Castor Oil-Based Polyurethane/S2 Glass/Aramid Hybrid Composites Manufactured by Vacuum Infusion

Abstract

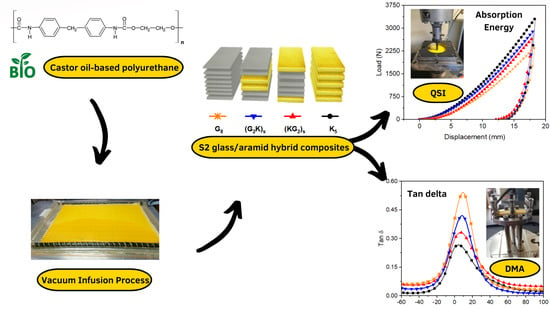

:1. Introduction

2. Materials and Methods

2.1. Materials and Laminate Manufacturing

2.2. Laminate Characterization

3. Results and Discussion

3.1. General Characterization

3.2. Mechanical Properties of the Laminates

3.3. Laminate Viscoelastic Response

3.4. QSI Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- da Silva, A.A.X.; Scazzosi, R.; Manes, A.; Amico, S.C. High-Velocity Impact Behavior of Aramid/S2-Glass Interply Hybrid Laminates. Appl. Compos. Mater. 2021, 28, 1899–1917. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Souza, S.D.B.; Botelho, E.C.; Amico, S.C. Carbon Fiber-Reinforced Epoxy Filament-Wound Composite Laminates Exposed to Hygrothermal Conditioning. J. Mater. Sci. 2016, 51, 4697–4708. [Google Scholar] [CrossRef] [Green Version]

- Parnas, R.S. Liquid Composite Molding; Carl Hanser Verlag: Munich, Germany, 2000. [Google Scholar] [CrossRef]

- Khodadadi, A.; Liaghat, G.; Bahramian, A.R.; Ahmadi, H.; Anani, Y.; Asemani, S.; Razmkhah, O. High Velocity Impact Behavior of Kevlar/Rubber and Kevlar/Epoxy Composites: A Comparative Study. Compos. Struct. 2019, 216, 159–167. [Google Scholar] [CrossRef] [Green Version]

- da Silva, A.A.X.; Souza, J.A.; Manes, A.; Amico, S.C. In-Plane Permeability and Mechanical Properties of R-Glass/Aramid Hybrid Composites. J. Mater. Eng. Perform. 2020, 29, 4484–4492. [Google Scholar] [CrossRef]

- Huang, J.; Tan, V.B.C.; Chew, E.; Chan, K.J.; Tay, T.E.; Guo, L.; Liu, J.L. A New Partially-Infused Fiber Reinforced Thermoplastic Composite for Improving Impact Resistance. Int. J. Impact Eng. 2022, 168, 104293. [Google Scholar] [CrossRef]

- Rana, S.; Fangueiro, R. Fibrous and Textile Materials for Composite Applications; Rana, S., Fangueiro, R., Eds.; Springer International Publishing: Guimarães, Portugal, 2016; ISBN 9789811002328. [Google Scholar]

- Engels, H.W.; Pirkl, H.G.; Albers, R.; Albach, R.W.; Krause, J.; Hoffmann, A.; Casselmann, H.; Dormish, J. Polyurethanes: Versatile Materials and Sustainable Problem Solvers for Today’s Challenges. Angew. Chem. Int. Ed. 2013, 52, 9422–9441. [Google Scholar] [CrossRef]

- Echeverria-Altuna, O.; Ollo, O.; Calvo-Correas, T.; Harismendy, I.; Eceiza, A. Effect of the Catalyst System on the Reactivity of a Polyurethane Resin System for RTM Manufacturing of Structural Composites. Express Polym. Lett. 2022, 16, 234–247. [Google Scholar] [CrossRef]

