Molecular Layer Deposition for Efficient Microwave Absorption. Carbon. N. Y. 2021, 173, 145–153. [Google Scholar] [CrossRef]

- Yan, D.; Liu, J.; Zhang, Z.; Wang, Y.; Zhang, M.; Song, D.; Zhang, T.; Liu, J.; He, F.; Wang, J. Dual-Functional Graphene Oxide-Based Nanomaterial for Enhancing the Passive and Active Corrosion Protection of Epoxy Coating. Compos. B Eng. 2021, 222, 109075. [Google Scholar] [CrossRef]

- Luo, D.; Wang, X.; Zhang, Z.; Gao, D.; Liu, Z.; Chen, J. Enhancement of Photocatalytic Hydrogen Evolution from Dye–Sensitized Amide–Functionalized Carbon Nanospheres by Superior Adsorption Performance. Int. J. Hydrog. Energy 2020, 45, 30375–30386. [Google Scholar] [CrossRef]

- Kim, Y.; Yang, H.-S.; Yoon, J.; Jun Jo, M.; Ho Youk, J.; Lee, B.-S.; Yu, W.-R. Electrochemical Properties of PVP-Derived Carbon Nanospheres with Various Porosity and Heteroatom Contents in Anode Voltage Range over Full-Cell Operation. J. Ind. Eng. Chem. 2022, 105, 146–157. [Google Scholar] [CrossRef]

- Liang, L.; Chang, Q.; Cai, T.; Li, N.; Xue, C.; Yang, J.; Hu, S. Combining Carbon Dots with WO3-x Nanodots for Utilizing the Full Spectrum of Solar Radiation in Photocatalysis. Chem. Eng. J. 2022, 428, 131139. [Google Scholar] [CrossRef]

- Khazaee, Z.; Mahjoub, A.R.; Cheshme Khavar, A.H. One-Pot Synthesis of CuBi Bimetallic Alloy Nanosheets-Supported Functionalized Multiwalled Carbon Nanotubes as Efficient Photocatalyst for Oxidation of Fluoroquinolones. Appl. Catal. B 2021, 297, 120480. [Google Scholar] [CrossRef]

- Neravathu, D.; Paloly, A.R.; Sajan, P.; Satheesh, M.; Bushiri, M.J. Hybrid Nanomaterial of ZnFe2O4/α-Fe2O3 Implanted Graphene for Electrochemical Glucose Sensing Application. Diam. Relat. Mater. 2020, 106, 107852. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Zheng, J. One-Pot Fabrication of AuNPs-Prussian Blue-Graphene Oxide Hybrid Nanomaterials for Non-Enzymatic Hydrogen Peroxide Electrochemical Detection. Microchem. J. 2021, 160, 105595. [Google Scholar] [CrossRef]

- Qin, X.; Huang, Y.; Wang, K.; Xu, T.; Li, S.; Zhao, M.; Wang, Y.; Chen, Q. Novel Hexagonal Bi2O2CO3 Porous Nanoplate/Nitrogen-Doped Graphene Nanomaterial Enhanced Electrochemical Properties of Oxygen Reduction Reaction in Acidic Medium for Fuel Cells. Carbon. N. Y. 2019, 152, 459–473. [Google Scholar] [CrossRef]

- Balakumar, V.; Selvarajan, S.; Baishnisha, A.; Kathiresan, S. In-Situ Growth of TiO2@B-Doped g-C3N4 Core-Shell Nanospheres for Boosts the Photocatalytic Detoxification of Emerging Pollutants with Mechanistic Insight. Appl. Surf. Sci. 2022, 577, 151924. [Google Scholar] [CrossRef]

- Wu, J.J.; Tao, Y.R.; Wu, Y.; Wu, X.C. Ultrathin SnS2 Nanosheets of Ultrasonic Synthesis and Their Photoresponses from Ultraviolet to Near-Infrared. Sens. Actuators B Chem. 2016, 231, 211–217. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Hou, C.; Zhang, Y.; Nan, Z. Scalable Low Temperature in Air Solid Phase Synthesis of Porous Flower-like Hierarchical Nanostructure SnS2 with Superior Performance in the Adsorption and Photocatalytic Reduction of Aqueous Cr(VI). Sep. Purif. Technol. 2017, 189, 153–161. [Google Scholar] [CrossRef]

- Liu, X.; Sakthivel, R.; Chen, Y.C.; Chang, N.; Dhawan, U.; Li, Y.; Zhao, G.; Lin, C.; Chung, R.J. Tin Disulfide–Graphene Oxide-β-Cyclodextrin Mediated Electro-Oxidation of Melatonin Hormone: An Efficient Platform for Electrochemical Sensing. J. Mater. Chem. B 2020, 8, 7539–7547. [Google Scholar] [CrossRef]

- Mahmud, S.T.; Mia, R.; Mahmud, S.; Sha, S.; Zhang, R.; Deng, Z.; Yanilmaz, M.; Luo, L.; Zhu, J. Recent Developments of Tin (II) Sulfide/Carbon Composites for Achieving High-Performance Lithium Ion Batteries: A Critical Review. Nanomaterials 2022, 12, 1246. [Google Scholar] [CrossRef]

- Zhan, S.; Zheng, L.; Xiao, Y.; Zhao, L.D. Phonon and Carrier Transport Properties in Low-Cost and Environmentally Friendly SnS2: A Promising Thermoelectric Material. Chem. Mater. 2020, 32, 10348–10356. [Google Scholar] [CrossRef]

- Munn, Z.; Peters, M.D.J.; Stern, C.; Tufanaru, C.; McArthur, A.; Aromataris, E. Systematic Review or Scoping Review? Guidance for Authors When Choosing between a Systematic or Scoping Review Approach. BMC Med. Res. Methodol. 2018, 18, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Hayashi, H.; Hakuta, Y. Hydrothermal Synthesis of Metal Oxide Nanoparticles in Supercritical Water. Materials 2010, 3, 3794–3817. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yahya, R.B.; Hayashi, H.; Nagase, T.; Ebina, T.; Onodera, Y.; Saitoh, N. Hydrothermal Synthesis of Potassium Hexatitanates under Subcritical and Supercritical Water Conditions and Its Application in Photocatalysis. Chem. Mater. 2001, 13, 842–847. [Google Scholar] [CrossRef]

- Bai, X.; Li, L.; Liu, H.; Tan, L.; Liu, T.; Meng, X. Solvothermal Synthesis of ZnO Nanoparticles and Anti-Infection Application in Vivo. ACS Appl. Mater. Interfaces 2015, 7, 1308–1317. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Li, J.; Xu, H.Y. One-Step in Situ Solvothermal Synthesis of SnS2/TiO2 Nanocomposites with High Performance in Visible Light-Driven Photocatalytic Reduction of Aqueous Cr(VI). Appl. Catal. B 2012, 123–124, 18–26. [Google Scholar] [CrossRef]

- Vakhrushev, A.Y.; Boitsova, T.B. TiO2 and TiO2/Ag Nanofibers: Template Synthesis, Structure, and Photocatalytic Properties. J. Porous Mater. 2021, 28, 1023–1030. [Google Scholar] [CrossRef]

- Tsukigase, H.; Suzuki, Y.; Berger, M.-H.; Sagawa, T.; Yoshikawa, S. Wet Chemical Synthesis and Self-Assembly of SnS2 Nanoparticles on TiO2 for Quantum Dot-Sensitized Solar Cells. J. Nanosci. Nanotechnol. 2011, 11, 3215–3221. [Google Scholar] [CrossRef]

- Al-Shakban, M.; Al-Dulaimi, N.; Xaba, T.; Raheel, A. Hot Injection Synthesis of Orthorhombic SnS Nanoparticles from Bis(O-n-Propyldithiocarbonato)Diphenyltin(IV). J. Nano Res. 2021, 66, 27–34. [Google Scholar] [CrossRef]

- Liang, Z.; Mu, J.; Mu, Y.; Shi, J.; Hao, W.; Dong, X.; Yu, H. Interface-Mediated Synthesis of Monodisperse ZnS Nanoparticles with Sulfate-Reducing Bacterium Culture. J. Environ. Sci. 2013, 25, S106–S109. [Google Scholar] [CrossRef]

- Chaki, S.H.; Deshpande, M.P.; Trivedi, D.P.; Tailor, J.P.; Chaudhary, M.D.; Mahato, K. Wet Chemical Synthesis and Characterization of SnS2 Nanoparticles. Appl. Nanosci. 2013, 3, 189–195. [Google Scholar] [CrossRef]

- Joseph, A.; Anjitha, C.R.; Aravind, A.; Aneesh, P.M. Structural, Optical and Magnetic Properties of SnS2 Nanoparticles and Photo Response Characteristics of p-Si/n-SnS2 Heterojunction Diode. Appl. Surf. Sci 2020, 528, 146977. [Google Scholar] [CrossRef]

- Song, H.; Wu, H.; Gao, Y.; Wang, K.; Su, X.; Yan, S.; Shi, Y. Production of SnS2 Nanostructure as Improved Light-Assisted Electrochemical Water Splitting. Nanomaterials 2019, 9, 1244. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ullah, S.; Bouich, A.; Ullah, H.; Mari, B.; Mollar, M. Enhanced Optical and Structural Properties of V-Doped Binary SnS2 Buffer Layer. Solar. Energy 2020, 204, 654–659. [Google Scholar] [CrossRef]

- Umar, A.; Akhtar, M.S.; Dar, G.N.; Abaker, M.; Al-Hajry, A.; Baskoutas, S. Visible-Light-Driven Photocatalytic and Chemical Sensing Properties of SnS2 Nanoflakes. Talanta 2013, 114, 183–190. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Xu, C.Y.; Ma, F.X.; Hu, S.P.; Zhang, Y.W.; Zhen, L. Monodisperse SnS2 Nanosheets for High-Performance Photocatalytic Hydrogen Generation. ACS Appl. Mater. Interfaces 2014, 6, 22370–22377. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Su, C.; Wang, S.; Han, Y.; Chen, X.; Xu, S.; Zhou, Z.; Hu, N.; Su, Y.; Zeng, M. Highly Sensitive NO2 Gas Sensors Based on Hexagonal SnS2 Nanoplates Operating at Room Temperature. Nanotechnology 2019, 31, 075501. [Google Scholar] [CrossRef] [PubMed]

- Parveen, N.; Ansari, S.A.; Alamri, H.R.; Ansari, M.O.; Khan, Z.; Cho, M.H. Facile Synthesis of SnS2 Nanostructures with Different Morphologies for High-Performance Supercapacitor Applications. ACS Omega 2018, 3, 1581–1588. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhou, J.; Wu, J.; Chen, F.; Li, P.; Han, N.; Huang, W.; Liu, Y.; Ye, H.; Zhao, F.; et al. Engineering SnS2 Nanosheet Assemblies for Enhanced Electrochemical Lithium and Sodium Ion Storage. J. Mater. Chem. A Mater. 2017, 5, 25618–25624. [Google Scholar] [CrossRef]

