Application of Response Surface Methodologies to Optimize High-Added Value Products Developments: Cosmetic Formulations as an Example

Abstract

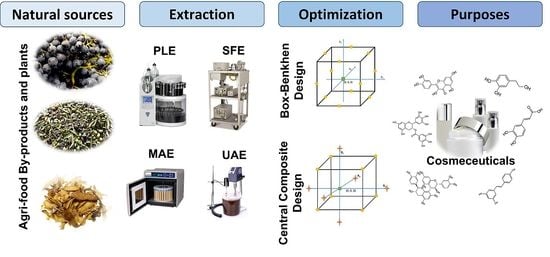

:1. Introduction

2. Advanced Extraction Methods to Develop Functional Ingredients

3. DoE: From Concept to Product Development

3.1. Basic Principles of DoE

3.2. Types of DoE

3.3. Data Processing and Statistical Analyses

3.4. Application of DoE to Optimize Phytochemicals Retrieval by Advanced Extraction Techniques from Natural Sources

4. RSM for Improving the Cosmeceutical Formulations

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cádiz-Gurrea, M.D.L.L.; Villegas-Aguilar, M., del C.; Leyva-Jiménez, F.J.; Pimentel-Moral, S.; Fernández-Ochoa, Á.; Alañón, M.E.; Segura-Carretero, A. Revalorization of bioactive compounds from tropical fruit by-products and industrial applications by means of sustainable approaches. Food Res. Int. 2020, 138, 109786. [Google Scholar] [CrossRef] [PubMed]

- European Commission Bioeconomy: The European way to use our natural resources. Action plan 2018, 2018, 1–26. [CrossRef]

- Goyal, A.; Sharma, A.; Kaur, J.; Kumari, S.; Garg, M.; Sindhu, R.K.; Rahman, M.H.; Akhtar, M.F.; Tagde, P.; Najda, A.; et al. Bioactive-Based Cosmeceuticals: An Update on Emerging Trends. Molecules 2022, 27, 828. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.M.; Pinto, D.; Moreira, M.M.; Costa, P.C.; Delerue-Matos, C.; Rodrigues, F. Valorization of Kiwiberry Leaves Recovered by Ultrasound-Assisted Extraction for Skin Application: A Response Surface Methodology Approach. Antioxidants 2022, 11, 763. [Google Scholar] [CrossRef] [PubMed]

- Averilla, J.N.; Oh, J.; Wu, Z.; Liu, K.; Jang, C.H.; Kim, H.J.; Kim, J.; Kim, J. Improved extraction of resveratrol and antioxidants from grape peel using heat and enzymatic treatments. J. Sci. Food Agric. 2019, 99, 4043–4053. [Google Scholar] [CrossRef]

- Xiong, J.; Matta, F. V.; Grace, M.; Lila, M.A.; Ward, N.I.; Felipe-Sotelo, M.; Esposito, D. Phenolic content, anti-inflammatory properties, and dermal wound repair properties of industrially processed and non-processed acai from the Brazilian Amazon. Food Funct. 2020, 11, 4903–4914. [Google Scholar] [CrossRef]

- Rodrigues, F.; Cádiz-Gurrea, M.D.L.L.; Nunes, M.A.; Pinto, D.; Vinha, A.F.; Linares, I.B.; Oliveira, M.B.P.P.; Carretero, A.S. Cosmetics. In Polyphenols: Properties, Recovery, and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 393–427. [Google Scholar]

- Leyva-Jiménez, F.J.; Manca, M.L.; Manconi, M.; Caddeo, C.; Vázquez, J.A.; Carbone, C.; Lozano-Sánchez, J.; Arráez-Román, D.; Segura-Carretero, A. Development of advanced phospholipid vesicles loaded with Lippia citriodora pressurized liquid extract for the treatment of gastrointestinal disorders. Food Chem. 2021, 337, 127746. [Google Scholar] [CrossRef]

- Ameer, K.; Shahbaz, H.M.; Kwon, J.H. Green Extraction Methods for Polyphenols from Plant Matrices and Their Byproducts: A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 295–315. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, I.J.; Alexandre, E.M.; Saraiva, J.A.; Pintado, M. Green emerging extraction technologies to obtain high-quality vegetable oils from nuts: A review. Innov. Food Sci. Emerg. Technol. 2022, 76, 102931. [Google Scholar] [CrossRef]

- García, P.; Fredes, C.; Cea, I.; Lozano-Sánchez, J.; Leyva-Jiménez, F.J.; Robert, P.; Vergara, C.; Jimenez, P. Recovery of Bioactive Compounds from Pomegranate (Punica granatum L.) Peel Using Pressurized Liquid Extraction. Foods 2021, 10, 203. [Google Scholar] [CrossRef]

- Pal, C.B.T.; Jadeja, G.C. Microwave-assisted extraction for recovery of polyphenolic antioxidants from ripe mango ( Mangifera indica L.) peel using lactic acid/sodium acetate deep eutectic mixtures. Food Sci. Technol. Int. 2020, 26, 78–92. [Google Scholar] [CrossRef] [PubMed]

- Leyva-Jiménez, F.J.; Lozano-Sánchez, J.; Borrás-Linares, I.; Arráez-Román, D.; Segura-Carretero, A. Manufacturing design to improve the attainment of functional ingredients from Aloysia citriodora leaves by advanced microwave technology. J. Ind. Eng. Chem. 2019, 79, 52–61. [Google Scholar] [CrossRef]

- García-Villegas, A.; Rojas-García, A.; Villegas-Aguilar, M.D.C.; Fernández-Moreno, P.; Fernández-Ochoa, Á.; Cádiz-Gurrea, M.D.L.L.; Arráez-Román, D.; Segura-Carretero, A. Cosmeceutical Potential of Major Tropical and Subtropical Fruit By-Products for a Sustainable Revalorization. Antioxidants 2022, 11, 203. [Google Scholar] [CrossRef] [PubMed]

- Rudke, A.R.; Mazzutti, S.; Andrade, K.S.; Vitali, L.; Ferreira, S.R.S. Optimization of green PLE method applied for the recovery of antioxidant compounds from buriti (Mauritia flexuosa L.) shell. Food Chem. 2019, 298, 125061. [Google Scholar] [CrossRef]

- Vieira, E.F.; Podlasiak, M.; Moreira, M.M.; Grosso, C.; Rodrigues, F.; Fernandes, V.C.; Delerue-Matos, C. New insights of phytochemical profile and in vitro antioxidant and neuroprotective activities from optimized extract of Horned Melon fruit. J. Food Meas. Charact. 2022, 16, 1847–1858. [Google Scholar] [CrossRef]

- Pinto, D.; de la Luz, C.-G.M.; Sut, S.; Ferreira, A.S.; Leyva-Jimenez, F.J.; Dall’Acqua, S.; Segura-Carretero, A.; Delerue-Matos, C.; Rodrigues, F. Valorisation of underexploited Castanea sativa shells bioactive compounds recovered by supercritical fluid extraction with CO2: A response surface methodology approach. J. CO2 Util. 2020, 40, 101194. [Google Scholar] [CrossRef]

