Sustainable Filtering Systems to Reduce Microfiber Emissions from Textiles during Household Laundering

Abstract

:1. Introduction

2. Materials and Methods

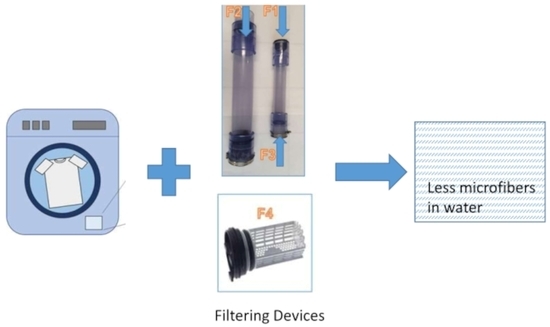

2.1. Tested Filtering Arrangements

2.2. Materials and Pre-Treatments

- is the difference between the mean values of the weight of the filters when a filtering arrangement was applied, mg, and

- is the difference between the mean values of the weight of the filters when no filtering arrangement was applied, mg.

2.3. Permeability Coefficient and Porosity

3. Results and Discussion

3.1. Efficiency of the Filtering Arrangements

3.2. Comparison with Other MFs Filtering Devices

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ritchie, H.; Roser, M. Plastic Pollution. 2018. Available online: https://ourworldindata.org/plastic-pollution (accessed on 1 June 2023).

- Walker, T.R.; Xanthos, D. A call for Canada to move toward zero plastic waste by reducing and recycling single-use plastics. Resour. Conserv. Recycl. 2018, 133, 99–100. [Google Scholar] [CrossRef]

- ECHA. Restriction Report—Proposal, 2019. Available online: https://echa.europa.eu/registry-of-restriction-intentions/-/dislist/details/0b0236e18244cd73 (accessed on 1 July 2022).

- Chen, G.; Li, Y.; Wang, J. Occurrence and ecological impact of microplastics in aquaculture ecosystems. Chemosphere 2021, 274, 129989. [Google Scholar] [CrossRef]

- van Sebille, E.; Wilcox, C.; Lebreton, L.; Maximenko, N.; Hardesty, B.D.; van Franeker, J.A.; Eriksen, M.; Siegel, D.; Galgani, F.; Law, K.L. A global inventory of small floating plastic debris. Environ. Res. Lett. 2015, 10, 124006. [Google Scholar] [CrossRef]

- UNEP; GRID-Arendal. Marine Litter Vital Graphics; United Nations Environment Programme, GRID-Arendal: Nairobi, Kenya; Arendal, Norway, 2016; Available online: http://www.unep.org/regionalseas/marinelitter/publications/docs/anl_oview.pdf (accessed on 1 January 2023).

- Barrett, J.; Chase, Z.; Zhang, J.; Holl, M.M.B.; Willis, K.; Williams, A.; Hardesty, B.D.; Wilcox, C.; Pennino, M.G. Microplastic Pollution in Deep-Sea Sediments from the Great Australian Bight. Front. Mar. Sci. 2020, 7, 808. [Google Scholar] [CrossRef]

- Boucher, J.; Friot, D. Primary Microplastics in the Oceans: A Global Evaluation of Sources; IUCN: Gland, Switzerland, 2017. [Google Scholar] [CrossRef]

- Watt, E.; Picard, M.; Maldonado, B.; Abdelwahab, M.A.; Mielewski, D.F.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Ocean plastics: Environmental implications and potential routes for mitigation—A perspective. RSC Adv. 2021, 11, 21447–21462. [Google Scholar] [CrossRef]

- Collignon, A.; Hecq, J.H.; Glagani, F.; Voisin, P.; Collard, F.; Goffart, A. Neustonic microplastic and zooplankton in the North Western Mediterranean Sea. Mar. Pollut. Bull. 2012, 64, 861–864. [Google Scholar] [CrossRef]