- Geng, H.; Su, Y.; Wei, H.; Xu, M.; Wei, L.; Yang, Z.; Zhang, Y. Controllable Synthesis and Photoelectric Property of Hexagonal SnS2 Nanoflakes by Triton X-100 Assisted Hydrothermal Method. Mater. Lett. 2013, 111, 204–207. [Google Scholar] [CrossRef]

- Liu, G.; Li, Z.; Hasan, T.; Chen, X.; Zheng, W.; Feng, W.; Jia, D.; Zhou, Y.; Hu, P.A. Vertically Aligned Two-Dimensional SnS2 Nanosheets with a Strong Photon Capturing Capability for Efficient Photoelectrochemical Water Splitting. J. Mater. Chem. A Mater. 2017, 5, 1989–1995. [Google Scholar] [CrossRef]

- Thangaraju, D.; Marnadu, R.; Santhana, V.; Durairajan, A.; Kathirvel, P.; Chandrasekaran, J.; Jayakumar, S.; Valente, M.A.; Greenidge, D.C. Solvent Influenced Synthesis of Single-Phase SnS2 Nanosheets for Solution-Processed Photodiode Fabrication. CrystEngComm 2020, 22, 525–533. [Google Scholar] [CrossRef]

- Du, W.; Deng, D.; Han, Z.; Xiao, W.; Bian, C.; Qian, X. Hexagonal Tin Disulfide Nanoplatelets: A New Photocatalyst Driven by Solar Light. CrystEngComm 2011, 13, 2071–2076. [Google Scholar] [CrossRef]

- Jana, M.K.; Rajendra, H.B.; Bhattacharyya, A.J.; Biswas, K. Green Ionothermal Synthesis of Hierarchical Nanostructures of SnS 2 and Their Li-Ion Storage Properties. CrystEngComm 2014, 16, 3994–4000. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, X.; Zhu, Y.; Shen, J.; Fan, K.; Li, C. In Situ Assembly of Graphene Sheets-Supported SnS2 Nanoplates into 3D Macroporous Aerogels for High-Performance Lithium Ion Batteries. J Power Sources 2013, 237, 178–186. [Google Scholar] [CrossRef]

- Luo, B.; Hu, Y.; Zhu, X.; Qiu, T.; Zhi, L.; Xiao, M.; Zhang, H.; Zou, M.; Cao, A.; Wang, L. Controllable Growth of SnS2 Nanostructures on Nanocarbon Surfaces for Lithium-Ion and Sodium-Ion Storage with High Rate Capability. J. Mater. Chem. A Mater. 2018, 6, 1462–1472. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, J.; Zhao, Y.; An, Y.; Tao, J.; Zhang, F.; Zhang, X. Hexagonal SnS2 Nanosheets Crosslinked by Bacterial Cellulose Derived Carbon Nanofibers for Fast Sodium Ion Batteries. J. Alloys Compd. 2019, 802, 269–275. [Google Scholar] [CrossRef]

- Cheng, Y.; Xie, H.; Zhou, L.; Shi, B.; Guo, L.; Huang, J. In-Situ Liquid-Phase Transformation of SnS2/CNTs Composite from SnO2/CNTs for High Performance Lithium-Ion Battery Anode. Appl. Surf. Sci. 2021, 566, 150645. [Google Scholar] [CrossRef]

- Zhai, C.; Du, N.; Zhang, H.; Yu, J.; Yang, D. Multiwalled Carbon Nanotubes Anchored with SnS2 Nanosheets as High-Performance Anode Materials of Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2011, 3, 4067–4074. [Google Scholar] [CrossRef]

- Qu, B.; Ma, C.; Ji, G.; Xu, C.; Xu, J.; Meng, Y.S.; Wang, T.; Lee, J.Y. Layered SnS2-Reduced Graphene Oxide Composite-A High-Capacity, High-Rate, and Long-Cycle Life Sodium-Ion Battery Anode Material. Adv. Mater. 2014, 26, 3854–3859. [Google Scholar] [CrossRef] [Green Version]

- Chauhan, H.; Soni, K.; Kumar, M.; Deka, S. Tandem Photocatalysis of Graphene-Stacked SnS2 Nanodiscs and Nanosheets with Efficient Carrier Separation. ACS Omega 2016, 1, 127–137. [Google Scholar] [CrossRef]

- Zhang, Z.; Feng, L.; Jing, P.; Hou, X.; Suo, G.; Ye, X.; Zhang, L.; Yang, Y.; Zhai, C. In Situ Construction of Hierarchical Polyaniline/SnS2@carbon Nanotubes on Carbon Fibers for High-Performance Supercapacitors. J. Colloid. Interface Sci. 2021, 588, 84–93. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Jin, L.N.; Jin, C.; Zhang, J.N.; Bian, S.W. Synthesis of Hierarchically Porous Silicate-1 and ZSM-5 by Hydrothermal Transformation of SiO2 Colloid Crystal/Carbon Composites. Microporous Mesoporous Mater. 2018, 262, 217–226. [Google Scholar] [CrossRef]

- Manikandan, V.S.; Palai, A.K.; Mohanty, S.; Nayak, S.K. Hydrothermally Synthesized Self-Assembled Multi-Dimensional TiO2/Graphene Oxide Composites with Efficient Charge Transfer Kinetics Fabricated as Novel Photoanode for Dye Sensitized Solar Cell. J. Alloys Compd. 2019, 793, 400–409. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, H.; Wu, M.; Yue, L.; Mi, J. One-Pot Solvothermal Synthesis 2D SnS2/CNTs Hybrid as a Superior Anode Material for Sodium-Ion Batteries. J. Alloys Compd. 2018, 737, 92–98. [Google Scholar] [CrossRef]

- Shen, C.; Ma, L.; Zheng, M.; Zhao, B.; Qiu, D.; Pan, L.; Cao, J.; Shi, Y. Synthesis and Electrochemical Properties of Graphene-SnS2 Nanocomposites for Lithium-Ion Batteries. J. Solid State Electrochem. 2012, 16, 1999–2004. [Google Scholar] [CrossRef]

- Anlin Lazar, K.; Cicily Rigi, V.J.; Divya, D.; Saji, K.J. Effect of Annealing on Structural and Optical Properties of SnS2 Thin Films Grown by Thermal Evaporation and Post Sulphur Annealing Technique. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1166, 012004. [Google Scholar] [CrossRef]

- Zhuang, S.; Lee, E.S.; Lei, L.; Nunna, B.B.; Kuang, L.; Zhang, W. Synthesis of Nitrogen-Doped Graphene Catalyst by High-Energy Wet Ball Milling for Electrochemical Systems. Int. J. Energy Res. 2016, 40, 2136–2149. [Google Scholar] [CrossRef]

- Heidari, M.; Hosseini, S.S.; Omidkhah Nasrin, M.R.; Ghadimi, A. Synthesis and Fabrication of Adsorptive Carbon Nanoparticles (ACNs)/PDMS Mixed Matrix Membranes for Efficient CO2/CH4 and C3H8/CH4 Separation. Sep. Purif. Technol. 2019, 209, 503–515. [Google Scholar] [CrossRef]

- Zhang, Z.; Wen, G. Synthesis and Characterization of Carbon-Encapsulated Magnetite, Martensite and Iron Nanoparticles by High-Energy Ball Milling Method. Mater. Charact. 2020, 167, 110502. [Google Scholar] [CrossRef]

- Zheng, Y.; Wan, Y.; Chen, J.; Chen, H.; Gao, B. MgO Modified Biochar Produced through Ball Milling: A Dual-Functional Adsorbent for Removal of Different Contaminants. Chemosphere 2020, 243, 125344. [Google Scholar] [CrossRef]

- Dogrusoz, M.; Demir-Cakan, R. Mechanochemical Synthesis of SnS Anodes for Sodium Ion Batteries. Int. J. Energy Res. 2020, 44, 10809–10820. [Google Scholar] [CrossRef]

- Lasio, B.; Torre, F.; Orrù, R.; Cao, G.; Cabibbo, M.; Delogu, F. Fabrication of Cu-Graphite Metal Matrix Composites by Ball Milling and Spark Plasma Sintering. Mater. Lett. 2018, 230, 199–202. [Google Scholar] [CrossRef]

- Li, X.; Yan, S.; Chen, X.; Hong, Q.; Wang, N. Microstructure and Mechanical Properties of Graphene-Reinforced Copper Matrix Composites Prepared by in-Situ CVD, Ball-Milling, and Spark Plasma Sintering. J. Alloys Compd. 2020, 834, 155182. [Google Scholar] [CrossRef]

- Bai, C.; An, L.; Zhang, J.; Zhang, X.; Zhang, B.; Qiang, L.; Yu, Y.; Zhang, J. Superlow Friction of Amorphous Diamond-like Carbon Films in Humid Ambient Enabled by Hexagonal Boron Nitride Nanosheet Wrapped Carbon Nanoparticles. Chem. Eng. J. 2020, 402, 126206. [Google Scholar] [CrossRef]

- Kapusta, K.; Drygas, M.; Janik, J.F.; Olejniczak, Z. New Synthesis Route to Kesterite Cu2ZnSnS4 Semiconductor Nanocrystalline Powders Utilizing Copper Alloys and a High Energy Ball Milling-Assisted Process. J. Mater. Res. Technol. 2020, 9, 13320–13331. [Google Scholar] [CrossRef]

- Al-Mamun, M.; Wang, Y.; Liu, P.; Zhong, Y.L.; Yin, H.; Su, X.; Zhang, H.; Yang, H.; Wang, D.; Tang, Z.; et al. One-Step Solid Phase Synthesis of a Highly Efficient and Robust Cobalt Pentlandite Electrocatalyst for the Oxygen Evolution Reaction. J. Mater. Chem. A Mater. 2016, 4, 18314–18321. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.C.; Du, Z.N.; Li, S.Y.; Zhang, M. Novel Synthesis and High Visible Light Photocatalytic Activity of SnS2 Nanoflakes from SnCl2·2H2O and S Powders. Appl. Catal. B 2010, 95, 153–159. [Google Scholar] [CrossRef]

- Kiruthigaa, G.; Manoharan, C.; Raju, C.; Dhanapandian, S.; Thanikachalam, V. Synthesis and Spectroscopic Analysis of Undoped and Zn Doped SnS2 Nanostructure by Solid State Reaction Method. Mater. Sci Semicond. Process. 2014, 26, 533–539. [Google Scholar] [CrossRef]

- Kiruthigaa, G.; Manoharan, C.; Raju, C.; Jayabharathi, J.; Dhanapandian, S. Solid State Synthesis and Spectral Investigations of Nanostructure SnS2. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2014, 129, 415–420. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, Y.C. In Air Synthesis of SnS2 Nanoplates from Tin, Sulfur and Ammonium Chloride Powders. Mater. Chem. Phys. 2008, 112, 742–744. [Google Scholar] [CrossRef]

