Processability of A6061 Aluminum Alloy Using Laser Powder Bed Fusion by In Situ Synthesis of Grain Refiners

Abstract

:1. Introduction

2. Materials and Methods

2.1. Powder Characterization

2.2. LPBF Process

2.3. Characterization of the Bulk Samples

3. Results and Discussion

3.1. Powder Characterization

3.2. A6061 RAM2 System

- -

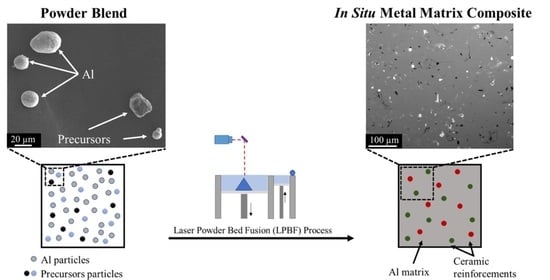

- TiC and TiB2 are commonly used as reinforcements for AMC because of their thermal and chemical stability, and good wettability. The use of these two ceramic phases makes it possible to improve mechanical properties (such as Young’s modulus, stiffness, strength, and hardness), and corrosion and wear performances [48,49];

- -

- The A6061 alloy has columnar dendritic solidification and a wide solidification range, which can result in cracking during solidification. The nucleant and grain-refining action of TiC and TiB2 for Al alloys [50,51,52] induces an equiaxed solidification, avoiding crack formation; in fact, both ceramic compounds have a lattice parameter comparable with that of the matrix and they can induce an equiaxed grain growth;

- -

- The in situ synthesis of the grain refiners is beneficial for nucleation sites distribution inside the matrix and the size distribution of these grain refiners [53].

- -

- After the LPBF process, the final microstructure would consist of TiC and TiB2 particles dispersed in the aluminum matrix;

- -

- The in situ reaction leads to the formation of 2% vol of ceramic reinforcements;

- -

- The system follows the stoichiometry of the reaction; therefore, Ti and B4C have a molar ratio of 3:1.

3.3. Bulk Characterization

4. Conclusions

- A6061 RAM2 is a suitable material for the LPBF process, designed to obtain an aluminum matrix composite reinforced with ceramic phases through the reactive LPBF process. The powder consists of three components—Al, Ti, and B4C particles—which are capable of reacting with each other to synthesize TiC and TiB2. These synthesized phases are expected to act as nucleants for the A6061 alloy.

- The process parameters optimization performed on the material showed that the highest density can be achieved using a laser power of 90 W and a scanning speed of 635 mm/s, resulting in a VED of 90 J/mm3. Specifically, for all tested VED values, a power of 90 W ensures higher densities.

- The LPBF process initiates the reaction mechanism, but this does not evolve into a complete reaction. Evidence of the presence of TiAl2 and TiAl3 was found in the processed material, in agreement with the reaction mechanism. However, TiC and TiB2 were not detected in the final microstructure.

- Despite the absence of TiC and TiB2, which are expected to act as grain refiners for the A6061 matrix, solidification cracking does not affect the processed material. This absence suggests that TiAl3 may act as a heterogeneous nucleation site and induces an equiaxial solidification of the matrix: TiAl3 is known as an effective nucleant for aluminum alloys, as confirmed in the literature. Chemical etching revealed partial refinement and a bimodal microstructure, consisting of fine equiaxial grain at the melt pool boundaries which can inhibit solidification cracks. At the same time, further investigation is required to understand the role of titanium particle size and process parameters in the synthesis of TiAl3 particles and their function as nucleants.

- Defects such as pores and microcracks can be observed in the microstructure. These defects are attributed to the interaction between the Al matrix and B4C particles, resulting from thermal mismatch and weak interfacial bonding. Further investigation is, however, needed to mitigate these phenomena, including exploring the role of preheating.

