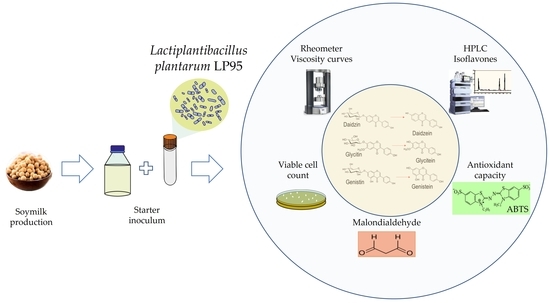

Antioxidative Properties of Fermented Soymilk Using Lactiplantibacillus plantarum LP95

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bacterial Strain

2.2. Chemicals

2.3. Preparation of Soymilk

2.4. Screening for Optimum Temperature

2.5. Production of Fermented Soymilk

2.6. Determination of Water-Holding Capacity (WHC)

2.7. Flow Behavior and Apparent Viscosity

2.8. Chemical Analysis

2.8.1. Determination of Isoflavones

2.8.2. Antioxidant Activity (ABTS Assay)

2.8.3. Thiobarbituric Acid Reactive Substance (TBARS) Assay

2.9. Statistical Analysis

3. Results

3.1. Preliminary Fermentation Trial

3.2. Microbiological and Physicochemical Parameters during Fermentation and Storage

3.3. Flow Behavior and Apparent Viscosity of Fermented Soymilk

3.4. Bioconversion of Isoflavones during Fermentation

3.5. Changes in Antioxidant Activity during Fermentation

3.6. Variation in MDA during Fermentation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shah, A.M.; Tarfeen, N.; Mohamed, H.; Song, Y. Fermented Foods: Their Health-Promoting Components and Potential Effects on Gut Microbiota. Fermentation 2023, 9, 118. [Google Scholar] [CrossRef]

- Messina, M. Soy and Health Update: Evaluation of the Clinical and Epidemiologic Literature. Nutrients 2016, 8, 754. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumari, M.; Kokkiligadda, A.; Dasriya, V.; Naithani, H. Functional Relevance and Health Benefits of Soymilk Fermented by Lactic Acid Bacteria. J. Appl. Microbiol. 2022, 133, 104–119. [Google Scholar] [CrossRef] [PubMed]

- Van Dyck, S. 3-The Impact of Singlet Oxygen on Lipid Oxidation in Foods. In Oxidation in Foods and Beverages and Antioxidant Applications; Decker, E.A., Ed.; Woodhead Publishing: Sawston, UK, 2010; pp. 57–75. ISBN 978-1-84569-648-1. [Google Scholar]

- Li, C.; Li, W.; Chen, X.; Feng, M.; Rui, X.; Jiang, M.; Dong, M. Microbiological, Physicochemical and Rheological Properties of Fermented Soymilk Produced with Exopolysaccharide (EPS) Producing Lactic Acid Bacteria Strains. LWT-Food Sci. Technol. 2014, 57, 477–485. [Google Scholar] [CrossRef]

- Subrota, H.; Shilpa, V.; Brij, S.; Vandna, K.; Surajit, M. Antioxidative Activity and Polyphenol Content in Fermented Soy Milk Supplemented with WPC-70 by Probiotic Lactobacilli. Int. Food Res. J. 2013, 20, 2125. [Google Scholar]

- Theodoropoulos, V.C.T.; Turatti, M.A.; Greiner, R.; Macedo, G.A.; Pallone, J.A.L. Effect of Enzymatic Treatment on Phytate Content and Mineral Bioacessability in Soy Drink. Food Res. Int. 2018, 108, 68–73. [Google Scholar] [CrossRef]

- Zhao, D.; Shah, N.P. Changes in Antioxidant Capacity, Isoflavone Profile, Phenolic and Vitamin Contents in Soymilk during Extended Fermentation. LWT-Food Sci. Technol. 2014, 58, 454–462. [Google Scholar] [CrossRef]

- Chun, J.; Kim, G.M.; Lee, K.W.; Choi, I.D.; Kwon, G.; Park, J.; Jeong, S.; Kim, J.; Kim, J.H. Conversion of Isoflavone Glucosides to Aglycones in Soymilk by Fermentation with Lactic Acid Bacteria. J. Food Sci. 2007, 72, M39–M44. [Google Scholar] [CrossRef]

