Design and Testing of Reverse-Rotating Soil-Taking-Type Hole-Forming Device of Pot Seedling Transplanting Machine for Rapeseed

Abstract

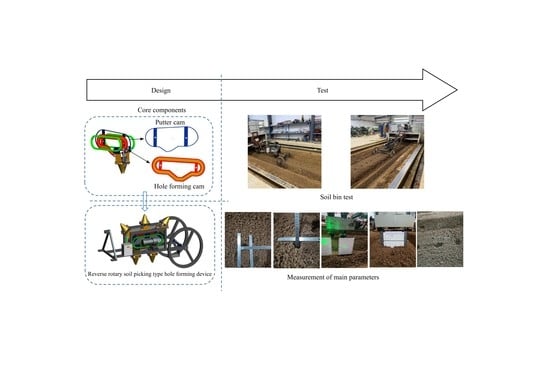

:1. Introduction

2. Materials and Methods

2.1. Agronomic and Technical Requirements

2.2. Overall Structure and Working Principle

2.3. Design of the Hole-Forming Mechanism

2.3.1. Overall Structure

2.3.2. Design of Soil Opener

2.3.3. Movement Trajectory Analysis of Soil Opener

2.3.4. Hole Contour and Shape Parametric Equations

2.4. Design of Putter Cam and Hole-Forming Cam

2.4.1. Parametric Equations of Putter Cam

2.4.2. Parametric Equations of the Hole-Forming Cam

2.5. Number of the Hole-Forming Mechanism

2.6. Soil Bin Test Condition and Equipment

2.6.1. Test Condition and Equipment

2.6.2. Test Method

3. Results and Discussion

3.1. Analysis of Hole Size and Hole-Forming Quality

3.2. Results and Analysis of Perpendicularity of Hole-Forming Operation

3.3. Analysis of the Soil Porosity of the Hole Wall and Soil Disturbance Effect

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| b—Cutting-edge section thickness (mm). | l—Bottom size of soil opener (mm). |

| H0—Height of soil opener (mm). | θ—Angle of entry (°). |

| H1—Soil-opening depth (mm). | L1—Center distance between two adjacent soil opener (mm). |

| h1—Arbitrary depth from the soil surface (mm). | lmn—Hole top size at h1 (mm). |

| n1—Number of chain pitches between the symmetrical centers of two adjacent hole-forming mechanisms. | p—Chain pitch (mm). |

| n2—Number of hole-forming mechanisms. | S1—Chain length (mm). |

| D—Diameter of sprocket graduation circle (mm). | L2—Center distance between the two sprockets (mm). |

| L3—Length of slider (mm). | a2—Side length of upper end face (mm). |

| l1/l2/l3—Center distance between adjacent holes (mm). | b2—Side length of lower end face (mm). |

| X1—Points on the contour line of the end face of the hole along the forward direction of the whole machine (mm). | c—Height of the pot seedling matrix (mm). |

| Y1—Two points on the contour line of the hole face perpendicular to the forward direction of the whole machine (mm). | h—Effective depth of hole (mm). |

| Q—Qualified rate of hole forming (%). | Nhg—Number of qualified holes. |

| N—Actual number of formed holes. | k—Change rate of hole size (%). |

| D0—Hole opening diameter of actual holes (mm); | d0—Hole opening diameter of theoretical holes (mm); |

| ε—Soil porosity of hole wall (%). | ρb—Soil bulk density (g/cm3). |

| ρs—Soil density (g/cm3). | P—Soil heave degree of hole mouth. |

| A—Cross-sectional area from the soil surface to the theoretical hole bottom before hole forming (%). | AL—Cross-sectional area from the soil surface to the theoretical hole bottom after the hole forming (%). |

| δ—Soil stability rate of hole wall (%). | Ah—Cross-sectional area from the soil surface to the actual hole bottom after the hole forming (mm2). |

References

- Jarecki, W. The Reaction of Winter Oilseed Rape to Different Foliar Fertilization with Macro- and Micronutrients. Agriculture 2021, 11, 515. [Google Scholar] [CrossRef]

