Uncertainties in Electric Circuit Analysis of Anisotropic Electrical Conductivity and Piezoresistivity of Carbon Nanotube Nanocomposites

Abstract

:1. Introduction

2. Uncertainty in Electrical Conductivity as Input Data

2.1. Intrinsic CNT Conductivity

2.1.1. Physical Phenomena

2.1.2. Implementation in the Nodal Analysis

2.2. Tunneling Conductance of CNT Contacts

2.2.1. Simmons’ Formula

2.2.2. Number of Conductive Channels

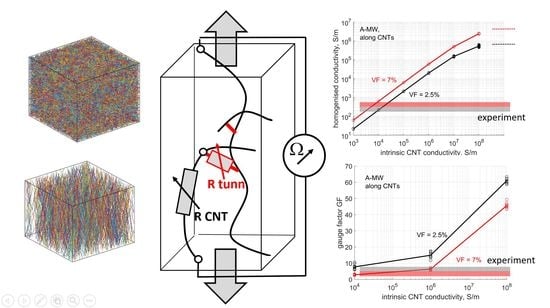

3. Geometrical and Electrical Models

3.1. Geometrical Model

3.1.1. Variants of CNT Geometry

3.1.2. The Algorithm

- (1)

- Maximal path curvature and torsion are limited: . This type of control was introduced recently in [71] that demonstrated, apart from adequate representation of CNT shapes, that these conditions suppress the segment length dependence of the homogenized conductivity. If for generated φn and θn the curvature and torsion do not satisfy these conditions, φn and θn are generated again;

- (2)

- Correlated random angles: the sequences of φn and θn pairs are auto-correlated along the CNT path, with the assumed correlation length of 100 nm (see [70]).

3.2. Electrical Model: Homogenized Conductivity

3.3. Electrical Model: Piezoresistive Response

3.3.1. Principles of the Model

3.3.2. Calculation of Gauge Factor

- Average deformation is transferred unchanged to sub-micrometer scale deformation elements around the contact points of CNTs;

- Length of a CNT does not change during the deformation.

4. Results and Discussion

4.1. Random RVE Instances

4.1.1. RVE Sets and Orientation Distribution

4.1.2. Distribution of CNT Contacts

4.1.3. Distribution of the Tunneling Conductances

4.2. Plan of Numerical Experiments

4.3. Uncertainty in Homogenized Conductivity

4.3.1. Conductivity at the Reference Point of the Plan for Numeric Experiments

4.3.2. Dependency of the Homogenized Conductivity on the CNT Intrinsic Conductivity

4.3.3. Dependency of the Homogenized Conductivity on the Tunneling Resistance Parameters and Minimal Inter-CNT Distance

4.4. Uncertainty of Deformation Sensitivity

4.4.1. Deformation Sensitivity at the Reference Point of the Numerical Plan

4.4.2. Dependency of Gauge Factors on Intrinsic CNT Conductivity and Tunneling Resistance

- -

- For the same ΔE1, a change of GF is approximately proportional to a change of log(gintr);

- -

- For the same gintr, a change of GF is approximately proportional to a change of ΔE1.

5. Conclusions

- The scatter of the homogenized conductivity and gauge factor, caused by the randomness of a CNT assembly, is limited to few percent of coefficient of variation (CV) and is much smaller that the variations which may be caused by the difference in assumed values of the input parameters.

- The influence of the assumed intrinsic conductivity on the homogenized conductivity and gauge factor is strong. For the intrinsic conductivity range 103–106 S/m, the dependency G(gintr) is nearly linear (to the power-law dependence with the exponent being close but below unity). For higher gintr values, its growth is asymptotically limited by the conductivity corresponding to the case of infinite intrinsic conductivity of CNTs. The assumption of infinite CNT intrinsic conductivity may bring unrealistically high simulated values for the homogenized conductivity.

- The choice of the CNT intrinsic conductivity ~104 S/m brings the simulated homogenized conductivity and gauge factor within one order of magnitude closeness to the experimentally measured values; a better choice asks for tuning of this parameter.

- The influence of the assumed potential barrier ΔE1 of the tunneling resistance on the homogenized conductivity is relatively weak for gintr ~ 104–106 S/m (limited to tens of percent variation for ΔE1 in the range 1–5 eV). The influence of ΔE1 becomes stronger if there are reasons to assume higher CNT intrinsic conductivity values.

