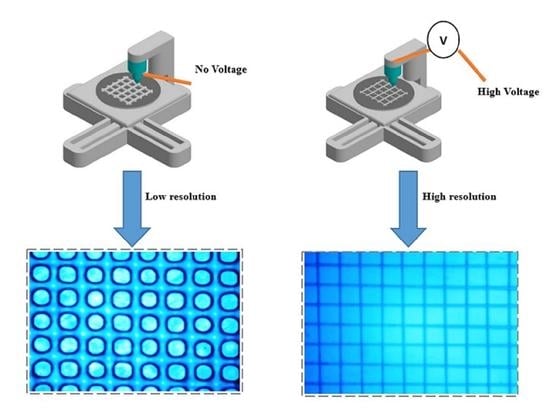

High-Resolution, Transparent, and Flexible Printing of Polydimethylsiloxane via Electrohydrodynamic Jet Printing for Conductive Electronic Device Applications

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sheng, X.; Robert, C.; Wang, S.; Pakeltis, G.; Corbett, B.; Rogers, J.A. Transfer Printing of Fully Formed Thin-Film Microscale GaAs Lasers on Silicon with a Thermally Conductive Interface Material. Laser Photonics Rev. 2015, 9, L17–L22. [Google Scholar] [CrossRef]

- Meitl, M.A.; Zhu, Z.T.; Kumar, V.; Lee, K.J.; Feng, X.; Huang, Y.Y.; Adesida, I.; Nuzzo, R.G.; Rogers, J.A. Transfer Printing by Kinetic Control of Adhesion to an Elastomeric Stamp. Nat. Mater. 2006, 5, 33–38. [Google Scholar] [CrossRef]

- Byun, D.; Kim, J.; Ko, H.S.; Park, H.C. Direct Measurement of Slip Flows in Superhydrophobic Microchannels with Transverse Grooves. Phys. Fluids 2008, 20, 113601. [Google Scholar] [CrossRef]

- Lee, H.; Lee, B.P.; Messersmith, P.B. A Reversible Wet/Dry Adhesive Inspired by Mussels and Geckos. Nature 2007, 448, 338–341. [Google Scholar] [CrossRef]

- Bartlett, M.D.; Croll, A.B.; King, D.R.; Paret, B.M.; Irschick, D.J.; Crosby, A.J. Looking beyond Fibrillar Features to Scale Gecko-like Adhesion. Adv. Mater. 2012, 24, 1078–1083. [Google Scholar] [CrossRef]

- Lee, H.; Seong, B.; Moon, H.; Byun, D. Directly Printed Stretchable Strain Sensor Based on Ring and Diamond Shaped Silver Nanowire Electrodes. RSC Adv. 2015, 5, 28379–28384. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, Y. Highly Conductive and Stretchable Silver Nanowire Conductors. Adv. Mater. 2012, 24, 5117–5122. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Rogers, J.A. Stretchable Electronics: Materials Strategies and Devices. Adv. Mater. 2008, 20, 4887–4892. [Google Scholar] [CrossRef]

- Erkal, J.L.; Selimovic, A.; Gross, B.C.; Lockwood, S.Y.; Walton, E.L.; McNamara, S.; Martin, R.S.; Spence, D.M. 3D Printed Microfluidic Devices with Integrated Versatile and Reusable Electrodes. Lab Chip 2014, 14, 2023–2032. [Google Scholar] [CrossRef] [Green Version]

- Symes, M.D.; Kitson, P.J.; Yan, J.; Richmond, C.J.; Cooper, G.J.T.; Bowman, R.W.; Vilbrandt, T.; Cronin, L. Integrated 3D-Printed Reactionware for Chemical Synthesis and Analysis. Nat. Chem. 2012, 4, 349–354. [Google Scholar] [CrossRef] [PubMed]

