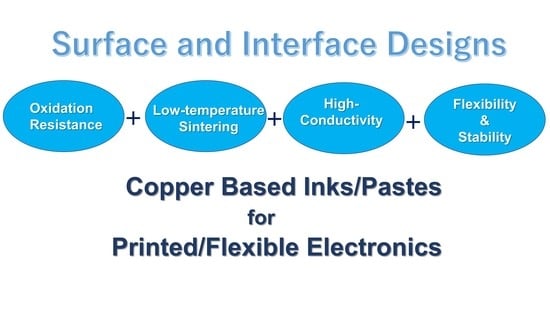

Surface and Interface Designs in Copper-Based Conductive Inks for Printed/Flexible Electronics

Abstract

:1. Introduction

2. Categories of Cu-Based Inks/Pastes

- Cu particles or their precursors (e.g., Cu salts or Cu formate-amine complex) as conductive fillers.

- Solvents for the stable dispersion of Cu particles or dissolution of their precursors, facilitation of transport/drying of the ink/pastes, and control of viscosity/surface tension for printing. Besides, reductive solvents, such as ethylene glycol (EG), can be used for Cu-based inks/pastes to suppress Cu oxidation at high temperatures.

- Dispersion and protective agents for the dispersion stability of Cu particles and the Cu oxidation resistance.

- Other additives to enhance or modify the properties of the ink/paste (e.g., antioxidants, binders, and adhesion promoters).

3. Surface Oxidation Behavior of Cu Nanoparticles

4. Surface Designs by Surface Protective Layers Against the Cu Oxidation in Cu-Based Inks/Pastes

4.1. Surface Designs by Polymers

4.1.1. Polyvinyl Pyrrolidone (PVP)

4.1.2. Gelatin

4.1.3. Polyethylene Glycol (PEG)

4.2. Surface Designs by Small Organic Ligands

4.2.1. Oleylamine

4.2.2. Alkanolamine

4.2.3. Short-Chain Carboxylic Acids

4.2.4. Oleic Acid

4.2.5. Alkanethiols

4.3. Surface Designs by Core-Shell or Alloy Structure of Nanoparticle

4.3.1. Metal shell/alloy

4.3.2. Carbon Shell

4.3.3. Copper Oxide Shell

5. Surface Activation of Cu Micro/Nanoparticles for Low (or Room)-Temperature Sintering

5.1. Surface Activation of Micron-Sized Cu Particles for Low-Temperature Sintering

5.2. Surface Activation of Cu Micro/Nanoparticles for Room Temperature Sintering

6. Formulation Designs in Cu-Based Mixed Inks/Pastes

6.1. Cu Nano/Microparticles

6.2. Metal-Organic Decomposition (MOD)/Cu Particles

6.3. Cu Nanowires/Cu Nano or MOD Inks

6.4. Carbon Nanotube/Cu-Based Inks

7. Adhesion Enhancement of Sintered Cu Films on a Flexible Substrate

8. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Davis, J.R. Asm Specialty Handbook: Copper and Copper Alloys; ASM International: Novelty, OH, USA, 2001. [Google Scholar]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A New Frontier of Printed Electronics: Flexible Hybrid Electronics. Adv. Mater. 2020, 32, 1905279. [Google Scholar] [CrossRef] [PubMed]

- Sreenilayam, S.P.; Ahad, I.U.; Nicolosi, V.; Acinas Garzon, V.; Brabazon, D. Advanced Materials of Printed Wearables for Physiological Parameter Monitoring. Mater. Today 2020, 32, 147–177. [Google Scholar] [CrossRef]

- Fernandes, D.F.; Majidi, C.; Tavakoli, M. Digitally Printed Stretchable Electronics: A Review. J. Mater. Chem. C 2019, 7, 14035–14068. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, X.; Chen, S.-C.; Zhao, N. Emerging Technologies of Flexible Pressure Sensors: Materials, Modeling, Devices, and Manufacturing. Adv. Funct. Mater. 2019, 29, 1808509. [Google Scholar] [CrossRef]

- Yu, Y.; Nyein, H.Y.Y.; Gao, W.; Javey, A. Flexible Electrochemical Bioelectronics: The Rise of In Situ Bioanalysis. Adv. Mater. 2020, 32, 902083. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Y.; Zhao, Y.; Ren, Z.; Guo, C.F. Flexible Electronics: Stretchable Electrodes and Their Future. Adv. Funct. Mater. 2019, 29, 1805924. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Cai, S.; Han, Z.; Liu, X.; Wang, F.; Cao, Y.; Wang, Z.; Li, H.; Chen, Y.; et al. Flexible Hybrid Electronics for Digital Healthcare. Adv. Mater. 2020, 32, 1902062. [Google Scholar] [CrossRef]

- Kim, D.C.; Shim, H.J.; Lee, W.; Koo, J.H.; Kim, D.H. Material-Based Approaches for the Fabrication of Stretchable Electronics. Adv. Mater. 2020, 32, 1902743. [Google Scholar] [CrossRef]

- Matsuhisa, N.; Chen, X.; Bao, Z.; Someya, T. Materials and Structural Designs of Stretchable Conductors. Chem. Soc. Rev. 2019, 48, 2946–2966. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Dong, L.; Ahmadivand, A.; Hu, H.; Nordlander, P.; Halas, N.J. Monolithic Metal Dimer-on-Film Structure: New Plasmonic Properties Introduced by the Underlying Meta. Nano Lett. 2020, 20, 2087–2093. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Bakan, G.; Ahuja, R.; Adam, J.; Mishra, Y.K.; Ahmadivand, A. The Role of Ge2Sb2Te5 in Enhancing the Performance of Functional Plasmonic Devices. Mater. Today Phys. 2020, 12, 2542–5293. [Google Scholar] [CrossRef]

- Xue, Z.; Song, H.; Rogers, J.A.; Zhang, Y.; Huang, Y. Mechanically-Guided Structural Designs in Stretchable Inorganic Electronics. Adv. Mater. 2020, 32, 1902254. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.; Ren, P.; Song, R.; Liu, Y.; Huang, Q.; Dong, J.; O’Connor, B.T.; Zhu, Y. Nanomaterial-Enabled Flexible and Stretchable Sensing Systems: Processing, Integration, and Applications. Adv. Mater. 2020, 32, 1902343. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.Z.; Wang, Y.; Cheng, T.; Yao, L.Q.; Li, X.; Lai, W.Y.; Huang, W. Printed Supercapacitors: Materials, Printing and Applications. Chem. Soc. Rev. 2019, 48, 3229–3264. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Kim, B.; Lee, C.H. Printing Flexible and Hybrid Electronics for Human Skin and Eye-Interfaced Health Monitoring Systems. Adv. Mater. 2020, 32, 1902051. [Google Scholar] [CrossRef]

- Xiang, L.; Zeng, X.; Xia, F.; Jin, W.; Liu, Y.; Hu, Y. Recent Advances in Flexible and Stretchable Sensing Systems: From the Perspective of System Integration. ACS Nano 2020, 14, 6449–6469. [Google Scholar] [CrossRef]

- Sajedi-Moghaddam, A.; Rahmanian, E.; Naseri, N. Inkjet-Printing Technology for Supercapacitor Application: Current State and Perspectives. ACS Appl. Mater. Interfaces 2020, 12, 34487–34504. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liang, J. Recent Development of Printed Micro-Supercapacitors: Printable Materials, Printing Technologies, and Perspectives. Adv. Mater. 2020, 32, 1805864. [Google Scholar] [CrossRef]

- Khan, S.; Ali, S.; Bermak, A. Recent Developments in Printing Flexible and Wearable Sensing Electronics for Healthcare Applications. Sensors 2019, 19, 1230. [Google Scholar] [CrossRef] [Green Version]

- Lopes, P.A.; Vaz Gomes, D.; Green Marques, D.; Faia, P.; Góis, J.; Patrício, T.F.; Coelho, J.; Serra, A.; De Almeida, A.T.; Majidi, C.; et al. Soft Bioelectronic Stickers: Selection and Evaluation of Skin-Interfacing Electrodes. Adv. Healthc. Mater. 2019, 8, 1900234. [Google Scholar] [CrossRef]

- Naghdi, S.; Rhee, K.Y.; Hui, D.; Park, S.J. A Review of Conductive Metal Nanomaterials as Conductive, Transparent, and Flexible Coatings, Thin Films, and Conductive Fillers: Different Deposition Methods and Applications. Coatings 2018, 8, 278. [Google Scholar] [CrossRef] [Green Version]

- Nayak, L.; Mohanty, S.; Nayak, S.K.; Ramadoss, A. A Review on Inkjet Printing of Nanoparticle Inks for Flexible Electronics. J. Mater. Chem. C 2019, 7, 8771–8795. [Google Scholar] [CrossRef]

- Joo, H.; Jung, D.; Sunwoo, S.H.; Koo, J.H.; Kim, D.H. Material Design and Fabrication Strategies for Stretchable Metallic Nanocomposites. Small 2020, 16, 1906270. [Google Scholar] [CrossRef]

- Abhinav, K.V.; Rao, R.V.K.; Karthik, P.S.; Singh, S.P. Copper Conductive Inks: Synthesis and Utilization in Flexible Electronics. RSC Adv. 2015, 5, 63985–64030. [Google Scholar] [CrossRef]

- Cano-Raya, C.; Denchev, Z.Z.; Cruz, S.F.; Viana, J.C. Chemistry of Solid Metal-Based Inks and Pastes for Printed Electronics—A Review. Appl. Mater. Today 2019, 15, 416–430. [Google Scholar] [CrossRef]