- The influence of both gintr and ΔE1 on the simulated gauge factor is strong, about one order of magnitude span for the studied range of the input parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Homogenization of Anisotropic Conductivity

Appendix B. Nodal Analysis

- Nb equations for sum of currents at boundary nodes. For the nodes shown in Figure A1a,where is intrinsic conductance of a CNT section between nodes p and q, calculated with Equation (1). The currents in these two equations are equal because of the periodicity of boundary conditions.

- Nb/2 equations expressing periodic boundary conditions of the applied electrical field. For the nodes shown in Figure A1awhere is the potential difference for the applied voltage, Equation (A4).

- Ni equations for the sum of currents at internal nodes. For the nodes shown in Figure A1a,where is tunneling conductance of a CNT between nodes p and q, calculated with Equation (2).

Appendix C. Change of Tunneling Contact Distances

- Contact C between two CNTs comprises two contact points C1 and C2 on the centrelines of these CNTs.

- The change of a tunnelling distance in contact C between two CNTs is defined by deformation of a “deformation element” (Figure A2a), which comprises sections (P11, P12) and (P21, P22) of the CNTs with length one-half of the inter-contact CNT lengths between subsequent contacts on both sides from contact C on each of the CNTs.

- The deformation element is approximated by two straight lines (Figure A2b), with contact points belonging to these lines, lengths of the lines equal to the lengths of CNT sections ||P11, P12|| and ||P21, P22||. The orientation of the lines is the same as of vectors and . The positions of contact points on the lines are the same as on CNT sections in terms of distance from contact points to the ends of sections.

- Average deformation state of all deformation elements is the same and is defined by the applied deformation:

- 5.

- Conformal deformation of CNTs in the deformation element has two components:

- Displacements of the centres of gravity (CG) of the CNT sections in the element according to deformation Equation (A9), the section length is not changed, see Figure A2b, and

- Rotation of the CNT sections around the displaced centres of gravity (CG’); the rotation increases the Z-distance between the ends of each CNT section by a factor (1 + ε) and preserves the section length, see Figure A2c

- 6.

- The new tunnelling distance is the distance defined by the new positions of contact points C″1 and C″2, which result from the conformal deformation of the CNTs.

References

- Kirkpatrick, S. Percolation and Conduction. Rev. Mod. Phys. 1973, 45, 574–588. [Google Scholar] [CrossRef]

- Grujicic, M.; Cao, G.; Roy, W.N. A computational analysis of the percolation threshold and the electrical conductivity of carbon nanotubes filled polymeric materials. J. Mater. Sci. 2004, 39, 4441–4449. [Google Scholar] [CrossRef]

- Dalmas, F.; Dendievel, R.; Chazeau, L.; Cavaillé, J.Y.; Gauthier, C. Carbon nanotube-filled polymer composites. Numerical simulation of electrical conductivity in three-dimensional entangled fibrous networks. Acta Mater. 2006, 54, 2923–2931. [Google Scholar] [CrossRef]

- Hu, N.; Masuda, Z.; Yan, C.; Yamamoto, G.; Fukunaga, H.; Hashida, T. The electrical properties of polymer nanocomposites with carbon nanotube fillers. Nanotechnology 2008, 19, 215701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, W.B.; Chou, T.W.; Thostenson, E.T. A three-dimensional model of electrical percolation thresholds in carbon nanotube-based composites. Appl. Phys. Lett. 2010, 96, 223106. [Google Scholar] [CrossRef]

- Bao, W.S.; Meguid, S.A.; Zhu, Z.H.; Weng, G.J. Tunneling resistance and its effect on the electrical conductivity of carbon nanotube nanocomposites. J. Appl. Phys. 2012, 111, 093726. [Google Scholar] [CrossRef]

- Bao, W.S.; Meguid, S.A.; Zhu, Z.H.; Pan, Y.; Weng, G.J. Effect of carbon nanotube geometry upon tunneling assisted electrical network in nanocomposites. J. Appl. Phys. 2013, 113, 234313. [Google Scholar] [CrossRef]

- Gong, S.; Zhu, Z.H.; Haddad, E.I. Modeling electrical conductivity of nanocomposites by considering carbon nanotube deformation at nanotube junctions. J. Appl. Phys. 2013, 114, 074303. [Google Scholar] [CrossRef]

- Fang, W.; Jang, H.W.; Leung, S.N. Evaluation and modelling of electrically conductive polymer nanocomposites with carbon nanotube networks. Compos. Part B Eng. 2015, 83, 184–193. [Google Scholar] [CrossRef]

