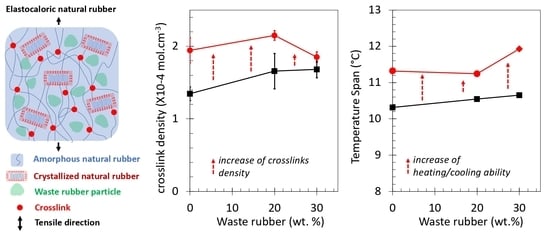

Elastocaloric Waste/Natural Rubber Materials with Various Crosslink Densities

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials and Processing

2.2. Swelling

2.3. Slow Strain Rate Uniaxial Tensile Stretching (UTS)

2.4. High Strain Rate In-Situ Infrared Thermography (In-Situ IR)

3. Results and Discussion

3.1. Tensile Behavior during Slow Strain Rate Single and Cyclic Loading

3.2. Elastocaloric Behavior during High Strain Rate Single and Cyclic Loading

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ikeda, Y.; Junkong, P.; Ohashi, T.; Phakkeeree, T.; Sakaki, Y.; Tohsan, A.; Kohjiya, S.; Cornish, K. Strain-induced crystallization behaviour of natural rubbers from guayule and rubber dandelion revealed by simultaneous time-resolved WAXD/tensile measurements: Indispensable function for sustainable resources. RSC Adv. 2016, 6, 95601–95610. [Google Scholar] [CrossRef]

- Tanaka, Y.; Tarachiwin, L. Recent advances in structural characterization of natural rubber. Rubber Chem. Technol. 2009, 82, 283–314. [Google Scholar] [CrossRef]

- Hagen, R.; Salmén, L.; Stenberg, B. Effects of the type of crosslink on viscoelastic properties of natural rubber. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 1997–2006. [Google Scholar] [CrossRef]

- Rubber, S.N. Natural rubber and reclaimed Rubber composites–A Systematic Review. Polymer 2016, 2, 1–19. [Google Scholar]

- Yamano, M.; Yamamoto, Y.; Saito, T.; Kawahara, S. Preparation and characterization of vulcanized natural rubber with high stereoregularity. Polymer 2021, 235, 124271. [Google Scholar] [CrossRef]

- Mars, W.V.; Fatemi, A. Factors that affect the fatigue life of rubber: A literature survey. Rubber Chem. Technol. 2004, 77, 391–412. [Google Scholar] [CrossRef]

- Bokobza, L. Natural rubber nanocomposites: A review. Nanomaterials 2018, 9, 12. [Google Scholar] [CrossRef] [Green Version]

- Sebald, G.; Komiya, A.; Jay, J.; Coativy, G.; Lebrun, L. Regenerative cooling using elastocaloric rubber: Analytical model and experiments. J. Appl. Phys. 2020, 127, 094903. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Q.; Li, C.; Fu, Y.; Zhang, H.; Ye, Z.; Zhou, X.; Li, Q.; Wang, T.; Wang, S.; et al. Solid-state cooling by elastocaloric polymer with uniform chain-lengths. Nat. Commun. 2022, 13, 9. [Google Scholar] [CrossRef]

- Xie, Z.; Sebald, G.; Guyomar, D. Comparison of elastocaloric effect of natural rubber with other caloric effects on different-scale cooling application cases. Appl. Therm. Eng. 2017, 111, 914–926. [Google Scholar] [CrossRef]

- Xie, Z.; Sebald, G.; Guyomar, D. Elastocaloric effect dependence on pre-elongation in natural rubber. Appl. Phys. Lett. 2015, 107, 081905. [Google Scholar] [CrossRef]

- Harbour, R.J.; Fatemi, A.; Mars, W.V. Fatigue life analysis and predictions for NR and SBR under variable amplitude and multiaxial loading conditions. Int. J. Fatigue 2008, 30, 1231–1247. [Google Scholar] [CrossRef]