- Yu, X.; Meenu, M.; Xu, B.; Yu, H. Impact of Processing Technologies on Isoflavones, Phenolic Acids, and Antioxidant Capacities of Soymilk Prepared from 15 Soybean Varieties. Food Chem. 2021, 345, 128612. [Google Scholar] [CrossRef]

- Hu, C.; Wong, W.-T.; Wu, R.; Lai, W.-F. Biochemistry and Use of Soybean Isoflavones in Functional Food Development. Crit. Rev. Food Sci. Nutr. 2020, 60, 2098–2112. [Google Scholar] [CrossRef]

- Zaheer, K.; Humayoun Akhtar, M. An Updated Review of Dietary Isoflavones: Nutrition, Processing, Bioavailability and Impacts on Human Health. Crit. Rev. Food Sci. Nutr. 2017, 57, 1280–1293. [Google Scholar] [CrossRef]

- Walle, T.; Browning, A.M.; Steed, L.L.; Reed, S.G.; Walle, U.K. Flavonoid Glucosides Are Hydrolyzed and Thus Activated in the Oral Cavity in Humans. J. Nutr. 2005, 135, 48–52. [Google Scholar] [CrossRef] [Green Version]

- Otieno, D.; Shah, N. Endogenous β-glucosidase and β-galactosidase Activities from Selected Probiotic Micro-organisms and Their Role in Isoflavone Biotransformation in Soymilk. J. Appl. Microbiol. 2007, 103, 910–917. [Google Scholar] [CrossRef]

- Setchell, K.D.; Brown, N.M.; Zimmer-Nechemias, L.; Brashear, W.T.; Wolfe, B.E.; Kirschner, A.S.; Heubi, J.E. Evidence for Lack of Absorption of Soy Isoflavone Glycosides in Humans, Supporting the Crucial Role of Intestinal Metabolism for Bioavailability. Am. J. Clin. Nutr. 2002, 76, 447–453. [Google Scholar] [CrossRef] [Green Version]

- Baú, T.; Garcia, S.; Ida, E. Changes in Soymilk during Fermentation with Kefir Culture: Oligosaccharides Hydrolysis and Isoflavone Aglycone Production. Int. J. Food Sci. Nutr. 2015, 66, 845–850. [Google Scholar] [CrossRef]

- Hur, H.-G.; Lay Jr, J.O.; Beger, R.D.; Freeman, J.P.; Rafii, F. Isolation of Human Intestinal Bacteria Metabolizing the Natural Isoflavone Glycosides Daidzin and Genistin. Arch. Microbiol. 2000, 174, 422–428. [Google Scholar] [CrossRef]

- Donkor, O.; Shah, N.P. Production of β-Glucosidase and Hydrolysis of Isoflavone Phytoestrogens by Lactobacillus acidophilus, Bifidobacterium lactis, and Lactobacillus casei in Soymilk. J. Food Sci. 2008, 73, M15–M20. [Google Scholar] [CrossRef]

- Li, C.; Fan, Y.; Li, S.; Zhou, X.; Park, K.-Y.; Zhao, X.; Liu, H. Antioxidant Effect of Soymilk Fermented by Lactobacillus plantarum HFY01 on D-Galactose-Induced Premature Aging Mouse Model. Front. Nutr. 2021, 8, 667643. [Google Scholar] [CrossRef]

- Feng, T.; Wang, J. Oxidative Stress Tolerance and Antioxidant Capacity of Lactic Acid Bacteria as Probiotic: A Systematic Review. Gut Microbes 2020, 12, 1801944. [Google Scholar] [CrossRef]

- EFSA Panel on Additives and Products or Substances Used in Animal Feed (FEEDAP); Rychen, G.; Aquilina, G.; Azimonti, G.; Bampidis, V.; de Bastos, M.L.; Bories, G.; Chesson, A.; Cocconcelli, P.S.; Flachowsky, G.; et al. Guidance on the Characterisation of Microorganisms Used as Feed Additives or as Production Organisms. EFSA J. 2018, 16, e05206. [Google Scholar] [CrossRef]

