Wire Arc Additive Manufacturing of Zinc as a Degradable Metallic Biomaterial

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

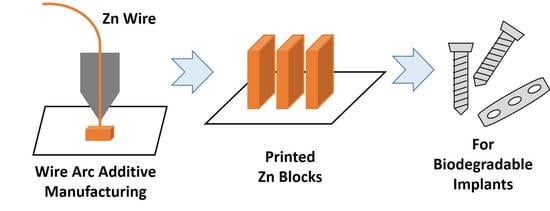

2.2. Additive Manufacturing of Zn

Microstructural Characterization and Texture Studies

2.3. Corrosion Studies

2.4. Microhardness Tests

2.5. Degradation Behavior

2.6. Cell Compatibility Studies

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Conventry, M.B.; Tapper, E.M. Pelvic Instability: A Consequence of Removing Iliac Bone for Grafting. J. Bone Jt. Surg. 1972, 54, 83–101. [Google Scholar] [CrossRef]

- Younger, E.M.; Chapman, M.W. Morbidity at Bone Graft Donor Sites. J. Orthop. Trauma 1989, 3, 192–195. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ryu, H.; Seo, M.H.; Rogers, J.A. Bioresorbable Metals for Biomedical Applications: From Mechanical Components to Electronic Devices. Adv. Healthc. Mater. 2021, 10, e200236. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.F.; Gu, X.N.; Witte, F. Biodegradable Metals. Mater. Sci. Eng. R Rep. 2014, 77, 1–34. [Google Scholar] [CrossRef]

- Tsakiris, V.; Tardei, C.; Clicinschi, F.M. Biodegradable Mg Alloys for Orthopedic Implants—A Review. J. Magnes. Alloy. 2021, 9, 1884–1905. [Google Scholar] [CrossRef]

- Peuster, M.; Hesse, C.; Schloo, T.; Fink, C.; Beerbaum, P.; von Schnakenburg, C. Long-Term Biocompatibility of a Corrodible Peripheral Iron Stent in the Porcine Descending Aorta. Biomaterials 2006, 27, 4955–4962. [Google Scholar] [CrossRef]

- Peuster, M.; Wohlsein, P.; Brügmann, M.; Ehlerding, M.; Seidler, K.; Fink, C.; Brauer, H.; Fischer, A.; Hausdorf, G. A Novel Approach to Temporary Stenting: Degradable Cardiovascular Stents Produced from Corrodible Metal-Results 6–18 Months after Implantation into New Zealand White Rabbits. Hearth 2001, 86, 563–569. [Google Scholar] [CrossRef] [Green Version]

- Bowen, P.K.; Drelich, J.; Goldman, J. Zinc Exhibits Ideal Physiological Corrosion Behavior for Bioabsorbable Stents. Adv. Mater. 2013, 25, 2577–2582. [Google Scholar] [CrossRef]

- Levy, G.K.; Goldman, J.; Aghion, E. The Prospects of Zinc as a Structural Material for Biodegradable Implants—A Review Paper. Metals 2017, 7, 402. [Google Scholar] [CrossRef] [Green Version]

- Dunne, C.F.; Levy, G.K.; Hakimi, O.; Aghion, E.; Twomey, B.; Stanton, K.T. Corrosion Behaviour of Biodegradable Magnesium Alloys with Hydroxyapatite Coatings. Surf. Coat. Technol. 2016, 289, 37–44. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Jhavar, S.; Paul, C.P.; Jain, N.K. Micro-Plasma Transferred Arc Additive Manufacturing for Die and Mold Surface Remanufacturing. JOM 2016, 68, 1801–1809. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef] [PubMed]

- Jhavar, S. Wire Arc Additive Manufacturing: Approaches and Future Prospects. In Additive Manufacturing; Woodhead Publishing: Cambridge, UK, 2021; pp. 183–208. [Google Scholar]

- Zhou, Y.; Wang, J.; Yang, Y.; Yang, M.; Zheng, H.; Xie, D.; Wang, D.; Shen, L. Laser Additive Manufacturing of Zinc Targeting for Biomedical Application. Int. J. Bioprint. 2022, 8, 74–95. [Google Scholar] [CrossRef]

- Demir, A.G.; Monguzzi, L.; Previtali, B. Selective Laser Melting of Pure Zn with High Density for Biodegradable Implant Manufacturing. Addit. Manuf. 2017, 15, 20–28. [Google Scholar] [CrossRef]

