1. Introduction

The nickel-based superalloy GH4169 has very stable physical and chemical properties, high creep resistance, and thermal stability [

1,

2]; however, due to its excellent performance, GH4169 is a material that is difficult to machine. In order to solve the problem of the difficult machining of GH4169, some scholars have started their research from the perspective of the cutting environment and applied different cooling and lubrication technologies, such as spray cooling [

3], high-pressure cooling [

4], liquid nitrogen cooling [

5], and low-temperature cold [

6], in the process of machining to obtain good machinability.

In recent years, with the continuous development of science and bionics technology, the method of machining micro-textures on the surface of tools to improve their cutting performance has been favored by most scholars. Additionally, these types of tools with micro-textures are collectively called “micro-textured tools”. The existence of micro-textures can effectively reduce the contact area between the tool and the chip being cut, thereby improving the cutting performance of the tool [

7,

8,

9,

10]. Moreover, when the tool is cutting in certain lubrication conditions, the advantages of the micro-texture will be more obvious.

Scholars at home and abroad have conducted extensive research on the morphologies, size parameters, and arrangements of the micro-textures of micro-textured tools.

Some scholars have studied micro-texture morphologies that are suitable for different workpiece materials. For instance, Ali, Shafahat et al. designed micro-textured tools with rectangular and triangular microgrooves for cutting stainless steel (AISI60), simulated and analyzed the performance of the two types of micro-texture shapes, and found that the rectangular microgroove-textured tools had a better performance [

11]. Tu et al. used laser technology to machine micropits and microgrooves on the rake face of Al

2O

3/TiC ceramic tools. They studied the cutting performances of two types of micro-textured self-lubricating tools on hardened steel and compared them with traditional non-textured ceramic tools. The results indicated that the reduction in the cutting force of the micropit-textured tools was greater than that of the microgroove-textured tools [

12]. Rajurkar, Avadhoot et al. analyzed the performance of two types of micro-textured tools for cutting chromium nickel iron alloy 718 in different cutting conditions. The results indicated that the microchannel-textured tools showed a notable improvement in tool life up to 60% over micro dimple-textured tools at lower cutting speeds; however, almost the same tool life was found with both tools at higher cutting speeds [

13]. Sagar Dhage et al. designed micro-textures in different directions on an insert and used these micro-textured inserts to cut AISI 1045 in dry cutting conditions. From the measured cutting force, it was found that the cutting force of the insert with a micro-texture parallel to the cutting edge was significantly lower than that of the insert with a micro-texture perpendicular to the cutting edge [

14].

Moreover, some scholars have also explored the influence of micro-texture parameters on the cutting performance of tools. Li Kun et al. used hard alloy micro-textured tools to conduct a simulation analysis of the cutting of Al7075-T6 aluminum alloy. The results showed that the parameters of the micro-texture greatly reduced the tool wear. The optimized micro-texture parameters with the best cutting performance were as follows: width, 40 μm; pitch, 80 μm; depth, 20 μm; spacing, 70 μm [

15]. Liu Yayun et al. designed carbide micro-textured tools with different texture parameters and conducted cutting experiments on Al

2O

3. From their analysis, the optimal micro-texture parameters that could achieve the optimal wear resistance and workpiece surface quality were as follows: the width of the micro-texture was 75 μm, the spacing was 100 μm, and the pitch was 75 μm [

16]. V. Sharma et al. designed micro-textured tools and analyzed the influence of the micro-texture parameters on the cutting force when cutting 4340 hardened steels, finally obtaining the optimal parameters of the micro-textured tools [

17]. Through an experiment, Guo et al. analyzed the influence of microgroove parameters, such as the width, depth, and spacing, on the cutting force when cutting TC4 [

18].

The above analysis indicates that, at present, the research on the micro-texture parameters of inserts mainly focuses on cutting aluminum alloy and titanium alloy and that the micro-texture parameters of inserts for nickel-based superalloy have not yet been studied. This paper studied the micro-texture parameters of micro-textured tools for cutting the GH4169 superalloy.

Research on the arrangement of micro-textures has also been reported in some studies. Tong Xin et al. studied the influence of variable-density micro-textured ball-end milling cutters on cutting titanium alloy and used a fuzzy algorithm to optimize the distribution of the ball-end milling cutters, obtaining variable spacings of 200 μm, 150 μm, and 175 μm for the studied micro-textures [

19]. D. Arulkirubakaran et al. simulated the cutting process of Ti-6AL-4V using WC/Co micro-textured tools while using DEFORM with SAE 40 as a semi-solid lubricant. Combined with turning experiments, it was found that the cutting temperature of the micro-textured tool decreased to varying degrees during the cutting process, and this effect was more pronounced when cutting with vertical micro-textured tools [

20]. Wang et al. conducted a simulation cutting of AISI 1045 carbon steel by using micro-textured tools and concluded that compared with non-textured and micro-textured tools, the cooling effect of the lateral micro-texture was more significant, and it exhibited a good chip-breaking performance during the cutting process [

21].