- Despite the presence of defects in the LPBF-ed material, the mechanical properties of the optimized process material are considerably superior to those obtained by processing pure A6061 using LPBF. A6061 RAM2, with Young’s modulus of 73 ± 6 GPa and a yield stress of 230 ± 6 MPa, exhibits significantly higher values compared to the pure A6061 alloy processed for LPBF, which has Young’s modulus of 27.6 GPa and a yield stress of 56.6 MPa, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khorasani, M.; Gibson, I.; Ghasemi, A.H.; Hadavi, E.; Rolfe, B. Laser Subtractive and Laser Powder Bed Fusion of Metals: Review of Process and Production Features. Rapid Prototyp. J. 2023, 29, 935–958. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Saboori, A.; Bassini, E.; Manfredi, D.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review. Materials 2019, 12, 1007. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sing, S.L.; Yeong, W.Y. Laser Powder Bed Fusion for Metal Additive Manufacturing: Perspectives on Recent Developments. Virtual Phys. Prototyp. 2020, 15, 359–370. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Gibson, I.; Veetil, J.K.; Ghasemi, A.H. A Review of Technological Improvements in Laser-Based Powder Bed Fusion of Metal Printers. Int. J. Adv. Manuf. Technol. 2020, 108, 191–209. [Google Scholar] [CrossRef]

- Campbell, I.; Bourell, D.; Gibson, I. Additive Manufacturing: Rapid Prototyping Comes of Age. Rapid Prototyp. J. 2012, 18, 255–258. [Google Scholar] [CrossRef] [Green Version]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D Printing of Aluminium Alloys: Additive Manufacturing of Aluminium Alloys Using Selective Laser Melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Galy, C.; Le Guen, E.; Lacoste, E.; Arvieu, C. Main Defects Observed in Aluminum Alloy Parts Produced by SLM: From Causes to Consequences. Addit. Manuf. 2018, 22, 165–175. [Google Scholar] [CrossRef]

- Padovano, E.; Badini, C.; Pantarelli, A.; Gili, F.; D’Aiuto, F. A Comparative Study of the Effects of Thermal Treatments on AlSi10Mg Produced by Laser Powder Bed Fusion. J. Alloys Compd. 2020, 831, 154822. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The Microstructure and Mechanical Properties of Selectively Laser Melted AlSi10Mg: The Effect of a Conventional T6-like Heat Treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and Strength of Selectively Laser Melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef] [Green Version]

- Hyer, H.; Zhou, L.; Park, S.; Gottsfritz, G.; Benson, G.; Tolentino, B.; McWilliams, B.; Cho, K.; Sohn, Y. Understanding the Laser Powder Bed Fusion of AlSi10Mg Alloy. Metallogr. Microstruct. Anal. 2020, 9, 484–502. [Google Scholar] [CrossRef]

- Azizi, A.; Hejripour, F.; Goodman, J.A.; Kulkarni, P.A.; Chen, X.; Zhou, G.; Schiffres, S.N. Process-Dependent Anisotropic Thermal Conductivity of Laser Powder Bed Fusion AlSi10Mg: Impact of Microstructure and Aluminum-Silicon Interfaces. Rapid Prototyp. J. 2023, 29, 1109–1120. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing Porosity in AlSi10Mg Parts Processed by Selective Laser Melting. Addit. Manuf. 2014, 1, 77–86. [Google Scholar] [CrossRef]

- Kimura, M.; Hirayama, A.; Yoshioka, J.; Maekawa, H.; Kusaka, M.; Kaizu, K.; Takahashi, T. Mechanical Properties of AlSi12 Alloy Manufactured by Laser Powder Bed Fusion Technique. J. Fail. Anal. Prev. 2020, 20, 1884–1895. [Google Scholar] [CrossRef]

- Ghasemi, A.; Fereiduni, E.; Balbaa, M.; Elbestawi, M.; Habibi, S. Unraveling the Low Thermal Conductivity of the LPBF Fabricated Pure Al, AlSi12, and AlSi10Mg Alloys through Substrate Preheating. Addit. Manuf. 2022, 59, 103148. [Google Scholar] [CrossRef]

- Vanzetti, M.; Virgillito, E.; Aversa, A.; Manfredi, D.; Bondioli, F.; Lombardi, M.; Fino, P. Short Heat Treatments for the F357 Aluminum Alloy Processed by Laser Powder Bed Fusion. Materials 2021, 14, 6157. [Google Scholar] [CrossRef]

- Lorenzetti, L.; Tonelli, L.; Ceschini, L.; Liverani, E.; Martini, C. A357 Aluminium Alloy Produced by LPBF: Tribological Behaviour in Dry Sliding Conditions. Wear 2022, 510–511, 204488. [Google Scholar] [CrossRef]