- Apraj, V.D.; Pandita, N.S. Evaluation of skin anti-aging potential of Citrus reticulata blanco peel. Pharmacognosy Res. 2016, 8, 160–168. [Google Scholar] [CrossRef] [Green Version]

- Luchian, C.E.; Cotea, V.V.; Vlase, L.; Toiu, A.M.; Colibaba, L.C.; Răschip, I.E.; Nadăş, G.; Gheldiu, A.M.; Tuchiluş, C.; Rotaru, L. Antioxidant and antimicrobial effects of grape pomace extracts. BIO Web Conf. 2019, 15, 4006. [Google Scholar] [CrossRef]

- Cvjetko Bubalo, M.; Vidović, S.; Radojčić Redovniković, I.; Jokić, S. New perspective in extraction of plant biologically active compounds by green solvents. Food Bioprod. Process. 2018, 109, 52–73. [Google Scholar] [CrossRef]

- Giacometti, J.; Bursać Kovačević, D.; Putnik, P.; Gabrić, D.; Bilušić, T.; Krešić, G.; Stulić, V.; Barba, F.J.; Chemat, F.; Barbosa-Cánovas, G.; et al. Extraction of bioactive compounds and essential oils from mediterranean herbs by conventional and green innovative techniques: A review. Food Res. Int. 2018, 113, 245–262. [Google Scholar] [CrossRef]

- Panja, P. Green extraction methods of food polyphenols from vegetable materials. Curr. Opin. Food Sci. 2018, 23, 173–182. [Google Scholar] [CrossRef]

- Alañón, M.E.; Pimentel-Moral, S.; Fernández-Ochoa, Á.; Cádiz-Gurrea, M.D.L.L.; del Carmen Villegas-Aguilar, M.; Leyva-Jiménez, F.J.; Segura-Carretero, A. Recent advances and new challenges of green solvents for the extraction of phenolic compounds from tropical fruits. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Elsevier: Amsterdam, The Netherlands, 2021; pp. 271–287. [Google Scholar]

- Azmir, J.; Zaidul, I.S.M.; Rahman, M.M.; Sharif, K.M.; Mohamed, A.; Sahena, F.; Jahurul, M.H.A.; Ghafoor, K.; Norulaini, N.A.N.; Omar, A.K.M. Techniques for extraction of bioactive compounds from plant materials: A review. J. Food Eng. 2013, 117, 426–436. [Google Scholar] [CrossRef]

- del Pilar Sánchez-Camargo, A.; Ibáñez, E.; Cifuentes, A.; Herrero, M. Bioactives Obtained From Plants, Seaweeds, Microalgae and Food By-Products Using Pressurized Liquid Extraction and Supercritical Fluid Extraction; Elsevier Science: Amsterdam, The Netherlands, 2017; ISBN 9780444638694. [Google Scholar]

- Pimentel-Moral, S.; Borrás-Linares, I.; Lozano-Sánchez, J.; Arráez-Román, D.; Martínez-Férez, A.; Segura-Carretero, A. Supercritical CO2 extraction of bioactive compounds from Hibiscus sabdariffa. J. Supercrit. Fluids 2018, 147, 213–221. [Google Scholar] [CrossRef]

- Aresta, A.; Cotugno, P.; De Vietro, N.; Massari, F.; Zambonin, C. Determination of Polyphenols and Vitamins in Wine-Making by-Products by Supercritical Fluid Extraction (SFE). Anal. Lett. 2020, 53, 2585–2595. [Google Scholar] [CrossRef]

- Del Castillo-Llamosas, A.; del Río, P.G.; Pérez-Pérez, A.; Yáñez, R.; Garrote, G.; Gullón, B. Recent advances to recover value-added compounds from avocado by-products following a biorefinery approach. Curr. Opin. Green Sustain. Chem. 2021, 28, 100433. [Google Scholar] [CrossRef]

- Mocan, A.; Diuzheva, A.; Carradori, S.; Andruch, V.; Massafra, C.; Moldovan, C.; Sisea, C.; Petzer, J.P.; Petzer, A.; Zara, S.; et al. Development of novel techniques to extract phenolic compounds from Romanian cultivars of Prunus domestica L. and their biological properties. Food Chem. Toxicol. 2018, 119, 189–198. [Google Scholar] [CrossRef]

- Varo, M.A.; Jacotet-Navarro, M.; Serratosa, M.P.; Mérida, J.; Fabiano-Tixier, A.-S.; Bily, A.; Chemat, F. Green Ultrasound-Assisted Extraction of Antioxidant Phenolic Compounds Determined by High Performance Liquid Chromatography from Bilberry (Vaccinium Myrtillus L.) Juice By-products. Waste Biomass Valorization 2019, 10, 1945–1955. [Google Scholar] [CrossRef]

- Machado, I.; Faccio, R.; Pistón, M. Characterization of the effects involved in ultrasound-assisted extraction of trace elements from artichoke leaves and soybean seeds. Ultrason. Sonochem. 2019, 59, 104752. [Google Scholar] [CrossRef]

- Chemat, F.; Tomao, V.; Virot, M. Ultrasound-Assisted Extraction in Food Analysis. In Handbook of Food Analysis Instruments; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Yadav, B.; Sellamuthu, B.; Tyagi, R.D. Degradation of organic micro-pollutants by ultraviolet radiation. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 427–455. [Google Scholar]

- Belwal, T.; Ezzat, S.M.; Rastrelli, L.; Bhatt, I.D.; Daglia, M.; Baldi, A.; Devkota, H.P.; Orhan, I.E.; Patra, J.K.; Das, G.; et al. A critical analysis of extraction techniques used for botanicals: Trends, priorities, industrial uses and optimization strategies. TrAC Trends Anal. Chem. 2018, 100, 82–102. [Google Scholar] [CrossRef]

- Roohinejad, S.; Koubaa, M.; Barba, F.J.; Greiner, R.; Orlien, V.; Lebovka, N.I. Negative pressure cavitation extraction: A novel method for extraction of food bioactive compounds from plant materials. Trends Food Sci. Technol. 2016, 52, 98–108. [Google Scholar] [CrossRef]

- Zhang, D.-Y.; Zhang, S.; Zu, Y.-G.; Fu, Y.-J.; Kong, Y.; Gao, Y.; Zhao, J.-T.; Efferth, T. Negative pressure cavitation extraction and antioxidant activity of genistein and genistin from the roots of pigeon pea [Cajanus cajan (L.) Millsp.]. Sep. Purif. Technol. 2010, 74, 261–270. [Google Scholar] [CrossRef]

- Yao, X.-H.; Zhang, D.-Y.; Luo, M.; Jin, S.; Zu, Y.-G.; Efferth, T.; Fu, Y.-J. Negative pressure cavitation-microwave assisted preparation of extract of Pyrola incarnata Fisch. rich in hyperin, 2′-O-galloylhyperin and chimaphilin and evaluation of its antioxidant activity. Food Chem. 2015, 169, 270–276. [Google Scholar] [CrossRef] [PubMed]