- Wang, S.; Peng, T.; Zhang, Y. NH4Cl-Assisted in Air, Low Temperature Synthesis of SnS2 Nanoflakes with High Visible-Light-Activated Photocatalytic Activity. Mater. Lett. 2019, 234, 361–363. [Google Scholar] [CrossRef]

- Wang, J.; Luo, C.; Mao, J.; Zhu, Y.; Fan, X.; Gao, T.; Mignerey, A.C.; Wang, C. Solid-State Fabrication of SnS2/C Nanospheres for High-Performance Sodium Ion Battery Anode. ACS Appl. Mater. Interfaces 2015, 7, 11476–11481. [Google Scholar] [CrossRef] [PubMed]

- Guan, H.; Zeng, T.; Zhang, C. Improve Electrochemical Performances of SnS2/C by Destroying the Crystal Structure. Ionics 2020, 26, 579–588. [Google Scholar] [CrossRef]

- Zhao, H.; Zeng, H.; Wu, Y.; Qi, W.; Zhang, S.; Li, B.; . Huang, Y. Facile Ball-Milled Synthesis of SnS2-Carbon Nanocomposites with Superior Lithium Storage. Prog. Nat. Sci. Mater. Int. 2018, 28, 676–682. [Google Scholar] [CrossRef]

- Liu, X.J.; Xu, Z.Z.; Xiao, H.; Park, D.K.; Kim, K.W.; Kim, Y.C.; Yeon, S.H.; Ahn, I.S. The Effect of Process Control Agents and Ball to Powder Rations on the Electrochemical Characteristics of Mechanically Alloyed SnS2 Anode Materials. Powder Technol. 2014, 259, 117–124. [Google Scholar] [CrossRef]

- Choi, H.; Lee, S.; Eom, K.S. Facile Phosphorus-Embedding into SnS2 Using a High-Energy Ball Mill to Improve the Surface Kinetics of P-SnS2 Anodes for a Li-Ion Battery. Appl. Surf. Sci. 2019, 466, 578–582. [Google Scholar] [CrossRef]

- Zhu, A.; Qiao, L.; Jia, Z.; Tan, P.; Liu, Y.; Ma, Y.; Pan, J. C-S Bond Induced Ultrafine SnS2 Dot/Porous g-C3N4 Sheet 0D/2D Heterojunction: Synthesis and Photocatalytic Mechanism Investigation. Dalton Trans. 2017, 46, 17032–17040. [Google Scholar] [CrossRef]

- Fan, Z.; Luan, J.; Zhu, C.; Liu, F. Depositing Ag2S Quantum Dots as Electron Mediators in SnS2/g-C3N4 Nanosheet Composites for Constructing Z-Scheme Heterojunction with Enhanced Photocatalytic Performance. Mater. Res. Bull. 2021, 133, 111045. [Google Scholar] [CrossRef]

- Wei, W.; Jia, F.F.; Wang, K.F.; Qu, P. SnS2/Graphene Nanocomposite: A High Rate Anode Material for Lithium Ion Battery. Chin. Chem. Lett. 2017, 28, 324–328. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, B.; Zhang, J.; Yu, W.; Zheng, J.; Ding, Z.; Li, H.; Ming, L.; Bengono, D.A.M.; Chen, S.; et al. In-Situ Grown SnS2 Nanosheets on RGO as an Advanced Anode Material for Lithium and Sodium Ion Batteries. Front. Chem. 2018, 6, 629. [Google Scholar] [CrossRef] [Green Version]

- Yella, A.; Mugnaioli, E.; Therese, H.A.; Panthöfer, M.; Kolb, U.; Tremel, W. Synthesis of Fullerene- and Nanotube-Like SnS2 Nanoparticles and Sn/S/Carbon Nanocomposites. Chem. Mater. 2009, 21, 2474–2481. [Google Scholar] [CrossRef]

- Xia, J.; Jiang, K.; Xie, J.; Guo, S.; Liu, L.; Zhang, Y.; Nie, S.; Yuan, Y.; Yan, H.; Wang, X. Tin Disulfide Embedded in N-, S-Doped Carbon Nanofibers as Anode Material for Sodium-Ion Batteries. Chem. Eng. J. 2019, 359, 1244–1251. [Google Scholar] [CrossRef]

- Wang, J.G.; Sun, H.; Liu, H.; Jin, D.; Liu, X.; Li, X.; Kang, F. Triaxial Nanocables of Conducting Polypyrrole@SnS2@Carbon Nanofiber Enabling Significantly Enhanced Li-Ion Storage. ACS Appl. Mater. Interfaces 2018, 10, 13581–13587. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Zhou, M.; Li, W.; Wang, K.; Cheng, S.; Jiang, K. Layered SnS2 Cross-Linked by Carbon Nanotubes as a High Performance Anode for Sodium Ion Batteries. RSC Adv. 2016, 6, 35197–35202. [Google Scholar] [CrossRef]

- Sun, H.; Ahmad, M.; Luo, J.; Shi, Y.; Shen, W.; Zhu, J. SnS2 Nanoflakes Decorated Multiwalled Carbon Nanotubes as High Performance Anode Materials for Lithium-Ion Batteries. Mater. Res. Bull. 2014, 49, 319–324. [Google Scholar] [CrossRef]

- Ren, Z.; Wen, J.; Liu, W.; Jiang, X.; Dong, Y.; Guo, X.; Zhao, Q.; Ji, G.; Wang, R.; Hu, N.; et al. Rational Design of Layered SnS2 on Ultralight Graphene Fiber Fabrics as Binder-Free Anodes for Enhanced Practical Capacity of Sodium-Ion Batteries. Nanomicro. Lett. 2019, 11, 66. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Huang, H.; Wu, A.; Gao, S.; Lei, M.; Zhao, J.; Gao, X.; Cao, G. Inverse Capacity Growth and Pocket Effect in SnS2 Semifilled Carbon Nanotube Anode. ACS Nano. 2018, 12, 8037–8047. [Google Scholar] [CrossRef]

- Lu, X.; Liu, D.; Han, T.; Zhu, M.; Ryu, S.O.; Huang, J. A Facile Synthesis of Sandwich-Structured SnS2@reduced Graphene Oxide with High Performance for Lithium-Ion Battery Anode. J. Alloys Compd. 2018, 765, 1061–1071. [Google Scholar] [CrossRef]

- Fan, L.; Li, X.; Song, X.; Hu, N.; Xiong, D.; Koo, A.; Sun, X. Promising Dual-Doped Graphene Aerogel/SnS2 Nanocrystal Building High Performance Sodium Ion Batteries. ACS Appl. Mater. Interfaces 2018, 10, 2637–2648. [Google Scholar] [CrossRef]

- Jiang, Y.; Wei, M.; Feng, J.; Ma, Y.; Xiong, S. Enhancing the Cycling Stability of Na-Ion Batteries by Bonding SnS2 Ultrafine Nanocrystals on Amino-Functionalized Graphene Hybrid Nanosheets. Energy Environ. Sci. 2016, 9, 1430–1438. [Google Scholar] [CrossRef]

- Prikhodchenko, P.V.; Yu, D.Y.W.; Batabyal, S.K.; Uvarov, V.; Gun, J.; Sladkevich, S.; Mikhaylov, A.A.; Medvedev, A.G.; Lev, O. Nanocrystalline Tin Disulfide Coating of Reduced Graphene Oxide Produced by the Peroxostannate Deposition Route for Sodium Ion Battery Anodes. J. Mater. Chem. A Mater. 2014, 2, 8431–8437. [Google Scholar] [CrossRef]

- Li, X.; Sun, X.; Gao, Z.; Hu, X.; Ling, R.; Cai, S.; Zheng, C.; Hu, W. A Simple One-Pot Strategy for Synthesizing Ultrafine SnS2 Nanoparticle/Graphene Composites as Anodes for Lithium/Sodium-Ion Batteries. ChemSusChem 2018, 11, 1549–1557. [Google Scholar] [CrossRef] [PubMed]

- Shown, I.; Samireddi, S.; Chang, Y.C.; Putikam, R.; Chang, P.H.; Sabbah, A.; Fu, F.Y.; Chen, W.F.; Wu, C.I.; Yu, T.Y.; et al. Carbon-Doped SnS2 Nanostructure as a High-Efficiency Solar Fuel Catalyst under Visible Light. Nat. Commun. 2018, 9, 169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, S.; Li, Y.; Hao, J.; Fang, H.; Yuan, Y.; Tsai, H.S.; Sun, Q.; Wan, P.; Zhang, X.; Wang, Y. Hierarchical Assembly of Graphene-Bridged SnO2-RGO/SnS2 Heterostructure with Interfacial Charge Transfer Highway for High-Performance NO2 Detection. Appl. Surf. Sci. 2021, 568, 150926. [Google Scholar] [CrossRef]

- Youn, D.H.; Stauffer, S.K.; Xiao, P.; Park, H.; Nam, Y.; Dolocan, A.; Henkelman, G.; Heller, A.; Mullins, C.B. Simple Synthesis of Nanocrystalline Tin Sulfide/N-Doped Reduced Graphene Oxide Composites as Lithium Ion Battery Anodes. ACS Nano. 2016, 10, 10778–10788. [Google Scholar] [CrossRef]

- Fang, F.; Li, H.; Yao, H.; Jiang, K.; Liu, Z.; Lin, C.; Chen, F.; Wang, Y.; Liu, L. Two-Dimensional Hybrid Composites of SnS2 Nanosheets Array Film with Graphene for Enhanced Photoelectric Performance. Nanomaterials 2019, 9, 1122. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Zong, X.; Wu, Z. Fabrication of Tin Disulfide/Graphene Oxide Nanoflower on Flexible Substrate for Ultrasensitive Humidity Sensing with Ultralow Hysteresis and Good Reversibility. Sens. Actuators B Chem. 2019, 287, 398–407. [Google Scholar] [CrossRef]

- Zeng, L.; Zhang, L.; Liu, X.; Zhang, C. SnS2 Nanocrystalline-Anchored Three-Dimensional Graphene for Sodium Batteries with Improved Rate Performance. Nanomaterials 2020, 10, 2336. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, L.; Wu, D.; Liang, F.; Li, X.; Rui, Y.; Tang, B. A Novel SnS2 Nanomaterial Based on Nitrogen-Doped Cubic-like Carbon Skeleton with Excellent Lithium Storage. J. Alloys Compd. 2021, 883, 160834. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.; Yao, Q.; Guan, L. Encapsulating SnS2 Nanosheets into Hollow Carbon Sphere: A Yolk-Shell SnS2@C Composite with Enhanced Sodium Storage Performance. Electrochim. Acta 2018, 270, 8. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, J.; Huang, X.; Ding, J. Three-Dimensional SnS2 Flowers/Carbon Nanotubes Network: Extraordinary Rate Capacity for Sodium-Ion Battery. Mater. Lett. 2017, 186, 57–61. [Google Scholar] [CrossRef]