- Feng, Y.; Zhu, J. Copper Nanomaterials and Assemblies for Soft Electronics. Sci. China Mater. 2019, 62, 1679–1708. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Sun, Q.; Li, L.; Jiu, J.; Liu, X.Y.; Kanehara, M.; Minari, T.; Suganuma, K. The Rise of Conductive Copper Inks: Challenges and Perspectives. Appl. Mater. Today 2020, 18, 100451. [Google Scholar] [CrossRef]

- Groza, J.R. Nanosintering. Nanostructured Mater. 1999, 12, 987–992. [Google Scholar] [CrossRef]

- Allen, G.L.; Bayles, R.A.; Gile, W.W.; Jesser, W.A. Small particle melting of pure metals. Thin Solid Films 1989, 144, 197–308. [Google Scholar] [CrossRef]

- Yabuki, A.; Tanaka, S. Oxidation Behavior of Copper Nanoparticles at Low Temperature. Mater. Res. Bull. 2011, 46, 2323–2327. [Google Scholar] [CrossRef]

- Jeong, S.; Woo, K.; Kim, D.; Lim, S.; Kim, J.S.; Shin, H.; Xia, Y.; Moon, J. Controlling the Thickness of the Surface Oxide Layer on Cu Nanoparticles for the Fabrication of Conductive Structures by Ink-Jet Printing. Adv. Funct. Mater. 2008, 18, 679–686. [Google Scholar] [CrossRef]

- Glaria, A.; Cure, J.; Piettre, K.; Coppel, Y.; Turrin, C.O.; Chaudret, B.; Fau, P. Deciphering Ligands’ Interaction with Cu and Cu2O Nanocrystal Surfaces by NMR Solution Tools. Chem. A Eur. J. 2015, 21, 1169–1178. [Google Scholar] [CrossRef] [PubMed]

- Cure, J.; Glaria, A.; Collière, V.; Fazzini, P.F.; Mlayah, A.; Chaudret, B.; Fau, P. Remarkable Decrease in the Oxidation Rate of Cu Nanocrystals Controlled by Alkylamine Ligands. J. Phys. Chem. C 2017, 121, 5253–5260. [Google Scholar] [CrossRef]

- Rice, K.P.; Paterson, A.S.; Stoykovich, M.P. Nanoscale Kirkendall Effect and Oxidation Kinetics in Copper Nanocrystals Characterized by Real-Time, in Situ Optical Spectroscopy. Part. Part. Syst. Charact. 2015, 32, 373–380. [Google Scholar] [CrossRef]

- Susman, M.D.; Vaskevich, A.; Rubinstein, I. A General Kinetic-Optical Model for Solid-State Reactions Involving the Nano Kirkendall Effect. the Case of Copper Nanoparticle Oxidation. J. Phys. Chem. C 2016, 120, 16140–16152. [Google Scholar] [CrossRef]

- Pacioni, N.L.; Filippenko, V.; Presseau, N.; Scaiano, J.C. Oxidation of Copper Nanoparticles in Water: Mechanistic Insights Revealed by Oxygen Uptake and Spectroscopic Methods. Dalt. Trans. 2013, 42, 5832–5838. [Google Scholar] [CrossRef]

- Tang, L.; Zhu, L.; Tang, F.; Yao, C.; Wang, J.; Li, L. Mild Synthesis of Copper Nanoparticles with Enhanced Oxidative Stability and Their Application in Antibacterial Films. Langmuir 2018, 34, 14570–14576. [Google Scholar] [CrossRef]

- Dabera, G.D.M.; Walker, M.; Sanchez, A.M.; Pereira, H.J.; Beanland, R.; Hatton, R.A. Retarding Oxidation of Copper Nanoparticles without Electrical Isolation and the Size Dependence of Work Function. Nat. Commun. 2017, 8, 1894. [Google Scholar] [CrossRef] [Green Version]

- Parveen, F.; Sannakki, B.; Mandke, M.V.; Pathan, H.M. Copper Nanoparticles: Synthesis Methods and Its Light Harvesting Performance. Sol. Energy Mater. Sol. Cells 2016, 144, 371–382. [Google Scholar] [CrossRef]

- Din, M.I.; Rehan, R. Synthesis, Characterization, and Applications of Copper Nanoparticles. Anal. Lett. 2017, 50, 50–62. [Google Scholar] [CrossRef]

- Gawande, M.B.; Goswami, A.; Felpin, F.X.; Asefa, T.; Huang, X.; Silva, R.; Zou, X.; Zboril, R.; Varma, R.S. Cu and Cu-Based Nanoparticles: Synthesis and Applications in Catalysis. Chem. Rev. 2016, 116, 3722–3811. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Toshima, N.; Yonezawa, T. Bimetallic Nanoparticles Novel Materials for Chemical and Physical Applications. New J. Chem. 1998, 22, 1179–1201. [Google Scholar] [CrossRef]

- Hirai, H.; Wakabayashi, H.; Komiyama, M. Preparation of Polymer-Protected Colloidal Dispersions of Copper. Bull. Chem. Soc. Jpn. 1986, 367–372. [Google Scholar] [CrossRef] [Green Version]

- Granata, G.; Onoguchi, A.; Tokoro, C. Preparation of Copper Nanoparticles for Metal-Metal Bonding by Aqueous Reduction with D-Glucose and PVP. Chem. Eng. Sci. 2019, 209, 115210. [Google Scholar] [CrossRef]

- Cheng, C.; Li, J.; Shi, T.; Yu, X.; Fan, J.; Liao, G.; Li, X.; Cheng, S.; Zhong, Y.; Tang, Z. A Novel Method of Synthesizing Antioxidative Copper Nanoparticles for High Performance Conductive Ink. J. Mater. Sci. Mater. Electron. 2017, 28, 13556–13564. [Google Scholar] [CrossRef]

- Liu, J.; Ji, H.; Wang, S.; Li, M. The Low Temperature Exothermic Sintering of Formic Acid Treated Cu Nanoparticles for Conductive Ink. J. Mater. Sci. Mater. Electron. 2016, 27, 13280–13287. [Google Scholar] [CrossRef]

- Lee, C.-J.; Kim, J.-H.; Hwang, B.-U.; Min, K.D.; Jung, S.-B. Effect of SDBS on the Oxidation Reliability of Screen-printed Cu Circuits. J. Mater. Sci. Mater. Electron. 2020, 31, 3035–3041. [Google Scholar] [CrossRef]

- Woo, K.; Kim, Y.; Lee, B.; Kim, J.; Moon, J. Effect of Carboxylic Acid on Sintering of Inkjet-Printed Copper Nanoparticulate Films. ACS Appl. Mater. Interfaces 2011, 3, 2377–2382. [Google Scholar] [CrossRef]

- Jang, Y.R.; Joo, S.J.; Chu, J.H.; Uhm, H.J.; Park, J.W.; Ryu, C.H.; Yu, M.H.; Kim, H.S. A Review on Intense Pulsed Light Sintering Technologies for Conductive Electrodes in Printed Electronics. Int. J. Precis. Eng. Manuf. Green Technol. 2020. [Google Scholar] [CrossRef]

- Hwang, H.-J.; Oh, K.-H.; Kim, H.-S. All-Photonic Drying and Sintering Process via Flash White Light Combined with Deep-UV and near-Infrared Irradiation for Highly Conductive Copper Nano-Ink. Sci. Rep. 2016, 6, 19696. [Google Scholar] [CrossRef]

- Hwang, Y.T.; Chung, W.H.; Jang, Y.R.; Kim, H.S. Intensive Plasmonic Flash Light Sintering of Copper Nanoinks Using a Band-Pass Light Filter for Highly Electrically Conductive Electrodes in Printed Electronics. ACS Appl. Mater. Interfaces 2016, 8, 8591–8599. [Google Scholar] [CrossRef] [PubMed]

- Chan, H.J.; Huang, B.C.; Wang, L.W.; Liao, K.H.; Lo, C.Y. Porosity Reduction in Inkjet-Printed Copper Film by Progressive Sintering on Nanoparticles. Thin Solid Film. 2017, 627, 33–38. [Google Scholar] [CrossRef]

- Kwon, J.; Cho, H.; Eom, H.; Lee, H.; Suh, Y.D.; Moon, H.; Shin, J.; Hong, S.; Ko, S.H. Low-Temperature Oxidation-Free Selective Laser Sintering of Cu Nanoparticle Paste on a Polymer Substrate for the Flexible Touch Panel Applications. ACS Appl. Mater. Interfaces 2016, 8, 11575–11582. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Kim, H.; Yoon, Y.; Lee, J.; Lee, D.; Suh, Y.D.; Ko, S.H.; Jung, J.; Cho, H.; Choi, S.H.; et al. Moiré-Free Imperceptible and Flexible Random Metal Grid Electrodes with Large Figure-of Merit by Photonic Sintering Control of Copper Nanoparticles. ACS Appl. Mater. Interfaces 2019, 11, 15773–15780. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, H.; Jiu, J.; Nagao, S.; Sugahara, T.; Suganuma, K. Fabrication of a Flexible Copper Pattern Based on a Sub-Micro Copper Paste by a Low Temperature Plasma Technique. RSC Adv. 2015, 5, 90202–90208. [Google Scholar] [CrossRef]

- Tomonari, M.; Ida, K.; Yamashita, H.; Yonezawa, T. Size-Controlled Oxidation-Resistant Copper Fine Particles Covered by Biopolymer Nanoskin. J. Nanosci. Nanotechnol. 2008, 8, 2468–2471. [Google Scholar] [CrossRef]