- Fossi, M.C.; Coppola, D.; Baini, M.; Giannetti, M.; Guerranti, C.; Marsili, L.; Panti, C.; de Sabata, E.; Clò, S. Large filter feeding marine organisms as indicators of microplastic in the pelagic environment: The case studies of the Mediterranean basking shark (Cetorhinus maximus) and fin whale (Balaenoptera physalus). Mar. Environ. Res. 2014, 100, 17–24. [Google Scholar] [CrossRef]

- GESAMP. Sources, Fate and Effects of Microplastics in the Marine Environment: A Global Assessment. 2015. Available online: http://ec.europa.eu/environment/marine/good-environmental-status/descriptor-10/pdf/GESAMP_microplasticsfullstudy.pdf (accessed on 22 January 2022).

- Keshavarzifard, M.; Vazirzadeh, A.; Sharifinia, M. Occurrence and characterization of microplastics in white shrimp, Metapenaeus affinis, living in a habitat highly affected by anthropogenic pressures, northwest Persian Gulf. Mar. Pollut. Bull. 2021, 169, 112581. [Google Scholar] [CrossRef]

- Rochman, C.M.; Kurobe, T.; Flores, I.; Teh, S.J. Early warning signs of endocrine disruption in adult fish from the ingestion of polyethylene with and without sorbed chemical pollutants from the marine environment. Sci. Total Environ. 2014, 493, 656–661. [Google Scholar] [CrossRef]

- Jemec, A.; Horvat, P.; Kunej, U.; Bele, M.; Krzan, A. Uptake and effects of microplastic textile fibers on freshwater crustacean Daphnia magna. Environ. Pollut. 2016, 219, 201–209. [Google Scholar] [CrossRef]

- Welden, N.A.C.; Cowie, P.R. Environment and gut morphology influence microplastic retention in langoustine, Nephrops norvegicus. Environ. Pollut. 2016, 214, 859–865. [Google Scholar] [CrossRef]

- Nelms, S.E.; Galloway, T.S.; Godley, B.J.; Jarvis, D.S.; Lindeque, P.K. Investigating microplastic trophic transfer in marine top predators. Environ. Pollut. 2018, 238, 999–1007. [Google Scholar] [CrossRef] [PubMed]

- Rochman, C.M.; Scherer, C.; Alvarez-Muñoz, D.; Brennholt, N.; Bourrain, X.; Buchinger, S.; Fries, E.; Grosbois, C.; Klasmeier, J.; Marti, T.; et al. Plastics and Priority Pollutants: A Multiple Stressor in Aquatic Habitats. Environ. Sci. Technol. 2013, 47, 2439–2440. [Google Scholar] [CrossRef]

- Browne, M.A.; Rochman, C.M.; Browne, M.A.; Halpern, B.S.; Hentschel, B.T.; Hoh, E.; Karapanagioti, H.K.; Rios-Mendoza, L.M.; Takada, H.; Teh, S.; et al. Policy: Classify plastic waste as hazardous. Nature 2013, 494, 169–171. [Google Scholar] [CrossRef]

- Van Cauwenberghe, L.; Janssen, C.R. Microplastics in bivalves cultured for human consumption. Environ. Pollut. 2014, 193, 65–70. [Google Scholar] [CrossRef] [PubMed]

- Rochman, C.M.; Kross, S.M.; Armstrong, J.B.; Bogan, M.T.; Darling, E.S.; Green, S.J.; Smyth, A.R.; Veríssimo, D. Scientific Evidence Supports a Ban on Microbeads. Environ. Sci. Technol. 2015, 49, 10759–10761. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Yang, J.; Wu, W.M.; Zhao, J.; Song, Y.; Gao, L.; Yang, R.; Jiang, L. Biodegradation and Mineralization of Polystyrene by Plastic-Eating Mealworms: Part 2. Role of Gut Microorganisms. Environ. Sci. Technol. 2015, 49, 12087–12093. [Google Scholar] [CrossRef]