- Cadwell, S.M.; Merrill, R.A.; Sloman, C.M.; Yost, F.L. Dynamic Fatigue Life of Rubber. Ind. Eng. Chem. Anal. Ed. 2002, 12, 19–23. [Google Scholar] [CrossRef]

- Saintier, N.; Cailletaud, G.; Piques, R. Multiaxial fatigue life prediction for a natural rubber. Int. J. Fatigue 2006, 28, 530–539. [Google Scholar] [CrossRef] [Green Version]

- Ruellan, B.; Le Cam, J.-B.; Jeanneau, I.; Canévet, F.; Mortier, F.; Robin, E. Fatigue of natural rubber under different temperatures. Int. J. Fatigue 2019, 124, 544–557. [Google Scholar] [CrossRef]

- Role of Strain-Induced Crystallization on Fatigue Properties of Natural Rubber after Realistic Aerobic Ageing; CRC Press: Boca Raton, FL, USA, 2017; pp. 65–69. [CrossRef]

- Sun, S.; Lu, Y.; Hsiao, B.S.; Wang, D.; Zhang, L. Comprehensive study on temperature-induced crystallisation and strain-induced crystallisation behaviours of natural rubber/isoprene rubber blends. Plast. Rubber Compos. 2017, 46, 290–300. [Google Scholar] [CrossRef]

- Wunde, M.; Klüppel, M. Influence of phase morphology and filler distribution in NR/BR and NR/SBR blends on fracture mechanical properties. Rubber Chem. Technol. 2016, 89, 588–607. [Google Scholar] [CrossRef]

- Ismail, H.; Leong, H. Curing characteristics and mechanical properties of natural rubber/chloroprene rubber and epoxidized natural rubber/chloroprene rubber blends. Polym. Test. 2001, 20, 509–516. [Google Scholar] [CrossRef]

- Poh, B.T.; Khok, G.K. Tensile property of epoxidized natural rubber/natural rubber blends. Polym.-Plast. Technol. Eng. 2007, 39, 151–161. [Google Scholar] [CrossRef]

- Candau, N.; Fernandes, J.P.C.; Vasmer, E.; Maspoch, M.L. Cellulose nanocrystals as nucleating agents for the strain induced crystallization in natural rubber. Soft Matter 2022, 18, 8663–8674. [Google Scholar] [CrossRef]

- Bokobza, L.; Rapoport, O. Reinforcement of natural rubber. J. Appl. Polym. Sci. 2002, 85, 2301–2316. [Google Scholar] [CrossRef]

- Trabelsi, S.; Albouy, P.-A.; Rault, J. Effective Local Deformation in Stretched Filled Rubber. Macromolecules 2003, 36, 9093–9099. [Google Scholar] [CrossRef]

- Chenal, J.-M.; Gauthier, C.; Chazeau, L.; Guy, L.; Bomal, Y. Parameters governing strain induced crystallization in filled natural rubber. Polymer 2007, 48, 6893–6901. [Google Scholar] [CrossRef] [Green Version]

- Effects of Graphene Oxide on the Strain-Induced Crystallization and Mechanical Properties of Natural Rubber Crosslinked by Different Vulcanization Systems—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0032386118306736 (accessed on 15 January 2023).

- Xie, Z.T.; Luo, M.C.; Huang, C.; Wei, L.Y.; Liu, Y.H.; Fu, X.; Huang, G.; Wu, J. New insights into thermodynamic description of strain-induced crystallization of peroxide cross-linked natural rubber filled with clay by tube model. Polymer 2011, 52, 3234–3242. [Google Scholar] [CrossRef]

- Comparison Properties of Natural Rubber/Virgin Acrylonitrile–Butadiene Rubber and Natural Rubber/Recycled Acrylonitrile–Butadiene Rubber Blends|SpringerLink. Available online: https://link.springer.com/article/10.1007/s13726-015-0310-y (accessed on 12 January 2023).