- Kulakov, V.; Aniskevich, A.; Ivanov, S.; Poltimae, T.; Starkova, O. Effective electrical conductivity of carbon nanotube–epoxy nanocomposites. J. Compos. Mater. 2016, 51, 2979–2988. [Google Scholar] [CrossRef]

- Bartels, J.; Kuhn, E.; Jürgens, J.-P.; Ploshikhin, V. Mesoscopic simulation of the electrical conductivity of carbon nanotube reinforced polymers regarding atomistic results. J. Compos. Mater. 2017, 52, 331–339. [Google Scholar] [CrossRef]

- Lubineau, G.; Mora, A.; Han, F.; Odeh, I.N.; Yaldiz, R. A morphological investigation of conductive networks in polymers loaded with carbon nanotubes. Comput. Mater. Sci. 2017, 130, 21–38. [Google Scholar] [CrossRef]

- Bartels, J.; Jurgens, J.-P.; Kuhn, E.; Ploshikhin, V. Effects of curvature and alignment of carbon nanotubes on the electrical conductivity of carbon nanotube-reinforced polymers investigated by mesoscopic simulations. J. Compos. Mater. 2019, 53, 1033–1047. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K.; Nankali, M. Analytical formulation for electrical conductivity and percolation threshold of epoxy multiscale nanocomposites reinforced with chopped carbon fibers and wavy carbon nanotubes considering tunneling resistivity. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105616. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. Prediction of electrical conductivity of carbon fiber-carbon nanotube-reinforced polymer hybrid composites. Compos. Part B Eng. 2019, 167, 728–735. [Google Scholar] [CrossRef]

- Tarlton, T.; Brown, J.; Beach, B.; Derosa, P.A. A stochastic approach towards a predictive model on charge transport properties in carbon nanotube composites. Compos. Part B Eng. 2016, 100, 56–67. [Google Scholar] [CrossRef]

- Seidel, G.D.; Lagoudas, D.C. A micromechanics model for the electrical conductivity of nanotube-polymer nanocomposites. J. Compos. Mater. 2009, 43, 917–941. [Google Scholar] [CrossRef]

- Feng, C.; Jiang, L. Micromechanics modeling of the electrical conductivity of carbon nanotube (CNT)–polymer nanocomposites. Compos. Part A Appl. Sci. Manuf. 2013, 47, 143–149. [Google Scholar] [CrossRef]

- Ivanov, S.G.; Aniskevich, A.; Kulakov, V. Simplified calculation of the electrical conductivity of composites with carbon nanotubes. Mech. Compos. Mater. 2018, 54, 61–70. [Google Scholar] [CrossRef]

- Hwang, M.-Y.; Kang, L.-H. CNT network modeling and simulation of the electrical properties of CNT/PNN-PZT/epoxy paint sensor. J. Mech. Sci. Technol. 2017, 31, 3787–3791. [Google Scholar] [CrossRef]

- Naghashpour, A.; Van Hoa, S. Requirements of amount of carbon nanotubes for damage detection in large polymer composite structures. Polym. Test. 2017, 63, 407–416. [Google Scholar] [CrossRef]

- Matos, M.A.S.; Tagarielli, V.L.; Baiz-Villafranca, P.M.; Pinho, S.T. Predictions of the electro-mechanical response of conductive CNT-polymer composites. J. Mech. Phys. Solids 2018, 114, 84–96. [Google Scholar] [CrossRef]

- Alian, A.R.; Meguid, S.A. Multiscale modeling of the coupled electromechanical behavior of multifunctional nanocomposites. Compos. Struct. 2019, 208, 826–835. [Google Scholar] [CrossRef]

- Lebedev, O.V.; Trofimov, A.; Abaimov, S.G.; Ozerin, A.N. Modeling of an effect of uniaxial deformation on electrical conductance of polypropylene-based composites filled with agglomerated nanoparticles. Int. J. Eng. Sci. 2019, 144, 103132. [Google Scholar] [CrossRef]

- Tanabi, H.; Erdal, M. Effect of CNTs dispersion on electrical, mechanical and strain sensing properties of CNT/epoxy nanocomposites. Results Phys. 2019, 12, 486–503. [Google Scholar] [CrossRef]

- Lebedev, O.V.; Abaimov, S.G.; Ozerin, A.N. Modeling the effect of uniaxial deformation on electrical conductivity for composite materials with extreme filler segregation. J. Compos. Mater. 2020, 54, 299–309. [Google Scholar] [CrossRef]

- Lebedev, O.V.; Ozerin, A.N.; Abaimov, S.G. Multiscale numerical modeling for prediction of piezoresistive effect for polymer composites with a highly segregated structure. Nanomaterials 2021, 11, 162. [Google Scholar] [CrossRef]