- Agnol, L.D.; Dias, F.T.G.; Nicoletti, N.F.; Marinowic, D.; Moura e Silva, S.; Marcos-Fernandez, A.; Falavigna, A.; Bianchi, O. Polyurethane Tissue Adhesives for Annulus Fibrosus Repair: Mechanical Restoration and Cytotoxicity. J. Biomater. Appl. 2019, 34, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Favero, D.; Marcon, V.; Agnol, L.D.; Gómez, C.M.; Cros, A.; Garro, N.; Sanchis, M.J.; Carsí, M.; Figueroa, C.A.; Bianchi, O. Effect of Chain Extenders on the Hydrolytic Degradation of Soybean Polyurethane. J. Appl. Polym. Sci. 2022, 139, e52623. [Google Scholar] [CrossRef]

- Chakraborty, I.; Chatterjee, K. Polymers and Composites Derived from Castor Oil as Sustainable Materials and Degradable Biomaterials: Current Status and Emerging Trends. Biomacromolecules 2020, 21, 4639–4662. [Google Scholar] [CrossRef]

- Acik, G. Synthesis of Soybean Oil Biomass Main Chain Poly(Acrylic Acid)-Poly(ε-Caprolactone) Based Heterograft Copolymer by Simultaneous Photo-Induced Metal-Free ATRP and Ring-Opening Polymerizations. J. Polym. Environ. 2022. [Google Scholar] [CrossRef]

- Huang, J.; Xiong, Y.; Zhou, X.; Yang, Z.; Yuan, T. A Novel Polyfunctional Polyurethane Acrylate Prepolymer Derived from Bio-Based Polyols for UV-Curable Coatings Applications. Polym. Test. 2022, 106, 107439. [Google Scholar] [CrossRef]

- Cruz, J.A.; Amico, S.C.; Bianchi, O. Effect of the Aramid Pulp on the Physicochemical, Viscoelastic Properties and Rheokinetics of Polyurethanes. 2022, pp. 1–19. Available online: https://doi.org/10.21203/rs.3.rs-1831592/v1 (accessed on 29 October 2022).

- McIlhagger, A.; Archer, E.; McIlhagger, R. Manufacturing Processes for Composite Materials and Components for Aerospace Applications. In Polymer Composites in the Aerospace Industry; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; pp. 59–81. ISBN 9780081026793. [Google Scholar]

- Mohamed, M.; Vuppalapati, R.R.; Bheemreddy, V.; Chandrashekhara, K.; Schuman, T. Characterization of Polyurethane Composites Manufactured Using Vacuum Assisted Resin Transfer Molding. Adv. Compos. Mater. 2015, 24, 13–31. [Google Scholar] [CrossRef]

- Mohamed, M.; Anandan, S.; Huo, Z.; Birman, V.; Volz, J.; Chandrashekhara, K. Manufacturing and Characterization of Polyurethane Based Sandwich Composite Structures. Compos. Struct. 2015, 123, 169–179. [Google Scholar] [CrossRef]

- Mohamed, M.M. Performance Evaluation of Polyurethane Composites Using Vacuum Infusion Process. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2014. [Google Scholar]

- Mohamed, M.; Hawkins, S.; Chandrashekhara, K. Manufacturing and Performance Evaluation of Polyurethane Composite Using One Part and Two Part Resin Systems. Polym. Polym. Compos. 2014, 23, 12. [Google Scholar] [CrossRef]

- Dai, X.; Wang, X.; Wang, J. Study on Processes and Properties of Continuous Woven Roving Reinforced Polyurethane Composites. Adv. Mater. Res. 2011, 306–307, 879–883. [Google Scholar] [CrossRef]

- Trindade, R.S.; Ribeiro, A.C.; Souza, J.A.; Amico, S.C. Experimental Investigation of Transverse Permeability Applied to Liquid Molding. Polym. Compos. 2019, 40, 3938–3946. [Google Scholar] [CrossRef]

- da Silva, A.A.X.; de Araújo Silva, Í.J.; Miranda, A.C.M.; Manes, A.; Campos Amico, S. Influence of Hybridization on the Mechanical and Dynamic Mechanical Properties of Aramid/S2-Glass Hybrid Laminates. Mater. Today Commun. 2022, 32, 104021. [Google Scholar] [CrossRef]

