Effect of Vegetable Oil on the Properties of Asphalt Binder Modified with High Density Polyethylene

Abstract

:1. Introduction

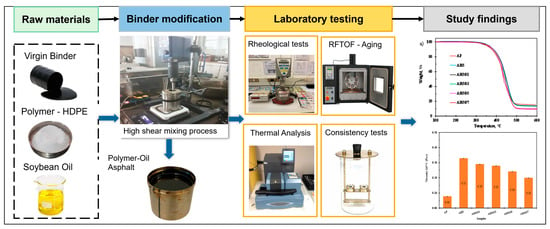

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified Asphalt by Wet Modification Method

2.3. Test Methods

2.3.1. Conventional Physical Tests

2.3.2. Short-Term Aging Test

2.3.3. Thermogravimetric Analysis (TGA)

3. Results and Discussion

3.1. Penetration

3.2. Softening Point

3.3. Thermal Susceptibility Index

3.4. Viscosity

3.5. Ductility

3.6. Effect of Thermal Oxidative Aging on Conventional Properties

3.7. Thermogravimetric Analysis

4. Conclusions

- The addition of HDPE modifier to conventional asphalt improves the viscoelastic behavior of the asphalt and changes its rheological properties. The incorporation of 5 wt.% HDPE as a stand-alone additive reduces the penetration values and increases the softening point, the viscosity, and the processing temperature of the neat asphalt. On the other hand, this composition exhibited the least ductility, brittleness, and fracture before deforming much under a tensile load. The negative effect on the ductility values caused by the addition of HDPE can be mitigated with the addition of the vegetable oil.

- With the addition of vegetable oil, the penetration value of modified asphalt gradually increases and the viscosity decreases, which indicates that the oil makes the modified asphalt softer.

- The ternary blend with a combination of 5 wt.% HDPE and 3 wt.% soybean vegetable oil presented the best results, with low susceptibility to temperature variations, a penetration value close to the neat asphalt (penetration grade 50/70), as well as a low percentage of mass change (0.01%) when subjected to aging.

- Although the analysis conducted in this research provides a promising indication of the performance of HDPE- and vegetable-oil-modified asphalt, a more comprehensive evaluation is recommended with different tests, such as long-term performance, so as to evaluate the effect on storage, rutting, and cracking resistance under various traffic conditions. Further studies should also consider applying recycled HDPE and waste vegetable oil as an alternative recycling method for plastic and oil waste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jafar, J.J. Utilisation of waste plastic in bituminous mix for improved performance of roads. KSCE J. Civ. Eng. 2015, 20, 243–249. [Google Scholar] [CrossRef]

- Kim, H.; Buttlar, W.G. Multi-scale fracture modeling of asphalt composite structures. Compos. Sci. Technol. 2009, 69, 2716–2723. [Google Scholar] [CrossRef]

- Anderson, D.A.; Christensen, D.W.; Dongre, R.; Sharma, M.G.; Antle, C.E. Binder Characterization and Evaluation. 1994. Available online: http://onlinepubs.trb.org/onlinepubs/shrp/SHRP-A-369.pdf (accessed on 1 April 2022).

- Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M. Reuse of deconstructed tires as anti-reflective cracking mat systems in asphalt pavements. Constr. Build. Mater. 2013, 53, 182–189. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Liu, S.; Peng, A.; Wu, J.; Zhou, S.B. Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr. Build. Mater. 2018, 191, 1210–1220. [Google Scholar] [CrossRef]

- Haghshenas, H.F.; Rea, R.; Reinke, G.; Yousefi, A.; Haghshenas, D.F.; Ayar, P. Effect of Recycling Agents on the Resistance of Asphalt Binders to Cracking and Moisture Damage. J. Mater. Civ. Eng. 2021, 33, 04021292. [Google Scholar] [CrossRef]

- Yan, K.; Liu, W.; You, L.; Ou, J.; Zhang, M. Evaluation of waste cooling oil and European Rock Asphalt modified asphalt with laboratory tests and economic cost comparison. J. Clean. Prod. 2021, 310, 127364. [Google Scholar] [CrossRef]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef]

- Du, Z.; Jiang, C.; Yuan, J.; Xiao, F.; Wang, J. Low temperature performance characteristics of polyethylene modified asphalts—A review. Constr. Build. Mater. 2020, 264, 120704. [Google Scholar] [CrossRef]

- Joni, H.H.; A Al-Rubaee, R.H.; A Al-Zerkani, M. Characteristics of asphalt binder modified with waste vegetable oil and waste plastics. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012126. [Google Scholar] [CrossRef]

