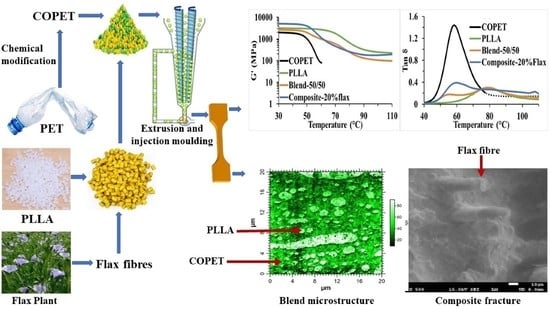

Eco-Friendly Blends of Recycled PET Copolymers with PLLA and Their Composites with Chopped Flax Fibres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blend and Composite Processing

2.3. Characterisation Techniques

2.3.1. Differential Scanning Calorimetry (DSC)

2.3.2. Polarized Light Optical Microscopy

2.3.3. Scanning Electron Microscopy (SEM)

2.3.4. Atomic Force Microscopy (AFM)

2.3.5. Dynamic Mechanical Analyses (DMA)

2.3.6. Nano-Indentation

2.3.7. Tensile Tests

3. Results and Discussion

3.1. Thermal Properties by DSC

3.2. Result of Polarized Light Optical Microscopy

3.3. Result of Scanning Electron Microscopy (SEM)

3.4. Result of Atomic Force Microscopy (AFM)

3.5. Thermomechanical Properties (DMA Analyses)

3.6. Result of Nano-Indentation Tests

3.7. Result of the Tensile Tests

3.8. Sustainability Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bassi, S.A.; Tonini, D.; Saveyn, H.; Astrup, T.F. Environmental and Socioeconomic Impacts of Poly(ethylene terephthalate) (PET) Packaging Management Strategies in the EU. Environ. Sci. Technol. 2022, 56, 501–511. [Google Scholar] [CrossRef] [PubMed]

- Alaerts, L.; Augustinus, M.; Van Acker, K. Impact of bio-based plastics on current recycling of plastics. Sustainability 2018, 10, 1487. [Google Scholar] [CrossRef]

- Torres-Huerta, A.M.; Palma-Ramírez, D.; Domínguez-Crespo, M.A.; Del Angel-López, D.; De La Fuente, D. Comparative assessment of miscibility and degradability on PET/PLA and PET/chitosan blends. Eur. Polym. J. 2014, 61, 285–299. [Google Scholar] [CrossRef]

- Kuete, M.A.; Van Velthem, P.; Ballout, W.; Nysten, B.; Devaux, J.; Ndikontar, M.K.; Pardoen, T.; Bailly, C. Integrated Approach to Eco-Friendly Thermoplastic Composites Based on Chemically Recycled PET Co-Polymers Reinforced with Treated Banana Fibres. Polymers 2022, 14, 4791. [Google Scholar] [CrossRef]

- Tsochatzis, E.D.; Lopes, J.A.; Corredig, M. Chemical testing of mechanically recycled polyethylene terephthalate for food packaging in the European Union. Resour. Conserv. Recycl. 2022, 179, 106096. [Google Scholar] [CrossRef]

- Farahat, M.S.; Abdel-Azim, A.A.; Abdel-Raowf, M.E. Modified unsaturated polyester resins synthesized from poly (ethylene terephthalate) waste, 1 Synthesis and curing characteristics. Macromol. Mater. Eng. 2000, 283, 1–6. [Google Scholar] [CrossRef]

- Webb, H.K.; Arnott, J.; Crawford, R.J.; Ivanova, E.P. Plastic degradation and its environmental implications with special reference to poly(ethylene terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef]

- McLauchlin, A.R.; Ghita, O.R. Studies on the thermal and mechanical behavior of PLA-PET blends. J. Appl. Polym. Sci. 2016, 133, 44147. [Google Scholar] [CrossRef]

- Bohre, A.; Jadhao, P.R.; Tripathi, K.; Pant, K.K.; Saha, B. Chemical Recycling Processes of Waste Polyethylene Terephthalate Using Solid Catalysts. ChemSusChem 2023, e202300142. [Google Scholar] [CrossRef]

- Ghosal, K.; Nayak, C. Recent advances in chemical recycling of polyethylene terephthalate waste into value added products for sustainable coating solutions-hope vs. hype. Mater. Adv. 2022, 3, 1974–1992. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Baochai, L.; Bakar, A.A.; Mohamad, Z. An overview of the recent advances in flame retarded poly(lactic acid). Polym. Adv. Technol. 2023, 34, 1435–1450. [Google Scholar] [CrossRef]

