Recent Advances in Functionalization of Cotton Fabrics with Nanotechnology

Abstract

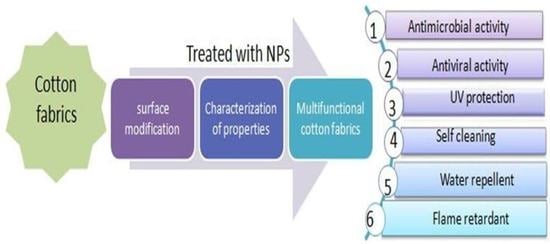

:1. Introduction

2. Common Types of Nanomaterials

2.1. Nanofinishing

2.2. Nanocoating

2.3. Nanofibers

2.4. Nanocomposites

3. Metal Nanoparticles (MNPs)

3.1. Silver Nanoparticles(AgNPs)

3.2. Titanium Dioxide Nanoparticles (TiO2NPs)

3.3. Silica Nanoparticles (SiO2NPs)

3.4. Zinc OxideNanoparticles (ZnONPs)

3.5. Copper/Copper Oxide Nanoparticles (Cu/CuONPs)

3.6. Gold Nanoparticles (AuNPs)

3.7. Mixtures of Metal Nanoparticles

4. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UV | Ultraviolet |

| ELS | Electrospinning |

| GNF | Graphite nanofibers |

| CNT | Carbon nanotubes |

| MNPs | Metal nanoparticles |

| NPs | Nanoparticles |

| AgNPs | Silver nanoparticles |

| TiO2NPs | Titanium dioxide nanoparticles |

| ROS | Reactive oxygen species |

| UPF | Ultraviolet protection factor |

| SiO2NPs | Silicon dioxide nanoparticles (Silica) |

| ZnONPs | Zinc oxide nanoparticles |

| GA | Gallic acid |

| Cu/CuONPs | Copper/Copper oxide nanoparticles |

| ATRP | Atom transfer radical polymerization |

| ELD | Electroless deposition |

| AuNPs | Gold nanoparticles |

| NRs | Nanorods |

| BMNPs | Bimetallic nanoparticles |

| PAD | Photo-Assisted Deposition |

| TEOS | Tetraethyl orthosilicate |

| FPEI | Functionalized polyethyleneimine |

| PMC | Polymethylol |

References

- Agrawal, N.; Sijia, P.; Tan, J.; Fong, E.; Lai, Y.; Chen, Z. Durable easy-cleaning and antibacterial cotton fabrics using fluorine-free silane coupling agents and CuO nanoparticles. Nano Mater. Sci. 2020, 2, 281–291. [Google Scholar] [CrossRef]

- Toprak, T.; Anis, P. Textile industry’s environmental effects and approaching cleaner production and sustainability, an overview. J. Text. Eng. Fash. Technol. 2017, 2, 429–442. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Yang, Y.; Zhang, Z.; Wang, Z.; Zhao, Y.; Sun, L. Fabrication of cotton fabrics with durable antibacterial activities finishing by Ag nanoparticles. Text. Res. J. 2019, 89, 867–880. [Google Scholar] [CrossRef]

- Elmaaty, T.A.; Abdelaziz, E.; Nasser, D.; Abdelfattah, K.; Elkadi, S.; El-Nagar, K. Microwave and Nanotechnology Advanced Solutions to Improve Eco-friendly Cotton’s Coloration and Performance Properties. Egypt. J. Chem. 2018, 61, 493–502. [Google Scholar] [CrossRef] [Green Version]

- Ali, S.; Mughal, M.A.; Shoukat, U.; Baloch, M.A.; Kim, S.H. Cationic starch (Q-TAC) pre-treatment of cotton fabric: Influence on dyeing with reactive dye. Carbohydr. Polym. 2015, 117, 271–278. [Google Scholar] [CrossRef]

- Shahidi, S.; Ghoranneviss, M. Plasma sputtering for fabrication of antibacterial and ultraviolet protective fabric.Clothing. Text. Res. J. 2015, 34, 37–47. [Google Scholar] [CrossRef] [Green Version]

- Ashayer, R.; Hunt, C.; Thomas, O. Fabrication of highly conductive stretchable textile with silver nanoparticles. Text. Res. J. 2015, 86, 1041–1049. [Google Scholar] [CrossRef]

- Yetisen, A.K.; Qu, H.; Manbachi, A.; Butt, H.; Dokmeci, M.R.; Hinestroza, J.P.; Skorobogatiy, M.; Khademhosseini, A.; Yun, S.H. Nanotechnology in textiles. ACS Nano 2016, 3, 3042–3068. [Google Scholar] [CrossRef] [PubMed]