- Lucena, L.C.D.F.L.; da Silveira, I.V.; da Costa, D.B. Asphalt binders modified with Moringa Oleifera Lam oil. Matéria 2016, 21, 72–82. [Google Scholar] [CrossRef]

- Sun, L.; Xin, X.; Ren, J. Asphalt modification using nano-materials and polymers composite considering high and low temperature performance. Constr. Build. Mater. 2017, 133, 358–366. [Google Scholar] [CrossRef]

- Manoel, G.F. Caracterização Físico-Química e Estudo Reológico de Asfaltos Modificados Pelos Polímeros PEAD, PEBD e PELBD e Contribuição ao Estudo do Envelhecimento do Cimento Asfáltico de Petróleo. Ph.D. Thesis, Universidade Federal De Minas Gerais Escola, Belo Horizonte, Brazil, 2015. [Google Scholar]

- Swamy, A.K.; Rongali, U.D.; Jain, P.K. Effect of HDPEH polymer on viscoelastic properties of SBS modified asphalt. Constr. Build. Mater. 2017, 136, 230–236. [Google Scholar] [CrossRef]

- Attaelmanan, M.; Feng, C.P.; Ai, A.-H. Laboratory evaluation of HMA with high density polyethylene as a modifier. Constr. Build. Mater. 2011, 25, 2764–2770. [Google Scholar] [CrossRef]

- Becker, Y.; Méndez, M.P.; Rodríguez, Y. Polymer Modified Asphalt. Vis. Tecnol. 2001, 9, 40–50. [Google Scholar]

- Nejad, F.M.; Gholami, M.; Naderi, K.; Rahi, M. Evaluation of rutting properties of high density polyethylene modified binders. Mater. Struct. 2014, 48, 3295–3305. [Google Scholar] [CrossRef]

- Abdel-Wahed, T.; Moussa, G.; Abdel-Raheem, A. Investigating the Moisture Susceptibility of Asphalt Mixtures Modified with High-Density Polyethylene. JES. J. Eng. Sci. 2020, 48, 765–782. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Wang, H.; Jiang, H.; Zhang, J.; Yao, Z. Phase behavior and hot storage characteristics of asphalt modified with various polyethylene: Experimental and numerical characterizations. Constr. Build. Mater. 2019, 203, 608–620. [Google Scholar] [CrossRef]

- Kakar, M.R.; Mikhailenko, P.; Piao, Z.; Bueno, M.; Poulikakos, L. Analysis of waste polyethylene (PE) and its by-products in asphalt binder. Constr. Build. Mater. 2021, 280, 122492. [Google Scholar] [CrossRef]

- Ghuzlan, K.A.; Al-Khateeb, G.G.; Qasem, Y. Rheological Properties of Polyethylene-Modified Asphalt Binder. Athens J. Τechnology Eng. 2015, 2, 75–88. [Google Scholar] [CrossRef]

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844. [Google Scholar] [CrossRef]

- Pereira, A.G.; da Silva, R.L.; Vieira, C.D.S. Ligantes asfálticos modificados: Uma análise bibliográfica. Res. Soc. Dev. 2021, 10, e35710414321. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Li, H.; Dong, B.; Wang, W.; Zhao, G.; Guo, P.; Ma, Q. Effect of Waste Engine Oil and Waste Cooking Oil on Performance Improvement of Aged Asphalt. Appl. Sci. 2019, 9, 1767. [Google Scholar] [CrossRef]

- Portugal, A.C.X. Avaliação Reológica de Cimentos Asfálticos de Petróleo Modificados com Óleo de Soja e de Milho. Master’s Thesis, Universidade Federal De Campina Grande Centro, Campina Grande, Brazil, 2016. [Google Scholar]

- Luz, P.M.S.G.; Martins, S.F.; Costa, D.B.; Lucena, L.C. Avaliação das propriedades mecânicas de misturas asfálticas mornas modificadas com adição de óleos vegetais. Transportes 2019, 27, 141–155. [Google Scholar] [CrossRef]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials 1. ASTM: West Conshohocken, PA, USA, 2006; Volume i, pp. 4–7.

- ASTM D036; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus) 1. ASTM: West Conshohocken, PA, USA, 2014. [CrossRef]

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer 1. ASTM: West Conshohocken, PA, USA, 2002; Volume 14, pp. 10–12.