- Li, S.; Zhao, Z.; Li, C.; Liu, Z.; Li, D. SnS2@C Hollow Nanospheres with Robust Structural Stability as High-Performance Anodes for Sodium Ion Batteries. Nanomicro. Lett. 2019, 11, 14. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Sun, L.; Zhang, Y.; Si, H.; Sun, C.; Gu, J.; Gong, Y.; Li, X.; Zhang, Y. SnS2 Nanodots Decorated on RGO Sheets with Enhanced Pseudocapacitive Performance for Asymmetric Supercapacitors. J Alloys. Compd. 2021, 853, 156903. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, Y.; Guo, J.; Zhang, S.; Lu, Y. Preparation of SnS2/g-C3N4 Composite as the Electrode Material for Supercapacitor. J. Alloys Compd. 2019, 806, 343–349. [Google Scholar] [CrossRef]

- Srivastava, R.R.; Singh, V.K.; Srivastava, A. Facile Synthesis of Highly Fluorescent Water-Soluble SnS2 QDs for Effective Detection of Fe3+ and Unveiling Its Fluorescence Quenching Mechanism. Opt. Mater. 2020, 109, 110337. [Google Scholar] [CrossRef]

- Fu, X.; Ilanchezhiyan, P.; Mohan Kumar, G.; Cho, H.D.; Zhang, L.; Chan, A.S.; Lee, D.J.; Panin, G.N.; Kang, T.W. Tunable UV-Visible Absorption of SnS2 Layered Quantum Dots Produced by Liquid Phase Exfoliation. Nanoscale 2017, 9, 1820–1826. [Google Scholar] [CrossRef]

- Lei, Y.M.; Zhou, J.; Chai, Y.Q.; Zhuo, Y.; Yuan, R. SnS2 Quantum Dots as New Emitters with Strong Electrochemiluminescence for Ultrasensitive Antibody Detection. Anal. Chem. 2018, 90, 12270–12277. [Google Scholar] [CrossRef]

- Tu, J.R.; Shi, X.F.; Lu, H.W.; Yang, N.X.; Yuan, Y.J. Facile Fabrication of SnS2 Quantum Dots for Photoreduction of Aqueous Cr(VI). Mater. Lett. 2016, 185, 303–306. [Google Scholar] [CrossRef]

- Srivastava, R.R.; Mishra, H.; Singh, V.K.; Vikram, K.; Srivastava, R.K.; Srivastava, S.K.; Srivastava, A. PH Dependent Luminescence Switching of Tin Disulfide Quantum Dots. J. Lumin. 2019, 213, 401–408. [Google Scholar] [CrossRef]

- Tan, F.; Qu, S.; Wu, J.; Liu, K.; Zhou, S.; Wang, Z. Preparation of SnS2 Colloidal Quantum Dots and Their Application in Organic/Inorganic Hybrid Solar Cells. Nanoscale Res. Lett. 2011, 6, 298. [Google Scholar] [CrossRef]

- Lin, Y.T.; Shi, J.B.; Chen, Y.C.; Chen, C.J.; Wu, P.F. Synthesis and Characterization of Tin Disulfide (SnS2) Nanowires. Nanoscale Res. Lett. 2009, 4, 694–698. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, E.; Gao, L.; Yang, S.; Wang, L.; Cao, J.; Ma, T. In Situ Fabrication of 2D SnS2 Nanosheets as a New Electron Transport Layer for Perovskite Solar Cells. Nano. Res. 2018, 11, 5913–5923. [Google Scholar] [CrossRef]

- Li, Q.; Wei, A.; Guo, Z.; Liu, J.; Zhao, Y.; Xiao, Z. Chemical Vapor Deposition of Two-Dimensional SnS2 Nanoflakes and Flower-Shaped SnS2. J. Mater. Sci. Mater. Electron. 2018, 29, 16057–16063. [Google Scholar] [CrossRef]

- Qin, Z.; Xu, K.; Yue, H.; Wang, H.; Zhang, J.; Ouyang, C.; Xie, C.; Zeng, D. Enhanced Room-Temperature NH3 Gas Sensing by 2D SnS2 with Sulfur Vacancies Synthesized by Chemical Exfoliation. Sens. Actuators B Chem. 2018, 262, 771–779. [Google Scholar] [CrossRef]

- Sun, W.; Rui, X.; Yang, D.; Sun, Z.; Li, B.; Zhang, W.; Zong, Y.; Madhavi, S.; Dou, S.; Yan, Q. Two-Dimensional Tin Disulfide Nanosheets for Enhanced Sodium Storage. ACS Nano. 2015, 9, 11371–11381. [Google Scholar] [CrossRef]

- Liu, G.; Li, Z.; Chen, X.; Zheng, W.; Feng, W.; Dai, M.; Jia, D.; Zhou, Y.; Hu, P. Non-Planar Vertical Photodetectors Based on Free Standing Two-Dimensional SnS2 Nanosheets. Nanoscale 2017, 9, 9167–9174. [Google Scholar] [CrossRef]

- Guan, D.; Li, J.; Gao, X.; Xie, Y.; Yuan, C. Growth Characteristics and Influencing Factors of 3D Hierarchical Flower-like SnS2 Nanostructures and Their Superior Lithium-Ion Intercalation Performance. J. Alloys Compd. 2016, 658, 190–197. [Google Scholar] [CrossRef]

- Liu, D.; Tang, Z.; Zhang, Z. Nanoplates-Assembled SnS2 Nanoflowers for Ultrasensitive Ppb-Level NO2 Detection. Sens. Actuators B Chem. 2018, 273, 473–479. [Google Scholar] [CrossRef]

- Wu, Q.; Jiao, L.; Du, J.; Yang, J.; Guo, L.; Liu, Y.; Wang, Y.; Yuan, H. One-Pot Synthesis of Three-Dimensional SnS2 Hierarchitectures as Anode Material for Lithium-Ion Batteries. J. Power Sources 2013, 239, 89–93. [Google Scholar] [CrossRef]

- Xiong, Y.; Xu, W.; Ding, D.; Lu, W.; Zhu, L.; Zhu, Z.; Wang, Y.; Xue, Q. Ultra-Sensitive NH3 Sensor Based on Flower-Shaped SnS 2 Nanostructures with Sub-Ppm Detection Ability. J. Hazard Mater. 2018, 341, 159–167. [Google Scholar] [CrossRef]

- Zai, J.; Wang, K.; Su, Y.; Qian, X.; Chen, J. High Stabilit.ty and Superior Rate Capability of Three-Dimensional Hierarchical SnS 2 Microspheres as Anode Material in Lithium Ion Batteries. J. Power Sources 2011, 196, 3650–3654. [Google Scholar] [CrossRef]

- Shi, W.; Huo, L.; Wang, H.; Zhang, H.; Yang, J.; Wei, P. Hydrothermal Growth and Gas Sensing Property of Flower-Shaped SnS2 Nanostructures. Nanotechnology 2006, 17, 2918–2924. [Google Scholar] [CrossRef]

- Ahsan, M.A.; He, T.; Eid, K.; Abdullah, A.M.; Curry, M.L.; Du, A.; Puente Santiago, A.R.; Echegoyen, L.; Noveron, J.C. Tuning the Intermolecular Electron Transfer of Low-Dimensional and Metal-Free BCN/C60Electrocatalysts via Interfacial Defects for Efficient Hydrogen and Oxygen Electrochemistry. J. Am. Chem. Soc. 2021, 143, 1203–1215. [Google Scholar] [CrossRef]

- Chen, D.; Huang, S.; Huang, R.; Zhang, Q.; Le, T.T.; Cheng, E.; Yue, R.; Hu, Z.; Chen, Z. Electron Beam-Induced Microstructural Evolution of SnS 2 Quantum Dots Assembled on N-Doped Graphene Nanosheets with Enhanced Photocatalytic Activity. Adv. Mater. Interfaces 2019, 6, 1801759. [Google Scholar] [CrossRef]

- Kong, D.; He, H.; Song, Q.; Wang, B.; Yang, Q.H.; Zhi, L. A Novel SnS2@graphene Nanocable Network for High-Performance Lithium Storage. RSC Adv. 2014, 4, 23372–23376. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, X.Y.; Fang, Y.; Zhu, X.; Bao, J.; Zhou, X.; Lou, X.W. (David) Confining SnS2 Ultrathin Nanosheets in Hollow Carbon Nanostructures for Efficient Capacitive Sodium Storage. Joule 2018, 2, 725–735. [Google Scholar] [CrossRef] [Green Version]

- Moradian, R.; Astinchap, B. Synthesis and Control Size of SnS2 Nanoparticles on the Surface Multi-Walled Carbon Nanotubes. Nano 2010, 5, 139–142. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, Y.; Yang, Y.; Yousaf, M.; Zou, M.; Cao, A.; Han, R.P.S. Flexible Hybrid Carbon Nanotube Sponges Embedded with SnS2 from Tubular Nanosheaths to Nanosheets as Free-Standing Anodes for Lithium-Ion Batteries. RSC Adv. 2016, 6, 30098–30105. [Google Scholar] [CrossRef]

- Li, H.; Zhang, B.; Wang, X.; Zhang, J.; An, T.; Ding, Z.; Yu, W.; Tong, H. Heterostructured SnO2-SnS2@C Embedded in Nitrogen-Doped Graphene as a Robust Anode Material for Lithium-Ion Batteries. Front. Chem 2019, 7, 339. [Google Scholar] [CrossRef]

- Jiang, Y.; Song, D.; Wu, J.; Wang, Z.; Huang, S.; Xu, Y.; Chen, Z.; Zhao, B.; Zhang, J. Sandwich-like SnS2/Graphene/SnS2 with Expanded Interlayer Distance as High-Rate Lithium/Sodium-Ion Battery Anode Materials. ACS Nano 2019, 13, 9100–9111. [Google Scholar] [CrossRef]

- Lonkar, S.P.; Pillai, V.V.; Patole, S.P.; Alhassan, S.M. Scalable in Situ Synthesis of 2D-2D-Type Graphene-Wrapped SnS2 Nanohybrids for Enhanced Supercapacitor and Electrocatalytic Applications. ACS Appl. Energy Mater. 2020, 3, 4995–5005. [Google Scholar] [CrossRef]

- Modarres, M.H.; Lim, J.H.-W.; George, C.; Volder, M. De Evolution of RGO-SnS2 Hybrid Nanoparticle Electrodes in Li-Ion Batteries. J. Phys. Chem. C 2017, 121, 13018–13024. [Google Scholar] [CrossRef] [Green Version]

- Luo, B.; Fang, Y.; Wang, B.; Zhou, J.; Song, H.; Zhi, L. Two Dimensional Graphene-SnS2 Hybrids with Superior Rate Capability for Lithium Ion Storage. Energy Environ. Sci. 2012, 5, 5226–5230. [Google Scholar] [CrossRef]

- Shi, X.; Yang, Z.; Liu, Y.; Tang, Y.; Liu, Y.; Gao, S.; Yang, Y.; Chen, X.; Zhong, Y.; Wu, Z.; et al. Three-Dimensional SnS2 Nanoarrays with Enhanced Lithium-Ion Storage Properties. ChemElectroChem 2020, 7, 4484–4491. [Google Scholar] [CrossRef]