- Tania, I.; Ali, M. Effect of the coating of zinc oxide (ZnO) nanoparticles with binder on the functional and mechanical properties of cotton fabric. Mater. Today 2020, 38, 2607–2611. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Eid, B.M.; Abd El-Aziz, E.; Abou Elmaaty, T.M.; Ramadan, S.M. Loading of chitosan—Nano metal oxide hybrids onto cotton/polyester fabrics to impart permanent and effective multi functions. Int. J. Biol. Macromol. 2017, 105, 769–776. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Abou Elmaaty, T.M.; Eid, B.M.; Abd El-Aziz, E. Combined antimicrobial finishing and pigment printing of cotton/polyester blends. Carbohydr. Polym. 2013, 95, 379–388. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, N.A.; Eid, B.M.; Abou Elmaaty, T.M.; Abd El-Aziz, E. A smart approach to add antibacterial functionality to cellulosic pigment prints. Carbohydr. Polym. 2013, 94, 612–618. [Google Scholar] [CrossRef] [PubMed]

- Ibahim, N.A.; Eid, B.M.; Abd El-Aziz, E.; Abou Elmaaty, T.M. Functionalization of linen/cotton pigment prints using inorganic nanostructure materials. Carbohydr. Polym. 2013, 97, 537–545. [Google Scholar] [CrossRef] [PubMed]

- Ibahim, N.A.; Eid, B.M.; Abd El-Aziz, E.; Abou Elmaaty, T.M.; Ramadan, S.M. Multifunctional cellulose-containing fabrics usingmodified finishing formulations. RSC Adv. 2017, 7, 33219–33230. [Google Scholar] [CrossRef] [Green Version]

- Abou Elmaaty, T.M.; Abdeldayem, S.A.; Elshafa, N. Simultaneous Thermochromic Pigment Printing and Se-NPMultifunctional Finishing ofCotton Fabrics forSmart Childrenswear. Cloth.Text. Res. J. 2020, 38, 182–195. [Google Scholar] [CrossRef]

- Sobha, K.; Surendranath, K.; Meena, V.; Jwala, T.K.; Swetha, N.; Latha, K.S.M. Emerging trends in nano biotechnology. Biotechnol. Mol. Biol. Rev. 2010, 5, 1–12. [Google Scholar] [CrossRef]

- Bhatia, S.C. Pollution Control in Textile Industry; Woodhead Publishing India Pvt. Ltd: New Delhi, India, 2017. [Google Scholar] [CrossRef]

- Raut, S.; Vasavada, S.; Chaudhari, S. Effect of Nano TiO2 Finish on Functional Performance of Fabric. Int. J. Innov. Res. Technol. Sci. Eng. 2017, 6, 117–130. [Google Scholar] [CrossRef]

- Mohamed, O. Opportunities, and risks of nanotechnology-changes in some of the main properties associated with comfortable in cellulose materials. J. Archit. Arts Humanist. Sci. 2018, 11, 423–435. [Google Scholar] [CrossRef]

- Ghosh, G.; Sidpara, A.; Bandyopadhyay, P.P. High efficiency chemical assisted nano finishing of HVOFsprayed WC-Co coating. Surf. Coat. Technol. 2018, 334, 204–214. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S. Sustainable Use of Nanomaterials in Textiles and Their Environmental Impact. Materials 2020, 13, 5134. [Google Scholar] [CrossRef]

- Montazer, M.; Harifi, T. Nano Finishing of Textile Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Joshi, M.; Adak, B. Advances in Nanotechnology Based Functional, Smart and Intelligent Textiles: A Review; Elsevier, B.V. Delhi: New Delhi, India, 2019. [Google Scholar] [CrossRef]

- Joshi, M.; Khanna, R.; Shekhar, R.; Jha, K. Chitosan Nanocoating on Cotton Textile Substrate UsingLayer-by-Layer Self-Assembly Technique. J. Appl. Polym. Sci. 2011, 119, 2793–2799. [Google Scholar] [CrossRef]

- Islam, S.; Ang, B.; Andriyana, A.; Afifi, A. A review on fabrication of nanofibers via electrospinning and their applications. SN Appl. Sci. 2019, 1, 1248. [Google Scholar] [CrossRef] [Green Version]

- Berton, F.; Porrelli, D.; Di Lenarda, R.; Turco, G. Critical Review on the Production of Electrospun Nano fibres for Guided Bone Regeneration in Oral Surgery. Nanomaterials 2019, 10, 16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Patra, J.K.; Gouda, S. Application of nanotechnology in textile engineering: An overview. J. Eng. Technol. Res. 2013, 5, 104–111. [Google Scholar] [CrossRef]

- Fernandes, M.; Padrão, J.; Ribeiro, A.; Fernandes, R.; Melro, L.; Nicolau, T.; Mehravani, B.; Alves, C.; Rodrigues, R.; Zille, A. Polysaccharides and Metal Nanoparticles for Functional Textiles: A Review. Nanomaterials 2022, 12, 1006. [Google Scholar] [CrossRef]