- Yonezawa, T.; Tsukamoto, H.; Matsubara, M. Low-Temperature Nanoredox Two-Step Sintering of Gelatin Nanoskin-Stabilized Submicrometer-Sized Copper Fine Particles for Preparing Highly Conductive Layers. RSC Adv. 2015, 5, 61290–61297. [Google Scholar] [CrossRef] [Green Version]

- Matsubara, M.; Yonezawa, T.; Tsukamoto, A.H. Effect of Glass Transition Temperature of Stabilizing Polymer of Air-Stable Gelatin-Stabilized Copper Fine Particles during Redox Two-Step Low-Temperature Sintering Process. Bull. Chem. Soc. Jpn. 2015, 88, 1755–1759. [Google Scholar] [CrossRef]

- Colacino, E.; Martinez, J.; Lamaty, F.; Patrikeeva, L.S.; Khemchyan, L.L.; Ananikov, V.P.; Beletskaya, I.P. PEG as an Alternative Reaction Medium in Metal-Mediated Transformations. Coord. Chem. Rev. 2012, 256, 2893–2920. [Google Scholar] [CrossRef]

- Dang, T.M.D.; Le, T.T.T.; Fribourg-Blanc, E.; Dang, M.C. Synthesis and Optical Properties of Copper Nanoparticles Prepared by a Chemical Reduction Method. Adv. Nat. Sci. Nanosci. Nanotechnol. 2011, 2, 015009. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Li, G.; Zhao, T.; Fu, X.; Sun, R.; Zhou, F.; Wong, C.P. Facile Preparation of Monodisperse, Impurity-Free, and Antioxidation Copper Nanoparticles on a Large Scale for Application in Conductive Ink. ACS Appl. Mater. Interfaces 2014, 6, 560–567. [Google Scholar] [CrossRef] [PubMed]

- Togashi, T.; Nakayama, M.; Hashimoto, A.; Ishizaki, M.; Kanaizuka, K.; Kurihara, M. Solvent-Free Synthesis of Monodisperse Cu Nanoparticles by Thermal Decomposition of an Oleylamine-Coordinated Cu Oxalate Complex. Dalt. Trans. 2018, 47, 5342–5347. [Google Scholar] [CrossRef]

- Oliva-Puigdomènech, A.; De Roo, J.; Kuhs, J.; Detavernier, C.; Martins, J.C.; Hens, Z. Ligand Binding to Copper Nanocrystals: Amines and Carboxylic Acids and the Role of Surface Oxides. Chem. Mater. 2019, 31, 2058–2067. [Google Scholar] [CrossRef] [Green Version]

- Dai, X.; Xu, W.; Zhang, T.; Wang, T. Self-Reducible Cu Nanoparticles for Conductive Inks. Ind. Eng. Chem. Res. 2018, 57, 2508–2516. [Google Scholar] [CrossRef]

- Oliva-Puigdomènech, A.; De Roo, J.; Van Avermaet, H.; De Buysser, K.; Hens, Z. Scalable Approaches to Copper Nanocrystal Synthesis under Ambient Conditions for Printed Electronics. ACS Appl. Nano Mater. 2020, 3, 3523–3531. [Google Scholar] [CrossRef]

- Hokita, Y.; Kanzaki, M.; Sugiyama, T.; Arakawa, R.; Kawasaki, H. High-Concentration Synthesis of Sub-10-Nm Copper Nanoparticles for Application to Conductive Nanoinks. ACS Appl. Mater. Interfaces 2015, 7, 19382–19389. [Google Scholar] [CrossRef]

- Sugiyama, T.; Kanzaki, M.; Arakawa, R.; Kawasaki, H. Low-Temperature Sintering of Metallacyclic Stabilized Copper Nanoparticles and Adhesion Enhancement of Conductive Copper Film to a Polyimide Substrate. J. Mater. Sci. Mater. Electron. 2016, 27, 7540–7547. [Google Scholar] [CrossRef]

- Li, J.; Shi, T.; Feng, C.; Liang, Q.; Yu, X.; Fan, J.; Cheng, S.; Liao, G.; Tang, Z. The Novel Cu Nanoaggregates Formed by 5 nm Cu Nanoparticles with High Sintering Performance at Low Temperature. Mater. Lett. 2018, 216, 20–23. [Google Scholar] [CrossRef]

- Deng, D.; Jin, Y.; Cheng, Y.; Qi, T.; Xiao, F. Copper Nanoparticles: Aqueous Phase Synthesis and Conductive Films Fabrication at Low Sintering Temperature. ACS Appl. Mater. Interfaces 2013, 5, 3839–3846. [Google Scholar] [CrossRef]

- Xiong, J.; Wang, Y.; Xue, Q.; Wu, X. Synthesis of Highly Stable Dispersions of Nanosized Copper Particles Using L-Ascorbic Acid. Green Chem. 2011, 13, 900–904. [Google Scholar] [CrossRef]

- Kuroda, K.; Keller, P.; Kawasaki, H. Mild Synthesis of Single-Nanosized Plasmonic Copper Nanoparticles and Their Catalytic Reduction of Methylene Blue. Colloids Interface Sci. Commun. 2019, 31, 100187. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, C.; Yang, B.; Zhang, K.; Zhu, P.; Li, G.; Sun, R.; Wong, C. Size-Controllable Copper Nanomaterials for Flexible Printed Electronics. J. Mater. Sci. 2018, 53, 12988–12995. [Google Scholar] [CrossRef]

- Yokoyama, S.; Takahashi, H.; Itoh, T.; Motomiya, K.; Tohji, K. Synthesis of Metallic Cu Nanoparticles by Controlling Cu Complexes in Aqueous Solution. Adv. Powder Technol. 2014, 25, 999–1006. [Google Scholar] [CrossRef]

- Yokoyama, S.; Motomiya, K.; Takahashi, H.; Tohji, K. Green Synthesis of Cu Micro/Nanoparticles for Low-Resistivity Cu Thin Films Using Ascorbic Acid in Aqueous Solution. J. Mater. Chem. C 2016, 4, 7494–7500. [Google Scholar] [CrossRef]

- Yokoyama, S.; Motomiya, K.; Takahashi, H.; Tohji, K. Formation of Closely Packed Cu Nanoparticle Films by Capillary Immersion Force for Preparing Low-Resistivity Cu Films at Low Temperature. J. Nanopart. Res. 2016, 18, 326. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, S.H.; Jo, Y.; Lee, S.S.; Seo, Y.-H.; Ahn, B.W.; Kim, G.; Jang, G.-E.; Park, J.-U.; Ryu, B.-H.; et al. Air-Stable, Surface-Oxide Free Cu Nanoparticles for Highly Conductive Cu Ink and Their Application to Printed Graphene Transistors. J. Mater. Chem. C 2013, 1, 2704–2710. [Google Scholar] [CrossRef] [Green Version]

- Oh, S.J.; Jo, Y.; Lee, E.J.; Lee, S.S.; Kang, Y.H.; Jeon, H.J.; Cho, S.Y.; Park, J.S.; Seo, Y.H.; Ryu, B.H.; et al. Ambient Atmosphere-Processable, Printable Cu Electrodes for Flexible Device Applications: Structural Welding on a Millisecond Timescale of Surface Oxide-Free Cu Nanoparticles. Nanoscale 2015, 7, 3997–4004. [Google Scholar] [CrossRef]

- Park, H.J.; Cho, M.K.; Jeong, Y.W.; Kim, D.; Lee, S.Y.; Choi, Y.; Jeong, S. Ultrathin Plasmonic Optical/Thermal Barrier: Flashlight-Sintered Copper Electrodes Compatible with Polyethylene Terephthalate Plastic Substrates. ACS Appl. Mater. Interfaces 2017, 9, 43814–43821. [Google Scholar] [CrossRef]

- Park, J.H.; Jeong, S.; Lee, E.J.; Lee, S.S.; Seok, J.Y.; Yang, M.; Choi, Y.; Kang, B. Transversally Extended Laser Plasmonic Welding for Oxidation-Free Copper Fabrication toward High-Fidelity Optoelectronics. Chem. Mater. 2016, 28, 4151–4159. [Google Scholar] [CrossRef]

- Kwon, J.; Park, S.; Lee, T.H.; Yang, J.M.; Lee, C.S. Investigation of Oxidation Inhibition Properties of Vaporized Self-Assembled Multilayers on Copper Nanopowders. Appl. Surf. Sci. 2011, 257, 5115–5120. [Google Scholar] [CrossRef]

- Her, J.; Cho, D.; Lee, C.S. Synthesis of Conductive Nano Ink Using 1-Octanethiol Coated Copper Nano Powders in 1-Octanol for Low Temperature Sintering Process. Mater. Trans. 2013, 54, 599–602. [Google Scholar] [CrossRef] [Green Version]

- Son, Y.H.; Jang, J.Y.; Kang, M.K.; Ahn, S.; Lee, C.S. Application of Flash-Light Sintering Method to Flexible Inkjet Printing Using Anti-Oxidant Copper Nanoparticles. Thin Solid Films 2018, 656, 61–67. [Google Scholar] [CrossRef]

- Grouchko, M.; Kamyshny, A.; Magdassi, S. Formation of Air-stable Copper–Silver Core–shell Nanoparticles for Inkjet Printing. J. Mater. Chem. 2009, 19, 3057–3062. [Google Scholar] [CrossRef]