- Behera, S.S.; Ray, R.C.; Zdolec, N. Lactobacillus plantarum with Functional Properties: An Approach to Increase Safety and Shelf-Life of Fermented Foods. BioMed Res. Int. 2018, 2018, 9361614. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iorizzo, M.; Lombardi, S.J.; Macciola, V.; Testa, B.; Lustrato, G.; Lopez, F.; De Leonardis, A. Technological Potential of Lactobacillus Strains Isolated from Fermented Green Olives: In Vitro Studies with Emphasis on Oleuropein-Degrading Capability. Sci. World J. 2016, 2016, 1917592. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iorizzo, M.; Testa, B.; Lombardi, S.J.; García-Ruiz, A.; Muñoz-González, C.; Bartolomé, B.; Moreno-Arribas, M.V. Selection and Technological Potential of Lactobacillus plantarum Bacteria Suitable for Wine Malolactic Fermentation and Grape Aroma Release. LWT 2016, 73, 557–566. [Google Scholar] [CrossRef] [Green Version]

- Letizia, F.; Albanese, G.; Testa, B.; Vergalito, F.; Bagnoli, D.; Di Martino, C.; Carillo, P.; Verrillo, L.; Succi, M.; Sorrentino, E. In Vitro Assessment of Bio-Functional Properties from Lactiplantibacillus plantarum Strains. Curr. Issues Mol. Biol. 2022, 44, 2321–2334. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Yu, R.-C.; Chou, C.-C. Antioxidative Activities of Soymilk Fermented with Lactic Acid Bacteria and Bifidobacteria. Food Microbiol. 2006, 23, 128–135. [Google Scholar] [CrossRef]

- Cofelice, M.; Cinelli, G.; Lopez, F.; Di Renzo, T.; Coppola, R.; Reale, A. Alginate-Assisted Lemongrass (Cymbopogon nardus) Essential Oil Dispersions for Antifungal Activity. Foods 2021, 10, 1528. [Google Scholar] [CrossRef]

- Cofelice, M.; Messia, M.C.; Marconi, E.; Cuomo, F.; Lopez, F. Effect of the Xanthan Gum on the Rheological Properties of Alginate Hydrogels. Food Hydrocoll. 2023, 142, 108768. [Google Scholar] [CrossRef]

- Koksoy, A.; Kilic, M. Use of Hydrocolloids in Textural Stabilization of a Yoghurt Drink, Ayran. Food Hydrocoll. 2004, 18, 593–600. [Google Scholar] [CrossRef]

- Jung, S.; Murphy, P.A.; Sala, I. Isoflavone Profiles of Soymilk as Affected by High-Pressure Treatments of Soymilk and Soybeans. Food Chem. 2008, 111, 592–598. [Google Scholar] [CrossRef]

- Fahmi, R.; Khodaiyan, F.; Pourahmad, R.; Emam-Djomeh, Z. Effect of Ultrasound Assisted Extraction upon the Genistin and Daidzin Contents of Resultant Soymilk. J. Food Sci. Technol. 2014, 51, 2857–2861. [Google Scholar] [CrossRef] [Green Version]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant Activity Applying an Improved ABTS Radical Cation Decolorization Assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Hodges, D.M.; DeLong, J.M.; Forney, C.F.; Prange, R.K. Improving the Thiobarbituric Acid-Reactive-Substances Assay for Estimating Lipid Peroxidation in Plant Tissues Containing Anthocyanin and Other Interfering Compounds. Planta 1999, 207, 604–611. [Google Scholar] [CrossRef]

- Landi, M. Commentary to:“Improving the Thiobarbituric Acid-Reactive-Substances Assay for Estimating Lipid Peroxidation in Plant Tissues Containing Anthocyanin and Other Interfering Compounds” by Hodges et al., Planta (1999) 207: 604–611. Planta 2017, 245, 1067. [Google Scholar] [CrossRef] [Green Version]

- Hamet, M.F.; Piermaria, J.A.; Abraham, A.G. Selection of EPS-Producing Lactobacillus Strains Isolated from Kefir Grains and Rheological Characterization of the Fermented Milks. LWT-Food Sci. Technol. 2015, 63, 129–135. [Google Scholar] [CrossRef]

- Garro, M.S.; Font de Valdez, G.; Savoy de Giori, G. Determination of Oligosaccharides in Fermented Soymilk Products by High-Performance Liquid Chromatography. In Environmental Microbiology: Methods and Protocols; Walker, J.M., Spencer, J.F.T., Ragout de Spencer, A.L., Eds.; Humana Press: Totowa, NJ, USA, 2004; pp. 135–138. ISBN 978-1-59259-765-9. [Google Scholar]

- Brereton, K.R.; Green, D.B. Isolation of Saccharides in Dairy and Soy Products by Solid-Phase Extraction Coupled with Analysis by Ligand-Exchange Chromatography. Talanta 2012, 100, 384–390. [Google Scholar] [CrossRef]