- Mannoor, M.S.; Jiang, Z.; James, T.; Kong, Y.L.; Malatesta, K.A.; Soboyejo, W.O.; Verma, N.; Gracias, D.H.; McAlpine, M.C. 3D Printed Bionic Ears. Nano Lett. 2013, 13, 2634–2639. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qin, Z.; Compton, B.G.; Lewis, J.A.; Buehler, M.J. Structural Optimization of 3D-Printed Synthetic Spider Webs for High Strength. Nat. Commun. 2015, 6, 7038. [Google Scholar] [CrossRef] [Green Version]

- Kolesky, D.B.; Truby, R.L.; Gladman, A.S.; Busbee, T.A.; Homan, K.A.; Lewis, J.A. 3D Bioprinting of Vascularized, Heterogeneous Cell-Laden Tissue Constructs. Adv. Mater. 2014, 26, 3124–3130. [Google Scholar] [CrossRef] [PubMed]

- Lipton, J.I.; Angle, S.; Lipson, H. 3D Printable Wax-Silicone Actuators. In Proceedings of the 2014 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014. [Google Scholar]

- Seemann, L.; Stemmer, A.; Naujoks, N. Local Surface Charges Direct the Deposition of Carbon Nanotubes and Fullerenes into Nanoscale Patterns. Nano Lett. 2007, 7, 3007–3012. [Google Scholar] [CrossRef]

- Mecozzi, L.; Gennari, O.; Rega, R.; Grilli, S.; Bhowmick, S.; Gioffrè, M.A.; Coppola, G.; Ferraro, P. Spiral Formation at the Microscale by μ-Pyro-Electrospinning. Soft Matter 2016, 12, 5542–5550. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rega, R.; Gennari, O.; Mecozzi, L.; Pagliarulo, V.; Bramanti, A.; Ferraro, P.; Grilli, S. Maskless Arrayed Nanofiber Mats by Bipolar Pyroelectrospinning. ACS Appl. Mater. Interfaces 2019, 11, 3382–3387. [Google Scholar] [CrossRef]

- Zhang, C.; McKeon, L.; Kremer, M.P.; Park, S.H.; Ronan, O.; Seral-Ascaso, A.; Barwich, S.; Coileáin, C.; McEvoy, N.; Nerl, H.C.; et al. Additive-Free MXene Inks and Direct Printing of Micro-Supercapacitors. Nat. Commun. 2019, 10, 1795. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tian, X. Direct Ink Writing of 2D Material-Based Supercapacitors. 2D Mater. 2022, 9, 012001. [Google Scholar] [CrossRef]

- Guo, Z.; Yu, P.; Liu, Y.; Zhao, J. Pre-Fatigue Enhancing Both Long-Term Stability and Sensitivity of Direct-Ink-Writing Printed Sensors. Int. J. Fatigue 2023, 166, 107237. [Google Scholar] [CrossRef]

- Zhu, W.B.; Xue, S.S.; Zhang, H.; Wang, Y.Y.; Huang, P.; Tang, Z.H.; Li, Y.Q.; Fu, S.Y. Direct Ink Writing of a Graphene/CNT/Silicone Composite Strain Sensor with a near-Zero Temperature Coefficient of Resistance. J. Mater. Chem. C 2022, 10, 8226–8233. [Google Scholar] [CrossRef]

- Guo, Z.; Yu, P.; Liu, Y.; Zhao, J. High-Precision Resistance Strain Sensors of Multilayer Composite Structure via Direct Ink Writing: Optimized Layer Flatness and Interfacial Strength. Compos. Sci. Technol. 2021, 201, 108530. [Google Scholar] [CrossRef]

- Duan, X.; Yao, Y.; Niu, M.; Luo, J.; Wang, R.; Liu, T. Direct Laser Writing of Functional Strain Sensors in Polyimide Tubes. ACS Appl. Polym. Mater. 2019, 1, 2914–2923. [Google Scholar] [CrossRef]