- Cheng, C.C.; Li, Z.; Dhillon, J.S.; Hudon, P.; Brochu, M. Influence of Powder Layer Thickness on Microstructure and T5 Heat Treatability of F357 Alloy Fabricated by Laser Powder Bed Fusion Process. J. Alloys Compd. 2023, 948, 169633. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Manfredi, D.; Lorusso, M.; Calignano, F.; Biamino, S.; Lombardi, M.; Fino, P.; Pavese, M. Laser Powder Bed Fusion of a High Strength Al-Si-Zn-Mg-Cu Alloy. Metals 2018, 8, 300. [Google Scholar] [CrossRef] [Green Version]

- Rometsch, P.A.; Zhu, Y.; Wu, X.; Huang, A. Review of High-Strength Aluminium Alloys for Additive Manufacturing by Laser Powder Bed Fusion. Mater. Des 2022, 219, 110779. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, H.; Yu, W. A Review on Solidification Cracks in High-Strength Aluminum Alloys via Laser Powder Bed Fusion. Mater. Today Proc. 2022, 70, 465–469. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D Printing of High-Strength Aluminium Alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. The Effect of Selective Laser Melting Process Parameters on the Microstructure and Mechanical Properties of Al6061 and AlSi10Mg Alloys. Materials 2018, 12, 12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, G.; Li, X.; Guo, C.; Zhou, Y.; Tan, Q.; Qu, W.; Li, X.; Hu, X.; Zhang, M.X.; Zhu, Q. Investigation into the Effect of Energy Density on Densification, Surface Roughness and Loss of Alloying Elements of 7075 Aluminium Alloy Processed by Laser Powder Bed Fusion. Opt. Laser Technol. 2022, 147, 107621. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Mehta, A.; Park, S.; Huynh, T.; Song, S.; Bai, Y.; Cho, K.; McWilliams, B.; Sohn, Y. Composition-Dependent Solidification Cracking of Aluminum-Silicon Alloys during Laser Powder Bed Fusion. Acta Mater. 2021, 208, 116698. [Google Scholar] [CrossRef]

- Montero Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; van Hooreweder, B.; Kruth, J.P.; van Humbeeck, J. Changing the Alloy Composition of Al7075 for Better Processability by Selective Laser Melting. J. Mater. Process Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Uddin, S.Z.; Murr, L.E.; Terrazas, C.A.; Morton, P.; Roberson, D.A.; Wicker, R.B. Processing and Characterization of Crack-Free Aluminum 6061 Using High-Temperature Heating in Laser Powder Bed Fusion Additive Manufacturing. Addit. Manuf. 2018, 22, 405–415. [Google Scholar] [CrossRef]

- Mehta, A.; Zhou, L.; Huynh, T.; Park, S.; Hyer, H.; Song, S.; Bai, Y.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; et al. Additive Manufacturing and Mechanical Properties of the Dense and Crack Free Zr-Modified Aluminum Alloy 6061 Fabricated by the Laser-Powder Bed Fusion. Addit. Manuf. 2021, 41, 101966. [Google Scholar] [CrossRef]

- Nuechterlein, J.S.; Iten, J.J. Reactive Additive Manufacturing. U.S. Patent US20160271878A1, 17 December 2019. pp. 1–20. [Google Scholar]

- Sullivan, E.; Polizzi, A.; Iten, J.; Nuechterlein, J.; Domack, M.; Liu, S. Microstructural Characterization and Tensile Behavior of Reaction Synthesis Aluminum 6061 Metal Matrix Composites Produced via Laser Beam Powder Bed Fusion and Electron Beam Freeform Fabrication. Int. J. Adv. Manuf. Technol. 2022, 121, 2197–2218. [Google Scholar] [CrossRef]

- Waller, D.; Polizzi, A.J.; Iten, J.J. Feasibility Study of Additively Manufactured Al-6061 Ram2 Parts for Aerospace Applications. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019; American Institute of Aeronautics and Astronautics Inc. (AIAA): Reston, VA, USA, 2019. [Google Scholar]

- Torbati-Sarraf, H.; Torbati-Sarraf, S.A.; Chawla, N.; Poursaee, A. A Comparative Study of Corrosion Behavior of an Additively Manufactured Al-6061 RAM2 with Extruded Al-6061 T6. Corros. Sci. 2020, 174, 108838. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and Reduction of Hydrogen Porosity during Selective Laser Melting of AlSi10Mg. J. Mater. Process Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An Overview of Powder Granulometry on Feedstock and Part Performance in the Selective Laser Melting Process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef] [Green Version]