- Compounding, Mechanical and Morphological Properties of Carbon-Black-Filled Natural Rubber/Recycled Ethylene-propylene-diene-monomer (NR/R-EPDM) Blends|Semantic Scholar. Available online: https://www.semanticscholar.org/paper/Compounding%2C-mechanical-and-morphological-of-blends-Nabil-Ismail/e0e2dcffc9f67043e73139a77b5a3cb7b30c1619 (accessed on 12 January 2023).

- Salleh, S.; Ahmad, M.; Ismail, H. Properties of Natural Rubber/Recycled Chloroprene Rubber Blend: Effects of Blend Ratio and Matrix. Procedia Chem. 2016, 19, 346–350. [Google Scholar] [CrossRef] [Green Version]

- Mathew, G.; Singh, R.; Nair, N.; Thomas, S. Recycling of natural rubber latex waste and its interaction in epoxidised natural rubber. Polymer 2001, 42, 2137–2165. [Google Scholar] [CrossRef]

- Candau, N.; Laghmach, R.; Chazeau, L.; Chenal, J.-M.; Gauthier, C.; Biben, T.; Munch, E. Strain-Induced Crystallization of Natural Rubber and Cross-Link Densities Heterogeneities. Macromolecules 2014, 47, 5815–5824. [Google Scholar] [CrossRef]

- Candau, N.; Vives, E.; Fernandez, A.I.; Oguz, O.; Corvec, G.; Federico, C.E.; Fernandes, J.P.C.; Stoclet, G.; Maspoch, M.L. Observation of heterogeneities in elastocaloric natural/wastes rubber composites. Express Polym. Lett. 2022, 16, 1331–1347. [Google Scholar] [CrossRef]

- Candau, N.; Vives, E.; Fernández, A.I.; Maspoch, M.L. Elastocaloric effect in vulcanized natural rubber and natural/wastes rubber blends. Polymer 2021, 236, 124309. [Google Scholar] [CrossRef]

- Candau, N.; Oguz, O.; Federico, C.E.; Stoclet, G.; Tahon, J.-F.; Maspoch, M.L. Strain induced crystallization in vulcanized natural rubber containing ground tire rubber particles with reinforcement and nucleation abilities. Polym. Test. 2021, 101, 107313. [Google Scholar] [CrossRef]

- Candau, N.; Oguz, O.; Albiter, N.L.; Förster, G.; Maspoch, M.L. Poly (Lactic Acid) (PLA)/Ground Tire Rubber (GTR) Blends Using Peroxide Vulcanization. Polymers 2021, 13, 1496. [Google Scholar] [CrossRef] [PubMed]

- Lorenz, O.; Parks, C.R. The crosslinking efficiency of some vulcanizing agents in natural rubber. J. Polym. Sci. 1961, 50, 299–312. [Google Scholar] [CrossRef]

- Kruželák, J.; Sýkora, R.; Hudec, I. Peroxide vulcanization of natural rubber. Part I: Effect of temperature and peroxide concentration. J. Polym. Eng. 2014, 34, 617–624. [Google Scholar] [CrossRef]

- Kruželák, J.; Sýkora, R.; Hudec, I. Vulcanization of rubber compounds with peroxide curing systems. Rubber Chem. Technol. 2017, 90, 60–88. [Google Scholar] [CrossRef]

- Kruželák, J.; Sýkora, R.; Hudec, I. Peroxide vulcanization of natural rubber. Part II: Effect of peroxides and co-agents. J. Polym. Eng. 2014, 35, 21–29. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical mechanics of cross-linked polymer networks II. Swelling. J. Chem. Phys. 1943, 11, 521–526. [Google Scholar] [CrossRef]

- Sheehan, C.J.; Bisio, A.L. Polymer/Solvent Interaction Parameters. Rubber Chem. Technol. 1966, 39, 149–192. [Google Scholar] [CrossRef]

- Kraus, G. Swelling of filler-reinforced vulcanizates. J. Appl. Polym. Sci. 1963, 7, 861–871. [Google Scholar] [CrossRef]