- Liu, Q.; Lomov, S.V.; Gorbatikh, L. Enhancing strength and toughness of hierarchical composites through optimization of position and orientation of nanotubes: A computational study. J. Compos. Sci. 2020, 4, 34. [Google Scholar] [CrossRef] [Green Version]

- Matos, M.A.S.; Tagarielli, V.L.; Pinho, S.T. On the electrical conductivity of composites with a polymeric matrix and a non-uniform concentration of carbon nanotubes. Compos. Sci. Technol. 2020, 188, 108003. [Google Scholar] [CrossRef]

- Matos, M.A.S.; Pinho, S.T.; Tagarielli, V.L. Application of machine learning to predict the multiaxial strain-sensing response of CNT-polymer composites. Carbon 2019, 146, 265–275. [Google Scholar] [CrossRef]

- Liu, Q.; Lomov, S.V.; Gorbatikh, L. Spatial distribution and orientation of nanotubes for suppression of stress concentrations optimized using genetic algorithm and finite element analysis. Mater. Des. 2018, 158, 136–146. [Google Scholar] [CrossRef]

- Manta, A.; Tserpes, K.I. Numerical computation of electrical conductivity of carbon nanotube-filled polymers. Compos. Part B Eng. 2016, 100, 240–246. [Google Scholar] [CrossRef]

- Talamadupula, K.K.; Seidel, G.D. Statistical analysis of effective electro-mechanical properties and percolation behavior of aligned carbon nanotube/polymer nanocomposites via computational micromechanics. Comput. Mater. Sci. 2021, 197, 110616. [Google Scholar] [CrossRef]

- Naeemi, A.; Meindl, J.D. Performance modeling for carbon nanotube interconnects. In Carbon Nanotube Electronics; Kong, J., Javey, A., Eds.; Springer: Boston, MA, USA, 2009; pp. 163–190. [Google Scholar] [CrossRef]

- Lee, D.H.; Lee, J.K. Initial compressional behaviour of fibre assembly. In Objective Measurement: Applications to Product Design and Process Control; Kawabata, S., Postle, R., Niwa, M., Eds.; The Textile Machinery Society of Japan: Osaka, Japan, 1985; pp. 613–622. [Google Scholar]

- Lomov, S.V.; Gorbatikh, L.; Verpoest, I. A model for the compression of a random assembly of carbon nanotubes. Carbon 2011, 49, 2079–2091. [Google Scholar] [CrossRef]

- Frank, S.; Poncharal, P.; Wang, Z.L.; De Heer, W.A. Carbon nanotube quantum resistors. Science 1998, 280, 1744–1746. [Google Scholar] [CrossRef] [Green Version]

- Poncharal, P.; Berger, C.; Yi, Y.; Wang, Z.L.; de Heer, W.A. Room temperature ballistic conduction in carbon nanotubes. J. Phys. Chem. B 2002, 106, 12104–12118. [Google Scholar] [CrossRef] [Green Version]

- Poncharal, P.; Wang, Z.L.; Ugarte, D.; de Heer, W.A. Electrostatic deflections and electromechanical resonances of carbon nanotubes. Science 1999, 283, 1513–1516. [Google Scholar] [CrossRef] [Green Version]

- Kobylko, M. Ballistic- and quantum-conductor carbon nanotubes: The limits of the liquid-metal contact method. Phys. Rev. B 2014, 90, 195432. [Google Scholar] [CrossRef]

- Kobylko, M.; Kociak, M.; Sato, Y.; Urita, K.; Bonnot, A.M.; Kasumov, A.; Kasumov, Y.; Suenaga, K.; Colliex, C. Ballistic- and quantum-conductor carbon nanotubes: A reference experiment put to the test. Phys. Rev. B 2014, 90, 195431. [Google Scholar] [CrossRef]

- Sammalkorpi, M.; Krasheninnikov, A.; Kuronen, A.; Nordlund, K.; Kaski, K. Mechanical properties of carbon nanotubes with vacancies and related defects. Phys. Rev. B 2004, 70, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Zeng, H.; Zhao, J.; Hu, H.F.; Leburton, J.P. Atomic vacancy defects in the electronic properties of semi-metallic carbon nanotubes. J. Appl. Phys. 2011, 109, 083716. [Google Scholar] [CrossRef]