- Heemann, A.C.W.; Heemann, R.; Kalegari, P.; Spier, M.R.; Santin, E. Enzyme-assisted extraction of polyphenols from green yerba mate. Brazilian J. Food Technol. 2019, 22, e2017222. [Google Scholar] [CrossRef] [Green Version]

- Štambuk, P.; Tomašković, D.; Tomaz, I.; Maslov, L.; Stupić, D.; Karoglan Kontić, J. Application of pectinases for recovery of grape seeds phenolics. 3 Biotech 2016, 6, 224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Puri, M.; Sharma, D.; Barrow, C.J. Enzyme-assisted extraction of bioactives from plants. Trends Biotechnol. 2012, 30, 37–44. [Google Scholar] [CrossRef] [PubMed]

- Kitrytė, V.; Kavaliauskaitė, A.; Tamkutė, L.; Pukalskienė, M.; Syrpas, M.; Rimantas Venskutonis, P. Zero waste biorefining of lingonberry (Vaccinium vitis-idaea L.) pomace into functional ingredients by consecutive high pressure and enzyme assisted extractions with green solvents. Food Chem. 2020, 322, 126767. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Rodríguez, G.; Marina, M.L.; Plaza, M. Enzyme-assisted extraction of bioactive non-extractable polyphenols from sweet cherry (Prunus avium L.) pomace. Food Chem. 2021, 339, 128086. [Google Scholar] [CrossRef]

- Frontuto, D.; Carullo, D.; Harrison, S.M.; Brunton, N.P.; Ferrari, G.; Lyng, J.G.; Pataro, G. Optimization of Pulsed Electric Fields-Assisted Extraction of Polyphenols from Potato Peels Using Response Surface Methodology. Food Bioprocess Technol. 2019, 12, 1708–1720. [Google Scholar] [CrossRef]

- Pashazadeh, B.; Elhamirad, A.H.; Hajnajari, H.; Sharayei, P.; Armin, M. Optimization of the pulsed electric field -assisted extraction of functional compounds from cinnamon. Biocatal. Agric. Biotechnol. 2020, 23, 101461. [Google Scholar] [CrossRef]

- Pataro, G.; Ferrari, G.; Donsì, F. Mass transfer enhancement by means of electroporation. In Mass Transfer in Chemical Engineering Processes; InTech: Rijeka, Croatia, 2011; pp. 151–176. ISBN 978-953-307-619-5. [Google Scholar]

- Roselló-Soto, E.; Barba, F.J.; Parniakov, O.; Galanakis, C.M.; Lebovka, N.; Grimi, N.; Vorobiev, E. High Voltage Electrical Discharges, Pulsed Electric Field, and Ultrasound Assisted Extraction of Protein and Phenolic Compounds from Olive Kernel. Food Bioprocess Technol. 2015, 8, 885–894. [Google Scholar] [CrossRef]

- Barbosa-Pereira, L.; Guglielmetti, A.; Zeppa, G. Pulsed Electric Field Assisted Extraction of Bioactive Compounds from Cocoa Bean Shell and Coffee Silverskin. Food Bioprocess Technol. 2018, 11, 818–835. [Google Scholar] [CrossRef]

- Gutiérrez-Pulido, H.; de la Vara-Salazar, R. Análisis y Diseño de Experimentos, 2nd ed.; McGraw-Hill/Interamericana Editores: New York, NY, USA, 2008; ISBN 978-970-10-6526-3. [Google Scholar]

- Condra, L.W. Reliability Improvement with Design of Experiments; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9781315274478. [Google Scholar]

- Kirk, R. Experimental Design: Procedures for the Behavioral Sciences, 4th ed.; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2013; ISBN 9781412974455. [Google Scholar]

- Khuri, A.I.; Cornell, J.A. Response Surfaces: Designs and Analyses; Routledge: Oxfordshire, UK, 2018; ISBN 9780203740774. [Google Scholar]

- Zhou, J.; Yu, X.; Ding, C.; Wang, Z.; Zhou, Q.; Pao, H.; Cai, W. Optimization of phenol degradation by Candida tropicalis Z-04 using Plackett-Burman design and response surface methodology. J. Environ. Sci. 2011, 23, 22–30. [Google Scholar] [CrossRef]

- Jia, M.-Z.; Fu, X.-Q.; Deng, L.; Li, Z.-L.; Dang, Y.-Y. Phenolic extraction from grape (Vitis vinifera) seed via enzyme and microwave co-assisted salting-out extraction. Food Biosci. 2021, 40, 100919. [Google Scholar] [CrossRef]

- Cea Pavez, I.; Lozano-Sánchez, J.; Borrás-Linares, I.; Nuñez, H.; Robert, P.; Segura-Carretero, A. Obtaining an Extract Rich in Phenolic Compounds from Olive Pomace by Pressurized Liquid Extraction. Molecules 2019, 24, 3108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Agudelo, C.; Bravo, K.; Ramírez-Atehortúa, A.; Torres, D.; Carrillo-Hormaza, L.; Osorio, E. Chemical and Skincare Property Characterization of the Main Cocoa Byproducts: Extraction Optimization by RSM Approach for Development of Sustainable Ingredients. Molecules 2021, 26, 7429. [Google Scholar] [CrossRef]

- Peng, X.; Yang, G.; Shi, Y.; Zhou, Y.; Zhang, M.; Li, S. Box–Behnken design based statistical modeling for the extraction and physicochemical properties of pectin from sunflower heads and the comparison with commercial low-methoxyl pectin. Sci. Rep. 2020, 10, 3595. [Google Scholar] [CrossRef] [PubMed]

- Box, G.E.P.; Wilson, K.B. On the Experimental Attainment of Optimum Conditions. J. R. Stat. Soc. Ser. B 1951, 13, 1–38. [Google Scholar] [CrossRef]

- Anderson, V.L.; McLean, R.A. Design of Experiments; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9781315141039. [Google Scholar]

- Corazza, G.O.; Bilibio, D.; Zanella, O.; Nunes, A.L.; Bender, J.P.; Carniel, N.; dos Santos, P.P.; Priamo, W.L. Pressurized liquid extraction of polyphenols from Goldenberry: Influence on antioxidant activity and chemical composition. Food Bioprod. Process. 2018, 112, 63–68. [Google Scholar] [CrossRef]

- Oehlert, G.W. A First Course in Design and Analysis of Experiments; Creative Commons: Minneapolis, MI, USA, 2010; ISBN 0-7167-3510-5. [Google Scholar]

- Shabbiri, K.; Adnan, A.; Jamil, S.; Ahmad, W.; Noor, B.; Rafique, H.M. Medium optimization of protease production by Brevibacterium linens DSM 20158, using statistical approach. Brazilian J. Microbiol. 2012, 43, 1051–1061. [Google Scholar] [CrossRef] [Green Version]

- Yusoff, N.I.; Leo, C.P. Microwave Assisted Extraction of Defatted Roselle ( Hibiscus sabdariffa L.) Seed at Subcritical Conditions with Statistical Analysis. J. Food Qual. 2017, 2017, 5232458. [Google Scholar] [CrossRef] [Green Version]

- Derringer, G.; Suich, R. Simultaneous Optimization of Several Response Variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar] [CrossRef]