- Wei, H.; Jun, L.; Xiaomei, W.; Qiao, L.; Xiaowei, Y. Current status of global rapeseed industry and problems, countermeasures of China’s rapeseed industry. China Oils Fats 2021, 1–8. [Google Scholar]

- Yin, Y.; Yin, L.; Zhang, X.; Guo, J.; Wang, J. Status and Countermeasure of the High-quality Development of Rapeseed Industry in China. J. Agric. Sci. Technol.-Iran 2021, 23, 1–7. [Google Scholar]

- Can, M.; Haifeng, L.; Yi, Z.; Beibei, Z.; Xiao, X. Research status and development trend of seeding transplanting machinery. J. Chin. Agric. Mech. 2020, 41, 215–222. [Google Scholar]

- Wang, X.; Huang, M. Application of rape planting mechanization technology model in rice stubble field. Hubei Agric. Mech. 2020, 3–4. [Google Scholar] [CrossRef]

- Mengyuan, C. Problems and Countermeasures of developing rape planting mechanization. Jiangxi Agric. 2020, 104. [Google Scholar]

- Yongtao, L.; Yaxiong, L.; Yang, L.; Bing, L.; Tao, W. Status analysis of abroad’s transplanting machine and transplanting technology. Xinjiang Agric. Mech. 2011, 3, 29–32. [Google Scholar]

- Qiming, P. Current situation and development trend of domestic and foreign transplanting machine technology. J. Anhui Agric. Sci. 2013, 41, 12478–12479. [Google Scholar]

- Chunyun, G. The development trend of China’s rape industry. Grain Sci. Technol. Econ. 2011, 36, 5–6. [Google Scholar]

- Jin, X.; Du, X.W.; Geng, G.S.; Ji, J.T.; Dong, X.; Liu, W.X. Experiment on Planting System of 2ZDJ-2 Transplanter. Trans. Chin. Soc. Agric. Mach. 2015, 46, 26–31. [Google Scholar]

- Xiaoxu, Y.; Yun, Z.; Baocheng, C.; Maile, Z.; Hao, Z.; Zhichao, Z. Current situation and prospect of transplanter. Trans. Chin. Soc. Agric. Mach. 2014, 45, 44–53. [Google Scholar]

- Subo, T.; Lichun, Q.; Naoshi, K.; Ting, Y. Development of Automatic Transplanter for Plug Seedling. IFAC Proc. Vol. 2010, 43, 79–82. [Google Scholar]

- Felezi, M.E.; Vahabi, S.; Nariman-Zadeh, N. Pareto optimal design of reconfigurable rice seedling transplanting mechanisms using multi-objective genetic algorithm. Neural Comput. Appl. 2016, 27, 1907–1916. [Google Scholar] [CrossRef]

- Nandede, B.M.; Raheman, H. Multi-Stage Metering Mechanism for Transplanting of Vegetable Seedlings in Paper Pots. J. Inst. Eng. Ser. A 2015, 96, 295–300. [Google Scholar] [CrossRef]

- Dihingia, P.C.; Prasanna, K.G.V.; Sarma, P.K. Development of a Hopper-Type Planting Device for a Walk-Behind Hand-Tractor-Powered Vegetable Transplanter. J. Biosyst. Eng. 2016, 41, 21–33. [Google Scholar] [CrossRef] [Green Version]

- Chandra, S.; Kumar, S.; Kumar, V. Comparative Performance Evaluation of Self Propelled Paddy Transplanters in Calcareous Soil. AMA Agric. Mech. Asia Afr. Lat. Am. 2013, 44, 33–38. [Google Scholar]

- Selvan, M.M.; Annamalai, S.J.K.; Thavaprakash, N.; Ananathakrishnan, D. Design and development of three-row improved pull-type rice transplanter for small farmers. Indian J. Agric. Sci. 2014, 84, 1422–1427. [Google Scholar]

- Wei, X. Experiment Study on Planting Hole Forming Device of Transplanting Machine for Rape. Master’s Thesis, Hunan Agriculture University, Changsha, China, 2014. [Google Scholar]

- Xiang, W.; Mingliang, W.; Chunyun, G. Design and experiment of planting hole forming device of crawler transplanter for rape (Brassica napus) seedlings. Trans. Chin. Soc. Agric. Eng. 2015, 31, 12–18. [Google Scholar]