- Pajor-Świerzy, A.; Farraj, Y.; Kamyshny, A.; Magdassi, S. Air Stable Copper-Silver Core-Shell Submicron ParticlesSynthesis and Conductive Ink Formulation. Colloids Surf. A Physicochem. Eng. Asp. 2017, 521, 272–280. [Google Scholar] [CrossRef]

- Yu, X.; Li, J.; Shi, T.; Cheng, C.; Liao, G.; Fan, J.; Li, T.; Tang, Z. A Green Approach of Synthesizing of Cu-Ag Core-Shell Nanoparticles and Their Sintering Behavior for Printed Electronics. J. Alloys Compd. 2017, 724, 365–372. [Google Scholar] [CrossRef]

- Tan, S.; Zu, X.; Yi, G.; Liu, X. Synthesis of Highly Environmental Stable Copper–silver Core–shell Nanoparticles for Direct Writing Flexible Electronics. J. Mater. Sci. Mater. Electron. 2017, 28, 15899–15906. [Google Scholar] [CrossRef]

- Li, W.; Wang, Y.; Wang, M.; Li, W.; Tan, J.; You, C.; Chen, M. Synthesis of Stable CucoreAgshell & Ag Particles for Direct Writing Flexible Paper-Based Electronics. RSC Adv. 2016, 6, 62236–62243. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Li, G.; Cui, Z.; Cui, C.; Zhang, K.; Gao, J.; Chen, X.; Zhang, G.; Sun, R.; et al. PVP-Mediated Galvanic Replacement Synthesis of Smart Elliptic Cu–Ag Nanoflakes for Electrically Conductive Pastes. ACS Appl. Mater. Interfaces 2018, 11, 8382–8390. [Google Scholar] [CrossRef]

- Dou, Q.; Li, Y.; Wong, K.W.; Ng, K.M. Facile Synthesis of Nearly Monodisperse AgCu Alloy Nanoparticles with Synergistic Effect against Oxidation and Electromigration. J. Mater. Res. 2019, 34, 2095–2104. [Google Scholar] [CrossRef]

- Kawamura, G.; Alvarez, S.; Stewart, I.E.; Catenacci, M.; Chen, Z.; Ha, Y.C. Production of Oxidation-Resistant Cu-Based Nanoparticles by Wire Explosion. Sci. Rep. 2015, 5, 1–8. [Google Scholar] [CrossRef]

- Gu, Y.; Wu, A.; Federici, J.F.; Zhang, X. Inkjet Printable Constantan Ink for the Fabrication of Flexible and Conductive Film. Chem. Eng. J. 2017, 313, 27–36. [Google Scholar] [CrossRef]

- Fang, Y.; Zeng, X.; Chen, Y.; Ji, M.; Zheng, H.; Xu, W.; Peng, D.L. Cu@Ni Core-Shell Nanoparticles Prepared via an Injection Approach with Enhanced Oxidation Resistance for the Fabrication of Conductive Films. Nanotechnology 2020, 31, 355601. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.G.; Park, H.J.; Woo, K.; Jeong, S.; Choi, Y.; Lee, S.Y. Enhanced Oxidation-Resistant Cu@Ni Core–Shell Nanoparticles for Printed Flexible Electrodes. ACS Appl. Mater. Interfaces 2018, 10, 1059–1066. [Google Scholar] [CrossRef]

- Oh, S.J.; Kim, T.G.; Kim, S.Y.; Jo, Y.; Lee, S.S.; Kim, K.; Ryu, B.H.; Park, J.U.; Choi, Y.; Jeong, S. Newly Designed Cu/Cu10Sn3 Core/Shell Nanoparticles for Liquid Phase-Photonic Sintered Copper Electrodes: Large-Area, Low-Cost Transparent Flexible Electronics. Chem. Mater. 2016, 28, 4714–4723. [Google Scholar] [CrossRef]

- Park, H.J.; Jo, Y.; Cho, M.K.; Young Woo, J.; Kim, D.; Lee, S.Y.; Choi, Y.; Jeong, S. Highly Durable Cu-Based Electrodes from a Printable Nanoparticle Mixture Ink: Flash-Light-Sintered, Kinetically-Controlled Microstructure. Nanoscale 2018, 10, 5047–5053. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, C.; Lee, G.; Rhee, C.; Lee, M. Expeditious Low-Temperature Sintering of Copper Nanoparticles with Thin Defective Carbon Shells. Nanoscale 2015, 7, 6627–6635. [Google Scholar] [CrossRef]

- Luechinger, N.A.; Athanassiou, E.K.; Stark, W.J. Graphene Stabilized Copper Nanoparticles as an Air-Stable Substitute for Silver and Gold in Low-Cost Ink-Jet Printable Electronics. Nanotechnology 2008, 19, 445201. [Google Scholar] [CrossRef]

- Tseng, C.A.; Chen, C.C.; Ulaganathan, R.K.; Lee, C.P.; Chiang, H.C.; Chang, C.F.; Chen, Y.T. One-Step Synthesis of Antioxidative Graphene-Wrapped Copper Nanoparticles on Flexible Substrates for Electronic and Electrocatalytic Applications. ACS Appl. Mater. Interfaces 2017, 9, 25067–25072. [Google Scholar] [CrossRef]

- Ryu, J.; Kim, H.S.; Hahn, H.T. Reactive Sintering of Copper Nanoparticles Using Intense Pulsed Light for Printed Electronics. J. Electron. Mater. 2011, 40, 42–50. [Google Scholar] [CrossRef]

- Öhlund, T.; Schuppert, A.K.; Hummelgård, M.; Bäckström, J.; Nilsson, H.E.; Olin, H. Inkjet Fabrication of Copper Patterns for Flexible Electronics: Using Paper with Active Precoatings. ACS Appl. Mater. Interfaces 2015, 7, 18273–18282. [Google Scholar] [CrossRef]

- Albrecht, A.; Rivadeneyra, A.; Abdellah, A.; Lugli, P.; Salmerón, J.F. Inkjet Printing and Photonic Sintering of Silver and Copper Oxide Nanoparticles for Ultra-Low-Cost Conductive Patterns. J. Mater. Chem. C 2016, 4, 3546–3554. [Google Scholar] [CrossRef]

- Rager, M.S.; Aytug, T.; Veith, G.M.; Joshi, P. Low-Thermal-Budget Photonic Processing of Highly Conductive Cu Interconnects Based on CuO Nanoinks: Potential for Flexible Printed Electronics. ACS Appl. Mater. Interfaces 2016, 8, 2441–2448. [Google Scholar] [CrossRef] [PubMed]

- Oh, G.H.; Hwang, H.J.; Kim, H.S. Effect of Copper Oxide Shell Thickness on Flash Light Sintering of Copper Nanoparticle Ink. RSC Adv. 2017, 7, 17724–17731. [Google Scholar] [CrossRef] [Green Version]

- Ryu, C.H.; Joo, S.J.; Kim, H.S. Two-Step Flash Light Sintering of Copper Nanoparticle Ink to Remove Substrate Warping. Appl. Surf. Sci. 2016, 384, 182–191. [Google Scholar] [CrossRef]

- Chung, W.Y.; Lai, Y.C.; Yonezawa, T.; Liao, Y.C. Sintering Copper Nanoparticles with Photonic Additive for Printed Conductive Patterns by Intense Pulsed Light. Nanomaterials 2019, 9, 1071. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kwon, Y.-T.; Yune, S.-J.; Song, Y.; Yeo, W.-H.; Choa, Y.-H. Green Manufacturing of Highly Conductive Cu2O and Cu Nanoparticles for Photonic-Sintered Printed Electronics. ACS Appl. Electron. Mater. 2019, 1, 2069–2075. [Google Scholar] [CrossRef]

- Yong, Y.; Yonezawa, T.; Matsubara, M.; Tsukamoto, H. The Mechanism of Alkylamine-Stabilized Copper Fine Particles towards Improving the Electrical Conductivity of Copper Films at Low Sintering Temperature. J. Mater. Chem. C 2015, 3, 5890–5895. [Google Scholar] [CrossRef]

- Yeshchenko, O.A.; Dmitruk, I.M.; Alexeenko, A.A.; Dmytruk, A.M. Size-Dependent Melting of Spherical Copper Nanoparticles Embedded in a Silica Matrix. Phys. Rev. B Condens Matter Mater. Phys. 2007, 75, 085434. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.S.; Chen, G.F.; Liu, P.S.; Chen, G.F. Chapter Two–Making Porous Metals. Porous Mater. 2014, 21–112. [Google Scholar] [CrossRef]

- Wu, C.J.; Cheng, S.L.; Sheng, Y.J.; Tsao, H.K. Reduction-Assisted Sintering of Micron-Sized Copper Powders at Low Temperature by Ethanol Vapor. RSC Adv. 2015, 5, 53275–53279. [Google Scholar] [CrossRef]

- Qi, T.; Wang, X.; Yang, J.; Xiao, F. Rapid Low Temperature Sintering in Air of Copper Submicron Particles with Synergistic Surface-Activation and Anti-Oxidative Protection. J. Mater. Sci. Mater. Electron. 2019, 30, 12669–12678. [Google Scholar] [CrossRef]

- Wakuda, D.; Hatamura, M.; Suganuma, K. Novel Method for Room Temperature Sintering of Ag Nanoparticle Paste in Air. Chem. Phys. Lett. 2007, 441, 305–308. [Google Scholar] [CrossRef]

- Grouchko, M.; Kamyshny, A.; Mihailescu, C.F.; Anghel, D.F.; Magdassi, S. Conductive Inks with a “Built-in” Mechanism That Enables Sintering at Room Temperature. ACS Nano 2011, 5, 3354–3359. [Google Scholar] [CrossRef] [PubMed]