- Bradford, R.L.; Cao, L.; Klosterman, D.; Herman, F.; Forman, L.; Browning, C. A Metal–Metal Powder Formulation Approach for Laser Additive Manufacturing of Difficult-to-Print High-Strength Aluminum Alloys. Mater. Lett 2021, 300, 130113. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H.; Fallah, V.; Ghassemali, E.; Saboori, A.; Pavese, M. Additive Manufacturing of Nano-Oxide Decorated AlSi10Mg Composites: A Comparative Study on Gd2O3 and Er2O3 Additions. Mater. Charact 2022, 192, 112206. [Google Scholar] [CrossRef]

- Martucci, A.; Aversa, A.; Manfredi, D.; Bondioli, F.; Biamino, S.; Ugues, D.; Lombardi, M.; Fino, P. Low-Power Laser Powder Bed Fusion Processing of Scalmalloy®. Materials 2022, 15, 3123. [Google Scholar] [CrossRef] [PubMed]

- ASTM International. Designation: E8/E8M—22 Standard Test Methods for Tension Testing of Metallic Materials 1; ASTM International: West Conshohocken, PA, USA, 2022. [Google Scholar]

- British Standards Institution. Metallic Materials: Tensile Testing. Part 1, Method of Test at Room Temperature; CEN-CENELEC Management Centre: Brussels, Belgium, 2020; ISBN 9780539047356. [Google Scholar]

- Riener, K.; Albrecht, N.; Ziegelmeier, S.; Ramakrishnan, R.; Haferkamp, L.; Spierings, A.B.; Leichtfried, G.J. Influence of Particle Size Distribution and Morphology on the Properties of the Powder Feedstock as Well as of AlSi10Mg Parts Produced by Laser Powder Bed Fusion (LPBF). Addit. Manuf. 2020, 34, 101286. [Google Scholar] [CrossRef]

- Chang, F.; Gu, D.; Dai, D.; Yuan, P. Selective Laser Melting of In-Situ Al4SiC4 + SiC Hybrid Reinforced Al Matrix Composites: Influence of Starting SiC Particle Size. Surf. Coat. Technol. 2015, 272, 15–24. [Google Scholar] [CrossRef]

- Gu, D.; Yang, Y.; Xi, L.; Yang, J.; Xia, M. Laser Absorption Behavior of Randomly Packed Powder-Bed during Selective Laser Melting of SiC and TiB2 Reinforced Al Matrix Composites. Opt. Laser. Technol. 2019, 119, 105600. [Google Scholar] [CrossRef]

- Ro, C.U.; Osán, J.; Van Grieken, R. Determination of Low-Z Elements in Individual Environmental Particles Using Windowless EPMA. Anal. Chem. 1999, 71, 1521–1528. [Google Scholar] [CrossRef]

- Elementum 3D. A6061-RAM2 (Highly Versatile and Cost Effective); Elementum 3D: Erie, CO, USA, 2021. [Google Scholar]

- Dadbakhsh, S.; Mertens, R.; Hao, L.; Van Humbeeck, J.; Kruth, J.P. Selective Laser Melting to Manufacture “In Situ” Metal Matrix Composites: A Review. Adv. Eng. Mater. 2019, 21, 1801244. [Google Scholar] [CrossRef] [Green Version]

- Shen, P.; Zou, B.; Jin, S.; Jiang, Q. Reaction Mechanism in Self-Propagating High Temperature Synthesis of TiC-TiB2/Al Composites from an Al-Ti-B4C System. Mater. Sci. Eng. A 2007, 454–455, 300–309. [Google Scholar] [CrossRef]

- Brodkin, D.; Kalidindi Surya, R.; Barsoum Michel, W.; Zavaliangos, A. Microstructural Evolution during Transient Plastic Phase Processing of Titanium Carbide-Titanium Boride Composites. J. Am. Ceram. Soc. 1996, 79, 1945–1952. [Google Scholar] [CrossRef]

- Minasyan, T.; Hussainova, I. Laser Powder-Bed Fusion of Ceramic Particulate Reinforced Aluminum Alloys: A Review. Materials 2022, 15, 2467. [Google Scholar] [CrossRef] [PubMed]

- Karabulut, Y.; Ünal, R. Additive Manufacturing of Ceramic Particle-Reinforced Aluminum-based Metal Matrix Composites: A Review. J. Mater. Sci. 2022, 57, 19212–19242. [Google Scholar] [CrossRef]