- Schymanski, D.; Goldbeck, C.; Humpf, H.U.; Fürst, P. Analysis of microplastics in water by micro-Raman spectroscopy: Release of plastic particles from different packaging into mineral water. Water Res. 2018, 129, 154–162. [Google Scholar] [CrossRef]

- Cox, K.D.; Covernton, G.A.; Davies, H.L.; Dower, J.F.; Juanes, F.; Dudas, S.E. Human Consumption of Microplastics. Environ. Sci. Technol. 2019, 53, 7068–7074. [Google Scholar] [CrossRef]

- Ossmann, B.E. Microplastics in drinking water? Present state of knowledge and open questions. Curr. Opin. Food Sci. 2021, 41, 44–51. [Google Scholar] [CrossRef]

- Rainieri, S.; Barranco, A. Microplastics, a food safety issue? Trends Food Sci. Technol. 2019, 84, 55–57. [Google Scholar] [CrossRef]

- Domenech, J.; Marcos, R. Pathways of human exposure to microplastics and estimation of the total burden. Curr. Opin. Food Sci. 2021, 39, 144–151. [Google Scholar] [CrossRef]

- Li, Q.; Ma, C.; Zhang, Q.; Shi, H. Microplastics in shellfish and implications for food safety. Curr. Opin. Food Sci. 2021, 40, 192–197. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Ita-Nagy, D.; Kahhat, R. Microplastics in fisheries and aquaculture: Implications to food sustainability and safety. Curr. Opin. Green Sustain. Chem. 2021, 29, 100464. [Google Scholar] [CrossRef]

- Prata, J.C.; da Costa, J.P.; Lopes, I.; Andrady, A.L.; Duarte, A.C.; Rocha-Santos, T. A One Health perspective of the impacts of microplastics on animal, human and environmental health. Sci. Total Environ. 2021, 777, 146094. [Google Scholar] [CrossRef]

- Belzagui, F.; Crespi, M.; Álvarez, A.; Gutiérrez-Bouzán, C.; Vilaseca, M. Microplastics’ emissions: Microfibers’ detachment from textile garments. Environ. Pollut. 2019, 248, 1028–1035. [Google Scholar] [CrossRef]

- De Falco, F.; Di Pace, E.; Cocca, M.; Avella, M. The contribution of washing processes of synthetic clothes to microplastic pollution. Sci. Rep. 2019, 9, 6633. [Google Scholar] [CrossRef] [PubMed]

- CoraBall. The Cora Ball. 2019. Available online: https://coraball.com/ (accessed on 20 May 2022).

- Environmental Enhancements. Lint LUV-R, MicroPlastics Lint LUV-R Washing Machine Discharge Filter; Environmental Enhancements: Dartmouth, NS, Canada, 2021; Available online: https://environmentalenhancements.com/store/index.php/products/products-lint-filter (accessed on 22 January 2022).

- Belzagui Elder, F. Microplastics and Microfibers Pollution: Study of Their Environmental Issues and Evaluation of Reduction Alternatives; Universitat Politècnica de Catalunya, Institut d’Investigació Tèxtil i Cooperació Industrial de Terrassa: Barcelona, Spain, 2022; Available online: http://hdl.handle.net/2117/376938 (accessed on 22 January 2022).

- Zhang, X.; Liu, C.; Liu, J.; Zhang, Z.; Gong, Y.; Li, H. Release of microplastics from typical rainwater facilities during aging process. Sci. Total Environ. 2022, 813, 152674. [Google Scholar] [CrossRef] [PubMed]

- Ye, X.; Wang, P.; Wu, Y.; Zhou, Y.; Sheng, Y.; Lao, K. Microplastic acts as a vector for contaminants: The release behavior of dibutyl phthalate from polyvinyl chloride pipe fragments in water phase. Environ. Sci. Pollut. Res. 2020, 27, 42082–42091. [Google Scholar] [CrossRef] [PubMed]