- Peng, P.; Li, L.; Guo, W.; Hui, Z.; Fu, J.; Jin, C.; Liu, Y.; Zhu, Y. Room-Temperature Joining of Silver Nanoparticles Using Potassium Chloride Solution for Flexible Electrode Application. J. Phys. Chem. C 2018, 122, 2704–2711. [Google Scholar] [CrossRef]

- Okada, S.; Nakahara, Y.; Watanabe, M.; Tamai, T.; Kobayashi, Y.; Yajima, S. Room-Temperature Sintering of Tri-n-Octylphosphine-Oxide- Capped Silver Nanoparticle Paste by Dipping into an Organic Solvent Containing a Sintering Agent. J. Phys. Chem. C 2019, 123, 14118–14125. [Google Scholar] [CrossRef]

- Song, Y.; Kim, D.; Kang, S.; Ko, Y.; Ko, J.; Huh, J.; Ko, Y.; Lee, S.W.; Cho, J. Room-Temperature Metallic Fusion-Induced Layer-by-Layer Assembly for Highly Flexible Electrode Applications. Adv. Funct. Mater. 2019, 29, 1806584. [Google Scholar] [CrossRef]

- Wu, C.J.; Sheng, Y.J.; Tsao, H.K. Copper Conductive Lines on Flexible Substrates Fabricated at Room Temperature. J. Mater. Chem. C 2016, 4, 3274–3280. [Google Scholar] [CrossRef]

- Lee, J.; Jun, J.; Na, W.; Oh, J.; Kim, Y.; Kim, W.; Jang, J. Fabrication of Sinter-Free Conductive Cu Paste Using Sub-10 Nm Copper Nanoparticles. J. Mater. Chem. C 2017, 5, 12507–12512. [Google Scholar] [CrossRef]

- Dai, X.; Xu, W.; Zhang, T.; Shi, H.; Wang, T. Room Temperature Sintering of Cu-Ag Core-Shell Nanoparticles Conductive Inks for Printed Electronics. Chem. Eng. J. 2019, 364, 310–319. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, T.; Shi, H.; Zhang, Y.; Wang, T. Reactive Sintering of Cu Nanoparticles at Ambient Conditions for Printed Electronics. ACS Omega 2020, 5, 13416–13423. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Xing, S.; Liu, L.; Zou, G.; Zhang, P. Structure Inheritance in Nanoparticle Ink Direct-Writing Processes and Crack-Free Nano-Copper Interconnects Printed by a Single-Run Approach. Materials 2019, 12, 1559. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dai, Y.Y.; Ng, M.Z.; Anantha, P.; Lin, Y.D.; Li, Z.G.; Gan, C.L.; Tan, C.S. Enhanced Copper Micro/Nano-Particle Mixed Paste Sintered at Low Temperature for 3D Interconnects. Appl. Phys. Lett. 2016, 108, 263103. [Google Scholar] [CrossRef]

- Tam, S.K.; Fung, K.Y.; Ng, K.M. Copper Pastes Using Bimodal Particles for Flexible Printed Electronics. J. Mater. Sci. 2016, 51, 1914–1922. [Google Scholar] [CrossRef]

- Kanzaki, M.; Kawaguchi, Y.; Kawasaki, H. Fabrication of Conductive Copper Films on Flexible Polymer Substrates by Low-Temperature Sintering of Composite Cu Ink in Air. ACS Appl. Mater. Interfaces 2017, 9, 20852–20858. [Google Scholar] [CrossRef]

- Park, H.J.; Jo, Y.; Lee, S.S.; Lee, S.Y.; Choi, Y.; Jeong, S. Printable Thick Copper Conductors from Optically Modulated Multidimensional Particle Mixtures. ACS Appl. Mater. Interfaces 2019, 11, 20134–20142. [Google Scholar] [CrossRef]

- Ryu, C.H.; Joo, S.J.; Kim, H.S. Intense Pulsed Light Sintering of Cu Nano Particles/Micro Particles-Ink Assisted with Heating and Vacuum Holding of Substrate for Warpage Free Printed Electronic Circuit. Thin Solid Film. 2019, 675, 23–33. [Google Scholar] [CrossRef]

- Ryu, C.H.; Moon, C.J.; Kim, H.S. A Study on the Relationship between Print-Ability and Flash Light Sinter-Ability of Cu Nano/Micro-Ink for Printed Electronics. Thin Solid Film. 2019, 671, 36–43. [Google Scholar] [CrossRef]

- Ryu, C.H.; Um, H.J.; Kim, H.S. Enhancing Intense Pulsed Light Sintering Characteristic of Cu Nanoparticle/Microparticle-Ink Using Ultraviolet Surface Modification on Polyimide Substrate. Thin Solid Film. 2020, 701, 137951. [Google Scholar] [CrossRef]

- Chen, X.; Wu, X.; Shao, S.; Zhuang, J.; Xie, L.; Nie, S.; Su, W.; Chen, Z.; Cui, Z. Hybrid Printing Metal-Mesh Transparent Conductive Films with Lower Energy Photonically Sintered Copper/Tin Ink. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Choi, Y.; Seong, K.-d.; Piao, Y. Metal−Organic Decomposition Ink for Printed Electronics. Adv. Mater. Interfaces 2019, 6, 1901002. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; List-Kratochvil, E.J.W.; Wang, C. Metal Particle-Free Inks for Printed Flexible Electronics. J. Mater. Chem. C 2019, 7, 15098–15117. [Google Scholar] [CrossRef]

- Yonezawa, T.; Tsukamoto, H.; Yong, Y.; Nguyen, M.T.; Matsubara, M. Low Temperature Sintering Process of Copper Fine Particles under Nitrogen Gas Flow with Cu2+-Alkanolamine Metallacycle Compounds for Electrically Conductive Layer Formation. RSC Adv. 2016, 6, 12048–12052. [Google Scholar] [CrossRef] [Green Version]

- Yong, Y.; Nguyen, M.T.; Tsukamoto, H.; Matsubara, M.; Liao, Y.C.; Yonezawa, T. Effect of Decomposition and Organic Residues on Resistivity of Copper Films Fabricated via Low-Temperature Sintering of Complex Particle Mixed Dispersions. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Yong, Y.; Nguyen, M.T.; Yonezawa, T.; Asano, T.; Matsubara, M.; Tsukamoto, H.; Liao, Y.C.; Zhang, T.; Isobe, S.; Nakagawa, Y. Use of Decomposable Polymer-Coated Submicron Cu Particles with Effective Additive for Production of Highly Conductive Cu Films at Low Sintering Temperature. J. Mater. Chem. C 2017, 5, 1033–1041. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Cong, S.; Jiu, J.; Nagao, S.; Suganuma, K. Self-Reducible Copper Inks Composed of Copper–Amino Complexes and Preset Submicron Copper Seeds for Thick Conductive Patterns on a Flexible Substrate. J. Mater. Chem. C 2016, 4, 8802–8809. [Google Scholar] [CrossRef]

- Li, Y.; Qi, T.; Chen, M.; Xiao, F. Mixed Ink of Copper Nanoparticles and Copper Formate Complex with Low Sintering Temperatures. J. Mater. Sci. Mater. Electron. 2016, 27, 11432–11438. [Google Scholar] [CrossRef]

- Tam, S.K.; Fung, K.Y.; Ng, K.M. High Copper Loading Metal Organic Decomposition Paste for Printed Electronics. J. Mater. Sci. 2017, 52, 5617–5625. [Google Scholar] [CrossRef]

- Kawaguchi, Y.; Hotta, Y.; Kawasaki, H. Cu-Based Composite Inks of a Self-Reductive Cu Complex with Cu Flakes for the Production of Conductive Cu Films on Cellulose Paper. Mater. Chem. Phys. 2017, 197, 87–93. [Google Scholar] [CrossRef]

- Sakurai, S.; Akiyama, Y.; Kawasaki, H. Filtration-Induced Production of Conductive/Robust Cu Films on Cellulose Paper by Low-Temperature Sintering in Air. R. Soc. Open Sci. 2018, 5, 172417. [Google Scholar] [CrossRef] [Green Version]

- Chung, W.H.; Hwang, H.J.; Kim, H.S. Flash Light Sintered Copper Precursor/Nanoparticle Pattern with High Electrical Conductivity and Low Porosity for Printed Electronics. Thin Solid Film. 2015, 580, 61–70. [Google Scholar] [CrossRef]

- Li, W.; Zhang, H.; Gao, Y.; Jiu, J.; Li, C.-F.; Chen, C.; Hu, D.; Goya, Y.; Wang, Y.; Koga, H.; et al. Highly Reliable and Highly Conductive Submicron Cu Particle Patterns Fabricated by Low Temperature Heat-Welding and Subsequent Flash Light Sinter-Reinforcement. J. Mater. Chem. C 2017, 5, 1155–1164. [Google Scholar] [CrossRef]

- Li, W.; Li, L.; Gao, Y.; Hu, D.; Li, C.-F.; Zhang, H.; Jiu, J.; Nagao, S.; Suganuma, K. Highly Conductive Copper Films Based on Submicron Copper Particles/Copper Complex Inks for Printed Electronics: Microstructure, Resistivity, Oxidation Resistance, and Long-Term Stability. J. Alloys Compd. 2018, 732, 240–247. [Google Scholar] [CrossRef]