- Zhai, S.; Liu, Q.; Zhao, Y.; Sun, H.; Yang, B.; Weng, Y. A review: Research progress in modification of poly (lactic acid) by lignin and cellulose. Polymers 2021, 13, 776. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.; Liu, L.; Liu, Y.; Leng, J. The compatibility of polylactic acid and polybutylene succinate blends by molecular and mesoscopic dynamics. Int. J. Smart Nano Mater. 2020, 11, 24–37. [Google Scholar] [CrossRef]

- Auras, R.A.; Harte, B.; Selke, S.; Hernandez, R. Mechanical, physical, and barrier properties of poly(lactide) films. J. Plast. Film Sheeting 2003, 19, 123–135. [Google Scholar] [CrossRef]

- Yu, W.; Wang, X.; Ferraris, E.; Zhang, J. Melt crystallization of PLA/Talc in fused filament fabrication. Mater. Des. 2019, 182, 108013. [Google Scholar] [CrossRef]

- Nutenki, R.; Van Velthem, P.; Kuete, M.; Lezaak, M.; Destoop, V.; Ballout, W.; Pardoen, T.; Bailly, C. Bio-Sourced Poly l-Lactide-Flax Composites with Close to Maximum Stiffness at Low Fiber Content through Two-Stage Annealing. Macromol. Mater. Eng. 2021, 306, 2100327. [Google Scholar] [CrossRef]

- Yu, L.; Dean, K.; Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Stein, G.E.; Laws, T.S.; Verduzco, R. Tailoring the Attraction of Polymers toward Surfaces. Macromolecules 2019, 52, 4787–4802. [Google Scholar] [CrossRef]

- Venetsanos, F.; Anogiannakis, S.D.; Theodorou, D.N. Mixing Thermodynamics and Flory-Huggins Interaction Parameter of Polyethylene Oxide/Polyethylene Oligomeric Blends from Kirkwood-Buff Theory and Molecular Simulations. Macromolecules 2022, 55, 4852–4862. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design, 4th ed.; Elsevier Ltd.: Oxford, UK, 2015; Volume 7. [Google Scholar]

- NatureWorks. IngeoTM Biopolymer 2500HP Technical Data Sheet. NatureWorks 2020, 1–5, [Online]. Available online: https://www.natureworksllc.com/~/media/Files/NatureWorks/Technical-Documents/Technical-Data-Sheets/TechnicalDataSheet_2500HP_extrusion_pdf.pdf?la=en (accessed on 10 May 2020).

- Majumdar, A.; Shukla, S.; Singh, A.A.; Arora, S. Resources, Conservation & Recycling Circular fashion: Properties of fabrics made from mechanically recycled poly-ethylene terephthalate (PET) bottles. Resour. Conserv. Recycl. 2020, 161, 104915. [Google Scholar] [CrossRef]

- Bijarimi, M.; Ahmad, S.; Rasid, R.; Khushairi, M.A.; Zakir, M. Poly(lactic acid)/Poly(ethylene glycol) blends: Mechanical, thermal and morphological properties. In AIP Conference Proceedings; AIP Publishing: New York, NY, USA, 2016; Volume 1727, p. 020002. [Google Scholar] [CrossRef]

- Dokukin, M.E.; Sokolov, I. Quantitative Mapping of the Elastic Modulus of Soft Materials with HarmoniX and PeakForce QNM AFM Modes. Langmuir 2012, 28, 16060–16071. [Google Scholar] [CrossRef] [PubMed]

- Wongwiwattana, P.; Thomas, N.L. Co-continuous phase prediction in poly(lactic acid) /poly(caprolactone) blends from melt viscosity measurements. Polym. Technol. Mater. 2021, 60, 1393–1410. [Google Scholar] [CrossRef]

- Chen, J.; Rong, C.; Lin, T.; Chen, Y.; Wu, J.; You, J.; Wang, H.; Li, Y. Stable Co-Continuous PLA/PBAT Blends Compatibilized by Interfacial Stereocomplex Crystallites: Toward Full Biodegradable Polymer Blends with Simultaneously Enhanced Mechanical Properties and Crystallization Rates. Macromolecules 2021, 54, 2852–2861. [Google Scholar] [CrossRef]