- Iqra, M.; Anwar, F.; Jan, R.; Mohammad, M.A. A Flexible Piezoresistive Strain Sensor Based on Laser Scribed Graphene Oxide on Polydimethylsiloxane. Sci. Rep. 2022, 12, 4882. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Yang, C.; Zhang, S.; Wang, Y.; Zou, R.; Alamusi; Deng, Q.; Hu, N. Laser Direct Writing of a Multifunctional Superhydrophobic Composite Strain Sensor with Excellent Corrosion Resistance and Anti-Icing/Deicing Performance. Mater. Des. 2022, 218, 110689. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Y.Q.; Liu, Y.; Han, B.; Wang, H.; Han, D.D.; Wang, J.N.; Zhang, Y.L.; Sun, H.B. Direct Laser Writing of Superhydrophobic PDMS Elastomers for Controllable Manipulation via Marangoni Effect. Adv. Funct. Mater. 2017, 27, 1702946. [Google Scholar] [CrossRef]

- Kang, H.; Kim, S.; Shin, J.; Ko, S. Inkjet-Printed Flexible Strain-Gauge Sensor on Polymer Substrate: Topographical Analysis of Sensitivity. Appl. Sci. 2022, 12, 3193. [Google Scholar] [CrossRef]

- Parameswaran, C.; Gupta, D. Large Area Flexible Pressure/Strain Sensors and Arrays Using Nanomaterials and Printing Techniques. Nano Converg. 2019, 6, 28. [Google Scholar] [CrossRef] [Green Version]

- Hassan, G.; Khan, M.U.; Bae, J.; Shuja, A. Inkjet Printed Self-Healable Strain Sensor Based on Graphene and Magnetic Iron Oxide Nano-Composite on Engineered Polyurethane Substrate. Sci. Rep. 2020, 10, 18234. [Google Scholar] [CrossRef]

- Kang, G.; Lee, H.; Moon, J.; Jang, H.S.; Cho, D.H.; Byun, D. Electrohydrodynamic Jet-Printed MAPbBr3 Perovskite/Polyacrylonitrile Nanostructures for Water-Stable, Flexible, and Transparent Displays. ACS Appl. Nano Mater. 2022, 5, 6726–6735. [Google Scholar] [CrossRef]

- Zhang, B.; Lee, H.; Byun, D. Direct Fabrication of Metallic Microgear via Electrohydrodynamic Inkjet 3D Printing. Adv. Eng. Mater. 2020, 22, 1901362. [Google Scholar] [CrossRef]

- Zhang, B.; Lee, H.; Byun, D. Electrohydrodynamic Jet Printed 3D Metallic Grid: Toward High-Performance Transparent Electrodes. Adv. Eng. Mater. 2020, 22, 1901275. [Google Scholar] [CrossRef]

- Seong, B.; Chae, I.; Lee, H.; Nguyen, V.D.; Byun, D. Spontaneous Self-Welding of Silver Nanowire Networks. Phys. Chem. Chem. Phys. 2015, 17, 7629–7633. [Google Scholar] [CrossRef] [PubMed]

- Jang, Y.; Kim, J.; Byun, D. Invisible Metal-Grid Transparent Electrode Prepared by Electrohydrodynamic (EHD) Jet Printing. J. Phys. D Appl. Phys. 2013, 46, 155103. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Zhao, W.; Zhang, W.; Chen, G. Preparation of Polymer/Oriented Graphite Nanosheet Composite by Electric Field-Inducement. Compos. Sci. Technol. 2008, 68, 238–243. [Google Scholar] [CrossRef]