- Deore, B.; Paquet, C.; Kell, A.J.; Lacelle, T.; Liu, X.; Mozenson, O.; Lopinski, G.; Brzezina, G.; Guo, C.; Lafrenière, S.; et al. Formulation of Screen-Printable Cu Molecular Ink for Conductive/Flexible/Solderable Cu Traces. ACS Appl. Mater. Interfaces 2019, 11, 38880–38894. [Google Scholar] [CrossRef] [PubMed]

- Yim, C.; Sandwell, A.; Park, S.S. Hybrid Copper−Silver Conductive Tracks for Enhanced Oxidation Resistance under Flash Light Sintering. ACS Appl. Mater. Interfaces 2016, 8, 22369–22373. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Hu, D.; Li, L.; Li, C.F.; Jiu, J.; Chen, C.; Ishina, T.; Sugahara, T.; Suganuma, K. Printable and Flexible Copper-Silver Alloy Electrodes with High Conductivity and Ultrahigh Oxidation Resistance. ACS Appl. Mater. Interfaces 2017, 9, 24711–24721. [Google Scholar] [CrossRef] [PubMed]

- Koch, C.C.; Morris, D.G.; Lu, K.; Inoue, A. Ductility of Nanostructured Materials. MRS Bull. 1999, 24, 54–58. [Google Scholar] [CrossRef]

- Rathmell, A.R.; Bergin, S.M.; Hua, Y.L.; Li, Z.Y.; Wiley, B.J. The Growth Mechanism of Copper Nanowires and Their Properties in Flexible, Transparent Conducting Films. Adv. Mater. 2010, 22, 3558–3563. [Google Scholar] [CrossRef]

- Ding, S.; Tian, Y. Recent Progress of Solution-Processed Cu Nanowires Transparent Electrodes and Their Applications. RSC Adv. 2019, 9, 26961–26980. [Google Scholar] [CrossRef] [Green Version]

- Joo, S.-J.; Park, S.-H.; Moon, C.-J.; Kim, H.-S. A Highly Reliable Copper Nanowire/Nanoparticle Ink Pattern with High Conductivity on Flexible Substrate Prepared via a Flash Light-Sintering Technique. ACS Appl. Mater. Interfaces 2015, 7, 5674–5684. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, C.; Li, W.; Yeom, J.; Suganuma, K. Well-Controlled Decomposition of Copper Complex Inks Enabled by Metal Nanowire Networks for Highly Compact, Conductive, and Flexible Copper Films. Adv. Mater. Interfaces 2020, 7, 1901550. [Google Scholar] [CrossRef]

- Hwang, H.J.; Joo, S.J.; Kim, H.S. Copper Nanoparticle/Multiwalled Carbon Nanotube Composite Films with High Electrical Conductivity and Fatigue Resistance Fabricated via Flash Light Sintering. ACS Appl. Mater. Interfaces 2015, 7, 25413–25423. [Google Scholar] [CrossRef] [PubMed]

- Rosen, Y.S.; Yakushenko, A.; Offenhäusser, A.; Magdassi, S. Self-Reducing Copper Precursor Inks and Photonic Additive Yield Conductive Patterns under Intense Pulsed Light. ACS Omega 2017, 2, 573–581. [Google Scholar] [CrossRef] [PubMed]

- Seong, K.D.; Kim, J.M.; Kang, J.; Hwang, M.; Lee, C.; Piao, Y. An Ultradurable and Uniform Cu Electrode by Blending Carbon Nanotube Fillers in Copper-Based Metal–Organic Decomposition Ink for Flexible Printed Electronics. Adv. Mater. Interfaces 2018, 5, 1800502. [Google Scholar] [CrossRef]

- Jeon, E.B.; Joo, S.J.; Ahn, H.; Kim, H.S. Two-Step Flash Light Sintering Process for Enhanced Adhesion between Copper Complex Ion/Silane Ink and a Flexible Substrate. Thin Solid Films 2016, 603, 382–390. [Google Scholar] [CrossRef]

- Kwon, Y.-T.; Kim, Y.-S.; Lee, Y.; Kwon, S.; Lim, M.; Song, Y.; Choa, Y.-H.; Yeo, W.-H. Ultrahigh Conductivity and Superior Interfacial Adhesion of a Nanostructured, Photonic-Sintered Copper Membrane for Printed Flexible Hybrid Electronics. ACS Appl. Mater. Interfaces 2018, 10, 44071–44079. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, Y.I.; Choa, Y.H. Adhesion Enhancement of Ink-Jet Printed Conductive Copper Patterns on a Flexible Substrate. J. Mater. Chem. 2012, 22, 12517–12522. [Google Scholar] [CrossRef]

- Sakurai, S.; Uda, T.; Kawasaki, H. Enhanced Flexibility and Environmental Durability of Copper Electrode Produced with Conductive Ink Containing Silane Coupling Agents with Diamine and Ether Spacer. J. Mater. Sci. Mater. Electron. 2019, 30, 12130–12139. [Google Scholar] [CrossRef]

- Cho, C.H.; Shin, I.K.; Kim, K.Y.; Choi, Y.J. Enhancing Adhesion Properties between Binder-Free Copper Nanoink and Flexible Substrate Using Chemically Generated Interlocking Structure. Appl. Surf. Sci. 2019, 485, 484–489. [Google Scholar] [CrossRef]

- Xu, M.; Obodo, D.; Yadavalli, V.K. The Design, Fabrication, and Applications of Flexible Biosensing devices. Biosens. Bioelectron. 2019, 124–125, 96–114. [Google Scholar] [CrossRef]

- Yang, X.; Cheng, H. Recent Developments of Flexible and Stretchable Electrochemical Biosensors. Micromachines 2020, 11, 243. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, Y.; Liang, Z.; Cao, Y.; Han, Z.; Feng, X. Flexible Inorganic Bioelectronics. NPJ Flex Electron. 2020, 4, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Neumann, T.V.; Dickey, M.D. Liquid Metal Direct Write and 3D Printing: A Review. Adv. Mater. Technol. 2020, 2000070. [Google Scholar] [CrossRef]

- Malakooti, M.H.; Bockstaller, M.R.; Matyjaszewski, K.; Majidi, C. Liquid Metal Nanocomposites. Nanoscale Adv. 2020, 2, 2668. [Google Scholar] [CrossRef]

- Tang, J.; Zhao, X.; Li, J.; Guo, R.; Zhou, Y.; Liu, J. Gallium-Based Liquid Metal Amalgams: Transitional-State Metallic Mixtures (TransM2ixes) with Enhanced and Tunable Electrical, Thermal, and Mechanical Properties. ACS Appl. Mater. Interfaces 2017, 9, 35977–35987. [Google Scholar] [CrossRef] [PubMed]

- Zhao, R.; Guo, R.; Xu, X.; Liu, J. A Fast and Cost-Effective Transfer Printing of Liquid Metal Inks for Three-Dimensional Wiring in Flexible Electronics. ACS Appl. Mater. Interfaces 2020, 12, 36723–36730. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Cui, B.; Zhao, X.; Duan, M.; Sun, X.; Zhao, R.; Sheng, L.; Liu, J.; Lu, J. Cu–EGaIn Enabled Stretchable E-skin for Interactive Electronics and CT Assistant Localization. Mater. Horiz. 2020, 7, 1845–1853. [Google Scholar] [CrossRef]

- Liu, J.; Chen, H.; Ji, H.; Li, M. Highly Conductive Cu−Cu Joint Formation by Low-Temperature Sintering of Formic Acid-Treated Cu Nanoparticles. ACS Appl. Mater. Interfaces 2016, 8, 33289–33298. [Google Scholar] [CrossRef]

- Zuo, Y.; Shen, J.; Hu, Y.; Gao, R. Improvement of Oxidation Resistance and Bonding Strength of Cu Nanoparticles Solder Joints of Cu–Cu Bonding by Phosphating the Nanoparticle. J. Mater. Process. Technol. 2018, 253, 27–33. [Google Scholar] [CrossRef]

- Gao, Y.; Li, W.; Chen, C.; Zhang, H.; Jiu, J.; Li, C.-F.; Nagao, S.; Suganuma, K. Novel Copper Particle Paste with Self-Reduction and Self-Protection Characteristics for Die Attachment of Power Semiconductor under a Nitrogen Atmosphere. Mater. Des. 2018, 160, 1265–1272. [Google Scholar] [CrossRef]

- Li, J.; Liang, Q.; Shi, T.; Fan, J.; Gong, B.; Feng, C.; Fan, J.; Liao, G.; Tang, Z. Design of Cu Nanoaggregates Composed of Ultra-Small Cu Nanoparticles for Cu-Cu Thermocompression Bonding. J. Alloys Compd. 2019, 772, 793–800. [Google Scholar] [CrossRef]

- Kamikoriyama, Y.; Imamura, H.; Muramatsu, A.; Kanie, K. Ambient Aqueous-Phase Synthesis of Copper Nanoparticles and Nanopastes with Low-Temperature Sintering and Ultra-High Bonding Abilities. Sci. Rep. 2019, 9, 899. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mou, Y.; Liu, J.; Cheng, H.; Peng, Y.; Chen, M. Facile Preparation of Self-Reducible Cu Nanoparticle Paste for Low Temperature Cu-Cu Bonding. JOM 2019, 71, 3076–3083. [Google Scholar] [CrossRef]

- Del Carro, L.; Zinn, A.A.; Ruch, P.; Bouville, F.; Studart, A.R.; Brunschwiler, T. Oxide-Free Copper Pastes for the Attachment of Large-Area Power Devices. J. Electron. Mater. 2019, 48, 6823–6834. [Google Scholar] [CrossRef]