- Yang, Y.; Yuan, F.; Gao, C.; Feng, P.; Xue, L.; He, S.; Shuai, C. A Combined Strategy to Enhance the Properties of Zn by Laser Rapid Solidification and Laser Alloying. J. Mech. Behav. Biomed. Mater. 2018, 82, 51–60. [Google Scholar] [CrossRef]

- Wen, P.; Jauer, L.; Voshage, M.; Chen, Y.; Poprawe, R.; Schleifenbaum, J.H. Densification Behavior of Pure Zn Metal Parts Produced by Selective Laser Melting for Manufacturing Biodegradable Implants. J. Mater. Process. Technol. 2018, 258, 128–137. [Google Scholar] [CrossRef]

- Wen, P.; Voshage, M.; Jauer, L.; Chen, Y.; Qin, Y.; Poprawe, R.; Schleifenbaum, J.H. Laser Additive Manufacturing of Zn Metal Parts for Biodegradable Applications: Processing, Formation Quality and Mechanical Properties. Mater. Des. 2018, 155, 36–45. [Google Scholar] [CrossRef]

- Voshage, M.; Wen, P.; Schaukellis, M.; Schleifenbaum, J.H. Formation Quality, Mechanical Properties, and Processing Behavior of Pure Zinc Parts Produced by Laser-Based Manufacturing for Biodegradable Implants. BHM Berg Hüttenmänni. Monatshefte 2019, 164, 133–140. [Google Scholar] [CrossRef]

- Li, Y.; Pavanram, P.; Zhou, J.; Lietaert, K.; Taheri, P.; Li, W.; San, H.; Leeflang, M.A.; Mol, J.M.C.; Jahr, H.; et al. Additively Manufactured Biodegradable Porous Zinc. Acta Biomater. 2020, 101, 609–623. [Google Scholar] [CrossRef]

- Li, Y.; Pavanram, P.; Zhou, J.; Lietaert, K.; Bobbert, F.S.L.; Kubo, Y.; Leeflang, M.A.; Jahr, H.; Zadpoor, A.A. Additively Manufactured Functionally Graded Biodegradable Porous Zinc. Biomater. Sci. 2020, 8, 2404–2419. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Li, W.; Bobbert, F.S.L.; Lietaert, K.; Dong, J.H.; Leeflang, M.A.; Zhou, J.; Zadpoor, A.A. Corrosion Fatigue Behavior of Additively Manufactured Biodegradable Porous Zinc. Acta Biomater. 2020, 106, 439–449. [Google Scholar] [CrossRef]

- Qin, Y.; Wen, P.; Xia, D.; Guo, H.; Voshage, M.; Jauer, L.; Zheng, Y.; Schleifenbaum, J.H.; Tian, Y. Effect of Grain Structure on the Mechanical Properties and in Vitro Corrosion Behavior of Additively Manufactured Pure Zn. Addit. Manuf. 2020, 33, 101134. [Google Scholar] [CrossRef]

- Lietaert, K.; Zadpoor, A.A.; Sonnaert, M.; Schrooten, J.; Weber, L.; Mortensen, A.; Vleugels, J. Mechanical Properties and Cytocompatibility of Dense and Porous Zn Produced by Laser Powder Bed Fusion for Biodegradable Implant Applications. Acta Biomater. 2020, 110, 289–302. [Google Scholar] [CrossRef]

- Dhaneshwaran, M.; Srinivasa Chari, V.; Jhavar, S. Plasma Metal Deposition of Stainless Steel 316L over Mild Steel Surface. Mater. Today Proc. 2021, 46, 1116–1121. [Google Scholar]

- Beausir, B.; Fundenberger, J.-J. Analysis Tools for Electron and X-ray Diffraction; ATEX-Software: Metz, France, 2017. [Google Scholar]

- Acharya, S.; Panicker, A.G.; Laxmi, D.V.; Suwas, S.; Chatterjee, K. Study of the Influence of Zr on the Mechanical Properties and Functional Response of Ti-Nb-Ta-Zr-O Alloy for Orthopedic Applications. Mater. Des. 2019, 164, 107555. [Google Scholar] [CrossRef]

- Rajput, M.; Mondal, P.; Yadav, P.; Chatterjee, K. Light-Based 3D Bioprinting of Bone Tissue Scaffolds with Tunable Mechanical Properties and Architecture from Photocurable Silk Fibroin. Int. J. Biol. Macromol. 2022, 202, 644–656. [Google Scholar] [CrossRef]