- Pirc, U.; Vidmar, M.; Mozer, A.; Krzan, A. Emissions of microplastic fibers from microfiber fleece during domestic washing. Environ. Sci. Pollut. Res. 2016, 23, 22206–22211. [Google Scholar] [CrossRef]

- Herweyers, L.; Carteny, C.C.; Scheelen, L.; Watts, R.; Du Bois, E. Consumers’ perceptions and attitudes toward products preventing microfiber pollution in aquatic environments as a result of the domestic washing of synthetic clothes. Sustainability 2020, 12, 2244. [Google Scholar] [CrossRef]

- Galvão, R.G.; Almeida, N.; Póvoas, Y.V.; de Azevedo Basto, P.E. Pervious concrete pavement system at polytechnic school of university of pernambuco, Brazil: Product design conception. Electron. J. Geotech. Eng. 2016, 21, 4657–4668. [Google Scholar]

- Belzagui, F.; Gutiérrez-Bouzán, C.; Carrillo-Navarrete, F. Novel Treatment to Immobilize and Use Textiles Microfibers Retained in Polymeric Filters through Their Incorporation in Composite Materials. Polymers 2022, 14, 2971. [Google Scholar] [CrossRef] [PubMed]

- McIlwraith, H.K.; Lin, J.; Erdle, L.M.; Mallos, N.; Diamond, M.L.; Rochman, C.M. Capturing microfibers—Marketed technologies reduce microfiber emissions from washing machines. Mar. Pollut. Bull. 2019, 139, 40–45. [Google Scholar] [CrossRef] [PubMed]

- Napper, I.E.; Barrett, A.C.; Thompson, R.C. The efficiency of devices intended to reduce microfibre release during clothes washing. Sci. Total Environ. 2020, 738, 140412. [Google Scholar] [CrossRef]

- XFiltra. XFiltra, Xeros Technology. 2021. Available online: https://www.xerostech.com/technologies (accessed on 22 January 2022).

- PlanetCare. PlanetCare. 2021. Available online: https://www.planetcare.org/en/ (accessed on 22 January 2022).

| Device | McIlwraith et al., 2019 [42] 1 | Napper et al., 2020 [43] 2 | Our Work | |||||

|---|---|---|---|---|---|---|---|---|

| Retention Efficiency (%) | Retention Efficiency by Weight (%) | |||||||

| By Count | By Weight | By Weight | ||||||

| In-Drum | Washing | 1st | 5th | 10th | 20th | |||

| Cora Ball (No mesh) | 26 | 5 | 31 | F4 | 64 | 76 | 77 | |

| GuppyFriend (50 µm) | - | - | 54 | |||||

| 4th element (50 µm) 3 | - | - | 21 | |||||

| External Filters | Washing | 1st | 5th | 10th | 20th | |||

| Lint LUV-R (150 µm) | 87 | 80 | 29 | F1 | 52 | 58 | 66 | 83 |

| XFiltra (60 µm) | - | - | 78 | F2 | 56 | 63 | 81 | 93 |

| PlanetCare (200 µm) | - | - | 25 | F3 | 86 | 88 | 95 | 99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belzagui, F.; Gutiérrez-Bouzán, C.; Carrillo-Navarrete, F.; López-Grimau, V. Sustainable Filtering Systems to Reduce Microfiber Emissions from Textiles during Household Laundering. Polymers 2023, 15, 3023. https://doi.org/10.3390/polym15143023

Belzagui F, Gutiérrez-Bouzán C, Carrillo-Navarrete F, López-Grimau V. Sustainable Filtering Systems to Reduce Microfiber Emissions from Textiles during Household Laundering. Polymers. 2023; 15(14):3023. https://doi.org/10.3390/polym15143023

Chicago/Turabian StyleBelzagui, Francisco, Carmen Gutiérrez-Bouzán, Fernando Carrillo-Navarrete, and Víctor López-Grimau. 2023. "Sustainable Filtering Systems to Reduce Microfiber Emissions from Textiles during Household Laundering" Polymers 15, no. 14: 3023. https://doi.org/10.3390/polym15143023