- ASTM D113; Standard Test Method for Ductility of Asphalt Materials 1. ASTM: West Conshohocken, PA, USA, 2015; Volume i, pp. 1–5. [CrossRef]

- Gigante, A.C. Avaliação Da Susceptibilidade Térmica E Do Efeito Das Condições Ambientais No Enrijecimento De Misturas Asfálticas Densas À Luz De Seus Comportamentos Resilientes. Master’s Thesis, Universidade de São Paulo, São Carlos, Brazil, 2007. [Google Scholar]

- ASTM D2872; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test) 1. ASTM: West Conshohocken, PA, USA, 2019; pp. 1–6. [CrossRef]

- Zhang, H. Self-healing property and road performance of asphalt binder and asphalt mixture containing urea-formaldehyde microcapsule. In Eco-Efficient Pavement Construction Materials 2020 Jan 1; Woodhead Publishing: Sawston, MA, USA, 2020; pp. 171–196. [Google Scholar] [CrossRef]

- Gama, D.A.; Júnior, J.M.R.; Melo, T.; Rodrigues, J.K.G. Rheological studies of asphalt modified with elastomeric polymer. Constr. Build. Mater. 2016, 106, 290–295. [Google Scholar] [CrossRef]

- Ge, D.; Yan, K.; You, Z.; Xu, H. Modification mechanism of asphalt binder with waste tire rubber and recycled polyethylene. Constr. Build. Mater. 2016, 126, 66–76. [Google Scholar] [CrossRef]

- Bala, N.; Kamaruddin, I.; Napiah, M.; Danlami, N. Rheological and rutting evaluation of composite nanosilica/polyethylene modified bitumen. IOP Conf. Series Mater. Sci. Eng. 2017, 201, 12012. [Google Scholar] [CrossRef]

- Rasman, M.; Hassan, N.A.; Hainin, M.R.; Jaya, R.P.; Haryati, Y.; Shukry, N.A.M.; Abdullah, M.E.; Kamaruddin, N.H.M. Engineering properties of bitumen modified with bio-oil. MATEC Web Conf. 2018, 250, 02003. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, Y.; Zhao, P. Long-term aging performance study of asphalt with different composition. IOP Conf. Series Earth Environ. Sci. 2021, 631, 012050. [Google Scholar] [CrossRef]

- Fang, C.; Yu, R.; Li, Y.; Zhang, M.; Hu, J.; Zhang, M. Preparation and characterization of an asphalt-modifying agent with waste packaging polyethylene and organic montmorillonite. Polym. Test. 2013, 32, 953–960. [Google Scholar] [CrossRef]

- Gibreil, H.A.; Feng, C.P. Effects of high-density polyethylene and crumb rubber powder as modifiers on properties of hot mix asphalt. Constr. Build. Mater. 2017, 142, 101–108. [Google Scholar] [CrossRef]

- Adesina, P.A.; Dahunsi, B.I. Blended waste utilization in road construction: Physical characteristics of bitumen modified with waste cooking oil and high-density polyethylene. Int. J. Pavement Res. Technol. 2021, 14, 98–104. [Google Scholar] [CrossRef]

- Ibrahim, A.-H.A. Laboratory investigation of aged HDPE-modified asphalt mixes. Int. J. Pavement Res. Technol. 2019, 12, 364–369. [Google Scholar] [CrossRef]

- Prasad, K.V.R. Use of PET (polyethylene teraphtalate) waste in Bituminous Road Construction—A Critical review. Int. J. Emerg. Technol. Eng. 2015, 2, 96–99. [Google Scholar]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Mansourian, A.; Goahri, A.R.; Khosrowshahi, F.K. Performance evaluation of asphalt binder modified with EVA/HDPE/nanoclay based on linear and non-linear viscoelastic behaviors. Constr. Build. Mater. 2019, 208, 554–563. [Google Scholar] [CrossRef]

- Din, I.M.U.; Mir, M.S. Experimental investigation of low viscosity grade binder modified with Fischer Tropsch-Paraffin wax. Int. J. Pavement Res. Technol. 2020, 14, 129–137. [Google Scholar] [CrossRef]

- Huang, X.; Eldouma, I.B. Experimental Study to Determine the Most Preferred Additive for Improving Asphalt Performance Using Polypropylene, Crumb Rubber, and Tafpack Super in Medium and High-Temperature Range. Appl. Sci. 2019, 9, 1567. [Google Scholar] [CrossRef]

- Rosyidi, S.A.P.; Idiajir, B.; Akhir, N.M.; Rahmad, S.; Lestari, N.P.; Widoanindyawati, V.; Al-Sabaeei, A.M.; Milad, A.; Mashaan, N.S.; Yusoff, N.I.M. Physical, Chemical and Thermal Properties of Palm Oil Boiler Ash/Rediset-Modified Asphalt Binder. Sustainability 2022, 14, 3016. [Google Scholar] [CrossRef]