- Ahmad, S.; Fatma, A.; Manal, E.; Ghada, A.M. Applications of Nanotechnology and Advancements in Smart Wearable Textiles:An Overview. Egypt. J. Chem. 2020, 63, 2177–2184. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Xu, Q.B.; Fu, F.Y.; Liu, X.D. Durable antimicrobial cotton textiles modified with inorganic nanoparticles. Cellulose 2016, 23, 2791–2808. [Google Scholar] [CrossRef]

- Ranjan, S.; Dasgupta, N.; Lichtfouse, E. Nanoscience in Food and Agriculture 1; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Shah, M.; Fawcett, D.; Sharma, S.; Tripathy, S.K.; Poinern, G.E.J. Green synthesis of metallic nanoparticles via biological entities. Materials 2015, 8, 7278–7308. [Google Scholar] [CrossRef] [Green Version]

- Parveen, K.; Banse, V.; Ledwani, L. Green Synthesis of Nanoparticles: Their Advantages and Disadvantages; AIP Publishing LLC: Melville, NY, USA, 2016; Volume 1724, p. 020048. [Google Scholar] [CrossRef]

- Gour, A.; Jain, N.K. Advances in green synthesis of nanoparticles. Artif. Cells Nanomed. Biotechnol. 2019, 47, 844–851. [Google Scholar] [CrossRef] [Green Version]

- Nair, G.; Sajini, T.; Mathew, B. Advanced green approaches for metal and metal oxide nanoparticles synthesis and their environmental applications. Talanta Open 2022, 5, 100030. [Google Scholar] [CrossRef]

- Abou Elmaaty, T.; Ramadan, S.; Nasr Eldin, S.; Elgamal, J. One Step Thermochromic Pigment Printing and AgNPs Antibacterial Functional Finishing of Cotton and Cotton/PET Fabrics. Fibers Polym. 2018, 19, 2317–2323. [Google Scholar] [CrossRef]

- Islam, S.; Butola, B. Advances in Functional and Protective Textiles; Woodhead Publishing: Shaston, UK, 2020. [Google Scholar] [CrossRef]

- Auria, C.; Nesma, T.; Juanes, P.; Viñuela, A.; Gomez, H.; Acebes, V.; Góngora, R.; Parra, M.; Roman, R.; Fuentes, M. Interactions of Nanoparticles and Biosystems: Microenvironment of Nanoparticles and Biomolecules in Nanomedicine. Nanomaterials 2019, 9, 1365. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pivec, T.; Hribernik, S.; Kola, M.; Kleinsche, K. Environmentally friendly procedure for in-situ coating of regenerated cellulose fibres with silver nanoparticles. Carbohydr. Polym. 2017, 163, 92–100. [Google Scholar] [CrossRef]

- Granados, A.; Pleixats, R.; Vallribera, A. Recent Advances on Antimicrobial and Anti-Inflammatory Cotton Fabrics Containing Nanostructures. Molecules 2021, 26, 3008. [Google Scholar] [CrossRef]

- Xu, Q.; Ke, X.; Shen, L.; Ge, N.; Zhang, Y.; Fu, F.; Liu, X. Surface modification by carboxymethyl chitosan via pad-dry-cure method for binding AgNPs onto cotton fabric. Int. J. Biol. Macromol. 2018, 111, 796–803. [Google Scholar] [CrossRef]

- Rajaboopathi, S.; Thambidurai, S. Evaluation of UPF and antibacterial activity of cotton fabriccoated with colloidal seaweed extract functionalized silver nanoparticles. J. Photochem. Photobiol. B Biol. 2018, 183, 75–87. [Google Scholar] [CrossRef]

- Patil, A.; Jadhav, S.; More, V.; Sonawane, K.; Patil, P. Novel One Step Sono synthesis and Deposition Technique to Prepare Silver Nanoparticles Coated Cotton Textile with Antibacterial Properties. ColloidJ. 2019, 81, 720–727. [Google Scholar] [CrossRef]

- Ramezani, M.; Kosak, A.; Lobnik, A.; Hadela, A. Synthesis and characterization of anantimicrobial textile by hexagon silver nanoparticles with a newcapping agent via the polyol process. Text. Res. J. 2019, 89, 5130–5143. [Google Scholar] [CrossRef]

- Maghimaa, M.; Alharbi, S. Green synthesis of silver nanoparticles from Curcuma longa L. and coating on the cotton fabrics for antimicrobial applications and wound healing activity. J. Photochem. Photobiol. B Biol. 2020, 204, 111806. [Google Scholar] [CrossRef]

- Aguda, O.N.; Latee, A. Novel biosynthesis of silver nanoparticles through valorization of Parkiabiglobosa fermented-seed wastewater: Antimicrobial properties and nanotextile application. Environ. Technol. Innov. 2021, 24, 102077. [Google Scholar] [CrossRef]