- Jiang, M.; Han, T.; Zhang, X. Hollow C@SnS2/SnS Nanocomposites: High Efficient Oxygen Evolution Reaction Catalysts. J. Colloid Interface Sci 2021, 583, 149–156. [Google Scholar] [CrossRef]

- FENG, Q.M.; QIN, L.; ZHANG, P.; LI, D.; LIU, M.K.; WANG, P. Ratiometric Electrochemical Detection of MicroRNA Based on Construction of A Hierarchical C@SnS2 Nanoflower Sensing Interface. Chin. J. Anal. Chem. 2021, 49, 21020–21028. [Google Scholar] [CrossRef]

- Kamali, K. UV Excited Enhanced Raman Scattering on Carbon-Doped SnS2 Nanoflowers. Mater. Res. Bull. 2022, 150, 111757. [Google Scholar] [CrossRef]

- Deng, W.; Chen, X.; Liu, Z.; Hu, A.; Tang, Q.; Li, Z.; Xiong, Y. Three-Dimensional Structure-Based Tin Disulfide/Vertically Aligned Carbon Nanotube Arrays Composites as High-Performance Anode Materials for Lithium Ion Batteries. J. Power Sources 2015, 277, 131–138. [Google Scholar] [CrossRef]

- Xu, H.; Peng, C.; Yan, Y.; Dong, F.; Sun, H.; Yang, J.; Zheng, S. “All-In-One” Integrated Ultrathin SnS2@3D Multichannel Carbon Matrix Power High-Areal–Capacity Lithium Battery Anode. Carbon. Energy 2019, 1, 276–288. [Google Scholar] [CrossRef] [Green Version]

- Gao, S.; Liu, Z.; Yang, L.; Shao, J.; Qu, Q.; Wu, Y.; Adelhelm, P.; Holze, R. Fabrication of S,N-Doped Carbon-Coated SnS2/SnS Heterostructures Supported by Hollow Carbon Microspheres for Sodium-Ion Storage. J. Electrochem. Soc. 2021, 168, 050527. [Google Scholar] [CrossRef]

- Muanchan, P.; Kurose, T.; Ito, H. Replication and Thermal Properties of One-Dimensional Composite Nanostructures with Enhanced Mechanical Robustness. J. Electrochem. Soc. 2019, 166, 3282–3289. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Wang, G.; Xia, Y.; Wang, H. One-Dimensional Hybrid Nanocomposite of High-Density Monodispersed Fe3O4 Nanoparticles and Carbon Nanotubes for High-Capacity Storage of Lithium and Sodium. J. Mater. Chem. A Mater. 2016, 4, 18532–18542. [Google Scholar] [CrossRef]

- Mai, L.; Sheng, J.; Xu, L.; Tan, S.; Meng, J. One-Dimensional Hetero-Nanostructures for Rechargeable Batteries. Acc. Chem. Res. 2018, 51, 950–959. [Google Scholar] [CrossRef]

- Du, N.; Zhang, H.; Yang, D. One-Dimensional Hybrid Nanostructures: Synthesis via Layer-by-Layer Assembly and Applications. Nanoscale 2012, 4, 5517–5526. [Google Scholar] [CrossRef]

- Wei, Q.; Xiong, F.; Tan, S.; Huang, L.; Lan, E.H.; Dunn, B.; Mai, L. Porous One-Dimensional Nanomaterials: Design, Fabrication and Applications in Electrochemical Energy Storage. Adv. Mater. 2017, 29, 1602300. [Google Scholar] [CrossRef]

- Jun, W.; Bing, C.; Qingqing, L.; Ailin, H.; Xiaoying, L.; Qi, J. Preparing a Composite Including SnS2, Carbon Nanotubes and S and Using as Cathode Material of Lithium-Sulfur Battery. Scr. Mater. 2020, 177, 208–213. [Google Scholar] [CrossRef]

- Jiang, S.; Chen, M.; Wang, X.; Zeng, P.; Li, Y.; Liu, H.; Li, X.; Huang, C.; Shu, H.; Luo, Z.; et al. A Tin Disulfide Nanosheet Wrapped with Interconnected Carbon Nanotube Networks for Application of Lithium Sulfur Batteries. Electrochim. Acta 2019, 313, 151–160. [Google Scholar] [CrossRef]

- Chen, G.; Yao, X.; Cao, Q.; Ding, S.; He, J.; Wang, S. Flexible Free-Standing SnS2/Carbon Nanofibers Anode for High Performance Sodium-Ion Batteries. Mater. Lett. 2019, 234, 121–124. [Google Scholar] [CrossRef]

- Liu, J.; Chen, X.; Zeng, L.; He, X.; Liu, J.; Huang, B.; Xiao, L.; Qian, Q.; Wei, M.; Chen, Q. SnS2 Nanosheets Anchored on Porous Carbon Fibers for High Performance of Sodium-Ion Batteries. J. Electroanal. Chem. 2020, 862, 114021. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, D.; Li, N.; Xu, Q.; Li, H.; He, J.; Lu, J. SnS2/SnO2 Heterostructured Nanosheet Arrays Grown on Carbon Cloth for Efficient Photocatalytic Reduction of Cr(VI). J. Colloid. Interface Sci. 2018, 514, 306–315. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, K.; Zhang, L.; Xie, Z.; Cai, Z.; Wang, Y. SnS2@Graphene Nanosheet Arrays Grown on Carbon Cloth as Freestanding Binder-Free Flexible Anodes for Advanced Sodium Batteries. J Alloys. Compd. 2016, 654, 357–362. [Google Scholar] [CrossRef]

- Wang, D.; Yan, X.; Zhou, C.; Wang, J.; Yuan, X.; Jiang, H.; Zhu, Y.; Cheng, X.; Li, R. A Free-Standing Electrode Based on 2D SnS2 Nanoplates@3D Carbon Foam for High Performance Supercapacitors. Int. J. Energy Res. 2020, 44, 8542–8554. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Yang, Y.; Pu, H.; Gao, R.Z.; Meng, W.J.; Yang, H.X.; Zhao, D.L. SnS2 Nanoparticle-Integrated Graphene Nanosheets as High-Performance and Cycle-Stable Anodes for Lithium and Sodium Storage. J. Alloys Compd. 2020, 822, 153686. [Google Scholar] [CrossRef]

- Sathish, M.; Mitani, S.; Tomai, T.; Honma, I. Ultrathin SnS2 Nanoparticles on Graphene Nanosheets: Synthesis, Characterization, and Li-Ion Storage Applications. J. Phys. Chem. C 2012, 116, 12475–12481. [Google Scholar] [CrossRef]

- Ye, J.; Qi, L.; Liu, B.; Xu, C. Facile Preparation of Hexagonal Tin Sulfide Nanoplates Anchored on Graphene Nanosheets for Highly Efficient Sodium Storage. J. Colloid. Interface Sci. 2018, 513, 188–197. [Google Scholar] [CrossRef]

- Hu, Y.; Ren, X.; Qiao, H.; Huang, Z.; Qi, X.; Zhong, J. Exploring Co-Catalytic Graphene Frameworks for Improving Photocatalytic Activity of Tin Disulfide Nanoplates. Solar Energy 2017, 157, 905–910. [Google Scholar] [CrossRef]

- Lee, W.; Liu, Y.; Lee, Y.; Sharma, B.K.; Shinde, S.M.; Kim, S.D.; Nan, K.; Yan, Z.; Han, M.; Huang, Y.; et al. Two-Dimensional Materials in Functional Three-Dimensional Architectures with Applications in Photodetection and Imaging. Nat. Commun. 2018, 9, 1417. [Google Scholar] [CrossRef]

- Guan, D.; Li, J.; Gao, X.; Yuan, C. Carbon Nanotube-Assisted Growth of Single-/Multi-Layer SnS2 and SnO2 Nanoflakes for High-Performance Lithium Storage. RSC Adv. 2015, 5, 58514–58521. [Google Scholar] [CrossRef] [Green Version]

- Tang, H.; Qi, X.; Han, W.; Ren, L.; Liu, Y.; Wang, X.; Zhong, J. SnS2 Nanoplates Embedded in 3D Interconnected Graphene Network as Anode Material with Superior Lithium Storage Performance. Appl. Surf. Sci. 2015, 355, 7–13. [Google Scholar] [CrossRef]

- Zhang, Q.; Sun, Y.; Zhang, X.; Guo, J. 3D Architecture Constructed by 2D SnS2-Graphene Hybrids towards Large and Fast Lithium Storage. Mater. Lett. 2016, 185, 311–314. [Google Scholar] [CrossRef]

- Liu, H.; Wei, C.; Ai, Z.; Li, M.; Xu, M.; Ma, C.; Shi, J. The Positive Effect of 3D Interpenetrating Network Porous Structure by Carbon Membranes on Alleviating the Volume Expansion of SnS2 Nanosheets for Enhancing Lithium and Sodium Storage. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125937. [Google Scholar] [CrossRef]

- Ren, Y.; Lv, W.; Wen, F.; Xiang, J.; Liu, Z. Microwave Synthesis of SnS2 Nanoflakes Anchored Graphene Foam for Flexible Lithium-Ion Battery Anodes with Long Cycling Life. Mater. Lett. 2016, 174, 24–27. [Google Scholar] [CrossRef]

- Zheng, J.; Xiong, X.; Wang, G.; Lin, Z.; Ou, X.; Yang, C.; Liu, M. SnS2 Nanoparticles Anchored on Three-Dimensional Reduced Graphene Oxide as a Durable Anode for Sodium Ion Batteries. Chem. Eng. J. 2018, 339, 78–84. [Google Scholar] [CrossRef]

- Tang, H.; Qi, X.; Zhang, Z.; Ai, G.; Liu, Y.; Huang, Z.; Zhong, J. Simple Self-Assembly of SnS2 Entrapped Graphene Aerogel and Its Enhanced Lithium Storage Performance. Ceram. Int. 2016, 42, 6572–6580. [Google Scholar] [CrossRef]

- Nishiyama, H.; Yamada, T.; Nakabayashi, M.; Maehara, Y.; Yamaguchi, M.; Kuromiya, Y.; Nagatsuma, Y.; Tokudome, H.; Akiyama, S.; Watanabe, T.; et al. Photocatalytic Solar Hydrogen Production from Water on a 100-M2 Scale. Nature 2021, 598, 304–307. [Google Scholar] [CrossRef]

- Jin, S.-E.; Jin, J.E.; Hwang, W.; Hong, S.W. Photocatalytic Antibacterial Application of Zinc Oxide Nanoparticles and Self-Assembled Networks under Dual UV Irradiation for Enhanced Disinfection. Int. J. Nanomed. 2019, 14, 1737. [Google Scholar] [CrossRef] [Green Version]

- Kong, H.; Song, J.; Jang, J. Photocatalytic Antibacterial Capabilities of TiO2−Biocidal Polymer Nanocomposites Synthesized by a Surface-Initiated Photopolymerization. Environ. Sci. Technol. 2010, 44, 5672–5676. [Google Scholar] [CrossRef]