From the above analysis, it can be seen that the current research on the arrangement of micro-textures uses a linear arrangement parallel or perpendicular to the cutting edge, and there is no research on arc-shaped arrangements. The research on these arrangement methods also targets aluminum alloy and titanium alloy workpieces. Research on the micro-texture arrangement of tools for GH4169 has not been conducted yet.

The optimization of micro-texture parameters has also been studied. Based on Oxely’s analysis model, Kishawy and Hossam A. optimized the microstructure parameters and obtained the microstructure parameters when cutting an AISI 1045 steel pipe with ceramic microgroove-textured tools, focusing on the cutting force. In addition, the examination showed no evidence of derivative cutting when using the optimized micro-textured insert, which also proved the efficacy of the proposed model [

22]. Cheng Yaotian et al. simulated and experimentally analyzed the cutting force and depth of the damage under the surface of the workpiece when cutting carbon-fiber-reinforced plastic with microgroove-textured tools. The surface response method was used to optimize the groove parameters, and the microgroove parameters with the lowest cutting force and depth of damage under the surface were obtained [

23]. Li Binbin et al. simulated and analyzed the cutting force of Inconel718 with sinusoidal-groove-textured tools and optimized the micro-texture parameters with the minimum cutting force by combining range analysis and effect analysis [

24]. Yu Yinghua et al. studied the influence of elliptical-opening offset parabolic micro-texture feature parameters on the cutting performance of a tool for cutting Ti6Al4V based on the response surface methodology. Through neural networks and genetic algorithms, the micro-texture parameters were optimized with the main cutting force and cutting temperature as the targets, obtaining a set of optimal parameters, resulting in a reduction of 11.24% and 15.28% in the cutting force and temperature, respectively [

25].

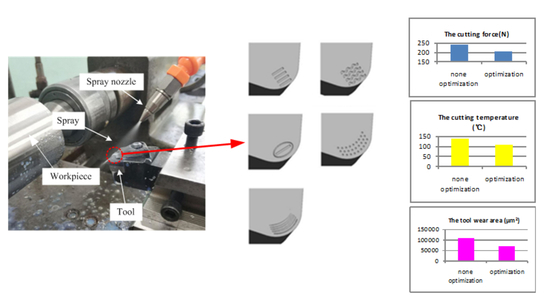

The results of different optimization methods may not necessarily be the same, and current research has mostly focused on single-objective optimization of micro-texture parameters using a single method. This paper considered the comprehensive performance of the studied tools—that is, taking the cutting force, cutting temperature, and tool wear as the targets, and considering the applicability and calculation efficiency of the optimization algorithm—and used two methods to carry out multi-objective optimization of micro-textured tools for cutting GH4169.

Based on the research of micro-textured tools mentioned above, the existing research achievements and further research on micro-textured cutting tools can be summarized as follows:

- (1)

Micro-textures with reasonable morphologies and size parameters on the rake/flank surfaces of the tool can reduce the contact between the tool and the chip in the cutting process. The existence of micro-textures reduces the total contact area between the tool and chip and improves the cutting performance.

- (2)

For the cutting performance of micro-textured tools, combinations of different morphologies and size parameters will have a positive or negative impact on the cutting performance. Generally speaking, reasonable morphologies and parameters of micro-textures can significantly improve the cutting performance of the tool; conversely, they may lead to a decrease in the cutting performance of the tool due to secondary cutting.

- (3)

For different workpiece materials, various micro-texture morphologies and size parameters can be used to achieve a good performance. At present, there is a lot of research on micro-textured tools for titanium, but there is relatively little research on micro-textured tools for nickel-based superalloys. The morphology that is suitable for titanium alloys is not necessarily suitable for aluminum alloys or nickel-based superalloys. For different variations of a single workpiece material, even if they have the same micro-texture morphology but different size parameters, their cutting performance will not be the same. The size parameters of a micro-texture that provide the most significant reduction in the cutting force may not necessarily have the best effect on the cutting temperature reduction or produce a good surface quality of the workpiece.

- (4)

Most scholars have only studied a single morphology of micro-textures or the impact of a single parameter of micro-textures on the cutting performance, rarely mentioning the study on the effect of the interaction effect of the micro-texture parameters on the cutting performance.

Based on the above analysis, in order to improve the process ability and tool life when cutting the nickel-based superalloy GH4169, micro-textured tools were designed to cut GH4169 during spray cooling. This paper explored the cutting performance of micro-textured tools with different morphologies and parameter combinations through experimental and simulation analyses during spray cooling. The response surface method and genetic algorithm were used in the multi-objective optimization of the micro-texture parameters to obtain suitable micro-texture morphologies and size parameters for cutting GH4169, providing the tools with a good, comprehensive performance.