- Deeksha, B.; Sadanand, V.; Hariram, N.; Rajulu, A. Preparation and properties of cellulose nanocomposite fabrics with in situ generated silver nanoparticles by bioreduction method. J. Bioresour. Bioprod. 2021, 6, 75–81. [Google Scholar] [CrossRef]

- Hamouda, T.; Ibrahim, H.; Kafafy, H.; Mashaly, H.; Mohamed, N.; Aly, N. Preparation of cellulose-based wipes treated with antimicrobial and antiviral silver nanoparticles as novel effective high-performance coronavirus fighter. Int. J. Biol. Macromol. 2021, 181, 990–1002. [Google Scholar] [CrossRef]

- Chávez, C.; Hollanda, L.; Esquive, A.; Risco, A.; Arcentales, S.; Yáñez, J.; Gonzales, C. Antibacterial and Antifungal Activity of Functionalized Cotton Fabric with Nanocomposite Based on Silver Nanoparticles and Carboxymethyl Chitosan. Processes 2022, 10, 1088. [Google Scholar] [CrossRef]

- AbouElmaaty, T.; Mandour, B. ZnO and TiO2 Nanoparticles as Textile Protecting Agents against UV Radiation: A Review. Asian J. Chem. Sci. 2018, 4, 1–14. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Abd El-Aziz, E.; Eid, B.M.; Abou Elmaaty, T.M. Single-stage process for bifunctionalization and eco-friendly pigment coloration of cellulosic fabrics. J. Text. Inst. 2015, 107, 1022–1029. [Google Scholar]

- Rashid, M.; Simoncic, B.; Tomsic, B. Recent advances in TiO2-functionalized textile surfaces. Surf. Interfaces 2021, 22, 100890. [Google Scholar] [CrossRef]

- Shah, M.; Pirzada, B.; Price, G.; Shibiru, A.; Qurashi, A. Applications of nanotechnology in smart textile industry. J. Adv. Res. 2022, 38, 55–75. [Google Scholar] [CrossRef]

- Pachaiappan, R.; Rajendran, S.; Show, P.; Manavalan, K.; Naushad, M. Metal/metal oxide nanocomposites for bactericidal effect: A review. Chemosphere 2020, 272, 128607. [Google Scholar] [CrossRef]

- Peter, A.; Cozmuta, A.; Nicula, C.; Cozmuta, L.; Vulpoi, A.; Baia, L. Fabric impregnated with TiO2 gel with self-cleaning property. Int. J. Appl. Ceram. Technol. 2018, 16, 666–681. [Google Scholar] [CrossRef]

- Wang, P.; Dong, Y.; Li, B.; Li, Z.; Bian, L. A sustainable and cost effective surface functionalization of cotton fabric using TiO2 hydrosol produced in a pilot scale: Condition optimization, sunlight-driven photocatalytic activity and practical applications. Ind. Crop. Prod. 2018, 123, 197–207. [Google Scholar] [CrossRef]

- Cheng, D.; He, M.; Cai, G.; Wang, X.; Ran, J.; Wu, J. Durable UV-protective cotton fabric by deposition of multilayer TiO2 nanoparticles films on the surface. J. Coat. Technol. Res. 2018, 15, 603–610. [Google Scholar] [CrossRef]

- Riaz, S.; Ashraf, M.; Hussain, T.; Hussain, M.; Younus, A. Fabrication of Robust Multifaceted Textiles by Application of Functionalized TiO2 Nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2019, 581, 123799. [Google Scholar] [CrossRef]

- Aalipourmohammadi, M.; Davodiroknabadi, A.; Nazari, A. Homogeneous coatings of titanium dioxide nanoparticles on corona-treated cotton fabric for enhanced self-cleaning and antibacterial properties. Autex Res. J. 2019, 21, 101–107. [Google Scholar] [CrossRef]

- Bekrani, M.; Zohoori, S.; Davodiroknabadi, A. Producing multifunctional doped with nano cotton TiO2 fabrics and ZnO using nano CeO2. Autex Res. J. 2019, 20, 78–84. [Google Scholar] [CrossRef] [Green Version]

- El-Bisi, M.; Othman, R.; Yassin, F. Improving Antibacterial and Ultraviolet Properties of Cotton Fabrics via Dual Effect of Nano-metal Oxide and Moringaoleifera Extract. Egypt. J. Chem. 2020, 63, 3441–3451. [Google Scholar] [CrossRef]

- Saleem, M.; Naz, M.; Shukrulla, S.; Ali, S.; Hamdani, S. Ultrasonic biosynthesis of TiO2 nanoparticles for improved self-cleaning and wettability coating of DBD plasma pre-treated cotton fabric. Appl. Phys. A 2021, 127, 608. [Google Scholar] [CrossRef]