- Tarani, E.; Črešnar, K.P.; Zemljič, L.F.; Chrissafis, K.; Papageorgiou, G.Z.; Lambropoulou, D.; Zamboulis, A.; Bikiaris, D.N.; Terzopoulou, Z. Cold crystallization kinetics and thermal degradation of pla composites with metal oxide nanofillers. Appl. Sci. 2021, 11, 3004. [Google Scholar] [CrossRef]

- Ageyeva, T.; Kovács, J.G.; Tábi, T. Comparison of the efficiency of the most effective heterogeneous nucleating agents for Poly(lactic acid). J. Therm. Anal. Calorim. 2022, 147, 8199–8211. [Google Scholar] [CrossRef]

- Zhou, Y.; He, L.; Gong, W. Effects of zinc acetate and cucurbit[6]uril on PP composites: Crystallization behavior, foaming performance and mechanical properties. E-Polymers 2018, 18, 491–499. [Google Scholar] [CrossRef]

- Wu, J.; Mai, Y.-W.; Yee, A.F. Fracture toughness and fracture mechanisms of polybutylene-terephthalate/polycarbonate/ impact-modifier blends—Part III Fracture toughness and mechanisms of PBT/PC blends without impact modifiers. J. Mater. Sci. 1994, 29, 4510–4522. [Google Scholar] [CrossRef]

- You, X.; Snowdon, M.R.; Misra, M.; Mohanty, A.K. Biobased Poly(ethylene terephthalate)/Poly(lactic acid) Blends Tailored with Epoxide Compatibilizers. ACS Omega 2018, 3, 11759–11769. [Google Scholar] [CrossRef] [PubMed]

- Bourmaud, A.; Pimbert, S. Investigations on mechanical properties of poly(propylene) and poly(lactic acid) reinforced by miscanthus fibers. Compos. Part A 2008, 39, 1444–1454. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.-B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-mechanical properties of PLA/short flax fiber biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.; Shi, J.; Ye, H.; Zhou, Q. Distinctive Tensile Properties of the Blends of Poly(l-lactic acid) (PLLA) and Poly(butylene succinate) (PBS). J. Polym. Environ. 2018, 26, 1737–1744. [Google Scholar] [CrossRef]

- Voleppe, Q.; Ballout, W.; Van Velthem, P.; Bailly, C.; Pardoen, T. Enhanced fracture resistance of thermoset/thermoplastic interfaces through crack trapping in a morphology gradient. Polymer 2021, 218, 123497. [Google Scholar] [CrossRef]

- Rodríguez, M.; Molina-Aldareguía, J.; González, C.; Llorca, J. Determination of the mechanical properties of amorphous materials through instrumented nanoindentation. Acta Mater. 2012, 60, 3953–3964. [Google Scholar] [CrossRef]

- Pardoen, T.; Klavzer, N.; Gayot, S.; Van Loock, F.; Chevalier, J.; Morelle, X.; Destoop, V.; Lani, F.; Camanho, P.; Brassart, L.; et al. Nanomechanics serving polymer-based composite research. Comptes Rendus Phys. 2021, 22, 331–352. [Google Scholar] [CrossRef]

- Available online: https://www.ansys.com/products/materials/granta-edupack (accessed on 28 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuété, M.A.; Van Velthem, P.; Ballout, W.; Klavzer, N.; Nysten, B.; Ndikontar, M.K.; Pardoen, T.; Bailly, C. Eco-Friendly Blends of Recycled PET Copolymers with PLLA and Their Composites with Chopped Flax Fibres. Polymers 2023, 15, 3004. https://doi.org/10.3390/polym15143004

Kuété MA, Van Velthem P, Ballout W, Klavzer N, Nysten B, Ndikontar MK, Pardoen T, Bailly C. Eco-Friendly Blends of Recycled PET Copolymers with PLLA and Their Composites with Chopped Flax Fibres. Polymers. 2023; 15(14):3004. https://doi.org/10.3390/polym15143004

Chicago/Turabian StyleKuété, Martial Aimé, Pascal Van Velthem, Wael Ballout, Nathan Klavzer, Bernard Nysten, Maurice Kor Ndikontar, Thomas Pardoen, and Christian Bailly. 2023. "Eco-Friendly Blends of Recycled PET Copolymers with PLLA and Their Composites with Chopped Flax Fibres" Polymers 15, no. 14: 3004. https://doi.org/10.3390/polym15143004