- Wu, S.; Xu, W.; Zhang, F.; Wu, H. Effect of Polyurethane on High- and Low-Temperature Performance of Graphene Oxide-Modified Asphalt and Analysis of the Mechanism Based on Infrared Spectrum. Coatings 2022, 12, 590. [Google Scholar] [CrossRef]

- Fernandes, M.R.S.; Forte, M.M.C.; Leite, L.F.M. Rheological evaluation of polymer-modified asphalt binders. Mater. Res. 2008, 11, 381–386. [Google Scholar] [CrossRef]

- Tauste-Martínez, R.; Navarro, F.M.M.; Sol-Sánchez, M.; Rubio-Gamez, M.C. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 2018, 192, 593–609. [Google Scholar] [CrossRef]

- Zhang, H.; Bai, Y.; Cheng, F. Rheological and self-healing properties of asphalt binder containing microcapsules. Constr. Build. Mater. 2018, 187, 138–148. [Google Scholar] [CrossRef]

- Ruiz, L.V.E. Analysis of Bio-Binders for Paving as a Total Substitute for Asphalt Binder. Master’s Thesis, Universidade de São Paulo, São Paulo, Brazil, 2020. [Google Scholar] [CrossRef]

- Polacco, G.; Cappello, M.; Cuciniello, G.; Filippi, S. Apparent Molecular Weight Distributions in Bituminous Binders. Materials 2022, 15, 4700. [Google Scholar] [CrossRef]

- Sánchez, A.; Maceiras, R.; Cancela, A.; Rodriguez, M. Influence of n-Hexane on in Situ Transesterification of Marine Macroalgae. Energies 2012, 5, 243–257. [Google Scholar] [CrossRef]

- Grando, A.J. Avaliação do óleo Lubrificante Usado ou Contaminado (OLUC) Como Agente Redutor de Viscosidade do Asfalto-borracha. Master’s Thesis, Universidade Federal da Integração Latino-Americana, Foz Do Iguaçu, Brazil, 2022. [Google Scholar]

| Properties | Standard Test | Value | Specifications |

|---|---|---|---|

| Penetration (25 °C, 0.1 mm) | ASTM D5 | 54.0 | 50–70 |

| Softening Point (°C, min) | ASTM D36 | 47.0 | 49–56 |

| Ductility (25 °C, 5 cm/min) | ASTM D113 | >100 | min 100 |

| Density (kg/m3) | D71 & D3289 | 990–1300 | 1010–1060 |

| Flashpoint (°C) | ASTM D92 | >230 | min 230 |

| Solubility (%, mass) | ASTM D2042 | Soluble in most organic solvents | min 99.0 |

| Sample Designation | AP | AH5 | AH5O1 | AH5O3 | AH5O5 | AH5O7 |

|---|---|---|---|---|---|---|

| HDPE, % | 0 | 5 | 5 | 5 | 5 | 5 |

| Soybean oil, % | 0 | 0 | 1 | 3 | 5 | 7 |

| Samples | Temperature, °C | %Residue (25–60 °C) | ||

|---|---|---|---|---|

| di | dmax | df | ||

| AP | 304 | 450 | 511 | 15.42 |

| AH5 | 325 | 465 | 522 | 13.27 |

| AH5O1 | 319 | 455 | 511 | 13.14 |

| AH5O3 | 315 | 457 | 515 | 13.51 |

| AH5O5 | 312 | 433 | 513 | 8.47 |

| AH5O7 | 307 | 429 | 515 | 8.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Langa, E.; Buonocore, G.; Squillace, A.; Muiambo, H. Effect of Vegetable Oil on the Properties of Asphalt Binder Modified with High Density Polyethylene. Polymers 2023, 15, 749. https://doi.org/10.3390/polym15030749

Langa E, Buonocore G, Squillace A, Muiambo H. Effect of Vegetable Oil on the Properties of Asphalt Binder Modified with High Density Polyethylene. Polymers. 2023; 15(3):749. https://doi.org/10.3390/polym15030749

Chicago/Turabian StyleLanga, Elizabeth, Giovanna Buonocore, Antonino Squillace, and Herminio Muiambo. 2023. "Effect of Vegetable Oil on the Properties of Asphalt Binder Modified with High Density Polyethylene" Polymers 15, no. 3: 749. https://doi.org/10.3390/polym15030749