- Smiechowicz, E.; Niekraszewicz, B.; Strzelinska, M.; Zielecka, M. Antibacterial fibers containing nanosilica with immobilized siliver nanoparticles. Autex Res.J. 2020, 20, 441–448. [Google Scholar] [CrossRef]

- AbouElmaaty, T.; Elsisi, H.; Elsayad, G.; Elhadad, H.; Ahmed, K.; Plutino, M. Fabrication of new multifunctional cotton/lycra composites protective textiles through deposition of nano silica coating. Polymers 2021, 13, 2888. [Google Scholar] [CrossRef]

- Rethinam, S.; Ramamoorthy, R.; Robert, B.; Nallathambi, G. Production of silica nanoparticles bound fabrics and evaluation ofits antibacterial/ultraviolet protection properties. Micro Nano Lett. 2018, 13, 1404–1407. [Google Scholar] [CrossRef]

- Riaz, S.; Ashraf, M.; Hussain, T.; Hussain, M. Modification of silica nanoparticles to develop highly durable superhydrophobic and antibacterial cotton fabrics. Cellulose 2019, 26, 5159–5175. [Google Scholar] [CrossRef]

- Zakir, K.; Shahzadi, S.; Rasool, S.; Kanwal, Z.; Riaz, S.; Naseem, S.; Raza, M. Fabrication, and characterization of superhydrophobic coatings on cotton fabrics using silica nanoparticles for self-cleaning applications. WorldJ. Adv.Res.Rev. 2020, 8, 33–39. [Google Scholar] [CrossRef]

- Kwon, J.; Jung, H.; Jung, H.; Lee, J. Micro/Nanostructured Coating for Cotton Textiles That Repel Oil, Water, and Chemical Warfare Agents. Polymers 2020, 12, 1826. [Google Scholar] [CrossRef]

- Shahidi, S.; Mohammadbagherloo, H.; Elahi, S.; Dalalsharifi, S.; Mongkholrattanasit, R. In Situ Synthesis of SiO2 Nanoparticles by Sol-Gel Method on Cotton Fabrics and Investigation of Their Physical and Chemical Properties. Key Eng. Mater. 2021, 891, 37–42. [Google Scholar] [CrossRef]

- Amibo, T.; Beyan, S.; Mustefa, M.; Prabhu, S.; Bayu, A. Development of Nanocomposite based Antimicrobial Cotton Fabrics Impregnated by Nano SiO2 Loaded AgNPs Derived from Eragrostis Teff straw. Mater. Res. Innov. 2021, 25, 1–10. [Google Scholar] [CrossRef]

- Ahmed, H.; Hassan, R. Fabrication of Super hydrophobicity of cotton fabric treated with silica Nano particles and water repellent agent. IJEAIS 2021, 5, 50–57. Available online: http://ijeais.org/wp-content/uploads/2021/10/IJEAIS211007.pdf (accessed on 4 August 2022).

- Gudkov, S.; Burmistrov, D.; Serov, D.; Rebezov, M.; Semenova, A.; Lisitsyn, A. A Mini Review of Antibacterial Properties of ZnO Nanoparticles. Front. Phys. 2021, 9, 641481. [Google Scholar] [CrossRef]

- Fouda, A.; Saad, E.; Salem, S.S.; Shaheen, T.I. In-Vitro cytotoxicity, antibacterial, and UV protection properties of the biosynthesized Zinc oxide nanoparticles for medical textile applications. Microb. Pathog. 2018, 125, 252–261. [Google Scholar] [CrossRef]

- Salat, M.; Petkova, P.; Hoyo, J.; Perelshtein, I.; Gedanken, A.; Tzanov, T. Durable antimicrobial cotton textiles coated sonochemically with ZnO nanoparticles embedded in an in-situ enzymatically generated bio adhesive. Carbohydr. Polym. 2018, 189, 198–203. [Google Scholar] [CrossRef]

- Souza, D.A.R.; Gusatti, M.; Ternus, R.Z.; Fiori, M.A.; Riella, H.G. In Situ Growth of ZnO Nanostructures on Cotton Fabric by Solochemical Process for Antibacterial Purposes. J. Nanomater. 2018, 2018, 9082191. [Google Scholar] [CrossRef] [Green Version]

- Roy, T.; Shamim, S.; Rahman, M.; Ahmed, F.; Gafur, M.A. The Development of ZnO Nanoparticle Coated Cotton Fabrics for Antifungal and Antibacterial Applications. Mater. Sci. Appl. 2020, 11, 601–610. [Google Scholar] [CrossRef]

- Mulchandani, N.; Karnad, V. Application of Zinc Oxide nanoparticles on Cotton fabric for imparting Antimicrobial properties. Int. J. Environ. Rehabil. Conserv. 2020, 1, 1–10. [Google Scholar] [CrossRef]