- Boyce, M.C.; Arruda, E.M. Constitutive Models of Rubber Elasticity: A Review. Rubber Chem. Technol. 2000, 73, 504–523. [Google Scholar] [CrossRef]

- Ikeda, Y.; Yasuda, Y.; Hijikata, K.; Tosaka, M.; Kohjiya, S. Comparative Study on Strain-Induced Crystallization Behavior of Peroxide Cross-Linked and Sulfur Cross-Linked Natural Rubber. Macromolecules 2008, 41, 5876–5884. [Google Scholar] [CrossRef]

- Treloar, L.R.G. The Physics of Rubber Elasticity; Oxford University Press: New York, NY, USA, 1975. [Google Scholar]

- Vieyres, A.; Pérez-Aparicio, R.; Albouy, P.-A.; Sanseau, O.; Saalwächter, K.; Long, D.R.; Sotta, P. Sulfur-Cured Natural Rubber Elastomer Networks: Correlating Cross-Link Density, Chain Orientation, and Mechanical Response by Combined Techniques. Macromolecules 2013, 46, 889–899. [Google Scholar] [CrossRef]

- Candau, N. Compréhension des Mécanismes de Cristallisation sous Tension des Elastomères en Conditions Quasi-Statiques et Dynamiques. Ph.D. Thesis, Lyon, INSA, Villeurbanne, France, 2014. Available online: https://www.theses.fr/2014ISAL0057 (accessed on 21 February 2023).

- The Science and Technology of Rubber, 4th ed.; Elsevier: Waltham, MA, USA, 2013; Available online: https://www.elsevier.com/books/the-science-and-technology-of-rubber/mark/978-0-12-394584-6 (accessed on 21 February 2023).

- Mullins, L. Softening of Rubber by Deformation. Rubber Chem. Technol. 1969, 42, 339–362. [Google Scholar] [CrossRef]

- Plagge, J.; Klüppel, M. Determining strain-induced crystallization of natural rubber composites by combined thermography and stress-strain measurements. Polym. Test. 2019, 66, 87–93. [Google Scholar] [CrossRef]

| Material Code | Mat. Thickness (mm) | GTR (wt.%) | DCP (wt.%) ** |

|---|---|---|---|

| NR1 | 2.57 (+/−0.04) | 0 | 1.5 |

| NR2 | 1.21 (+/−0.05) | 0 | 1.5 |

| NR3 | 1.03 (+/−0.03) | 0 | 1.5 |

| NR4 | 0.75 (+/−0.03) | 0 | 1.5 |

| NR5 * | 0.75 (+/−0.03) | 0 | 1.5 |

| NR(1.5) | 0.67 (+/−0.03) | 0 | 1.5 |

| NR(2) | 0.69 (+/−0.03) | 0 | 2 |

| NR/GTR20(1.5) | 0.62 (+/−0.04) | 20 | 1.5 |

| NR/GTR20(2) | 0.64 (+/−0.02) | 20 | 2 |

| NR/GTR30(1.5) | 0.62 (+/−0.02) | 30 | 1.5 |

| NR/GTR30(2) | 0.63 (+/−0.02) | 30 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candau, N.; Zimny, A.; Vives, E.; Maspoch, M.L. Elastocaloric Waste/Natural Rubber Materials with Various Crosslink Densities. Polymers 2023, 15, 2566. https://doi.org/10.3390/polym15112566

Candau N, Zimny A, Vives E, Maspoch ML. Elastocaloric Waste/Natural Rubber Materials with Various Crosslink Densities. Polymers. 2023; 15(11):2566. https://doi.org/10.3390/polym15112566

Chicago/Turabian StyleCandau, Nicolas, Adele Zimny, Eduard Vives, and Maria Lluïsa Maspoch. 2023. "Elastocaloric Waste/Natural Rubber Materials with Various Crosslink Densities" Polymers 15, no. 11: 2566. https://doi.org/10.3390/polym15112566