- Mertens, A.I.; Lecomte-Beckers, J. On the Role of Interfacial Reactions, Dissolution and Secondary Precipitation during the Laser Additive Manufacturing of Metal Matrix Composites: A Review. In New Trends in 3D Printing; InTech: Vienna, Austria, 2016. [Google Scholar]

- Aversa, A.; Marchese, G.; Lorusso, M.; Calignano, F.; Biamino, S.; Ambrosio, E.P.; Manfredi, D.; Fino, P.; Lombardi, M.; Pavese, M. Microstructural and Mechanical Characterization of Aluminum Matrix Composites Produced by Laser Powder Bed Fusion. Adv. Eng. Mater. 2017, 19, 1700180. [Google Scholar] [CrossRef]

- Yi, J.; Zhang, X.; Rao, J.H.; Xiao, J.; Jiang, Y. In-Situ Chemical Reaction Mechanism and Non-Equilibrium Microstructural Evolution of (TiB2 + TiC)/AlSi10Mg Composites Prepared by SLM-CS Processing. J. Alloys Compd. 2021, 857, 157553. [Google Scholar] [CrossRef]

- Jiang, H.; Song, Y.; Zhang, L.; He, J.; Li, S.; Zhao, J. Efficient Grain Refinement of Al Alloys Induced by In-Situ Nanoparticles. J. Mater. Sci. Technol. 2022, 124, 14–25. [Google Scholar] [CrossRef]

- Buchbinder, D.; Meiners, W.; Pirch, N.; Wissenbach, K.; Schrage, J. Investigation on Reducing Distortion by Preheating during Manufacture of Aluminum Components Using Selective Laser Melting. J. Laser Appl. 2014, 26, 012004. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T. Microstructures and Mechanical Properties of A356 (AlSi7Mg0.3) Aluminum Alloy Fabricated by Selective Laser Melting. Mater. Des. 2016, 89, 1294–1301. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A Review on Selective Laser Sintering/Melting (SLS/SLM) of Aluminium Alloy Powders: Processing, Microstructure, and Properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Dadkhah, M.; Mosallanejad, M.H.; Iuliano, L.; Saboori, A. A Comprehensive Overview on the Latest Progress in the Additive Manufacturing of Metal Matrix Composites: Potential, Challenges, and Feasible Solutions. Acta Metall. Sin. 2021, 34, 1173–1200. [Google Scholar] [CrossRef]

- Malaki, M.; Tehrani, A.F.; Niroumand, B.; Gupta, M. Wettability in Metal Matrix Composites. Metals 2021, 11, 1034. [Google Scholar] [CrossRef]

- Kimmari, E.; Kommel, L. Thermally Induced Cracking in Aluminum/Boron Carbide Composite. In Proceedings of the Proceedings of the International Conference of DAAAM Baltic “Industrial Engineering”, Tallinn, Estonia, 24–26 April 2008; Kyttner, R., Ed.; DAAAM International: Tallinn, Estonia, 2008. [Google Scholar]

- Dash, K.; Sukumaran, S.; Ray, B.C. The Behaviour of Aluminium Matrix Composites under Thermal Stresses. Sci. Eng. Compos. Mater. 2016, 23, 1–20. [Google Scholar] [CrossRef]

- Essien, U.; Vaudreuil, S. Issues in Metal Matrix Composites Fabricated by Laser Powder Bed Fusion Technique: A Review. Adv. Eng. Mater. 2022, 24, 2200055. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M. The Wettability of SiC Particles by Molten Aluminium Alloy. J. Mater. Process Technol. 2001, 119, 324–328. [Google Scholar] [CrossRef]

- Dai, D.; Gu, D.; Xia, M.; Ma, C.; Chen, H.; Zhao, T.; Hong, C.; Gasser, A.; Poprawe, R. Melt Spreading Behavior, Microstructure Evolution and Wear Resistance of Selective Laser Melting Additive Manufactured AlN/AlSi10Mg Nanocomposite. Surf. Coat. Technol. 2018, 349, 279–288. [Google Scholar] [CrossRef]