- Chiodarelli, N.; Masahito, S.; Kashiwagi, Y.; Li, Y.L.; Arstila, K.; Richard, O.; Cott, D.J.; Heyns, M.; De Gendt, S.; Groeseneken, G.; et al. Measuring the electrical resistivity and contact resistance of vertical carbon nanotube bundles for application as interconnects. Nanotechnology 2011, 22, 085302. [Google Scholar] [CrossRef] [PubMed]

- Chiodarelli, N.; Richard, O.; Bender, H.; Heyns, M.; De Gendt, S.; Groeseneken, G.; Vereecken, P.M. Correlation between number of walls and diameter in multiwall carbon nanotubes grown by chemical vapor deposition. Carbon 2012, 50, 1748–1752. [Google Scholar] [CrossRef]

- Gao, B.; Chen, Y.F.; Fuhrer, M.S.; Glattli, D.C.; Bachtold, A. Four-point resistance of individual single-wall carbon nanotubes. Phys. Rev. Lett. 2005, 95, 196802. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ebbesen, T.W.; Lezec, H.J.; Hiura, H.; Bennett, J.W.; Ghaemi, H.F.; Thio, T. Electrical conductivity of individual carbon nanotubes. Nature 1996, 382, 54–56. [Google Scholar] [CrossRef]

- Langer, L.; Bayot, V.; Grivei, E.; Issi, J.P.; Heremans, J.P.; Olk, C.H.; Stockman, L.; Van Haesendonck, C.; Bruynseraede, Y. Quantum transport in a multiwalled carbon nanotube. Phys. Rev. Lett. 1996, 76, 479–482. [Google Scholar] [CrossRef] [Green Version]

- Svatos, V.; Sun, W.X.; Kalousek, R.; Gablech, I.; Pekarek, J.; Neuzil, P. Single measurement determination of mechanical, electrical, and surface properties of a single carbon nanotube via force microscopy. Sens. Actuators A-Phys. 2018, 271, 217–222. [Google Scholar] [CrossRef]

- Ageev, O.A.; Il'in, O.I.; Rubashkina, M.V.; Smirnov, V.A.; Fedotov, A.A.; Tsukanova, O.G. Determination of the electrical resistivity of vertically aligned carbon nanotubes by scanning probe microscopy. Tech. Phys. 2015, 60, 1044–1050. [Google Scholar] [CrossRef]

- Nanocyl. Technical Data Sheet NC7000 tm, V08. Available online: https://www.nanocyl.com/product/nc7000/attachment/technical-data-sheet-nc7000-v08/ (accessed on 4 April 2021).

- Gau, C.; Kuo, C.Y.; Ko, H.S. Electron tunneling in carbon nanotube composites. Nanotechnology 2009, 20, 395705. [Google Scholar] [CrossRef]

- Eken, A.E.; Tozzi, E.J.; Klingenberg, D.J.; Bauhofer, W. A simulation study on the combined effects of nanotube shape and shear flow on the electrical percolation thresholds of carbon nanotube/polymer composites. J. Appl. Phys. 2011, 109, 084342. [Google Scholar] [CrossRef]

- Xu, S.; Rezvanian, O.; Peters, K.; Zikry, M.A. Tunneling effects and electrical conductivity of cnt polymer composites. MRS Proc. 2011, 1304, 906–912. [Google Scholar] [CrossRef]

- Safdari, M.; Al-Haik, M. Electrical conductivity of synergistically hybridized nanocomposites based on graphite nanoplatelets and carbon nanotubes. Nanotechnology 2012, 23, 405202. [Google Scholar] [CrossRef] [PubMed]

- Di Ventra, M. Electrical Transport in Nanoscale Systems; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Simmons, J.G. Generalized formula for the electric tunnel effect between similar electrodes separated by a thin insulating film. J. Appl. Phys. 1963, 34, 1793–1803, Comment: J. Appl. Phys. 2018, 123, 136101. [Google Scholar] [CrossRef] [Green Version]

- Penazzi, G.; Carlsson, J.M.; Diedrich, C.; Olf, G.; Pecchia, A.; Frauenheim, T. Atomistic modeling of charge transport across a carbon nanotube-polyethylene junction. J. Phys. Chem. C 2013, 117, 8020–8027. [Google Scholar] [CrossRef]

- Lomov, S.V.; Akhatov, I.S.; Lee, J.; Wardle, B.L.; Abaimov, S.G. Non-linearity of electrical conductivity for aligned multi-walled carbon nanotube nanocomposites: Numerical estimation of significance of influencing factors. In Proceedings of the 21st IEEE International Conference on Nanotechnology (IEEE-NANO), Montreal, QC, Canada, 28–30 July 2021; pp. 378–381. [Google Scholar]