- Lee, H.; Lee, J.; Seong, B.; Jang, H.S.; Byun, D. Printing Conductive Micro-Web Structures via Capillary Transport of Elastomeric Ink for Highly Stretchable Strain Sensors. Adv. Mater. Technol. 2018, 3, 1700228. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Cui, Y.L.; Mi, W.T.; Yang, Y.; Xie, D.; Ren, T.L. Scalable Fabrication of High-Performance and Flexible Graphene Strain Sensors. Nanoscale 2014, 6, 699–705. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A Stretchable Carbon Nanotube Strain Sensor for Human-Motion Detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M.; Wang, K.; Wu, D.; Zhu, H. Wearable and Highly Sensitive Graphene Strain Sensors for Human Motion Monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire-Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Park, J.J.; Hyun, W.J.; Mun, S.C.; Park, Y.T.; Park, O.O. Highly Stretchable and Wearable Graphene Strain Sensors with Controllable Sensitivity for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Lee, J.; Yang, D.; Park, B.C.; Ryu, S.; Park, I. A Stretchable Strain Sensor Based on a Metal Nanoparticle Thin Film for Human Motion Detection. Nanoscale 2014, 6, 11932–11939. [Google Scholar] [CrossRef]

- Obata, K.; Slobin, S.; Schonewille, A.; Hohnholz, A.; Unger, C.; Koch, J.; Suttmann, O.; Overmeyer, L. UV Laser Direct Writing of 2D/3D Structures Using Photo-Curable Polydimethylsiloxane (PDMS). Appl. Phys. A Mater. Sci. Process. 2017, 123, 2–6. [Google Scholar] [CrossRef]

- Cosson, S.; Aeberli, L.G.; Brandenberg, N.; Lutolf, M.P. Ultra-Rapid Prototyping of Flexible, Multi-Layered Microfluidic Devices via Razor Writing. Lab Chip 2015, 15, 72–76. [Google Scholar] [CrossRef]

- Zhu, P.; Yang, W.; Wang, R.; Gao, S.; Li, B.; Li, Q. Direct Writing of Flexible Barium Titanate/Polydimethylsiloxane 3D Photonic Crystals with Mechanically Tunable Terahertz Properties. Adv. Opt. Mater. 2017, 5, 1–6. [Google Scholar] [CrossRef]

- Wei, H.; Li, K.; Liu, W.G.; Meng, H.; Zhang, P.X.; Yan, C.Y. 3D Printing of Free-Standing Stretchable Electrodes with Tunable Structure and Stretchability. Adv. Eng. Mater. 2017, 19, 1–6. [Google Scholar]

- Nezhad, A.S.; Ghanbari, M.; Agudelo, C.G.; Packirisamy, M.; Bhat, R.B.; Geitmann, A. PDMS Microcantilever-Based Flow Sensor Integration for Lab-on-a-Chip. IEEE Sens. J. 2013, 13, 601–609. [Google Scholar] [CrossRef]

| Materials | Weight (%) |

|---|---|

| PDMS (base) | 10 |

| PDMS (reagent) Xylene | 1 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, R.U.; Khalil, S.M.; Khan, S.A.; Ali, S.; Moon, J.; Cho, D.-H.; Byun, D. High-Resolution, Transparent, and Flexible Printing of Polydimethylsiloxane via Electrohydrodynamic Jet Printing for Conductive Electronic Device Applications. Polymers 2022, 14, 4373. https://doi.org/10.3390/polym14204373

Hassan RU, Khalil SM, Khan SA, Ali S, Moon J, Cho D-H, Byun D. High-Resolution, Transparent, and Flexible Printing of Polydimethylsiloxane via Electrohydrodynamic Jet Printing for Conductive Electronic Device Applications. Polymers. 2022; 14(20):4373. https://doi.org/10.3390/polym14204373

Chicago/Turabian StyleHassan, Rizwan Ul, Shaheer Mohiuddin Khalil, Saeed Ahmed Khan, Shahzaib Ali, Joonkyeong Moon, Dae-Hyun Cho, and Doyoung Byun. 2022. "High-Resolution, Transparent, and Flexible Printing of Polydimethylsiloxane via Electrohydrodynamic Jet Printing for Conductive Electronic Device Applications" Polymers 14, no. 20: 4373. https://doi.org/10.3390/polym14204373