- Chaopeng, C.; Wei, Q.; Mingliang, W.; Wentao, Z. Parameter optimization of vertical soil-filling hole-forming parts for rapeseed transplantation based on discrete element method. J. Hunan Agric. Univ. Nat. Sci. 2019, 45, 433–439. [Google Scholar]

- Changjie, H.; Yang, X.; Jia, Y.; Jing, Z.; Panpan, Y. Parameter optimization of opener of semi-automatic transplanter for watermelon seedlings raised on compression substrate. Trans. Chin. Soc. Agric. Eng. 2019, 35, 48–56. [Google Scholar]

- Wei, X.; Mingliang, W.; Chunyun, G.; Yiming, H.; Haifeng, L.; Bo, Y. Design and Test of Transplanting Hole-forming Machine for Rapeseed Potted Seedlings. Trans. Chin. Soc. Agric. Mach. 2017, 48, 40–48. [Google Scholar]

- Zhang, Y.L.H.H. Design and experiment on rear suspended passive aerator in saline-alkali land. Trans. Chin. Soc. Agric. Eng. 2016, 32. [Google Scholar]

- Maile, Z.; Xianglei, X.; Mengbo, Q.; Daqing, Y. Optimal Design and Experiment of Potted Vegetable Seedling Transplanting Mechanism with Punching Hole. Trans. Chin. Soc. Agric. Mach. 2020, 51, 77–83. [Google Scholar]

- Wei, S.; Xiaolong, L.; Hucun, W.; Hua, Z.; Jianmin, W.; Xiaoping, Y.; Guanping, W. Design and test of double crank multi-rod hill-drop potato planter on plastic film. Trans. Chin. Soc. Agric. Eng. 2018, 34, 34–42. [Google Scholar]

- Rasool, K.; Islam, N.; Ali, M.; Jang, B.E.; Kwon, H.J. Onion transplanting mechanisms: A review. Precis. Agric. Sci. Technol. 2020, 2, 196. [Google Scholar]

- Chen, Y.; Cheng, Y.; Chen, J.; Zheng, Z.; Hu, C.; Cao, J. Design and Experiment of the Buckwheat Hill-Drop Planter Hole Forming Device. Agriculture 2021, 11, 1085. [Google Scholar] [CrossRef]

- Changjie, H.; Yang, X.; Jing, Z.; Jia, Y.; Hui, G. Design and experiment of semi-automatic transplanter for watermelon seedlings raised on compression substrate. Trans. Chin. Soc. Agric. Eng. 2018, 34, 54–61. [Google Scholar]

- Wei, Q.; Mingliang, W.; Haifeng, L.; Chaopeng, C.; Wei, X. Optimization of soil hole opening method and parameters of pot seedling transplanting machine for rapeseed. Trans. Chin. Soc. Agric. Eng. 2020, 36, 13–21. [Google Scholar]

- Lihua, Y.; Changshou, H.; Zhibo, X.; Fugui, Z.; Delong, F. Design and Test of Spiral Cavitation Device for Transplanting in Large Den. J. Agric. Mech. Res. 2020, 42, 198–202. [Google Scholar]

- Chen, J.W.B.Z. Kinematics modeling and characteristic analysis of multi-linkage transplanting mechanism of pot seeding transplanter with zero speed. Trans. Chin. Soc. Agric. Eng. 2011, 27, 7–12. [Google Scholar]

- Wang, Y.H.Z.W. Experiment on transplanting performance of automatic vegetable pot seedling transplanter for dry land. Trans. Chin. Soc. Agric. Eng. 2018, 34, 19–25. [Google Scholar]

- Xin, J.; Jiangtao, J.; Weixiang, L.; Yakai, H.; Du, X. Structural optimization of duckbilled transplanter based on dynamic model of pot seedling movement. Trans. Chin. Soc. Agric. Eng. 2018, 34, 58–67. [Google Scholar]

- Zhou, Y.; Chaohai, C.; Jieli, D.; Guoqi, Y.; Xuewen, P.; Liangli, Y.; Jialong, L. Performance test of hand-held electric hole-digger for fertilization in orchard. Trans. Chin. Soc. Agric. Eng. 2013, 29, 25–31. [Google Scholar]