- Momotaz, F.; Siddika, A.; Shaihan, T.; Islam, A. The Effect of Zno Nano Particle Coating and their Finishing Process on the Antibacterial Property of Cotton Fabrics. J. Eng. Sci. 2020, 11, 61–65. [Google Scholar] [CrossRef]

- Mousa, M.A.; Khairy, M. Synthesis of nano-zinc oxide with different morphologies and its application on fabrics for UV protection and microbe resistant defense clothing. Text. Res. J. 2020, 90, 2492–2503. [Google Scholar] [CrossRef]

- Tania, I.S.; Ali, M. Coating of ZnO nanoparticle on cotton fabric to create afunctional textile with enhanced mechanical properties. Polymers 2021, 13, 2701. [Google Scholar] [CrossRef]

- Patil, A.H.; Jadhav, S.A.; More, V.B.; Sonawane, K.D.; Vhanbatte, S.H.; Kadole, P.V.; Patil, P.S. A new method for single step sono synthesis and incorporation of ZnO nanoparticles in cotton fabrics for imparting antimicrobial property. Chem. Pap. 2021, 75, 1247–1257. [Google Scholar] [CrossRef]

- Shah, K.; Lu, Y. Morphology, large scale synthesis and building applications of copper nanomaterials. Constr. Build. Mater. 2018, 180, 544–578. [Google Scholar] [CrossRef]

- Santhoshkumar, J.; Agarwal, H.; Menon, S.; Rajeshkumar, S.; Venkat Kumar, S.A. Biological Synthesis of Coppernanoparticles and Its Potential Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Harishchandra, B.; Pappuswamy, M.; Pu, A.; Shama, G.; Pragatheesh, A.; Arumugam, V.; Periyaswamy, T.; Sundaram, R. Copper Nanoparticles: A Review on Synthesis, Characterization and Applications. AsianPac. J. Cancer Biol. 2020, 5, 201–210. [Google Scholar] [CrossRef]

- Nourbakhsh, S.; Iranfa, S. Investigation on Durability of Copper Nano Particles onCotton Fiber. J. Appl. Chem. Res. 2018, 12, 30–41. Available online: https://journals.iau.ir/article_540390_ec96b3a1a01318a52aaddd782d7b2ee3.pdf (accessed on 4 August 2022).

- Sun, C.; Li, Y.; Li, Z.; Su, Q.; Wang, Y.; Liu, X. Durable and Washable Antibacterial Copper Nanoparticles Bridged by Surface Grafting Polymer Brushes on Cotton and Polymeric Materials. J. Nanomater. 2018, 2018, 6546193. [Google Scholar] [CrossRef] [Green Version]

- Paramasivan, S.; Nagarajan, E.R.; Nagarajan, R.; Anumakonda, V.R.; Hariram, N. Characterization of cotton fabric nanocomposites with in situ generated copper nanoparticles for antimicrobial applications. Prep. Biochem. Biotechnol. 2018, 48, 574–581. [Google Scholar] [CrossRef] [PubMed]

- Shaheen, T.; Fouda, A.; Salem, S. Integration of Cotton Fabrics with Biosynthesized CuONanoparticles for Bactericidal Activity in the Terms of Their Cytotoxicity Assessment. Ind. Eng. Chem. Res. 2021, 60, 1553–1563. [Google Scholar] [CrossRef]

- Alagarasan, D.; Harikrishnan, A.; Surendiran, M.; Indira, K.; Khalifa, A.; Elesawy, B. Synthesis and characterization of CuO nanoparticles and evaluation of their bactericidal and fungicidal activities in cotton fabrics. Appl. Nanosci. 2021. [Google Scholar] [CrossRef] [PubMed]

- El-Nahhal, I.; Salem, J.; Kodeh, F.; Anbar, R.; Elmanama, A. Preparation of CuO-NPs Coated Cotton, Starched Cotton and its CuO-Ag Nanocomposite, Cu(II) Curcumin Complex Coated Cotton and their Antimicrobial Activities. J. Nanomed. Nanotechnol. 2021, 12, 566. [Google Scholar] [CrossRef]

- Alamer, F.; Beyari, R. Overview of the Influence of Silver, Gold, and Titanium Nanoparticles on the Physical Properties of PEDOT:PSS-Coated Cotton Fabrics. Nanomaterials 2022, 12, 1609. [Google Scholar] [CrossRef]

- Shanmugasundaram, O.L.; Ramkumar, M. Characterization and Study of Physical Properties and Antibacterial Activities of Human Hair Keratin–Silver Nanoparticles and Keratin–Gold Nanoparticles Coated Cotton Gauze Fabric. J. Ind. Text. 2018, 47, 798–814. [Google Scholar] [CrossRef]