- Yoon, Y.G.; Mazzoni, M.S.C.; Choi, H.J.; Ihm, J.; Louie, S.G. Structural deformation and intertube conductance of crossed carbon nanotube junctions. Phys. Rev. Lett. 2001, 86, 688–691. [Google Scholar] [CrossRef] [PubMed]

- Hu, N.; Karube, Y.; Yan, C.; Masuda, Z.; Fukunaga, H. Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater. 2008, 56, 2929–2936. [Google Scholar] [CrossRef] [Green Version]

- Shiraishi, M.; Ata, M. Work function of carbon nanotubes. Carbon 2001, 39, 1913–1917. [Google Scholar] [CrossRef]

- Büttiker, M.; Imry, Y.; Landauer, R.; Pinhas, S. Generalized many-channel conductance formula with application to small rings. Phys. Rev. B 1985, 31, 6207–6215. [Google Scholar] [CrossRef] [Green Version]

- Li, H.J.; Lu, W.G.; Li, J.J.; Bai, X.D.; Gu, C.Z. Multichannel ballistic transport in multiwall carbon nanotubes. Phys. Rev. Lett. 2005, 95, 086601. [Google Scholar] [CrossRef]

- Butt, H.A.; Lomov, S.V.; Akhatov, I.; Abaimov, S. Self-diagnostic carbon nanocomposites manufactured from industrial epoxy masterbatches. Compos. Struct. 2021, 259, 113244. [Google Scholar] [CrossRef]

- Liddle, J.A. Transmission Electron Microscope Tomographic Data of Aligned Carbon Nanotubes in Epoxy at Volume Fractions of 0.44%, 2.6%, 4%, and 6.9%; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2020. [CrossRef]

- Natarajan, B.; Lachman, N.; Lam, T.; Jacobs, D.; Long, C.; Zhao, M.; Wardle, B.L.; Sharma, R.; Liddle, J.A. The evolution of carbon nanotube network structure in unidirectional nanocomposites resolved by quantitative electron tomography. ASC Nano 2015, 9, 6050–6058. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, B.; Stein, I.Y.; Lachman, N.; Yamamoto, N.; Jacobs, D.; Sharma, R.; Liddle, J.A.; Wardle, B. Aligned Carbon Nanotube Morphogenesis Predicts Physical Properties of their Polymer Nanocomposites. Nanoscale 2019, 11, 16327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cebeci, H.; Guzman de Villoria, R.; Hart, A.J.; Wardle, B.L. Multifunctional properties of high volume fraction aligned carbon nanotube polymer composites with controlled morphology. Compos. Sci. Technol. 2009, 69, 2649–2656. [Google Scholar] [CrossRef]

- Lomov, S.V.; Lee, J.; Wardle, B.L.; Gudkov, N.A.; Akhatov, I.S.; Abaimov, S.G. Computational description of the geometry of aligned carbon nanotubes in polymer nanocomposites. In Proceedings of the 36th ASC Technical VIRTUAL Conference (ASC 2021), Virtual, 19–22 September 2021; pp. 1606–1613. [Google Scholar] [CrossRef]

- Gudkov, N.A.; Lomov, S.V.; Akhatov, I.S.; Abaimov, S.G. Conductive CNT-polymer nanocomposites digital twins for self-diagnostic structures: Sensitivity to CNT parameters. Compos. Struct. 2022, 291, 115617. [Google Scholar] [CrossRef]

- Romanov, V.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Modelling evidence of stress concentration mitigation at the micro-scale in polymer composites by the addition of carbon nanotubes. Carbon 2015, 82, 184–194. [Google Scholar] [CrossRef]

- Stein, I.Y.; Wardle, B.L. Mechanics of aligned carbon nanotube polymer matrix nanocomposites simulated via stochastic three-dimensional morphology. Nanotechnology 2016, 27, 035701. [Google Scholar] [CrossRef]

- Aviles, F.; Oliva-Aviles, A.I.; Cen-Puc, M. Piezoresistivity, strain, and damage self-sensing of polymer composites filled with carbon nanostructures. Adv. Eng. Mater. 2018, 20, 1701159. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Artigas, J.; Jiménez-Suárez, A.; Sánchez, M.; Güemes, A.; Ureña, A. Critical parameters of carbon nanotube reinforced composites for structural health monitoring applications: Empirical results versus theoretical predictions. Compos. Sci. Technol. 2019, 171, 44–53. [Google Scholar] [CrossRef]