- Orzech, K.; Wanic, M.; Załuski, D. The Effects of Soil Compaction and Different Tillage Systems on the Bulk Density and Moisture Content of Soil and the Yields of Winter Oilseed Rape and Cereals. Agriculture 2021, 11, 666. [Google Scholar] [CrossRef]

- Hu, H.L.H.W. Design and experiment of targeted hole-pricking and deep-application fertilizer applicator between corn rows. Trans. Chin. Soc. Agric. Eng. 2016, 32, 26–35. [Google Scholar]

- Jinwu, W.; Wenqi, Z.; Chunfeng, Z.; Zhenwei, P.; Jinfeng, W.; Han, T. Reverse Design and Experiment of Non-circular Gear Planetary System Picking Hole Mechanism. Trans. Chin. Soc. Agric. Eng. 2015, 46, 70–75. [Google Scholar]

- Mingliang, W.; Bo, Y.; Shijie, F.; Wentao, Z. Design of movable tray for bowl seedlings. J. Hunan Agric. Univ. Nat. Sci. 2018, 44, 666–671. [Google Scholar]

- Honglin, C.; Shanghong, C.; Xueshan, S.; Liangcai, J.; Dinghui, L. Effects of Different Density to the Agronomic Traits and Yield of Transplanting Rapeseed in the Hilly Area of Sichuan Basin. Chin. Agric. Sci. Bull. 2012, 28, 142–145. [Google Scholar]

- Wei, Q.; Mingliang, W.; Chunyun, G.; Haifeng, L. Experimental Study on the Shape Optimization of Soil Opener for Rapeseed Pot Seedling Transplanter. J. Agrc. Sci. Technol.-Iran 2021, 23, 97–106. [Google Scholar]

- Xueqing, Z.; Hongwen, L.; Jin, H.; Qingjie, W.; Xirui, Z. Design of multi-segment in situ soil sampler testing bulk density. Trans. Chin. Soc. Agric. Eng. 2008, 127–130. [Google Scholar] [CrossRef]

- Zhengxing, L. Fundamentals of Mechanical Design; Chongqing University Press: Chongqing, China, 2016. [Google Scholar]

- Chengguang, H.; Xijie, G.; Mengchan, Y.; Yuxiang, H.; Ruixiang, Z. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar]

- Yuxiang, H.; Chengguang, H.; Mengchan, Y.; Botao, W.; Ruixiang, Z. Discrete Element Simulation and Experiment on Disturbance Behavior of Subsoiling. Trans. Chin. Soc. Agric. Eng. 2016, 47, 80–88. [Google Scholar]

- Wei, Y.; Liang, G.Z.; Feng, B. Effect of Plants at Different Fertilization Treatments on Soil Bulk Density and Porosity in the Gully Region of Loess Plateau. Shaanxi For. Sci. Technol. 2014, 1–5. [Google Scholar] [CrossRef]

| Overall Dimensions (mm) | Hole-Forming Method | Transplant Row Number | Hole-Forming Mechanism Number | Distance between Adjacent Hole-Forming Mechanisms (mm) | Maximum Transplant Depth (mm) |

|---|---|---|---|---|---|

| L × W × H: 2130 × 1130 × 1340 | soil picking | 1 | 5 | 300 | 80 |

| Test Number | Forward Speed (m/s) | Hole Distance (mm) | Hole-Opening Diameter (mm) | Effective Depth (mm) | Qualified Number of Holes | Qualified Rate of Hole (%) | Change Rate of Hole Size (%) |