- Alias, A.H.; Norizan, M.N.; Sabaruddin, F.A.; Asyraf, M.R.M.; Norrrahim, M.N.F.; Ilyas, A.R.; Kuzmin, A.M.; Rayung, M.; Shazleen, S.S.; Nazrin, A.; et al. Hybridization of MMT/Lignocellulosic Fiber Reinforced Polymer Nanocomposites for Structural Applications: A Review. Coatings 2021, 11, 1355. [Google Scholar] [CrossRef]

- Bulut, M.; Erkliğ, A. The Investigation of Quasi-Static Indentation Effect on Laminated Hybrid Composite Plates. Mech. Mater. 2018, 117, 225–234. [Google Scholar] [CrossRef]

- Castellano, A.; Fraddosio, A.; Piccioni, M.D. Quantitative Analysis of QSI and LVI Damage in GFRP Unidirectional Composite Laminates by a New Ultrasonic Approach. Compos. Part B Eng. 2018, 151, 106–117. [Google Scholar] [CrossRef]

- Ud Din, I.; Panier, S.; Hao, P.; Franz, G.; Bijwe, J.; Hui, L. Finite Element Modeling of Indentation and Adhesive Wear in Sliding of Carbon Fiber Reinforced Thermoplastic Polymer against Metallic Counterpart. Tribol. Int. 2019, 135, 200–212. [Google Scholar] [CrossRef]

- Reddy, P.R.S.; Reddy, T.S.; Mogulanna, K.; Rao, G.S.; Madhu, V.; Rao, K.V. Role of Laminate Fracture Energy on Ballistic Performance of Glass Composite Laminates. Procedia Struct. Integr. 2019, 14, 676–683. [Google Scholar] [CrossRef]

- Yudhanto, A.; Wafai, H.; Lubineau, G.; Yaldiz, R.; Verghese, N. Characterizing the Influence of Matrix Ductility on Damage Phenomenology in Continuous Fiber-Reinforced Thermoplastic Laminates Undergoing Quasi-Static Indentation. Compos. Struct. 2018, 186, 324–334. [Google Scholar] [CrossRef] [Green Version]

- Correa, C.A.; Razzino, C.A.; Hage, E. Role of Maleated Coupling Agents on the Interface Adhesion of Polypropylene-Wood Composites. J. Thermoplast. Compos. Mater. 2007, 20, 323–339. [Google Scholar] [CrossRef]

- Acha, B.A.; Reboredo, M.M.; Marcovich, N.E. Creep and Dynamic Mechanical Behavior of PP-Jute Composites: Effect of the Interfacial Adhesion. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1507–1516. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Raju, K.V.S.N. Structural Engineering of Polyurethane Coatings for High Performance Applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Petrucci, R.; Santulli, C.; Puglia, D.; Sarasini, F.; Torre, L.; Kenny, J.M. Mechanical Characterisation of Hybrid Composite Laminates Based on Basalt Fibres in Combination with Flax, Hemp and Glass Fibres Manufactured by Vacuum Infusion. Mater. Des. 2013, 49, 728–735. [Google Scholar] [CrossRef]

- Menard, K.P. Dynamic Mechanical Anaylsis A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-1-4200-5312-8. [Google Scholar]

- Ornaghi, H.L.; Bolner, A.S.; Fiorio, R.; Zattera, A.J.; Amico, S.C. Mechanical and Dynamic Mechanical Analysis of Hybrid Composites Molded by Resin Transfer Molding. J. Appl. Polym. Sci. 2010, 116, 887–896. [Google Scholar] [CrossRef]

- Pach, J.; Kuterek, E. Investigation of the Quasi-Static Penetration Resistance Behaviour of Carbon/Aramid Fibre-Reinforced Pp Laminate. Materials 2021, 14, 709. [Google Scholar] [CrossRef] [PubMed]