- Gong, S.; Wu, D.; Li, Y.; Jin, M.; Xiao, T.; Wang, Y.; Xiao, Z.; Zhu, Z.; Li, Z. Temperature-independent piezoresistive sensors based on carbon nanotube/polymer nanocomposite. Carbon 2018, 137, 188–195. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, K.; Dai, X.X.; Li, Y.; Guo, J.; Liu, H.; Li, G.H.; Tan, Y.J.; Zeng, J.B.; Guo, Z.H. Enhanced electrical conductivity and piezoresistive sensing in multi-wall carbon nanotubes/polydimethylsiloxane nanocomposites via the construction of a self-segregated structure. Nanoscale 2017, 9, 11017–11026. [Google Scholar] [CrossRef]

- Lomov, S.V.; Lee, J.; Wardle, B.L.; Akhatov, I.; Abaimov, S. Piezoresistivity of nanocomposites: Accounting for cnt contact configuration changes. In Proceedings of the 20th European Conference on Composite Materials (ECCM-20), Lausanne, Switzerland, 26–30 June 2022. [Google Scholar]

- Lisunova, M.O.; Mamunya, Y.P.; Lebovka, N.I.; Melezhyk, A.V. Percolation behaviour of ultrahigh molecular weight polyethylene/multi-walled carbon nanotubes composites. Eur. Polym. J. 2007, 43, 949–958. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Fiedler, B.; Kinloch, I.A.; Bauhofer, W.; Windle, A.H.; Schulte, K. Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites. Polymer 2006, 47, 2036–2045. [Google Scholar] [CrossRef]

- Moisala, A.; Li, Q.; Kinloch, I.A.; Windle, A.H. Thermal and electrical conductivity of single- and multi-walled carbon nanotube-epoxy composites. Compos. Sci. Technol. 2006, 66, 1285–1288. [Google Scholar] [CrossRef]

- Huang, Y.; Li, N.; Ma, Y.; Du, F.; Li, F.; He, X.; Lin, X.; Gao, H.; Chen, Y. The influence of single-walled carbon nanotube structure on the electromagnetic interference shielding efficiency of its epoxy composites. Carbon 2007, 45, 1614–1621. [Google Scholar] [CrossRef]

- Thess, A.; Lee, R.; Nikolaev, P.; Dai, H.; Petit, P.; Robert, J.; Xu, C.; Lee, Y.H.; Kim, S.G.; Rinzler, A.G.; et al. Crystalline ropes of metallic carbon nanotubes. Science 1996, 273, 483. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Futaba, D.N.; Sakurai, S.; Yumura, M.; Hata, K. Interplay of wall number and diameter on the electrical conductivity of carbon nanotube thin films. Carbon 2014, 67, 318–325. [Google Scholar] [CrossRef]

- Lee, J.; Stein, I.Y.; Devoe, M.E.; Lewis, D.J.; Lachman, N.; Kessler, S.S.; Buschhorn, S.T.; Wardle, B.L. Impact of carbon nanotube length on electron transport in aligned carbon nanotube networks. Appl. Phys. Lett. 2015, 106, 053110. [Google Scholar] [CrossRef]

- Wang, D.; Song, P.; Liu, C.; Wu, W.; Fan, S. Highly oriented carbon nanotube papers made of aligned carbon nanotubes. Nanotechnology 2008, 19, 075609. [Google Scholar] [CrossRef]

- Marschewski, J.; In, J.B.; Poulikakos, D.; Grigoropoulos, C.P. Synergistic integration of Ni and vertically aligned carbon nanotubes for enhanced transport properties on flexible substrates. Carbon 2014, 68, 308–318. [Google Scholar] [CrossRef]

- Maffucci, A.; Micciulla, F.; Cataldo, A.E.; Miano, G.; Bellucci, S. Modeling, Fabrication, and Characterization of Large Carbon Nanotube Interconnects With Negative Temperature Coefficient of the Resistance. Ieee Trans. Compon. Packag. Manuf. Technol. 2017, 7, 485–493. [Google Scholar] [CrossRef]

- Oskouyi, A.B.; Sundararaj, U.; Mertiny, P. Tunneling Conductivity and Piezoresistivity of Composites Containing Randomly Dispersed Conductive Nano-Platelets. Materials 2014, 7, 2501. [Google Scholar] [CrossRef] [PubMed]

- Oskouyi, A.B.; Sundararaj, U.; Mertiny, P. A Numerical Model to Study the Effect of Temperature on Electrical Conductivity of Polymer-CNT Nanocomposites. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, San Diego, CA, USA, 15–21 November 2013; Volume 9. [Google Scholar]