- Bhogaraju, S.K.; Mokhtari, O.; Conti, F.; Elger, G. Die-Attach Bonding for High Temperature Applications Using Thermal Decomposition of Copper(II) Formate with Polyethylene Glycol. Scr. Mater. 2020, 182, 74–80. [Google Scholar] [CrossRef]

- Tan, H.W.; An, J.; Chua, C.L.; Tran, T. Metallic Nanoparticle Inks for 3D Printing of Electronics. Adv. Electron. Mater. 2019, 5, 1800831. [Google Scholar] [CrossRef]

- Elder, B.; Neupane, R.; Tokita, E.; Ghosh, U.; Hales, S.; Kong, Y.L. Nanomaterial Patterning in 3D Printing. Adv. Mater. 2020, 32, 1907142. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J.H.; Wajahat, M.; Jeong, H.; Chang, W.S.; Cho, S.H.; Kim, J.T.; Seol, S.K. Three-Dimensional Printing of Silver Microarchitectures Using Newtonian Nanoparticle Inks. ACS Appl. Mater. Interfaces 2017, 9, 18918–18924. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, S.; Wajahat, M.; Ahn, J.; Pyo, J.; Chang, W.S.; Seol, S.K. 3D Printing of Highly Conductive Silver Architectures Enabled to Sinter at Low Temperatures. Nanoscale 2019, 11, 17682–17688. [Google Scholar] [CrossRef]

- Li, Z.; Khuje, S.; Chivate, A.; Huang, Y.; Hu, Y.; An, L.; Shao, Z.; Wang, J.; Chang, S.; Ren, S. Printable Copper Sensor Electronics for High Temperature. ACS Appl. Electron. Mater. 2020, 2, 1867–1873. [Google Scholar] [CrossRef]

| Metal Source | Protective Agents | Sintering Process | Resistivity (μΩ·cm) | Ref. |

|---|---|---|---|---|

| Cu nanoparticle (NPs) /particle size of 30–200 nm | PVP | 300 °C/air (95%)-formic acid (5%)/15 min | 36 on glass | [45] |

| Cu NPs/140 nm | PVP | 250 °C/Ar (96%)–H2 (4%)/120 min | 17.0 on PI | [46] |

| Formic acid-treated Cu NPs/30 nm | PVP | 260 °C/N2 (95%)–H2 (5%)/60 min | 6.1 on glass | [47] |

| Cu NPs with 1.6 nm CuO layer/65 ± 3 nm | PVP | 250 °C/formic acid vapor/60 min 250 °C/oxalic acid vapor/60 min | 2.30 on glass 3.82 on glass | [49] |

| Cu NPs with oxide layer of more than 2 nm/20–30 nm | PVP | IPL combined with NIR and deep UV in air | 7.62 on PI | [51] |

| Cu NPs, oxygen <3%/<100 nm | PVP | IPL with a bandpass filter (from 500 to 600 nm) | 6.97 on PI | [52] |

| Cu NPs/70 nm | PVP | sequential low-pressure drying, near-infrared sintering, and IPL reduction | 7.9 on PI | [53] |

| Cu NPs/< 50 nm | PVP | Laser 532 nm in the air; Selective laser sintering | Below 1 Ω/sq | [54] |

| Cu NPs/40 nm | PVP | Thermal conduction layer-assisted IPL; metal grid transparent conductors | 4.7 Ω/sq | [55] |

| Cu particle/2.5–6.5 mm Cu particles/250–700 nm | PVP | 200 W Plasma (argon and H2 (<10 wt%))/10 min | 15.9 on PET | [56] |

| Cu particle/130 nm | Gelatin | Annealing at 200 °C in air for more than 3 h and subsequently reduced at 200 °C in 3% H2 gas for 3 h | 8.2 on Al2O3 substrate | [58] |

| Cu particles/135 ± 30 nm | PEG2000 | 250 °C/N2/30 min | 15.8 on PI | [62] |

| Metal Source | Protective Agents | Sintering Process | Resistivity (μΩ·cm) | Ref. |

|---|---|---|---|---|

| Cu NPs/10.6 nm | Oleylamine (OAM) | 300 °C/N2/60 min; self-reduction with OAM; IPL; self-reduction ability | 84.2 on PI 25.3 on PI | [65] |

| Cu NPs | Oleylamine (OAM) | 400 °C/N2/60 min; self-reduction with OAM | 23 on glass | [66] |

| Cu NPs/3.5 ± 1 nm | 1-amino-2-propanol (AmIP) | 150 °C/N2/15 min; self-reduction with AmIP | 30 on PET | [67] |

| Cu NPs/4.4 nm | 2-amino-1-butanol (AB) | 150 °C/N2/60 min; self-reduction with AB | 52 on PI | [68] |

| Cu nano-aggregates covered with 5 nm Cu NPs | 1-amino-2-propanol (AmIP) | 250 °C/Ar (95%)–H2 (5%)/60 min | 4.37 on glass | [69] |

| Cu NPs/<10 nm | Lactic acid | 200 °C/N2/60 min; self-reduction with lactic acid | 9.1 on glass | [70] |

| Cu NPs/50 nm | Ascorbic acid | 240 °C/N2/40 min | 16.2 on PI | [73] |

| Mixture of Cu NPs and Cu particles | Citric acid | 300 °C/Ar/60 min | 8.2 on glass | [75] |

| Cu NPs/61.7 nm | Citric acid | 200 °C/Ar (98%)–H2 (2%)/60 min, closely packed Cu nanoparticle films by capillary immersion force | 7.6 on glass | [76] |

| Cu NPs with bimodal distribution of 42.3 and 108.3 nm | Oleic acid | 250 °C/Ar (90%)–H2 (10%)/120 min | 3.9 on glass | [77] |

| Cu NPs with bimodal distribution of 42.3 and 108.3 nm | Oleic acid | IPL | 6.7, 19.1 and 51.2 on PI, PES, and PET | [78] |

| Cu NPs/90 nm | Oleic acid | IPL combined with ultrathin plasmonic optical/thermal barrier | 0.24 Ω/sq, 22.6 on PET | [79] |

| Cu NPs/<110 nm | Oleic acid | 1046 nm NIR laser 532 nm green laser | 4.6 on glass38.9 on glass | [80] |

| Cu NPs/100 nm | 1-octanethiol | 230 °C/H2/8 h | 5.4 on glass | [82] |

| Cu NPs/106 ± 16 nm | 1-octanethiol | IPL | 24 on PI | [83] |

| Metal Source | Protective Agents | Sintering Process | Resistivity (μΩ·cm) | Ref. |

|---|---|---|---|---|

| Cu@Ag NPs/about 1 mm Cu core with 20 nm Ag shell | PAA | 250 °C/N2/15 min | 11.34 on glass | [85] |

| Cu@Ag NPs with Ag:Cu atomic ratio of 1:10/50 nm | PVP | 250 °C and 350 °C/H2 (2%)/60 min | 102.7 and 27.1 on glass | [86] |

| Cu@Ag NPs with Ag:Cu atomic ratio of 1:4/3–50 nm | CTAB | 150 °C/N2/60 min | 13.8 on photo-paper | [87] |

| Mixture of Cu@Ag particles with a diameter of 1.7 mm and Ag NPs with 60 nm | PVP and CTAB | 160 °C/Ar/120 min | 5.0 on photo-paper | [88] |

| Cu-Ag alloy nanoflakes/700 nm long and 500 nm wide | PVP | 150 °C/N2/120 min | 37.5 on PI and PET | [89] |

| Cu5Ag5 alloy NPs /10.95 nm | Oleic acid and oleylamine | 250 °C/N2 (95%)–H2 (5%)/180 min | 58 on photo-paper | [90] |

| Cu-Ni alloy NPs by Wire Explosion | − | 200 °C/H2/30 min | 599 on glass (95Cu-5Ni) 857 on glass (70Cu-30Ni) | [91] |

| CuNi (55Cu-45Ni) alloy NPs/100 nm | PVP | 350 °C in vacuum furnace/120 min/chemical reduction process | 400 on PI | [92] |

| Cu@Ni NPs (Cu:Ni = 8:1) | PVP | 350 °C | 27 | [93] |

| Cu@Ni NPs (Cu:Ni = 5:1)/bimodal size distribution of 56.3 and 146.8 nm | Oleicacid and oleylamine | IPL | 52, 84 and 900 for PI, PES and PEN. | [94] |

| Cu and Cu10Sn3 core-shell NPs (5 wt%)/20–60 nm | Oleic acid | IPL | 12.2 on PI | [95] |

| Cu, Ni and Cu10Sn3 core-shell NPs (30 wt% Ni NPs) | Oleicacid and oleylamine | IPL | 49 on PI | [96] |

| Cu@carbon NPs/20.6 nm | Defective carbon of 1.0 nm | 200 °C for 10 min in air and subsequently reduction process under H2 (10%) | 25.1 on PI | [97] |

| Cu@graphene NPs/52 ± 9 nm | Multilayer graphene of 3.0 nm | No thermal annealing | 170 on PI | [99] |

| Metal Source | Protective Agents | Sintering Process | Resistivity (μΩ·cm) | Ref. |

|---|---|---|---|---|

| CuO NPs/10−300 nm (Novacentrix Metalon ICI-002HV) | N.A | IPL | 3.1 on CaCO3 precoating paper | [101] |

| CuO NPs/10−300 nm (Novacentrix Metalon ICI-002HV) | N.A | IPL | 335 mΩ/sq on paper | [102] |

| CuO NPs/10−300 nm (Novacentrix Metalon ICI-002HV) | N.A | IPL | 10 on PET | [103] |