- Li, X.; Chen, F.; Li, S.; Jia, J.; Gu, H.; Yang, L. An efficient homogenate-microwave-assisted extraction of flavonols and anthocyanins from blackcurrant marc: Optimization using combination of Plackett-Burman design and Box-Behnken design. Ind. Crops Prod. 2016, 94, 834–847. [Google Scholar] [CrossRef]

- Pereira, D.T.V.; Tarone, A.G.; Cazarin, C.B.B.; Barbero, G.F.; Martínez, J. Pressurized liquid extraction of bioactive compounds from grape marc. J. Food Eng. 2019, 240, 105–113. [Google Scholar] [CrossRef]

- Hatami, T.; Johner, J.C.F.; Meireles, M.A.A. Investigating the effects of grinding time and grinding load on content of terpenes in extract from fennel obtained by supercritical fluid extraction. Ind. Crops Prod. 2017, 109, 85–91. [Google Scholar] [CrossRef]

- Zaghdoudi, K.; Framboisier, X.; Frochot, C.; Vanderesse, R.; Barth, D.; Kalthoum-Cherif, J.; Blanchard, F.; Guiavarc’h, Y. Response surface methodology applied to Supercritical Fluid Extraction (SFE) of carotenoids from Persimmon (Diospyros kaki L.). Food Chem. 2016, 208, 209–219. [Google Scholar] [CrossRef]

- Kurtulbaş, E.; Sevgen, S.; Samli, R.; Şahin, S. Microwave-assisted extraction of bioactive components from peach waste: Describing the bioactivity degradation by polynomial regression. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Weremfo, A.; Adulley, F.; Adarkwah-Yiadom, M. Simultaneous Optimization of Microwave-Assisted Extraction of Phenolic Compounds and Antioxidant Activity of Avocado ( Persea americana Mill.) Seeds Using Response Surface Methodology. J. Anal. Methods Chem. 2020, 2020, 7541927. [Google Scholar] [CrossRef]

- Hannachi, H.; Benmoussa, H.; Saadaoui, E.; Saanoun, I.; Negri, N.; Elfalleh, W. Optimization of ultrasound and microwave-assisted extrction of phenolic compounds from olive leaves by response surface methodology. Res. J. Biotechnol. 2019, 14, 28–37. [Google Scholar]

- Pingret, D.; Fabiano-Tixier, A.-S.; Bourvellec, C. Le; Renard, C.M.G.C.; Chemat, F. Lab and pilot-scale ultrasound-assisted water extraction of polyphenols from apple pomace. J. Food Eng. 2012, 111, 73–81. [Google Scholar] [CrossRef]

- Gómez-López, I.; Lobo-Rodrigo, G.; Portillo, M.P.; Cano, M.P. Ultrasound-Assisted “Green” Extraction (UAE) of Antioxidant Compounds (Betalains and Phenolics) from Opuntia stricta var. Dilenii’s Fruits: Optimization and Biological Activities. Antioxidants 2021, 10, 1786. [Google Scholar] [CrossRef]

- Chakraborty, S.; Uppaluri, R.; Das, C. Optimization of ultrasound-assisted extraction (UAE) process for the recovery of bioactive compounds from bitter gourd using response surface methodology (RSM). Food Bioprod. Process. 2020, 120, 114–122. [Google Scholar] [CrossRef]

- Feuereisen, M.M.; Gamero Barraza, M.; Zimmermann, B.F.; Schieber, A.; Schulze-Kaysers, N. Pressurized liquid extraction of anthocyanins and biflavonoids from Schinus terebinthifolius Raddi: A multivariate optimization. Food Chem. 2017, 214, 564–571. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Martínez, J.D.; Alvarez-Rivera, G.; Gallego, R.; Fagundes, M.B.; Valdés, A.; Mendiola, J.A.; Ibañez, E.; Cifuentes, A. Neuroprotective potential of terpenoid-rich extracts from orange juice by-products obtained by pressurized liquid extraction. Food Chem. X 2022, 13, 100242. [Google Scholar] [CrossRef] [PubMed]

- Shang, Y.-F.; Xu, J.-L.; Lee, W.-J.; Um, B.-H. Antioxidative polyphenolics obtained from spent coffee grounds by pressurized liquid extraction. South African J. Bot. 2017, 109, 75–80. [Google Scholar] [CrossRef]

- Buelvas-Puello, L.M.; Franco-Arnedo, G.; Martínez-Correa, H.A.; Ballesteros-Vivas, D.; Sánchez-Camargo, A.D.P.; Miranda-Lasprilla, D.; Narváez-Cuenca, C.-E.; Parada-Alfonso, F. Supercritical Fluid Extraction of Phenolic Compounds from Mango (Mangifera indica L.) Seed Kernels and Their Application as an Antioxidant in an Edible Oil. Molecules 2021, 26, 7516. [Google Scholar] [CrossRef]

- de Andrade Lima, M.; Andreou, R.; Charalampopoulos, D.; Chatzifragkou, A. Supercritical Carbon Dioxide Extraction of Phenolic Compounds from Potato (Solanum tuberosum) Peels. Appl. Sci. 2021, 11, 3410. [Google Scholar] [CrossRef]

- Syrpas, M.; Valanciene, E.; Augustiniene, E.; Malys, N. Valorization of Bilberry (Vaccinium myrtillus L.) Pomace by Enzyme-Assisted Extraction: Process Optimization and Comparison with Conventional Solid-Liquid Extraction. Antioxidants 2021, 10, 773. [Google Scholar] [CrossRef]

- Solaberrieta, I.; Jiménez, A.; Garrigós, M.C. Valorization of Aloe vera Skin By-Products to Obtain Bioactive Compounds by Microwave-Assisted Extraction: Antioxidant Activity and Chemical Composition. Antioxidants 2022, 11, 1058. [Google Scholar] [CrossRef]

- Kaanin-Boudraa, G.; Brahmi, F.; Wrona, M.; Nerín, C.; Moudache, M.; Mouhoubi, K.; Madani, K.; Boulekbache-Makhlouf, L. Response surface methodology and UPLC-QTOF-MSE analysis of phenolic compounds from grapefruit (Citrus✕ paradisi) by-products as novel ingredients for new antioxidant packaging. LWT 2021, 151, 112158. [Google Scholar] [CrossRef]

- Dairi, S.; Dahmoune, F.; Belbahi, A.; Remini, H.; Kadri, N.; Aoun, O.; Bouaoudia, N.; Madani, K. Optimization of microwave extraction method of phenolic compounds from red onion using response surface methodology and inhibition of lipoprotein low-density oxidation. J. Appl. Res. Med. Aromat. Plants 2021, 22, 100301. [Google Scholar] [CrossRef]

- Kashyap, P.; Riar, C.S.; Jindal, N. Optimization of ultrasound assisted extraction of polyphenols from Meghalayan cherry fruit (Prunus nepalensis) using response surface methodology (RSM) and artificial neural network (ANN) approach. J. Food Meas. Charact. 2021, 15, 119–133. [Google Scholar] [CrossRef]