- Zare, M.; Namratha, K.; Alghamdi, S.; Mohammad, Y.H.E.; Hezam, A.; Zare, M.; Drmosh, Q.A.; Byrappa, K.; Chandrashekar, B.N.; Ramakrishna, S.; et al. Novel Green Biomimetic Approach for Synthesis of ZnO-Ag Nanocomposite; Antimicrobial Activity against Food-Borne Pathogen, Biocompatibility and Solar Photocatalysis. Sci. Rep. 2019, 9, 8303. [Google Scholar] [CrossRef] [Green Version]

- Šuligoj, A.; Štangar, U.; Tušar, N. Photocatalytic Air-Cleaning Using TiO2 Nanoparticles in Porous Silica Substrate. Chem. Pap. 2014, 68, 1265–1272. [Google Scholar] [CrossRef]

- Fónagy, O.; Szabó-Bárdos, E.; Horváth, O. 1,4-Benzoquinone and 1,4-Hydroquinone Based Determination of Electron and Superoxide Radical Formed in Heterogeneous Photocatalytic Systems. J. Photochem. Photobiol. A Chem. 2021, 407, 113057. [Google Scholar] [CrossRef]

- Wang, J.; Wang, C.; Guo, H.; Ye, T.; Liu, Y.; Cheng, X.; Li, W.; Yang, B.; Du, E. Crucial Roles of Oxygen and Superoxide Radical in Bisulfite-Activated Persulfate Oxidation of Bisphenol AF: Mechanisms, Kinetics and DFT Studies. J. Hazard. Mater. 2020, 391, 122228. [Google Scholar] [CrossRef] [PubMed]

- Tahir, M.B.; Rafique, M.; Rafique, M.S.; Nawaz, T.; Rizwan, M.; Tanveer, M. Photocatalytic Nanomaterials for Degradation of Organic Pollutants and Heavy Metals. In Nanotechnology and Photocatalysis for Environmental Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 119–138. [Google Scholar]

- Yasin, S.A.; Abbas, J.A.; Ali, M.M.; Saeed, I.A.; Ahmed, I.H. Methylene Blue Photocatalytic Degradation by TiO2 Nanoparticles Supported on PET Nanofibres. Mater. Today Proc. 2020, 20, 482–487. [Google Scholar] [CrossRef]

- Shanmugaratnam, S.; Selvaratnam, B.; Baride, A.; Koodali, R.; Ravirajan, P.; Velauthapillai, D.; Shivatharsiny, Y. SnS2/TiO2 Nanocomposites for Hydrogen Production and Photodegradation under Extended Solar Irradiation. Catalysts 2021, 11, 589. [Google Scholar] [CrossRef]

- Fakhri, A.; Behrouz, S. Assessment of SnS2 Nanoparticles Properties for Photocatalytic and Antibacterial Applications. Solar Energy 2015, 117, 187–191. [Google Scholar] [CrossRef]

- Zou, W.; Sun, L.H.; Cong, S.N.; Leng, R.X.; Zhang, Q.; Zhao, L.; Kang, S.Z. Preparation of Worm-like SnS2 Nanoparticles and Their Photocatalytic Activity. J. Exp. Nanosci. 2020, 15, 100–108. [Google Scholar] [CrossRef] [Green Version]

- Kgoetlana, C.M.; Malinga, S.P.; Dlamini, L.N. Photocatalytic Degradation of Chlorpyrifos with Mn-WO3/SnS2 Heterostructure. Catalysts 2020, 10, 699. [Google Scholar] [CrossRef]

- Meng, S.; Ogawa, T.; Okumura, H.; Ishihara, K.N. Enhanced Photocatalytic Activity of BiVO4/Bi2S3/SnS2 Heterojunction under Visible Light. Catalysts 2020, 10, 1294. [Google Scholar] [CrossRef]

- Fakhri, A.; Behrouz, S.; Pourmand, M. Synthesis, Photocatalytic and Antimicrobial Properties of SnO2, SnS2 and SnO2/SnS2 Nanostructure. J. Photochem. Photobiol. B 2015, 149, 45–50. [Google Scholar] [CrossRef]

- Lucena, R.; Fresno, F.; Conesa, J.C. Hydrothermally Synthesized Nanocrystalline Tin Disulphide as Visible Light-Active Photocatalyst: Spectral Response and Stability. Appl. Catal. A Gen. 2012, 415, 111–117. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.C.; Li, J.; Zhang, M.; Dionysiou, D.D. Size-Tunable Hydrothermal Synthesis of SnS2 Nanocrystals with High Performance in Visible Light-Driven Photocatalytic Reduction of Aqueous Cr(VI). Environ. Sci. Technol. 2011, 45, 9324–9331. [Google Scholar] [CrossRef]

- Srinivas, B.; Pandit, M.A.; Muralidharan, K. Importance of Clean Surfaces on the Catalyst: SnS2 Nanorings for Environmental Remediation. ACS Omega 2019, 4, 14970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheraghizade, M.; Jamali-Sheini, F.; Yousefi, R.; Niknia, F.; Mahmoudian, M.R.; Sookhakian, M. The Effect of Tin Sulfide Quantum Dots Size on Photocatalytic and Photovoltaic Performance. Mater. Chem. Phys. 2017, 195, 187–194. [Google Scholar] [CrossRef]

- Wang, S. Solvothermal Synthesis of Porous SnS2 Nanotubes with Higher Adsorption and Photocatalytic Activity. Surf. Sci. 2019, 690, 121469. [Google Scholar] [CrossRef]

- Damkale, S.R.; Arbuj, S.S.; Umarji, G.G.; Panmand, R.P.; Khore, S.K.; Sonawane, R.S.; Rane, S.B.; Kale, B.B. Two-Dimensional Hexagonal SnS2 Nanostructures for Photocatalytic Hydrogen Generation and Dye Degradation. Sustain. Energy Fuels. 2019, 3, 3406–3414. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, H.; Gao, S.; Sun, Z.; Liu, Q.; Leu, Q.; Lei, F.; Yao, T.; He, J.; Wei, S.; et al. Freestanding Tin Disulfide Single-Layers Realizing Efficient Visible-Light Water Splitting. Angew. Chem. Int. Ed. 2012, 51, 8727–8731. [Google Scholar] [CrossRef]

- Ullah, S.; Bouich, A.; Ullah, H.; Mari, B.; Mollar, M. Comparative Study of Binary Cadmium Sulfide (CdS) and Tin Disulfide (SnS2) Thin Buffer Layers. Solar Energy 2020, 208, 637–642. [Google Scholar] [CrossRef]

- Zhang, G.; Du, X.; Wang, Y.; Wang, H.; Wang, W.; Fu, Z. Controllable Synthesis of SnS2 Nanostructures with High Adsorption and Photocatalytic Activities. Mater. Sci. Semicond. Process. 2017, 64, 77–84. [Google Scholar] [CrossRef]

- Park, S.; Park, J.; Selvaraj, R.; Kim, Y. Facile Microwave-Assisted Synthesis of SnS2 Nanoparticles for Visible-Light Responsive Photocatalyst. J. Ind. Eng. Chem. 2015, 31, 269–275. [Google Scholar] [CrossRef]

- Srivastava, R.R.; Kumar Vishwakarma, P.; Yadav, U.; Rai, S.; Umrao, S.; Giri, R.; Saxena, P.S.; Srivastava, A. 2D SnS2 Nanostructure-Derived Photocatalytic Degradation of Organic Pollutants Under Visible Light. Front. Nanotechnol. 2021, 3, 61. [Google Scholar] [CrossRef]

- Zhang, F.; Hou, P.X.; Liu, C.; Wang, B.W.; Jiang, H.; Chen, M.L.; Sun, D.M.; Li, J.C.; Cong, H.T.; Kauppinen, E.I.; et al. Growth of Semiconducting Single-Wall Carbon Nanotubes with a Narrow Band-Gap Distribution. Nat. Commun. 2016, 7, 11160. [Google Scholar] [CrossRef]

- Dong, R.; Zhong, Y.; Chen, D.; Li, N.; Xu, Q.; Li, H.; He, J.; Lu, J. Morphology-Controlled Fabrication of CNT@MoS2/SnS2 Nanotubes for Promoting Photocatalytic Reduction of Aqueous Cr(VI) under Visible Light. J. Alloys Compd. 2019, 784, 282–292. [Google Scholar] [CrossRef]

- Huang, N.; Liu, J.; Gan, L.; Long, M. Preparation of Size-Tunable SnS2 Nanocrystals in Situ Adjusted by Nanoporous Graphitic Carbon Nitride in the Process of Hydrothermal Synthesis with Enhanced Photocatalytic Performance. Mater. Lett. 2017, 195, 224–227. [Google Scholar] [CrossRef]

- Xue, K.; Wang, J.; He, R.; Yang, T.; Yan, Y.; Peng, Y.; Omeoga, U.; Wang, W. Photoredox Catalysis of As(III) by Constructed -C=Sn-S Bonds: Using Biomass as Templates Leads to Bio-carbon/SnS2 Nanosheets Capable of the Efficient Photocatalytic Conversion of As(III) and Calcium Arsenate Capture. Sci. Total Environ. 2020, 732, 138963. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Yu, K.; Wen, Z.; Chen, J. Semiconducting Graphene: Converting Graphene from Semimetal to Semiconductor. Nanoscale 2013, 5, 1353–1368. [Google Scholar] [CrossRef]

- Yuan, Y.J.; Chen, D.Q.; Shi, X.F.; Tu, J.R.; Hu, B.; Yang, L.X.; Yu, Z.T.; Zou, Z.G. Facile Fabrication of “Green” SnS2 Quantum Dots/Reduced Graphene Oxide Composites with Enhanced Photocatalytic Performance. Chem. Eng. J. 2017, 313, 1438–1446. [Google Scholar] [CrossRef]

- Han, L.; Zhong, Y.L.; Lei, K.; Mao, D.; Dong, Y.Z.; Hong, G.; Zhou, Y.T.; Fang, D. Carbon Dot-SnS2 Heterojunction Photocatalyst for Photoreduction of Cr(VI) under Visible Light: A Combined Experimental and First-Principles DFT Study. J. Phys. Chem. C 2019, 123, 2398–2409. [Google Scholar] [CrossRef]

- Wang, S.; Li, L.; Zhu, Z.; Zhao, M.; Zhang, L.; Zhang, N.; Wu, Q.; Wang, X.; Li, G. Remarkable Improvement in Photocatalytic Performance for Tannery Wastewater Processing via SnS2 Modified with N-Doped Carbon Quantum Dots: Synthesis, Characterization, and 4-Nitrophenol-Aided Cr(VI) Photoreduction. Small 2019, 15, 1804515. [Google Scholar] [CrossRef]