- Ganesan, R.M.; Prabu, H.G. Synthesis of gold nanoparticles using herbal Acoruscalamus rhizome extract and coating on cotton fabric for antibacterial and UV blocking applications. Arab. J. Chem. 2019, 12, 2166–2174. [Google Scholar] [CrossRef]

- Baruah, B.; Downer, L.; Agyeman, D. Fabric-Based Composite Materials Containing ZnO-NRs and ZnO-NRs-AuNPs and Their Application in Photocatalysis. Mater. Chem. Phys. 2019, 231, 252–259. [Google Scholar] [CrossRef]

- Boomi, P.; Ganesan, R.M.; Poorani, G.; Gurumallesh Prabu, H.; Ravikumar, S.; Jeyakanthan, J. Biological Synergy of Greener Gold Nanoparticles by Using Coleus Aromaticus Leaf Extract. Mater. Sci. Eng. C 2019, 99, 202–210. [Google Scholar] [CrossRef]

- Boomi, P.; Poorani, G.P.; Selvam, S.; Palanisamy, S.; Jegatheeswaran, S.; Anand, K.; Balakumar, C.; Premkumar, K.; Prabu, H.G. Green Biosynthesis of Gold Nanoparticles Using Croton Sparsiflorus Leaves Extract and Evaluation of UV Protection, Antibacterial and Anticancer Applications. Appl. Organomet. Chem. 2020, 34, e5574. [Google Scholar] [CrossRef]

- Boomi, P.; Ganesan, R.; Poorani, G.P.; Jegatheeswaran, S.; Balakumar, C.; Prabu, H.G.; Anand, K.; Prabhu, N.M.; Jeyakanthan, J.; Saravanan, M. Phyto-engineered gold nanoparticles (AuNPs) with potential antibacterial, antioxidant, and wound healing activities under in vitro and in vivo conditions. Int. J. Nanomed. 2020, 15, 7553–7568. [Google Scholar] [CrossRef] [PubMed]

- Dakineni, S.; Budiredla, N.; Kolli, D.; Rudraraju, R. Gold nanoparticles synthesized from Pergulariadaemia leaves extract for Antibacterial, anticancer and UV protection. Mater. Today 2022, 51, 928–934. [Google Scholar] [CrossRef]

- Butola, B.S.; Garg, A.; Garg, A.; Chauhan, I. Development of Multi-functional Properties on Cotton Fabricby In Situ Application of TiO2 and ZnO Nanoparticles. J. Inst. Eng. India Ser. E 2018, 99, 93–100. [Google Scholar] [CrossRef]

- Mamatha, G.; Rajulu, A.V.; Madhukar, K. In situ generation of bimetallic nanoparticles in cotton fabric using aloe vera leaf extractas reducing agent. J. Nat. Fibers 2018, 17, 1121–1129. [Google Scholar] [CrossRef]

- Rao, A.V.; Ashok, B.; Mahesh, M.U.; Subbareddy, V.C.; Sekhar, V.C.; Ramanamurth, G.V.; Rajulu, A.V. Antibacterial cotton fabrics with in situ generated silver copper bimetallic nanoparticles using red sanders power extract as reducing agent. Int. J. Polym. Anal. Charact. 2019, 24, 346–354. [Google Scholar] [CrossRef]

- Saraswat, M.; Permadani, R.L.; Slamet, A. The innovation of antimicrobial and self-cleaning using Ag/TiO2 nanocomposite coated on cotton fabric for footwear application. IOP Conf. Ser. Mater. Sci. Eng. 2019, 509, 012091. [Google Scholar] [CrossRef]

- Hassabo, A.H.; El-Naggar, M.E.; Mohamed, A.L.; Hebeish, A.A. Development of multifunctional modified cotton fabric withtri-component nanoparticle of silver, copper and zinc oxide. Carbohydr. Polym. 2019, 210, 144–156. [Google Scholar] [CrossRef]

- Ansari, M.; Sajjadi, S.A.; Sahebian, S.; Heidari, E.K. Photocatalytic and antibacterial activity of silver/titanium dioxide/zinc oxide nanoparticles coated on cotton fabrics. ChemistrySelect 2020, 5, 8370–8378. [Google Scholar] [CrossRef]

- Gao, D.; Liu, J.; Lyu, L.; Li, Y.; Ma, J.; Baig, W. Construct the multifunction of cotton fabric by synergism between nano ZnO and Ag. Fiber Polym. 2020, 21, 505–512. [Google Scholar] [CrossRef]

- Mateescu, A.O.; Mateescu, G.; Burducea, I.; Mereuta, P.; Chirila, L.; Popescu, A.; Stroe, M.; Nila, A.; Baibara, M. Textile Materials Treatment With Mixture of TiO2: And SiO2 Nanoparticles for Improvement of Their Self-Cleaning Properties. J. Nat. Fibers. 2020, 19, 2443–2456. [Google Scholar] [CrossRef]