- Iadecola, R.; Ciccoritti, R.; Ceccantoni, B.; Bellincontro, A.; Amoriello, T. Optimization of Phenolic Compound Extraction from Brewers’ Spent Grain Using Ultrasound Technologies Coupled with Response Surface Methodology. Sustainability 2022, 14, 3309. [Google Scholar] [CrossRef]

- Mohamed Ahmed, I.A.; Al-Juhaimi, F.; Adisa, A.R.; Adiamo, O.Q.; Babiker, E.E.; Osman, M.A.; Gassem, M.A.; Ghafoor, K.; Alqah, H.A.S.; Elkareem, M.A. Optimization of ultrasound-assisted extraction of phenolic compounds and antioxidant activity from Argel (Solenostemma argel Hayne) leaves using response surface methodology (RSM). J. Food Sci. Technol. 2020, 57, 3071–3080. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Cui, Q.; Yin, L.-J.; Li, Y.; Gao, M.-Z.; Meng, Y.; Li, J.; Zhang, S.-D.; Wang, W. Negative pressure cavitation based ultrasound-assisted extraction of main flavonoids from Flos Sophorae Immaturus and evaluation of its extraction kinetics. Sep. Purif. Technol. 2020, 244, 115805. [Google Scholar] [CrossRef]

- Rahmah, N.L.; Kamal, S.M.M.; Sulaiman, A.; Taip, S.F.; Siajam, S.I. Optimization Of Phenolic Compounds And Antioxidant Extraction From Piper Betle Linn. Leaves Using Pressurized Hot Water. J. Appl. Sci. Eng. 2022, 26, 175–184. [Google Scholar] [CrossRef]

- Espada-Bellido, E.; Ferreiro-González, M.; Barbero, G.F.; Carrera, C.; Palma, M.; Barroso, C.G. Alternative Extraction Method of Bioactive Compounds from Mulberry (Morus nigra L.) Pulp Using Pressurized-Liquid Extraction. Food Anal. Methods 2018, 11, 2384–2395. [Google Scholar] [CrossRef]

- Supasatyankul, B.; Saisriyoot, M.; Klinkesorn, U.; Rattanaporn, K.; Sae-Tan, S. Extraction of Phenolic and Flavonoid Compounds from Mung Bean (Vigna radiata L.) Seed Coat by Pressurized Liquid Extraction. Molecules 2022, 27, 2085. [Google Scholar] [CrossRef]

- Tyśkiewicz, K.; Konkol, M.; Rój, E. Supercritical Carbon Dioxide (scCO2) Extraction of Phenolic Compounds from Lavender (Lavandula angustifolia) Flowers: A Box-Behnken Experimental Optimization. Molecules 2019, 24, 3354. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Camargo, D.P.A.; Gutiérrez, L.-F.; Vargas, S.M.; Martinez-Correa, H.A.; Parada-Alfonso, F.; Narváez-Cuenca, C.-E. Valorisation of mango peel: Proximate composition, supercritical fluid extraction of carotenoids, and application as an antioxidant additive for an edible oil. J. Supercrit. Fluids 2019, 152, 104574. [Google Scholar] [CrossRef]

- Valadez-Carmona, L.; Ortiz-Moreno, A.; Ceballos-Reyes, G.; Mendiola, J.A.; Ibáñez, E. Valorization of cacao pod husk through supercritical fluid extraction of phenolic compounds. J. Supercrit. Fluids 2018, 131, 99–105. [Google Scholar] [CrossRef]

- Zhou, Z.; Shao, H.; Han, X.; Wang, K.; Gong, C.; Yang, X. The extraction efficiency enhancement of polyphenols from Ulmus pumila L. barks by trienzyme-assisted extraction. Ind. Crops Prod. 2017, 97, 401–408. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, C.; Zhai, X.; Zhang, Y.; Duan, Z.; Sun, J. Optimization of enzyme assisted extraction of polysaccharides from pomegranate peel by response surface methodology and their anti-oxidant potential. Chinese Herb. Med. 2018, 10, 416–423. [Google Scholar] [CrossRef]

- Meini, M.-R.; Cabezudo, I.; Boschetti, C.E.; Romanini, D. Recovery of phenolic antioxidants from Syrah grape pomace through the optimization of an enzymatic extraction process. Food Chem. 2019, 283, 257–264. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.Y.; Wang, H.H.; Li, M.Y.; Liu, W.; Zhang, T.H. Optimization of high-intensity pulsed electric field-assisted extraction of procyanidins from Vitis amurensis seeds using response surface methodology. E3S Web Conf. 2020, 189, 2029. [Google Scholar] [CrossRef]

- Md Yusof, A.; Abd Gani, S.; Zaidan, U.; Halmi, M.; Zainudin, B. Optimization of an Ultrasound-Assisted Extraction Condition for Flavonoid Compounds from Cocoa Shells (Theobroma cacao) Using Response Surface Methodology. Molecules 2019, 24, 711. [Google Scholar] [CrossRef] [Green Version]

- Soroush, D.R.; Solaimanimehr, S.; Azizkhani, M.; Kenari, R.E.; Dehghan, B.; Mohammadi, G.; Sadeghi, E. Optimization of microwave-assisted solvent extraction of hemp (Cannabis sativa L.) seed oil using RSM: Evaluation of oil quality. J. Food Meas. Charact. 2021, 15, 5191–5202. [Google Scholar] [CrossRef]

- Zhao, C.-N.; Zhang, J.-J.; Li, Y.; Meng, X.; Li, H.-B. Microwave-Assisted Extraction of Phenolic Compounds from Melastoma sanguineum Fruit: Optimization and Identification. Molecules 2018, 23, 2498. [Google Scholar] [CrossRef] [Green Version]

- Gomes, S.V.F.; Portugal, L.A.; dos Anjos, J.P.; de Jesus, O.N.; de Oliveira, E.J.; David, J.P.; David, J.M. Accelerated solvent extraction of phenolic compounds exploiting a Box-Behnken design and quantification of five flavonoids by HPLC-DAD in Passiflora species. Microchem. J. 2017, 132, 28–35. [Google Scholar] [CrossRef]

- Rai, A.; Mohanty, B.; Bhargava, R. Supercritical extraction of sunflower oil: A central composite design for extraction variables. Food Chem. 2016, 192, 647–659. [Google Scholar] [CrossRef]

- Ahmadian-Kouchaksaraie, Z.; Niazmand, R. Supercritical carbon dioxide extraction of antioxidants from Crocus sativus petals of saffron industry residues: Optimization using response surface methodology. J. Supercrit. Fluids 2017, 121, 19–31. [Google Scholar] [CrossRef]

- MacDonald-Wicks, L.K.; Wood, L.G.; Garg, M.L. Methodology for the determination of biological antioxidant capacityin vitro: A review. J. Sci. Food Agric. 2006, 86, 2046–2056. [Google Scholar] [CrossRef]

- Villegas-Aguilar, M.D.C.; Leyva-Jiménez, F.J.; Cádiz-Gurrea, M.D.L.L.; Segura-Carretero, A.; Arráez-Román, D. Comprehensive Analysis of Antioxidant Compounds from Lippia citriodora and Hibiscus sabdariffa Green Extracts Attained by Response Surface Methodology. Antioxidants 2020, 9, 1175. [Google Scholar] [CrossRef] [PubMed]