| Cu NPs with an oxide shell of 3.6 nm/20–50 nm | PVP | IPL | 43.83 on PI | [104] |

| Cu NPs with an oxide shell of more than 2 nm/40 nm | PVP | IPL (preheating and main sintering) | 3.81 on PI | [105] |

| Cu NPs (100 nm) with an oxide shell of 20 nm and CuO NPs (50 nm); Cu/CuO weight ratio of 1/80 | PVP | IPL | 6.5 on PET | [106] |

| Cu2O NPs/5.1 ± 0.4 nm | L-ascorbic acid | IPL | 4.2 on PI | [107] |

| Cu NPs from CuO particles by chemical reduction/280 nm | Octylamine | Annealing at 250 °C in air for 4 h, and subsequently reduced at 250 °C in 3% H2 in N2 gas for 3 h | 7.8 on Al2O3 substrate | [108] |

| Metal Source | Protective Agents | Sintering Process with Surface Activation Process | Resistivity (μΩ·cm) | Ref. |

|---|---|---|---|---|

| Cu flakes/50 mm width, 1 mm thickness | N.A. | 120 and 140 °C/reduction-assisted sintering with ethanol vapor | about 1000 and 100 on PEN | [111] |

| Cu particles/820 nm | N.A. | 200 °C for 50 s in air/surface modification with Cu–HCOOH–DMAPD complex (DMAPD: 3-dimethylamino-1,2-propanediol) | 54 on PI | [112] |

| Cu flakes/50 mm width, 1 mm thickness | N.A. | Room temperature under vacuum-drying (No thermal annealing)/reduction-assisted sintering with immersion in ascorbic acid solution | 6900, 7400, 7700, 5700, and 3270 on PI, PEN, PC, PMMA, and PET | [118] |

| Cu NPs/<10 nm | 1-amino-2-propanol and Poly(vinyl imidazole-co-vinyltrimethoxysilane) | Room temperature under ambient conditions for 3–4 h (No thermal annealing) | 12,000 on glass | [119] |

| Cu@Ag NPs/11.7 nm | 1-amino-2-propanol (AmIP) | Room temperature (No thermal annealing)/ligand exchange from OAM to AmIP and reduction-assisted sintering with immersionin a NaBH4 solution | 36.3 on PET | [120] |

| Cu NPs/11.9 nm | Oleylamine (OAM) | Room temperature (No thermal annealing)/reduction-assisted sintering with OAM removing by HCOOH and reduction by NaBH4 | 16.93 on PET | [121] |

| Conductive Sources | Protective Agents | Sintering Process | Resistivity (μΩ·cm) | Ref. |

|---|---|---|---|---|

| 1. Cu NPs (60.8 nm) 2. Cu flakes (9.3 μm) | Decanoic acid | 120 °C/N2 (95%)–H2 (5%)/180 min | 29 on PET (NP:Flake =80 wt%:20 wt%) | [124] |

| 1. Cu NPs (3–5 nm) 2. Cu particles (Ps) (300 nm) | 1-amino-2-propanol (AmIP) | 150 °C/in air/10 s 120 °C/N2/60 min | 55 on PI (NPs:Ps = 1:3) (mass ratio) 8.4 on PI (NPs:Ps = 1:3) (mass ratio) | [125] |

| 1. Cu NPs (93 nm) 2. Cu flakes (3 μm) | Oleic acid | IPL | 11.4 on PI (NP:Flake = 4:6) (mass ratio) | [126] |

| 1. Cu NPs (100 nm) 2. Cu particles (Ps) (1.8 μm) | N.A. | IPL | 6.94 on PI (NPs:Ps = 1:1) (mass ratio) | [127] |

| 1. Cu NPs (100 nm) 2. Cu particles (Ps) (6–8 μm) | N.A. | IPL | 6.16 on PI (NPs:Ps = 1:1) (mass ratio) | [128] |

| 1. Cu NPs (180 nm) 2. Cu particles (Ps) (2 μm) | N.A. | IPL | 5.94 on PI (NPs:Ps = 1:1) (mass ratio) | [129] |

| 1.Cu NPs (150 nm) 2.SnNPs (100–300 nm) | PVP | IPL | 14 Ω/sq on metal-mesh (CuNPs:SnNPs = 2:1) (mass ratio) | [130] |

| 1.Cu particles (Ps) (800 nm) 2. CuF–AmIP complex | N.A. | 100 °C/N2/60 min | 900 on alumina (complex: Ps = 1:6) (molar ratio) | [133] |

| 1.Cu particles (Ps) (400 nm) 2. CuF–AmIP complex | N.A. | 120 °C/N2/30 min | 32 on alumina (70 wt% Cu particle) | [134] |

| 1.Cu particles (Ps) (154 nm) 2. CuF-AmIP complex | poly(propylenecarbonate) | 100 °C/N2/60 min | 88 on alumina (complex: Ps = 1:2) (molar ratio) | [135] |

| 1.Cu particles (Ps) (700 nm) 2.CuF–2-amino-2-methyl-1-propanol (AMP) complex | N.A. | 140 °C/N2/15 min | 11.3 on PET (complex: Ps = 3: 1) (mass ratio) | [136] |

| 1.Cu NPs (60–100 nm) 2.CuF–3-dimethylamino-2-propanediol (DEAPD) complex | N.A. | 200 °C/N2/60 min | 18 on PI (NPs: 0.15 g, complex:0.092 g) | [137] |

| 1. AMP + Cu(OH)2 + formic acid 2. Cu flake (9.5 μm) | Decanoic acid | 200 °C/N2/3 min | 21 on PI [Cu(OH)2/Formic acid ratio of 0.875 (22.7 wt% copper) and Cu flake 7.3 wt%] | [138] |

| 1.Cu flake (1–2 mm) 2. CuF–AmIP complex | N.A. | 150 °C/N2/60 min | 62 on cellulose paper (Flake: complex = 3:1) (mass ratio) | [139] |

| 1. Formic acid-treated Cu flake (1–2 μm) 2. CuF–AmIP complex | N.A. | 100 °C/in air/15 s | 70 on cellulose paper (Flake: complex = 3:1) (mass ratio) | [140] |

| 1.Cu NPs (10–70 nm) 2.Cu nitrate trihydrate | PVP | IPL | 27.3 on PI (30 wt% Cu nitrate) | [141] |

| 1.Cu particles (Ps) (250 nm) 2.CuF–AMP complex | N.A. | 140 °C in N2 for 10 min, and IPL | 7.2, 26.5 and 15.9 on PI, PET, and PEN (5 g of Cu formate tetrahydrate,3.95 g of AMP, and 2.98 g of Cu particles) | [142] |

| 1.Cu particles (Ps) (350 nm) 2.CuF–AMP complex | N.A. | 140 °C in N2 for 10 min, and IPL | 5.8 on PI (10 g of Cu formate tetrahydrate, 7.9 g of AMP, and 5.96 g of Cu particles) | [143] |

| 1.Cu NPs 2.CuF–DEAPD complex | N.A. | 100–135 °C for 20 min, and IPL | 20−38 on 70−550 μm trace widths on PI [Cu(II) formate (40.20%), DEAPD (43.70%), CuNP (0.40%)] | [144] |

| 1.Cu particles (Ps) (350 nm) 2. Ag-amino complex | N.A. | 140 °C in N2 for 10 min, and IPL | 3.4 on PI [Ag(I) β-ketocarboxylate:2-ethylhexylamine = 1:2 (molar ratio), Cu:Ag =80 wt%: 20 wt%] | [146] |

| 1.Cu NWs (150 nm in diameter, 1−2 μm in length) 2. Cu NPs (20–50 nm) | PVP | IPL | 22.77 on PI (CnNP:Cu NW = 95 wt%:5 wt%) | [150] |

| 1.Cu NWs (150 nm in diameter, 1−2 μm in length) 2. CuF–2-ethylhexylamine complex | Octadecyl amine | 140 °C/N2/30 min | 14.9 on PET (10 wt% Cu NW) | [151] |

| 1.MWCNT (length = 200 μm) 2. Cu NPs (30–50 nm) | PVP | IPL | 7.86 on PI (0.5 wt% CNT) | [152] |

| 1 SWCNT (length = 200 μm) 2. Cu formate particles (50–500 nm) | PVP | IPL | 0.104 S om PI | [153] |

| 1.MWCNT 2. CuF–AMP complex | Octyl amine | 140 °C/N2/30 min | 25.31 on PET (1 wt% MWCNT) | [154] |

| 1.Cu NPs (10–70 nm) 2.Cu nitrate trihydrate | PVP 3 wt% APS | IPL | 7.6 on PI (30 wt% Cu NPs) | [155] |

| Cu ion/Formic acid/ammonia/citric acid | N.A. | IPL | 2.3 on SAM surface treatment PI | [156] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomotoshi, D.; Kawasaki, H. Surface and Interface Designs in Copper-Based Conductive Inks for Printed/Flexible Electronics. Nanomaterials 2020, 10, 1689. https://doi.org/10.3390/nano10091689

Tomotoshi D, Kawasaki H. Surface and Interface Designs in Copper-Based Conductive Inks for Printed/Flexible Electronics. Nanomaterials. 2020; 10(9):1689. https://doi.org/10.3390/nano10091689

Chicago/Turabian StyleTomotoshi, Daisuke, and Hideya Kawasaki. 2020. "Surface and Interface Designs in Copper-Based Conductive Inks for Printed/Flexible Electronics" Nanomaterials 10, no. 9: 1689. https://doi.org/10.3390/nano10091689