- Kaiser, A.B.; Skakalova, V. Electronic conduction in polymers, carbon nanotubes and graphene. Chem. Soc. Rev. 2011, 40, 3786–3801. [Google Scholar] [CrossRef] [PubMed]

- Abaimov, S.G. Statistical Physics of Non-Thermal Phase Transitions: From Foundations to Applications; Springer: Berlin/Heidelberg, Germany, 2015; p. 493. [Google Scholar] [CrossRef]

- Chung-Wen, H.; Ruehli, A.; Brennan, P. The modified nodal approach to network analysis. IEEE Trans. Circuits Syst. 1975, 22, 504–509. [Google Scholar] [CrossRef] [Green Version]

- Dastgerdi, J.N.; Marquis, G.; Salimi, M. Micromechanical modeling of nanocomposites considering debonding and waviness of reinforcements. Compos. Struct. 2014, 110, 1–6. [Google Scholar] [CrossRef]

| Parameter | R-SW | A-MW |

|---|---|---|

| Data source | [65] | [66,68] |

| CNT outer diameter, nm | 1.6 | 8.0 |

| CNT length | ||

| Distribution type | Weibull | constant |

| Mean length, µm | 2.0 | 20 |

| Weibull modulus | 3.0 | n/a |

| Weibull scale, µm | 2.24 | n/a |

| CNT orientation | ||

| Distribution type | uniform | aligned |

| CNT shape | ||

| Maximal curvature, 1/µm | 5 | 5 |

| Maximal torsion, 1/µm | 5 | 5 |

| Volume fraction variants | 0.5%; 1% | 2.5%; 7% |

| Parameter Variation Type | Intrinsic CNT Conductivity, S/M | Potential Barrier ΔE1, eV | Minimal CNT Distance, Nm |

|---|---|---|---|

| Varying intrinsic CNT conductivity and potential barrier for tunneling conductivity | 103 104 105 106 107 108 ∞ | 1 3 5 | 0.34 |

| Varying minimal CNT distance | 104 | 3 | 0.25 |

| Type | VF | Diagonal Components, S/M | Off-Diagonal Components, S/M | ||

|---|---|---|---|---|---|

| Signed Values | Absolute Values | ||||

| R-SW | 0.5% | 12.7 ± 0.33 (2.5%) | −0.007 ± 0.290 | 0.217 ± 0.195 (87%) | |

| 1% | 28.6 ± 0.55 (1.9%) | 0.030 ± 0.422 | 0.334 ± 0.258 (77%) | ||

| A-MW | along CNTs | across CNTs | |||

| 2.5% | 217 ± 1.44 (0.66%) | 3.03 ± 0.23 (7.5%) | −0.0015 ± 1.20 | 0.816 ± 0.874 (107%) | |

| 7.0% | 630 ± 0.86 (0.13%) | 13.8 ± 0.32 (2.3%) | −0.140 ± 2.11 | 1.47± 1.52 (103%) | |

| Type | VF | Gauge Factor GF |

|---|---|---|

| R-SW | 0.5% | 8.18 ± 0.57 (7.0%) |

| 1% | 4.07 ± 0.21 (2.5%) | |

| A-MW, along CNTs | 2.5% | 7.32 ± 1.34 (18.3%) |

| 7.0% | 2.91 ± 0.27 (9.3%) | |

| A-MW, across CNTs | 2.5% | 4.89 ± 0.62 (12.6%) |

| 7.0% | 5.69 ± 0.28 (4.9%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lomov, S.V.; Gudkov, N.A.; Abaimov, S.G. Uncertainties in Electric Circuit Analysis of Anisotropic Electrical Conductivity and Piezoresistivity of Carbon Nanotube Nanocomposites. Polymers 2022, 14, 4794. https://doi.org/10.3390/polym14224794

Lomov SV, Gudkov NA, Abaimov SG. Uncertainties in Electric Circuit Analysis of Anisotropic Electrical Conductivity and Piezoresistivity of Carbon Nanotube Nanocomposites. Polymers. 2022; 14(22):4794. https://doi.org/10.3390/polym14224794

Chicago/Turabian StyleLomov, Stepan V., Nikita A. Gudkov, and Sergey G. Abaimov. 2022. "Uncertainties in Electric Circuit Analysis of Anisotropic Electrical Conductivity and Piezoresistivity of Carbon Nanotube Nanocomposites" Polymers 14, no. 22: 4794. https://doi.org/10.3390/polym14224794