- Leyva-Jiménez, F.J.; Lozano-Sánchez, J.; Borrás-Linares, I.; Arráez-Román, D.; Segura-Carretero, A. Comparative study of conventional and pressurized liquid extraction for recovering bioactive compounds from Lippia citriodora leaves. Food Res. Int. 2018, 109, 213–222. [Google Scholar] [CrossRef] [PubMed]

- Pimentel-Moral, S.; Borrás-Linares, I.; Lozano-Sánchez, J.; Arráez-Román, D.; Martínez-Férez, A.; Segura-Carretero, A. Microwave-assisted extraction for Hibiscus sabdariffa bioactive compounds. J. Pharm. Biomed. Anal. 2018, 156, 313–322. [Google Scholar] [CrossRef]

- Leyva-Jiménez, F.J.; Lozano-Sánchez, J.; Fernández-Ochoa, Á.; Cádiz-Gurrea, M.D.L.L.; Arráez-Román, D.; Segura-Carretero, A. Optimized Extraction of Phenylpropanoids and Flavonoids from Lemon Verbena Leaves by Supercritical Fluid System Using Response Surface Methodology. Foods 2020, 9, 931. [Google Scholar] [CrossRef]

- Karnik, S.R.; Gaitonde, V.N.; Davim, J.P. A comparative study of the ANN and RSM modeling approaches for predicting burr size in drilling. Int. J. Adv. Manuf. Technol. 2008, 38, 868–883. [Google Scholar] [CrossRef]

- Rebollo-Hernanz, M.; Cañas, S.; Taladrid, D.; Segovia, Á.; Bartolomé, B.; Aguilera, Y.; Martín-Cabrejas, M.A. Extraction of phenolic compounds from cocoa shell: Modeling using response surface methodology and artificial neural networks. Sep. Purif. Technol. 2021, 270, 118779. [Google Scholar] [CrossRef]

- Moosavi, S.R.; Wood, D.A.; Ahmadi, M.A.; Choubineh, A. ANN-Based Prediction of Laboratory-Scale Performance of CO2-Foam Flooding for Improving Oil Recovery. Nat. Resour. Res. 2019, 28, 1619–1637. [Google Scholar] [CrossRef]

- Dudnyk, V.; Sinenko, Y.; Matsyk, M.; Demchenko, Y.; Zhyvotovskyi, R.; Repilo, I.; Zabolotnyi, O.; Simonenko, A.; Pozdniakov, P.; Shyshatskyi, A. Development of a method for training artificial neural networks for intelligent decision support systems. Eastern-European J. Enterp. Technol. 2020, 3, 37–47. [Google Scholar] [CrossRef]

- Poomanee, W.; Khunkitti, W.; Chaiyana, W.; Leelapornpisid, P. Optimization of Mangifera indica L. Kernel Extract-Loaded Nanoemulsions via Response Surface Methodology, Characterization, Stability, and Skin Permeation for Anti-Acne Cosmeceutical Application. Pharmaceutics 2020, 12, 454. [Google Scholar] [CrossRef]

- Lee, M.; Park, H.Y.; Jung, K.H.; Kim, D.H.; Rho, H.S.; Choi, K. Anti-melanogenic Effects of Kojic Acid and Hydroxycinnamic Acid Derivatives. Biotechnol. Bioprocess Eng. 2020, 25, 190–196. [Google Scholar] [CrossRef]

- Roselan, M.A.; Ashari, S.E.; Faujan, N.H.; Mohd Faudzi, S.M.; Mohamad, R. An Improved Nanoemulsion Formulation Containing Kojic Monooleate: Optimization, Characterization and In Vitro Studies. Molecules 2020, 25, 2616. [Google Scholar] [CrossRef] [PubMed]

- Hübner, A.A.; Sarruf, F.D.; Oliveira, C.A.; Neto, A. V.; Fischer, D.C.H.; Kato, E.T.M.; Lourenço, F.R.; Baby, A.R.; Bacchi, E.M. Safety and Photoprotective Efficacy of a Sunscreen System Based on Grape Pomace (Vitis vinifera L.) Phenolics from Winemaking. Pharmaceutics 2020, 12, 1148. [Google Scholar] [CrossRef] [PubMed]

- Rulhisham, N.S.; Razak, A.H. Optimisation of Droplet Size and pH Via Taguchi and Response Surface Method (RSM) For Stabilised Cosmeceutical Cream Containing Virgin Coconut Oil (VCO). Prog. Eng. Appl. Technol. 2021, 2, 27–37. [Google Scholar] [CrossRef]

- Nilforoushzadeh, M.A.; Amirkhani, M.A.; Zarrintaj, P.; Salehi Moghaddam, A.; Mehrabi, T.; Alavi, S.; Mollapour Sisakht, M. Skin care and rejuvenation by cosmeceutical facial mask. J. Cosmet. Dermatol. 2018, 17, 693–702. [Google Scholar] [CrossRef]

- Chong, W.-T.; Tan, C.-P.; Cheah, Y.-K.; Lajis, A.F.B.; Habi Mat Dian, N.L.; Kanagaratnam, S.; Lai, O.-M. Optimization of process parameters in preparation of tocotrienol-rich red palm oil-based nanoemulsion stabilized by Tween80-Span 80 using response surface methodology. PLoS ONE 2018, 13, e0202771. [Google Scholar] [CrossRef] [Green Version]

- Gong, Y.; Fan, L.; Wang, L.; Li, J. Flos Sophorae Immaturus: Phytochemistry, bioactivities, and its potential applications. Food Rev. Int. 2021, 1–19. [Google Scholar] [CrossRef]

- Jang, H.S.; Ma, X.; Lee, S.B. Preparation of Cosmeceuticals Containing Wheat Sprout Extracts: Optimization of Emulsion Stability Using CCD-RSM. Korean Soc. Ind. Eng. Chem. 2021, 32, 320–325. [Google Scholar] [CrossRef]

- Yoo, B.-H.; Zuo, C.; Lee, S.B. Preparation of Cosmeceuticals Containing Flos Sophorae Immaturus Extracts: Optimization Using Box-Behnken Design Model. Korean Soc. Ind. Eng. Chem. 2020, 31, 404–410. [Google Scholar] [CrossRef]