- Müller, S.; Woizeschke, P. Feasibility of a Laser Powder Bed Fusion Process for Additive Manufacturing of Hybrid Structures Using Aluminum-Titanium Powder-Substrate Pairings. Addit. Manuf. 2021, 48, 102377. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Zhou, Z.; Wang, K.; Zhan, Q.; Xiao, X. Grain Refinement and Crack Inhibition of Selective Laser Melted AA2024 Aluminum Alloy via Inoculation with TiC–TiH2. Mater. Sci. Eng. A 2021, 813, 141171. [Google Scholar] [CrossRef]

- Fan, Z.; Yan, X.; Fu, Z.; Niu, B.; Chen, J.; Hu, Y.; Chang, C.; Yi, J. In Situ Formation of D022-Al3Ti during Selective Laser Melting of Nano-TiC/AlSi10Mg Alloy Prepared by Electrostatic Self-Assembly. Vacuum 2021, 188, 110179. [Google Scholar] [CrossRef]

- Tan, Q.; Zhang, J.; Sun, Q.; Fan, Z.; Li, G.; Yin, Y.; Liu, Y.; Zhang, M.X. Inoculation Treatment of an Additively Manufactured 2024 Aluminium Alloy with Titanium Nanoparticles. Acta Mater. 2020, 196, 1–16. [Google Scholar] [CrossRef]

- Zhou, L.; Hyer, H.; Park, S.; Pan, H.; Bai, Y.; Rice, K.P.; Sohn, Y. Microstructure and Mechanical Properties of Zr-Modified Aluminum Alloy 5083 Manufactured by Laser Powder Bed Fusion. Addit. Manuf. 2019, 28, 485–496. [Google Scholar] [CrossRef]

- Xi, L.; Gu, D.; Guo, S.; Wang, R.; Ding, K.; Prashanth, K.G. Grain Refinement in Laser Manufactured Al-Based Composites with TiB2 Ceramic. J. Mater. Res. Technol. 2020, 9, 2611–2622. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Kang, N.; Lin, X.; EL Mansori, M.; Huang, W.D. High Strength Al-Cu-Mg Based Alloy with Synchronous Improved Tensile Properties and Hot-Cracking Resistance Suitable for Laser Powder Bed Fusion. J. Mater. Sci. Technol. 2023, 141, 155–170. [Google Scholar] [CrossRef]

- Greer, A.L.; Bunn, A.M.; Tronche, A.; Evans, P.V.; Bristow, D.J. Modelling of Inoculation of Metallic Melts: Application to Grain Refinement of Aluminium by Al-Ti-B. Acta Mater. 2000, 48, 2823–2835. [Google Scholar] [CrossRef]

| Volumetric Energy Density (J/mm3) | Scanning Speed (mm/s) | |||

|---|---|---|---|---|

| Power 80 W | Power 85 W | Power 90 W | Power 95 W | |

| 60 | 847 | 899 | 952 | 1005 |

| 70 | 726 | 771 | 816 | 862 |

| 80 | 635 | 675 | 714 | 754 |

| 90 | 564 | 600 | 635 | 670 |

| 100 | 508 | 540 | 571 | 603 |

| 110 | 462 | 491 | 519 | 548 |

| 120 | 423 | 450 | 476 | 503 |

| 130 | 391 | 415 | 440 | 464 |

| Component | vol.% | wt.% |

|---|---|---|

| Al | 97.5 | 96.6 |

| Ti | 1.5 | 2.5 |

| B4C | 1 | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosito, M.; Vanzetti, M.; Padovano, E.; Gili, F.; Sampieri, R.; Bondioli, F.; Badini, C.F. Processability of A6061 Aluminum Alloy Using Laser Powder Bed Fusion by In Situ Synthesis of Grain Refiners. Metals 2023, 13, 1128. https://doi.org/10.3390/met13061128

Rosito M, Vanzetti M, Padovano E, Gili F, Sampieri R, Bondioli F, Badini CF. Processability of A6061 Aluminum Alloy Using Laser Powder Bed Fusion by In Situ Synthesis of Grain Refiners. Metals. 2023; 13(6):1128. https://doi.org/10.3390/met13061128

Chicago/Turabian StyleRosito, Michele, Matteo Vanzetti, Elisa Padovano, Flavia Gili, Roberta Sampieri, Federica Bondioli, and Claudio Francesco Badini. 2023. "Processability of A6061 Aluminum Alloy Using Laser Powder Bed Fusion by In Situ Synthesis of Grain Refiners" Metals 13, no. 6: 1128. https://doi.org/10.3390/met13061128