- Huang, R.; Wu, C.; Huang, S.; Chen, D.; Zhang, Q.; Wang, Q.; Hu, Z.; Jiang, Y.; Zhao, B.; Chen, Z. Construction of SnS2–SnO2 Heterojunctions Decorated on Graphene Nanosheets with Enhanced Visible-Light Photocatalytic Performance. Acta Crystallogr. C Struct. Chem. 2019, 75, 812–821. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Deng, L.; Zhang, Z.; Guan, J.; Yang, Y.; Zhu, Z. One-Step in-Situ Hydrothermal Synthesis of SnS2/Reduced Graphene Oxide Nanocomposites with High Performance in Visible Light-Driven Photocatalytic Reduction of Aqueous Cr(VI). J. Mater. Sci. 2015, 50, 3207–3211. [Google Scholar] [CrossRef]

- Zhong, Y.L.; Han, L.; Yin, X.; Li, H.; Fang, D.; Hong, G. Three Dimensional Functionalized Carbon/Tin(IV) Sulfide Biofoam for Photocatalytical Purification of Chromium(VI)-Containing Wastewater. ACS Sustain. Chem. Eng. 2018, 6, 10660–10667. [Google Scholar] [CrossRef]

- Raccichini, R.; Varzi, A.; Passerini, S.; Scrosati, B. The Role of Graphene for Electrochemical Energy Storage. Nat. Mater. 2015, 14, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Duan, R.; Zhang, S.; Jiang, N.; Zhang, Y.; Zhu, J. The Application of Graphene in Lithium Ion Battery Electrode Materials. J. Korean Phys. Soc. 2014, 3, 585. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, Y.; Yang, Y.; Shi, X.L.; Suo, G.; Chen, H.; Noman, M.; Tao, X.; Chen, Z.G. Hierarchical SnS2/Carbon Nanotube@reduced Graphene Oxide Composite as an Anode for Ultra-Stable Sodium-Ion Batteries. Chem. Eng. J. Adv. 2020, 4, 100053. [Google Scholar] [CrossRef]

- Sui, D.; Si, L.; Li, C.; Yang, Y.; Zhang, Y.; Yan, W. A Comprehensive Review of Graphene-Based Anode Materials for Lithium-Ion Capacitors. Chemistry 2021, 3, 1215–1246. [Google Scholar] [CrossRef]

- Wang, G.; Shen, X.; Yao, J.; Park, J. Graphene Nanosheets for Enhanced Lithium Storage in Lithium Ion Batteries. Carbon. N. Y. 2009, 47, 2049–2053. [Google Scholar] [CrossRef]

- Cui, J.; Yao, S.; Lu, Z.; Huang, J.Q.; Chong, W.G.; Ciucci, F.; Kim, J.K. Revealing Pseudocapacitive Mechanisms of Metal Dichalcogenide SnS2/Graphene-CNT Aerogels for High-Energy Na Hybrid Capacitors. Adv. Energy Mater. 2018, 8, 1702488. [Google Scholar] [CrossRef]

- Wang, L.; Zhuo, L.; Yu, Y.; Zhao, F. High-Rate Performance of SnS2 Nanoplates without Carbon-Coating as Anode Material for Lithium Ion Batteries. Electrochim. Acta 2013, 112, 439–447. [Google Scholar] [CrossRef]

- Kim, H.S.; Chung, Y.H.; Kang, S.H.; Sung, Y.E. Electrochemical Behavior of Carbon-Coated SnS2 for Use as the Anode in Lithium-Ion Batteries. Electrochim. Acta 2009, 54, 3606–3610. [Google Scholar] [CrossRef]

- Guan, S.; Wang, T.; Fu, X.; Fan, L.Z.; Peng, Z. Coherent SnS2/NiS2 Hetero-Nanosheet Arrays with Fast Charge Transfer for Enhanced Sodium-Ion Storage. Appl. Surf. Sci. 2020, 508, 145241. [Google Scholar] [CrossRef]

- Zhou, P.; Wang, X.; Guan, W.; Zhang, D.; Fang, L.; Jiang, Y. SnS2 Nanowall Arrays toward High-Performance Sodium Storage. ACS Appl. Mater. Interfaces 2017, 9, 6979–6987. [Google Scholar] [CrossRef]

- Yin, K.; Zhang, M.; Hood, Z.D.; Pan, J.; Meng, Y.S.; Chi, M. Self-Assembled Framework Formed during Lithiation of SnS2 Nanoplates Revealed by in Situ Electron Microscopy. Acc Chem. Res. 2017, 50, 1513–1520. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, S. Chemomechanical Modeling of Lithiation-Induced Failure in High-Volume-Change Electrode Materials for Lithium Ion Batteries. NPJ Comput. Mater. 2017, 3, 7. [Google Scholar] [CrossRef] [Green Version]

- Eom, K.S.; Jung, J.; Lee, J.T.; Lair, V.; Joshi, T.; Lee, S.W.; Lin, Z.; Fuller, T.F. Improved Stability of Nano-Sn Electrode with High-Quality Nano-SEI Formation for Lithium Ion Battery. Nano. Energy 2015, 12, 314–321. [Google Scholar] [CrossRef]

- Wang, J.; Fan, F.; Liu, Y.; Jungjohann, K.L.; Lee, S.W.; Mao, S.X.; Liu, X.; Zhu, T. Structural Evolution and Pulverization of Tin Nanoparticles during Lithiation-Delithiation Cycling. J. Electrochem. Soc. 2014, 161, F3019–F3024. [Google Scholar] [CrossRef] [Green Version]

- Demarconnay, L.; Coutanceau, C.; Léger, J.M. Electroreduction of Dioxygen (ORR) in Alkaline Medium on Ag/C and Pt/C Nanostructured Catalysts-Effect of the Presence of Methanol. Electrochim. Acta 2004, 49, 4513–4521. [Google Scholar] [CrossRef]

- Chia, X.; Lazar, P.; Sofer, Z.; Luxa, J.; Pumera, M. Layered SnS versus SnS2: Valence and Structural Implications on Electrochemistry and Clean Energy Electrocatalysis. J. Phys. Chem. C 2016, 120, 24098–24111. [Google Scholar] [CrossRef]

- Yin, L.; Chai, S.; Ma, J.; Huang, J.; Kong, X.; Bai, P.; Liu, Y. Effects of Binders on Electrochemical Properties of the SnS2nanostructured Anode of the Lithium-Ion Batteries. J. Alloys Compd. 2017, 698, 828–834. [Google Scholar] [CrossRef]

- Huang, Y.; Ling, C.; Chen, X.; Zhou, D.; Wang, S. SnS2 Nanotubes: A Promising Candidate for the Anode Material for Lithium Ion Batteries. RSC Adv. 2015, 5, 32505–32510. [Google Scholar] [CrossRef]

- Khan, Z.; Parveen, N.; Ansari, S.A.; Senthilkumar, S.T.; Park, S.; Kim, Y.; Cho, M.H.; Ko, H. Three-Dimensional SnS2 Nanopetals for Hybrid Sodium-Air Batteries. Electrochim. Acta 2017, 257, 328–334. [Google Scholar] [CrossRef]

- Xia, F.; Yang, F. SnS2 Monolayer-Supported Transition Metal Atoms as Efficient Bifunctional Oxygen Electrocatalysts: A Theoretical Investigation. Energy Fuels 2022, 36, 4992–4998. [Google Scholar] [CrossRef]

- Li, J.; Wu, P.; Lou, F.; Zhang, P.; Tang, Y.; Zhou, Y.; Lu, T. Mesoporous Carbon Anchored with SnS2 Nanosheets as an Advanced Anode for Lithium-Ion Batteries. Electrochim. Acta 2013, 111, 862–868. [Google Scholar] [CrossRef]

- Liu, Z.; Daali, A.; Xu, G.L.; Zhuang, M.; Zuo, X.; Sun, C.J.; Liu, Y.; Cai, Y.; Hossain, M.D.; Liu, H.; et al. Highly Reversible Sodiation/Desodiation from a Carbon-Sandwiched Sns2 Nanosheet Anode for Sodium Ion Batteries. Nano. Lett. 2020, 20, 3844–3851. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Zhang, Z.; Gao, L.; Lin, H.; Xue, L.; Zhou, Z.; Zhou, J.; Zhuo, S. Tin Disulphide/Nitrogen-Doped Reduced Graphene Oxide/Polyaniline Ternary Nanocomposites with Ultra-High Capacitance Properties for High Rate Performance Supercapacitor. RSC Adv. 2018, 8, 40252–40260. [Google Scholar] [CrossRef] [PubMed]

- Ji, L.; Xin, H.L.; Kuykendall, T.R.; Wu, S.L.; Zheng, H.; Rao, M.; Cairns, E.J.; Battaglia, V.; Zhang, Y. SnS2 Nanoparticle Loaded Graphene Nanocomposites for Superior Energy Storage. Phys. Chem. Chem. Physics 2012, 14, 6981–6986. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Z.; Zhang, P.; Wang, J.; Yan, Y.; Yu, Y.; Wang, Q.; Liu, M. Hierarchical Carbon@SnS2 Aerogel with “Skeleton/Skin” Architectures as a High-Capacity, High-Rate Capability and Long Cycle Life Anode for Sodium Ion Storage. ACS Appl. Mater. Interfaces 2018, 10, 37434–37444. [Google Scholar] [CrossRef] [PubMed]

- Zhou, N.; Dong, W.D.; Zhang, Y.J.; Wang, D.; Wu, L.; Wang, L.; Hu, Z.Y.; Liu, J.; Mohamed, H.S.H.; Li, Y.; et al. Embedding Tin Disulfide Nanoparticles in Two-Dimensional Porous Carbon Nanosheet Interlayers for Fast-Charging Lithium-Sulfur Batteries. Sci. China Mater. 2021, 64, 2697–2709. [Google Scholar] [CrossRef]

- Shi, X.; Yang, L.; Li, S.; Wang, Y.; Chen, X.; Wu, Z.; Zhong, Y.; Chen, Y.; Gao, S.; Wang, G.; et al. Promoting Electrochemical Kinetics of Li-S Batteries with C@SnS2 Modified Separator via Synergic Effect between Porous Carbon Matrix and Polar SnS2. Electrochim. Acta 2021, 390, 138829. [Google Scholar] [CrossRef]

- Wei, C.; Han, Y.; Liu, H.; Gan, R.; Li, Q.; Wang, Y.; Hu, P.; Ma, C.; Shi, J. Advanced Lithium-Sulfur Batteries Enabled by a SnS2-Hollow Carbon Nanofibers Flexible Electrocatalytic Membrane. Carbon. N. Y. 2021, 184, 11. [Google Scholar] [CrossRef]

- Chang, K.; Wang, Z.; Huang, G.; Li, H.; Chen, W.; Lee, J.Y. Few-Layer SnS2/Graphene Hybrid with Exceptional Electrochemical Performance as Lithium-Ion Battery Anode. J. Power Sources 2012, 201, 259–266. [Google Scholar] [CrossRef]