- Baygut, H.; Cais-Sokolińska, D.; Bielska, P.; Teichert, J. Fermentation Kinetics, Microbiological and Physical Properties of Fermented Soy Beverage with Acai Powder. Fermentation 2023, 9, 324. [Google Scholar] [CrossRef]

- Mei, J.; Feng, F.; Li, Y. Effective of Different Homogeneous Methods on Physicochemical, Textural and Sensory Characteristics of Soybean (Glycine max L.) Yogurt. CyTA-J. Food 2017, 15, 21–26. [Google Scholar]

- Huang, K.; Liu, Y.; Zhang, Y.; Cao, H.; Luo, D.; Yi, C.; Guan, X. Formulation of Plant-Based Yoghurt from Soybean and Quinoa and Evaluation of Physicochemical, Rheological, Sensory and Functional Properties. Food Biosci. 2022, 49, 101831. [Google Scholar] [CrossRef]

- O’ Flynn, T.D.; Hogan, S.A.; Daly, D.F.; O’ Mahony, J.A.; McCarthy, N.A. Rheological and Solubility Properties of Soy Protein Isolate. Molecules 2021, 26, 3015. [Google Scholar] [CrossRef]

- Xu, Y.; Ye, Q.; Zhang, H.; Yu, Y.; Li, X.; Zhang, Z.; Zhang, L. Naturally Fermented Acid Slurry of Soy Whey: High-Throughput Sequencing-Based Characterization of Microbial Flora and Mechanism of Tofu Coagulation. Front. Microbiol. 2019, 10, 1088. [Google Scholar] [CrossRef]

- Shun-Tang, G.; Ono, T.; Mikami, M. Incorporation of Soy Milk Lipid into Protein Coagulum by Addition of Calcium Chloride. J. Agric. Food Chem. 1999, 47, 901–905. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.-S.; Chang, S.K.-C. Effect of Soy Milk Characteristics and Cooking Conditions on Coagulant Requirements for Making Filled Tofu. J. Agric. Food Chem. 2004, 52, 3405–3411. [Google Scholar] [CrossRef] [PubMed]

- Zannini, E.; Waters, D.M.; Coffey, A.; Arendt, E.K. Production, Properties, and Industrial Food Application of Lactic Acid Bacteria-Derived Exopolysaccharides. Appl. Microbiol. Biotechnol. 2016, 100, 1121–1135. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Liao, Y.; Ren, K.; Liu, Y.; Wang, M.; Yu, A.; Tian, T.; Liao, P.; Huang, Z.; Wang, H. Fermentation Performance, Nutrient Composition, and Flavor Volatiles in Soy Milk after Mixed Culture Fermentation. Process Biochem. 2022, 121, 286–297. [Google Scholar] [CrossRef]

- Yovanoudi, M.; Dimitreli, G.; Raphaelides, S.; Antoniou, K. Flow Behavior Studies of Kefir Type Systems. J. Food Eng. 2013, 118, 41–48. [Google Scholar] [CrossRef]

- Pang, Z.; Xu, R.; Zhu, Y.; Li, H.; Bansal, N.; Liu, X. Comparison of Rheological, Tribological, and Microstructural Properties of Soymilk Gels Acidified with Glucono-δ-Lactone or Culture. Food Res. Int. 2019, 121, 798–805. [Google Scholar] [CrossRef]

- Arancibia, C.; Bayarri, S.; Costell, E. Effect of Hydrocolloid on Rheology and Microstructure of High-Protein Soy Desserts. J. Food Sci. Technol. 2015, 52, 6435–6444. [Google Scholar] [CrossRef]

- Masiá, C.; Geppel, A.; Jensen, P.E.; Buldo, P. Effect of Lactobacillus rhamnosus on Physicochemical Properties of Fermented Plant-Based Raw Materials. Foods 2021, 10, 573. [Google Scholar] [CrossRef]

- Jurášková, D.; Ribeiro, S.C.; Silva, C.C. Exopolysaccharides Produced by Lactic Acid Bacteria: From Biosynthesis to Health-Promoting Properties. Foods 2022, 11, 156. [Google Scholar] [CrossRef]

- Zhao, X.; Liang, Q. EPS-Producing Lactobacillus plantarum MC5 as a Compound Starter Improves Rheology, Texture, and Antioxidant Activity of Yogurt during Storage. Foods 2022, 11, 1660. [Google Scholar] [CrossRef]