| Run | Factor 1 (X1) | Factor 2 (X2) | Factor 3 (X3) |

|---|---|---|---|

| 1 | 0 | 0 | 0 |

| 2 | 0 | 0 | 0 |

| 3 | 0 | 0 | 0 |

| 4 | 1 | 0 | 1 |

| 5 | −1 | 0 | 1 |

| 6 | 1 | 0 | −1 |

| 7 | −1 | 0 | −1 |

| 8 | 0 | 1 | 1 |

| 9 | 0 | −1 | 1 |

| 10 | 0 | 1 | −1 |

| 11 | 0 | −1 | −1 |

| 12 | 1 | 1 | 0 |

| 13 | −1 | 1 | 0 |

| 14 | 1 | −1 | 0 |

| 15 | −1 | −1 | 0 |

| Run | Factor 1 (X1) | Factor 2 (X2) |

|---|---|---|

| 1 | 0 | 0 |

| 2 | 0 | α |

| 3 | 0 | −α |

| 4 | α | 0 |

| 5 | −α | 0 |

| 6 | 1 | 1 |

| 7 | −1 | 1 |

| 8 | 1 | −1 |

| 9 | −1 | −1 |

| Run | Factor 1 (X1) | Factor 2 (X2) | Factor 3 (X3) |

|---|---|---|---|

| 1 | 0 | 0 | 0 |

| 2 | 0 | 0 | α |

| 3 | 0 | 0 | −α |

| 4 | 0 | α | 0 |

| 5 | 0 | −α | 0 |

| 6 | α | 0 | 0 |

| 7 | −α | 0 | 0 |

| 8 | 1 | 1 | 1 |

| 9 | −1 | 1 | 1 |

| 10 | 1 | −1 | 1 |

| 11 | −1 | −1 | 1 |

| 12 | 1 | 1 | −1 |

| 13 | −1 | 1 | −1 |

| 14 | 1 | −1 | −1 |

| 15 | −1 | −1 | −1 |

| Experimental Design | Technique | Factors | Levels | Runs | Response Variable | Fitting Parameters | Botanical Source | Reference |

|---|---|---|---|---|---|---|---|---|

| CCD | MAE | Extraction time (min) Power (W) Solid–liquid ratio (mL/g) | 4 to 10 min 10 to 300 W 25 to 100 mL/g | 20 | Yield TPC TFC | Model adequacy Lack-of-fit R2 | Hibiscus Sabdariffa | [62] |

| Extraction time (s) Power (W) Ethanol (% v/v) | 30–90 s 350–500 W 20–80% | 20 | TPC Total anthocyanins | Model adequacy Lack-of-fit R2 | Peach peels | [68] | ||

| Ethanol concentration (%) Power (W) Extraction time (Min) | 40–80% 80–400 W 1–5 min | 17 | TFC TAA | Model adequacy Lack-of-fit R2 | Avocado seeds | [69] | ||

| UAE | Solid–liquid ratio Time (min) Power (W) | 4–20 1–5 min 100–300 W | 20 | TPC TFC | Model adequacy Lack-of-fit R2 | Olive leaves | [70] | |

| Sonication time (min) Ultrasonic intensity (W/cm2) | 15 to 45 min 0.431 to 0.719 W/cm2 16 to 34 °C | 20 | TPC | R2 | Apple pomace | [71] | ||

| Amplitude (%) Ethanol (%) Temperature (°C) Temperature (°C) | 20–50% 15–80% 20–50 °C | 16 | Yield TAA Hyaluronidase inhibition Bioactive compound content | Model adequacy Lack of fit R2 | Opuntia stricta fruits | [72] | ||

| Solid–liquid ratio (g/mL) Extraction time (min) Temperature (°C) | 0.1–0.5 g/mL 1 to 15 min 25 to 80 °C | 20 | TPC TAA | R2 Lack-of-fit | Bitter gourds | [73] | ||

| NPC | Solid–liquid ratio (mL/g) Negative pressure (MPa) Ethanol concentration (%) | 30–50 mL/g (−0.035)–(−0.065) MPa 60–80% | 20 | Genistein extraction | R2 | Cajanus cajan roots | [36] | |

| PLE | Static time (min) Ethanol concentration (%) Temperature (°C) Acetic acid (%) | 0 to 10 min 0 to 100% 40 to 120 °C 0 to 5% | 30 | Total anthocyanins TFC TPC | R2 | Schius terebinthifolius | [74] | |

| Temperature (°C) Extraction time (min) | 25–100 °C 10–30 min | 11 | Yield AChE, BChE LOX TAA | Model adequacy Lack-of-fit R2 | Orange peels and seeds | [75] | ||

| Ethanol concentration (%) Temperature (°C) | 1 to 2% 80 to 160 °C | 13 | TPCCaffeine retrievalTAA | R2 | Coffee | [76] | ||

| Ethanol concentration (%) Temperature (°C) | 10–90 55–185 °C | TPC Punicalagin content Antimicrobial activity | R2 Lack-of-fit | Pomegranate peel | [11] | |||

| SFE | Co-solvent (%) Pressure (bar) Temperature (°C) | 5 to 15% 11 to 21 bars 40 to 60 °C | 19 | Yield TPC TFC DPPH | Lack-of-fit | Mango seed kernels | [77] | |

| Co-solvent (%) CO2 flow (g/min) | 10–20% 8–18 g/min | 11 | TPC Caffeic acid content TAA | R2 | Potato peels | [78] | ||

| Co-solvent (%) Pressure (MPa) Temperature (°C) | 7–11% 15–35 MPa 40–50 °C | 16 | FRAP DPPH ABTS | Lack-of-fit R2 | Castanea sativa shells | [17] | ||

| EAE | Temperature (°C) Enzyme (AU/g) Reaction time (h) pH | 30–50 °C 2–10 AU/g 1–7 h 3–5 | 28 | Yield ABTS TPC | Model adequacy Lack-of-fit R2 | Bilberry pomace | [79] | |

| Temperature (°C) Enzyme (FGBU/100 g) Reaction time (min) pH | 40 to 60 °C 68 to 268 FGBU/100 g 60 to 18 min 3.5 to 5.5 | 20 | TPC | Lack-of-fit R2 | Yerba mate | [38] | ||

| PEF | Ethanol concentration (%) Extraction time (min) Temperature (°C) | 0–100% 30–240 min 20–50°C | 15 | TPC DPPH | Model adequacy Lack-of-fit R2 | Potato peel | [43] | |

| Number of voltage Voltage (kV) | 40–60 2–6 kV | 10 | TPC DPPH | Model adequacy Lack-of-fit CV | Cinnamon | [44] | ||

| BBD | MAE | Ethanol concentration (%) Temperature (°C) Extraction time (min) Solvent volume (mL) | 40–80% 40–80 °C 5–40 min 50–80 mL | 29 | TPC DPPH FRAP Aloin content | Lack-of-fit R2 | Aloe vera skin | [80] |

| Ethanol concentration (%)Power (W) Extraction time (s) Solid–liquid ratio | 40–80% 100–900 W 30–120 s 1:10–1:70 | 27 | TPC | Model adequacy R2 | Grapefruit skin | [81] | ||

| Ethanol concentration (%) Power (W) Extraction time (s)Solid–liquid ratio | 30–80% 500–900 W 30–120 s 20–40 | 27 | TPC | Model adequacy Lack-of-fit R2 | Red onions | [82] | ||

| UAE | Solvent/solid ratio (mL/g) Amplitude (%) Time (min) Ethanol concentration (%) | 10–30 mL/g 20–40% 20–40 min 40–80% | 29 | Yield TPC | Lack-of-fit R2 | Meghalayan cherry fruit | [83] | |

| Temperature(°C)Time (min) Ethanol concentration (%) | 70–80 °C 50–70 (min) 50–80% | 15 | TPC | Lack-of-fit R2 | Brewers’ spent grain | [84] | ||