- Du, N.; Wu, X.; Zhai, C.; Zhang, H.; Yang, D. Large-Scale Synthesis and Application of SnS2-Graphene Nanocomposites as Anode Materials for Lithium-Ion Batteries with Enhanced Cyclic Performance and Reversible Capacity. J. Alloys Compd. 2013, 580, 457–464. [Google Scholar] [CrossRef]

- Cui, Z.; He, S.; Zhu, J.; Gao, M.; Wang, H.; Zhang, H.; Zou, R. Tailoring the Void Space Using Nanoreactors on Carbon Fibers to Confine SnS2 Nanosheets for Ultrastable Lithium/Sodium-Ion Batteries. Small Methods 2022, 6, 2101484. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Guo, Y.; Wang, Y.; Peng, T.; Lu, Y.; Luo, R.; Wang, Y.; Liu, X.; Kim, J.K.; Luo, Y. Rational Design of 3D Honeycomb-Like SnS2 Quantum Dots/RGO Composites as High-Performance Anode Materials for Lithium/Sodium-Ion Batteries. Nanoscale Res. Lett. 2018, 13, 389. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, Y.; Zhou, Y.; Yang, D.R.; Xu, W.X.; Wang, C.; Wang, F.B.; Xu, J.J.; Xia, X.H.; Chen, H.Y. Energy Level Engineering of MoS2 by Transition-Metal Doping for Accelerating Hydrogen Evolution Reaction. J. Am. Chem. Soc. 2017, 139, 15479–15485. [Google Scholar] [CrossRef]

- Agarwal, S.; Yu, X.; Manthiram, A. A Pair of Metal Organic Framework (MOF)-Derived Oxygen Reduction Reaction (ORR) and Oxygen Evolution Reaction (OER) Catalysts for Zinc-Air Batteries. Mater. Today Energy 2020, 16, 100405. [Google Scholar] [CrossRef]

- Kim, S.; Kim, G.; Manthiram, A. A Bifunctional Hybrid Electrocatalyst for Oxygen Reduction and Oxygen Evolution Reactions: Nano-Co3O4-Deposited La0.5Sr0.5MnO3 via Infiltration. Molecules 2021, 26, 277. [Google Scholar] [CrossRef]

- Zhao, J.; Sarkar, A.; Manthiram, A. Synthesis and Characterization of Pd-Ni Nanoalloy Electrocatalysts for Oxygen Reduction Reaction in Fuel Cells. Electrochim. Acta 2010, 55, 1756–1765. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, F.; Shifa, T.A.; Liu, K.; Huang, Y.; Liu, Q.; Jiang, C.; He, J. Carbon Dots Decorated Vertical SnS2 Nanosheets for Efficient Photocatalytic Oxygen Evolution. Appl. Phys. Lett. 2016, 109, 053905. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Liu, T.; Ding, T.; Pang, B.; Wang, L.; Liu, X.; Shen, X.; Wang, S.; Wu, D.; Liu, D.; et al. Surface Oxygen Injection in Tin Disulfide Nanosheets for Efficient CO2 Electroreduction to Formate and Syngas. Nanomicro. Lett. 2021, 13, 189. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, B.; Yao, Q.; Li, J.; Zhang, J.; Hou, K.; Guan, L. A Rational Microstructure Design of SnS2-Carbon Composites for Superior Sodium Storage Performance. Nanoscale 2018, 10, 7999–8008. [Google Scholar] [CrossRef]

- Li, D.; Dai, L.; Ren, X.; Ji, F.; Sun, Q.; Zhang, Y.; Ci, L. Foldable Potassium-Ion Batteries Enabled by Free-Standing and Flexible SnS2@C Nanofibers. Energy Environ. Sci. 2021, 14, 424–436. [Google Scholar] [CrossRef]

- He, X.; Liu, J.; Kang, B.; Li, X.; Zeng, L.; Liu, Y.; Qiu, J.; Qian, Q.; Wei, M.; Chen, Q. Preparation of SnS2/Enteromorpha Prolifera Derived Carbon Composite and Its Performance of Sodium-Ion Batteries. J. Phys. Chem. Solids 2021, 152, 109976. [Google Scholar] [CrossRef]

- Li, J.; Han, S.; Zhang, C.; Wei, W.; Gu, M.; Meng, L. High-Performance and Reactivation Characteristics of High-Quality, Graphene-Supported SnS2 Heterojunctions for a Lithium-Ion Battery Anode. ACS Appl. Mater. Interfaces 2019, 11, 22314–22322. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Cao, H.; Zhou, Z.; Zhang, J.; Qu, M. SnS2@reduced Graphene Oxide Nanocomposites as Anode Materials with High Capacity for Rechargeable Lithium Ion Batteries. J. Mater. Chem. 2012, 22, 23963–23970. [Google Scholar] [CrossRef]

- Liu, S.; Yin, X.; Chen, L.; Li, Q.; Wang, T. Synthesis of Self-Assembled 3D Flowerlike SnS2 Nanostructures with Enhanced Lithium Ion Storage Property. Solid State. Sci. 2010, 12, 712–718. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, H.; Du, Z.; Chang, X.; Zhao, L.; Du, X.; Li, Z.; Teng, Y.; Fang, J.; Świerczek, K. (101) Plane-Oriented SnS2 Nanoplates with Carbon Coating: A High-Rate and Cycle-Stable Anode Material for Lithium Ion Batteries. ACS Appl. Mater. Interfaces 2017, 9, 35880–35887. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Zhao, Y.S.; Meng, W.J.; Xie, Y.; Zhang, J.; He, C.J.; Zhao, D.L. Nanoplates-Assembled SnS2 Nanoflowers with Carbon Coating Anchored on Reduced Graphene Oxide for High Performance Li-Ion Batteries. Appl. Surf. Sci. 2021, 539, 148283. [Google Scholar] [CrossRef]

| Dimension | Synthesis Method | SnS2/Carbon Composites | Applications | Ref. |

|---|---|---|---|---|

| 0D | Solid-State Synthesis | SnS2/Fullerene | - | [91] |

| 1D | Facile Electrospinning Technique | SnS2/ NSDC 1 Nanofibers | SIBs 2 | [92] |

| Hydrothermal Method | Polypyrrole@SnS2@Carbon Nanofiber | LIBs 3 | [93] | |

| Facile Sintering Route | SnS2 Cross-Linked/ CNTs 4 | SIBs | [94] | |

| Solvothermal Method | SnS2 Nanoflakes/CNT | LIBs | [95] | |

| Hydrothermal Method | SnS2@rGF 5 | SIBs | [96] | |

| Plasma Evaporation and Post Sulfurization | SnS2 Semi-Filled CNT | LIBs | [97] | |

| 2D | Hydrothermal Method | SnS2/rGO 6 | LIBs | [98] |

| Hydrothermal Method | SnS2/Graphene Aerogel | SIBs | [99] | |

| Hydrothermal Method | SnS2/Graphene | SIBs | [100] | |

| Thermal Annealing | SnS2/rGO | SIBs | [101] | |

| Ultrasonication | SnS2/Graphene | LIBs/ SIBs | [102] | |

| Hydrothermal Method | Carbon-Doped SnS2 | CO2 Reduction in Fuel Cell | [103] | |

| Solvothermal Method | SnO2-rGO/SnS2 | NO2 detection | [104] | |

| Thermal Annealing | SnS2/N-Doped rGO | LIBs | [105] | |

| Wet Chemical Transfer Method | Graphene/SnS2 Heterojunction | Photoelectric Performance | [106] | |

| 3D | Solvothermal Method | SnS2/GO Nanoflower | Ultrasensitive Humidity Sensor | [107] |

| Hydrothermal Method | SnS2/Graphene Monolith | SIBs | [108] | |

| Thermally Annealing | SnS2/N-Doped Cubic-Like Carbon | LIBs | [109] | |

| Solvothermal Method | SnS2/Carbon Yolk-Shell | SIBs | [110] | |

| Hydrothermal Method | SnS2 Flowers/Carbon Nanotubes | SIBs | [111] | |

| Hydrothermal Method | SnS2@Carbon Hollow Nanospheres | SIBs | [112] | |

| Hydrothermal Method | SnS2/rGO Spheres | Asymmetric Supercapacitors | [113] | |

| Hydrothermal Method | SnS2/g-C3N4 7 Amorphous Spheres | Supercapacitors | [114] |

| Dimension | Photocatalysts | Pollutants | Photocatalytic Efficiency (%) | Irradiation Time (min) | Ref. |

|---|---|---|---|---|---|

| 0D | SnS2 Quantum Dots | Chromium (VI) | 92 | 120 | [118] |

| SnS2 Nanoparticles | Methyl Orange | 90 | 60 | [199] | |

| SnS2 QDs/rGO | Chromium (VI) | 95.3 | 120 | [206] | |

| SnS2 QDs/N-doped Graphene | Methyl Orange | 95.6 | 60 | [134] | |

| 1D | SnS2 Nanotubes | Chromium (VI) | 53.0 | 60 | [194] |

| CNT@MoS2/SnS2 | Chromium (VI) | ~100 | 90 | [202] | |

| 2D | SnS2 Nanoflakes | Rhodamine B | 61 | 120 | [44] |

| SnS2 Nanoflakes | RR 120 Dye | - | 180 | [78] | |

| SnS2 Nanoplates | Methyl Blue | 85 | 120 | [195] | |

| SnS2/rGO | Chromium (VI) | 94.0 | 90 | [60] | |

| Bio-carbon/SnS2 Nanosheets | Arsenic (III) | 95.1 | - | [204] | |

| SnS2/N-Doped Carbon QDs | Chromium (VI) | 100 | 25 | [208] | |

| SnS2-SnO2/Graphene | Rhodamine Blue | 97.1 | 60 | [209] | |

| 3D | SnS2 Nanoflowers | Chromium (VI) | 83.8 | - | [27] |

| SnS2 Nanoflowers | Methyl Orange | 79.8 | 120 | [198] | |

| Carbon Dot-SnS2 | Chromium (VI) | 77.3 | - | [207] | |

| SnS2/rGO | Chromium (VI) | 90.0 | 150 | [210] | |

| Carbon/SnS2 | Chromium (VI) | 99.7 | 120 | [211] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diko, C.S.; Abitonze, M.; Liu, Y.; Zhu, Y.; Yang, Y. Synthesis and Applications of Dimensional SnS2 and SnS2/Carbon Nanomaterials. Nanomaterials 2022, 12, 4497. https://doi.org/10.3390/nano12244497

Diko CS, Abitonze M, Liu Y, Zhu Y, Yang Y. Synthesis and Applications of Dimensional SnS2 and SnS2/Carbon Nanomaterials. Nanomaterials. 2022; 12(24):4497. https://doi.org/10.3390/nano12244497

Chicago/Turabian StyleDiko, Catherine Sekyerebea, Maurice Abitonze, Yining Liu, Yimin Zhu, and Yan Yang. 2022. "Synthesis and Applications of Dimensional SnS2 and SnS2/Carbon Nanomaterials" Nanomaterials 12, no. 24: 4497. https://doi.org/10.3390/nano12244497