- Hendrich, S. Bioavailability of Isoflavones. J. Chromatogr. B Analyt. Technol. Biomed. Life. Sci. 2002, 777, 203–210. [Google Scholar] [CrossRef]

- Rekha, C.; Vijayalakshmi, G. Isoflavone Phytoestrogens in Soymilk Fermented with β-Glucosidase Producing Probiotic Lactic Acid Bacteria. Int. J. Food Sci. Nutr. 2011, 62, 111–120. [Google Scholar] [CrossRef]

- De Mello Andrade, J.M.; Fasolo, D. Polyphenol Antioxidants from Natural Sources and Contribution to Health Promotion. In Polyphenols in Human Health and Disease; Elsevier: Amsterdam, The Netherlands, 2014; pp. 253–265. [Google Scholar]

- Cetinkaya, H.; Kulak, M.; Karaman, M.; Karaman, H.S.; Kocer, F. Flavonoid Accumulation Behavior in Response to the Abiotic Stress: Can a Uniform Mechanism Be Illustrated for All Plants? In Flavonoids; Justino, G.C., Ed.; IntechOpen: Rijeka, Croatia, 2017; Chapter 8; ISBN 978-953-51-3424-4. [Google Scholar]

- Fernández, J.; Pérez-Álvarez, J.A.; Fernández-López, J.A. Thiobarbituric Acid Test for Monitoring Lipid Oxidation in Meat. Food Chem. 1997, 59, 345–353. [Google Scholar] [CrossRef]

- Spickett, C.; Fedorova, M.; Hoffmann, R.; Forman, H. An Introduction to Redox Balance and Lipid Oxidation. In Lipid Oxidation in Health and Disease; CRC Press: Boca Raton, FL, USA, 2015; pp. 1–24. [Google Scholar]

- Ghani, M.A.; Barril, C.; Bedgood, D.R., Jr.; Prenzler, P.D. Measurement of Antioxidant Activity with the Thiobarbituric Acid Reactive Substances Assay. Food Chem. 2017, 230, 195–207. [Google Scholar] [CrossRef]

| Isoflavones (µmol/100 g D.W.) | Fermentation Stage (hours) | ||||

|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 24 | |

| Daidzin | 11.26 ± 0.27 a | 11.08 ± 0.26 a | 0.57 ± 0.02 b | 0.00 ± 0.00 c | 0.00 ± 0.00 c |

| Glycitin | 39.34 ± 1.00 a | 37.78 ± 0.55 b | 1.45 ± 0.10 c | 0.00 ± 0.00 d | 0.00 ± 0.00 d |

| Genistin | 40.39 ± 1.27 a | 40.11 ± 0.02 a | 4.60 ± 0.09 b | 0.00 ± 0.00 c | 0.00 ± 0.00 c |

| Daidzein | 25.64 ± 0.02 b | 25.76 ± 1.11 b | 47.71 ± 0.72 a | 48.45 ±1.74 a | 48.45 ± 1.30 a |

| Glycitein | 1.58 ± 0.18 d | 1.65 ± 0.04 d | 2.61 ± 0.17 c | 3.69 ± 0.01 b | 5.10 ± 0.16 a |

| Genistein | 21.58 ± 0.39 c | 21.77 ± 0.80 c | 51.14 ± 0.84 b | 54.75 ± 2.11 a | 56.35 ± 1.02 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Letizia, F.; Fratianni, A.; Cofelice, M.; Testa, B.; Albanese, G.; Di Martino, C.; Panfili, G.; Lopez, F.; Iorizzo, M. Antioxidative Properties of Fermented Soymilk Using Lactiplantibacillus plantarum LP95. Antioxidants 2023, 12, 1442. https://doi.org/10.3390/antiox12071442

Letizia F, Fratianni A, Cofelice M, Testa B, Albanese G, Di Martino C, Panfili G, Lopez F, Iorizzo M. Antioxidative Properties of Fermented Soymilk Using Lactiplantibacillus plantarum LP95. Antioxidants. 2023; 12(7):1442. https://doi.org/10.3390/antiox12071442

Chicago/Turabian StyleLetizia, Francesco, Alessandra Fratianni, Martina Cofelice, Bruno Testa, Gianluca Albanese, Catello Di Martino, Gianfranco Panfili, Francesco Lopez, and Massimo Iorizzo. 2023. "Antioxidative Properties of Fermented Soymilk Using Lactiplantibacillus plantarum LP95" Antioxidants 12, no. 7: 1442. https://doi.org/10.3390/antiox12071442