|---|---|---|---|---|---|---|---|

| 1 | 0.25 | 299.8 | 76.3 | 48.5 | 47.0 | 94.0 | 3.1 |

| 2 | 0.25 | 302.2 | 75.2 | 49.7 | 47.0 | 94.0 | 1.6 |

| 3 | 0.25 | 298.7 | 75.7 | 48.9 | 49.0 | 98.0 | 2.3 |

| Average value | 0.25 | 300.2 | 75.7 | 49.0 | 47.6 | 95.2 | 2.3 |

| 4 | 0.35 | 296.5 | 75.8 | 49.5 | 47.0 | 94.0 | 2.4 |

| 5 | 0.35 | 302.1 | 77.5 | 47.8 | 46.0 | 92.0 | 4.7 |

| 6 | 0.35 | 298.7 | 75.2 | 48.9 | 48.0 | 96.0 | 1.6 |

| Average value | 0.35 | 299.1 | 76.2 | 48.7 | 47.0 | 94.0 | 2.9 |

| 7 | 0.45 | 299.2 | 77.5 | 47.4 | 48.0 | 96.0 | 4.7 |

| 8 | 0.45 | 297.9 | 78.7 | 46.9 | 46.0 | 92.0 | 6.4 |

| 9 | 0.45 | 297.8 | 78.1 | 47.3 | 46.0 | 92.0 | 5.5 |

| Average value | 0.45 | 298.3 | 78.1 | 47.2 | 46.7 | 93.3 | 5.5 |

| Forward Speed (m/s) | Test Index | Mean Value (°) | Standard Deviation | Coefficient of Variation (%) |

|---|---|---|---|---|

| 0.25 | Angle of penetration trajectory | 88.4 | 0.47 | 0.53 |

| Angle of unearthed trajectory | 88.7 | 0.56 | 0.64 | |

| 0.35 | Angle of penetration trajectory | 88.0 | 0.14 | 0.16 |

| Angle of unearthed trajectory | 88.5 | 0.48 | 0.54 | |

| 0.45 | Angle of penetration trajectory | 88.1 | 0.34 | 0.40 |

| Angle of unearthed trajectory | 88.1 | 0.41 | 0.47 |

| Test Number | Forward Speed (m/s) | Soil Porosity before Test (%) | Soil Porosity of the Hole Wall after Test (%) | The Change Rate of Porosity (%) | Soil Heave Degree of the Hole Mouth (%) | Soil Stability Rate (%) |

|---|---|---|---|---|---|---|

| 1 | 0.25 | 51.8 | 47.8 | 7.7 | 3.9 | 92.5 |

| 2 | 0.25 | 53.5 | 48.9 | 8.6 | 3.7 | 91.5 |

| 3 | 0.25 | 52.9 | 48.6 | 8.5 | 4.0 | 91.6 |

| Average value | 0.25 | 52.7 | 48.4 | 8.2 | 3.9 | 91.9 |

| 4 | 0.35 | 52.7 | 47.9 | 9.1 | 4.3 | 91.6 |

| 5 | 0.35 | 53.2 | 48.7 | 8.4 | 3.8 | 90.8 |

| 6 | 0.35 | 53.9 | 48.3 | 10.4 | 4.1 | 91.3 |

| Average value | 0.35 | 53.3 | 48.3 | 9.3 | 4.1 | 91.2 |

| 7 | 0.45 | 52.9 | 47.5 | 10.2 | 4.3 | 91.3 |

| 8 | 0.45 | 51.8 | 48.3 | 6.8 | 4.3 | 90.7 |

| 9 | 0.45 | 52.7 | 47.6 | 9.7 | 4.1 | 91.1 |

| Average value | 0.45 | 52.5 | 47.8 | 8.9 | 4.2 | 91.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quan, W.; Wu, M.; Dai, Z.; Luo, H.; Shi, F. Design and Testing of Reverse-Rotating Soil-Taking-Type Hole-Forming Device of Pot Seedling Transplanting Machine for Rapeseed. Agriculture 2022, 12, 319. https://doi.org/10.3390/agriculture12030319

Quan W, Wu M, Dai Z, Luo H, Shi F. Design and Testing of Reverse-Rotating Soil-Taking-Type Hole-Forming Device of Pot Seedling Transplanting Machine for Rapeseed. Agriculture. 2022; 12(3):319. https://doi.org/10.3390/agriculture12030319

Chicago/Turabian StyleQuan, Wei, Mingliang Wu, Zhenwei Dai, Haifeng Luo, and Fanggang Shi. 2022. "Design and Testing of Reverse-Rotating Soil-Taking-Type Hole-Forming Device of Pot Seedling Transplanting Machine for Rapeseed" Agriculture 12, no. 3: 319. https://doi.org/10.3390/agriculture12030319