| Solvent/solid ratio (% w/v) Amplitude (W/m2) Time (min) | 2.5–10% (w/v) 30–70(W/m2) 20–60 min | 17 | TPC FRAP DPPH ABTS | Model adequacy Lack-of-fit R2 | Kiwiberry leaves | [4] | ||

| Temperature(°C)Time (min) Ethanol concentration (%) | 40–60 °C 20–40 min 25–50% | 17 | TPC TAA | Lack-of-fit | Argel leaves | [85] | ||

| NPC | Ethanol concentration (%) Solvent/solid ratio (mL/g) Time (min) | 20–30% 1:10–1:20 60–80 min | 17 | Rutin, quercetin, kaempherol, isorhamenitin, narcissin yield | Model adequacy Lack-of-fit R2 | Flos sophorae immaturus | [86] | |

| PLE | Extraction time (min) Solid loading (%) Temperature (°C) | 5–25 min 5–15% 150–250 °C | 17 | TPC TAA | Model adequacy Lack-of-fit R2 | Piper bitle leaves | [87] | |

| Methanol concentration (%) Temperature (°C) Pressure (bar) pH Purge (s) Flushing (%) | 25 to 75% 50 to 100 °C100 to 200 bar 30 to 90 s 3 to 7 50 to 100% | 54 | TPC Total anthocyanins | R2 | Morus nigra | [88] | ||

| Ethanol concentration (%) Temperature (°C) Pressure (bar) | 5–95% 80–160 °C 81–122 bar | 15 | TPC TFC ABTS | Lack-of-fit R2 | Mung vean seed coat | [89] | ||

| SFE | Extraction time (min) Pressure (bar) Temperature (°C) | 15–45 min 200–300 bar 40–60 °C | 15 | Yield TPC TAA | Model adequacy R2 Lack-of-fit | Lavender flowers | [90] | |

| Co-solvent flow rate (%) Pressure (bar) Temperature (°C) | 5–15% 250–350 bar 40–50 °C | 15 | Yield Carotenoid content | R2 Lack-of-fit | Mango peel | [91] | ||

| Co-solvent flow rate (%) Pressure (bar) Temperature (°C) | 5–15% 100–300 bar 40–60 °C | 15 | Yield TPC TAA | R2 Lack-of-fit | Cacao pod husk | [92] | ||

| EAE | pH Temperature (°C) Extraction time (min) | 4 to 6 40 to 60 °C 30 to 90 min | 17 | TPC Total sugar content | Model adequacy Lack-of-fit R2 | Ulmus pumila | [93] | |

| Enzymolysis time (min) Dosage of cellulose (%) Solvent:sample ratio (mL/g) | 75 to 105 min 0.7 to 1.1% 15 to 25 mL/g | 17 | Polysaccharides retrieval | Model adequacy Lack-of-fit R2 | Pomegranate | [94] | ||

| Temperature (°C) Enzyme (AU/g) Extraction time (h) pH | 25–45 °C 0–200 Au/g 2–6 h 4–5.5 | 15 | TPCABTS | Model adequacy Lack-of-fit R2 | Grape pomace | [95] | ||

| PEF | Ethanol concentration (%) Pulse number Electric field strength (kV/cm)Solvent:sample ratio (mL/g) | 50–70% 8–12 20–30 kV/cm 1:15–1:25 | 29 | Proanthocyanidin recovery DPPH Ferous ion chelating | Model adequacy Lack-of-fit | Vitis amurensis seeds | [96] |

| Formulation | Activity | Extract | Factors | Response Variables | Optimal Conditions | Ref. |

|---|---|---|---|---|---|---|

| Safflower oil-based nanoemulsions | Anti-acne | Mango kernel | HLB value PEG-7 glyceryl cocoate Surfactant/oil ratio | Droplet size PDI Z-potential | HLB: 10 PEG-7 glyceryl cocoate: 2% Surfactant/oil ratio: 1.9:1 | [112] |

| Castor oil-kojic monooleate nanoemulsion | Skin hyperpigmentation | Kojic monooleate acid | Time of shear Speed of shear Sonication time | Particle size | Time of shear: 11.16 min Speed of shear: 218 rpm Sonication time: 16.75 min | [114] |

| Rapeseed oil-mineral oil-isopropyl palmitate emulsion | Photoprotection | Grape pomace | Concentration of sunscreens filtersConcentration of extract | SPF AA UVA transmittance UVB transmittance UVA/UVB ratio | Concentration of sunscreens filters: 11.5% Concentration of extract: 10% | [115] |

| Wheat germ oil emulsion | - | Wheat sprout | Emulsifier Emulsification time Extract concentration | Droplets size Viscosity Emulsion stability index | Emulsifier: 7.7% Emulsification time: 23.6 min Extract concentration: 3.9% | [120] |

| Virgin coconut oil emulsion | - | Chromoleana odorata | Coconut oil/water ratio Emulsifier concentration Speed | pH Droplet size | Coconut oil/water ratio: 5:95 Emulsifier concentration: 3% Speed: 7500 rpm | [116] |

| Vitamin E-rich red palm oil-based nanoemulsion | - | - | Tween 80/Span 80 concentration Glycerol Homogenization pressure | Droplet size PDI | Tween 80/Span 80 concentration: 63/37 Glycerol: 20% Homogenization pressure: 500 bar | [118] |

| Coconut oil emulsion | - | Flos Sophorae Immaturus | Emulsification time Speed Amounts of the emulsifier Amounts of additive | Droplets size Viscosity Emulsion stability index | Emulsification time: 17.8 min Speed: 5505 rpm Amounts of the emulsifier: 2.28% Amounts of additive: 1.05% | [121] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leyva-Jiménez, F.-J.; Fernández-Ochoa, Á.; Cádiz-Gurrea, M.d.l.L.; Lozano-Sánchez, J.; Oliver-Simancas, R.; Alañón, M.E.; Castangia, I.; Segura-Carretero, A.; Arráez-Román, D. Application of Response Surface Methodologies to Optimize High-Added Value Products Developments: Cosmetic Formulations as an Example. Antioxidants 2022, 11, 1552. https://doi.org/10.3390/antiox11081552

Leyva-Jiménez F-J, Fernández-Ochoa Á, Cádiz-Gurrea MdlL, Lozano-Sánchez J, Oliver-Simancas R, Alañón ME, Castangia I, Segura-Carretero A, Arráez-Román D. Application of Response Surface Methodologies to Optimize High-Added Value Products Developments: Cosmetic Formulations as an Example. Antioxidants. 2022; 11(8):1552. https://doi.org/10.3390/antiox11081552

Chicago/Turabian StyleLeyva-Jiménez, Francisco-Javier, Álvaro Fernández-Ochoa, María de la Luz Cádiz-Gurrea, Jesús Lozano-Sánchez, Rodrigo Oliver-Simancas, M. Elena Alañón, Ines Castangia, Antonio Segura-Carretero, and David Arráez-Román. 2022. "Application of Response Surface Methodologies to Optimize High-Added Value Products Developments: Cosmetic Formulations as an Example" Antioxidants 11, no. 8: 1552. https://doi.org/10.3390/antiox11081552