- Khodadadi, A.; Liaghat, G.; Taherzadeh-Fard, A.; Shahgholian-Ghahfarokhi, D. Impact Characteristics of Soft Composites Using Shear Thickening Fluid and Natural Rubber–A Review of Current Status. Compos. Struct. 2021, 271, 114092. [Google Scholar] [CrossRef]

- Pach, J.; Frączek, N.; Kaczmar, J. The Effects of Hybridisation of Composites Consisting of Aramid, Carbon, and Hemp Fibres in a Quasi-Static Penetration Test. Materials 2020, 13, 4686. [Google Scholar] [CrossRef] [PubMed]

| Laminate | Vv [%] | VK [%] | VG [%] | Vf [%] | Density [g/cm3] | Thickness [mm] |

|---|---|---|---|---|---|---|

| K5 | 11.1 ± 0.2 | 59.4 ± 1.0 | -- | 59.4 ± 0.4 | 1.05 ± 0.03 | 3.01 ± 0.03 |

| (KG2)S | 8.1 ± 0.1 | 32.0 ± 0.3 | 25.4 ± 0.2 | 57.4 ± 0.6 | 1.13 ± 0.02 | 2.28 ± 0.18 |

| (G2K)S | 7.3 ± 0.1 | 33.5 ± 0.1 | 24.6 ± 0.2 | 58.1 ± 1.5 | 1.21 ± 0.04 | 2.39 ± 0.03 |

| G8 | 5.9 ± 0.1 | -- | 52.7 ± 0.6 | 52.7 ± 1.0 | 1.57 ± 0.09 | 2.41 ± 0.11 |

| Sample | Et [GPa] | TS [MPa] | εfirst failure [%] | SBS [MPa] |

|---|---|---|---|---|

| K5 | 9.56 ± 0.81 (A) | 251.9 ± 8.9 (A) | 8.89 ± 0.71 (A) | 13.53 ± 0.95 (A) |

| (KG2)S | 11.98 ± 0.95 (B) | 208.5 ± 12.5 (B) | 4.47 ± 0.21 (B) | 13.95 ± 0.65 (A) |

| (G2K)S | 14.98 ± 1.62 (C) | 275.7 ± 14.0 (C) | 5.88 ± 0.37 (C) | 15.07 ± 0.96 (AB) |

| G8 | 19.79 ± 0.06 (D) | 315.8 ± 28.5 (CD) | 4.11 ± 0.97 (B) | 15.67 ± 1.60 (B) |

[GPa] | [GPa] | C Parameter | Tg [°C] | tan δ | A Parameter | |

|---|---|---|---|---|---|---|

| Polyurethane | 1.96 | 0.02 | -- | 8.6 | 0.90 | -- |

| K5 | 4.99 | 0.13 | 0.35 | 7.0 | 0.27 | 0.74 |

| (KG2)S | 6.50 | 0.18 | 0.31 | 7.7 | 0.33 | 0.54 |

| (G2K)S | 12.79 | 1.14 | 0.10 | 8.3 | 0.41 | 0.69 |

| G8 | 20.50 | 2.13 | 0.08 | 8.6 | 0.53 | 0.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cruz, J.A.d.; Kerche, E.F.; Bianchi, O.; Manes, A.; Amico, S.C. Castor Oil-Based Polyurethane/S2 Glass/Aramid Hybrid Composites Manufactured by Vacuum Infusion. Polymers 2022, 14, 5150. https://doi.org/10.3390/polym14235150

Cruz JAd, Kerche EF, Bianchi O, Manes A, Amico SC. Castor Oil-Based Polyurethane/S2 Glass/Aramid Hybrid Composites Manufactured by Vacuum Infusion. Polymers. 2022; 14(23):5150. https://doi.org/10.3390/polym14235150

Chicago/Turabian StyleCruz, Joziel Aparecido da, Eduardo Fischer Kerche, Otávio Bianchi, Andrea Manes, and Sandro Campos Amico. 2022. "Castor Oil-Based Polyurethane/S2 Glass/Aramid Hybrid Composites Manufactured by Vacuum Infusion" Polymers 14, no. 23: 5150. https://doi.org/10.3390/polym14235150