- Karunakaran, R.; Ortgies, S.; Tamayol, A.; Bobaru, F.; Sealy, M.P. Additive Manufacturing of Magnesium Alloys. Bioact. Mater. 2020, 5, 44–54. [Google Scholar] [CrossRef]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of Processing Parameters on Microstructure and Tensile Properties of Austenitic Stainless Steel 304L Made by Directed Energy Deposition Additive Manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.L.; Mazumder, J.; DebRoy, T. Evolution of Solidification Texture during Additive Manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef] [Green Version]

- Bahl, S.; Suwas, S.; Chatterjee, K. The Control of Crystallographic Texture in the Use of Magnesium as a Resorbable Biomaterial. RSC Adv. 2014, 4, 55677–55684. [Google Scholar] [CrossRef]

- Bahl, S.; Suwas, S.; Chatterjee, K. The Importance of Crystallographic Texture in the Use of Titanium as an Orthopedic Biomaterial. RSC Adv. 2014, 4, 38078–38087. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Valiev, R.Z.; Langdon, T.G. Microhardness Measurements and the Hall-Petch Relationship in an Al-Mg Alloy with Submicrometer Grain Size. Acta Mater. 1996, 44, 4619–4629. [Google Scholar] [CrossRef]

- Bormann, T.; Mai, P.T.; Gibmeier, J.; Sonntag, R.; Müller, U.; Kretzer, J.P. Corrosion Behavior of Surface-Treated Metallic Implant Materials. Materials 2020, 13, 2011. [Google Scholar] [CrossRef]

- Behera, M.; Rajput, M.; Acharya, S.; Nadammal, N.; Suwas, S.; Chatterjee, K. Zinc and Cerium Synergistically Enhance the Mechanical Properties, Corrosion Resistance, and Osteogenic Activity of Magnesium as Resorbable Biomaterials. Biomed. Mater. 2021, 16, 044109. [Google Scholar] [CrossRef]

| Parameter | Arc Power | Wire Feed Rate | Travel Speed | Standoff Distance |

|---|---|---|---|---|

| Values | 400 W | 160 mm/min | 120 mm/min | 5 mm |

| Sample | Ecorr V | Icorr μA/cm2 | Corrosion Rate mmpy | Microhardness HV0.3 |

|---|---|---|---|---|

| WAAM-Zn | −1.18 ± 0.03 | 8.8 ± 1 | 0.45 ± 0.2 | 35 ± 2 |

| WR-Zn | −1.13 ± 0.16 | 5.9 ± 0.8 | 0.3 ± 0.1 | 41 ± 1 |

| WAAM-Zn | WR-Zn | ||||

|---|---|---|---|---|---|

| Time | Sample Weight (mg) | Degradation Rate (mm/yr) | Time | Sample Weight (mg) | Degradation Rate (mm/yr) |

| Day 0 | 308.6 | - | Day 0 | 291.6 | - |

| Day 7 | 308.3 | 0.023 | Day 7 | 290.8 | 0.063 |

| Day 14 | 307.9 | 0.030 | Day 14 | 290.3 | 0.040 |

| Day 21 | 307.1 | 0.061 | Day 21 | 289.8 | 0.040 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soni, R.; Jhavar, S.; Tyeb, S.; Gupta, S.K.; Suwas, S.; Chatterjee, K. Wire Arc Additive Manufacturing of Zinc as a Degradable Metallic Biomaterial. J. Funct. Biomater. 2022, 13, 212. https://doi.org/10.3390/jfb13040212

Soni R, Jhavar S, Tyeb S, Gupta SK, Suwas S, Chatterjee K. Wire Arc Additive Manufacturing of Zinc as a Degradable Metallic Biomaterial. Journal of Functional Biomaterials. 2022; 13(4):212. https://doi.org/10.3390/jfb13040212

Chicago/Turabian StyleSoni, Rishabh, Suyog Jhavar, Suhela Tyeb, Saurabh Kumar Gupta, Satyam Suwas, and Kaushik Chatterjee. 2022. "Wire Arc Additive Manufacturing of Zinc as a Degradable Metallic Biomaterial" Journal of Functional Biomaterials 13, no. 4: 212. https://doi.org/10.3390/jfb13040212