- Silva, D.; Souza, A.; Ferreira, G.; Duran, A.; Cabral, A.; Fonseca, F.; Bueno, R.; Rosa, D. Cotton Fabrics Decorated with Antimicrobial Ag-Coated TiO2 Nanoparticles Are Unable to Fully and Rapidly Eradicate SARS-CoV-2. ACS Appl. Nano. Mater. 2021, 4, 12949–12956. [Google Scholar] [CrossRef]

| Nanomaterials | NPs Size | Synthesis Method | Application Method | Functionality | Ref Year |

|---|---|---|---|---|---|

| AgNPs | n.a * | - | Pad-dry-cure | Antibacterial | [41] 2018 |

| AgNPs | n.a * | Seaweed (Padina gymnospora) extract | Pad-dry-cure | Antibacterial and UV protection | [42] 2018 |

| AgNPs | n.a * | Sonochemical | - | Antibacterial | [43] 2019 |

| AgNPs | 50–100 nm | Polyol method | Dip coating | Antibacterial and Antifungal | [44] 2019 |

| AgNPs | 15–40 nm | Peltophorum pterocarpum leaf extracts | Coating | antimicrobial and wound healing activity | [45] 2020 |

| AgNPs | 11.00–83.30 nm | Parkia biglobosa wastewater | Pad-dry-cure | Antibacterial and Antifungal | [46] 2021 |

| AgNPs | 91–100 nm | Medicinal plant Vitex leaf extract | - | Antibacterial | [47] 2021 |

| AgNPs | n.a * | Chemical method | Coating | Antibacterial, antifungal, and antiviral | [48] 2021 |

| AgNPs | 5–20 nm | Chemical method | Exhaustion method | Antibacterial and Antifungal | [49] 2022 |

| Nanomaterials | NPs Size | Synthesis Method | Application Method | Functionality | Ref Year |

|---|---|---|---|---|---|

| TiO2NPs | n.a | In situ sol-gel | Immersion, drying | Self-cleaning | [55] 2018 |

| TiO2NPs | n.a | Sol-gel | Pad-dry-cure | Self-cleaning | [56] 2018 |

| TiO2NPs | 50–120 nm | In situ hydrothermal under sonication | Layer-by-layer self-assembly | UV protection | [57] 2018 |

| TiO2NPs | 40 nm | Chemical method | Dip coating | Durable super-hydrophobicity, self-cleaning and antibacterial | [58] 2019 |

| TiO2NPs | 20–25 nm | In situ ultrasonic assisted sol-gel | Immersion, drying, curing | Self-cleaning and antibacterial | [59] 2019 |

| TiO2NPs | Less than 50 nm | - | Immersion, heating, drying | Antibacterial and UV protection | [60] 2019 |

| TiO2NPs | n.a | - | Immersion, pad-dry-cure | Antibacterial and UV protection | [61] 2020 |

| TiO2NPs | 11.27 nm | Aloe vera extract in a green method | Pad dry | Self-cleaning | [62] 2021 |

| Nanomaterials | NPs Size | Synthesis Method | Application Method | Functionality | Ref Year |

|---|---|---|---|---|---|

| SiO2NPs | 20–100 nm | Xerogels synthesized from cotton pods | Immersion, drying | Antibacterial and UV protection | [65] 2018 |

| SiO2NPs | 20–30 nm | - | Pad-dry-cure | Durable superhydrophobic and antibacterial | [66] 2019 |

| SiO2NPs | 90–150 nm | Stöber method | Dip-coating | Superhydrophobic | [67] 2020 |

| SiO2NPs | 200 nm | Stöber method | Dip-dry-cure | Oil and water repellency | [68] 2020 |

| SiO2NPs | n.a | In-situ sol-gel | Immersion, drying | Flame-retardant | [69] 2021 |

| SiO2/AgNPs | n.a | SiO2NPs by sol-gel AgNPs by green synthesis | - | Antibacterial | [70] 2021 |

| SiO2NPs | 150–300 nm | Sol-gel | Immersion, pad-dry-cure | Super hydrophobicity Water-repellent | [71] 2021 |

| Nanomaterials | NPs Size | Synthesis Method | Application Method | Functionality | Ref Year |

|---|---|---|---|---|---|

| ZnONPs | n.a | (Biological method) secreted proteins by the isolated fungus Aspergillus terreus AF-1 | Pad-dry-cure | Antibacterial and UV protection | [73] 2018 |

| ZnONPs | <100 nm | In situ sono-chemical | Coating | Antibacterial | [74] 2018 |

| ZnONPs | n.a | Solochemical | Immersion, drying | Antibacterial | [75] 2018 |

| ZnONPs | n.a | Chemical method | Dip coating | Antibacterial and Antifungal | [76] 2020 |

| ZnONPs | n.a | Wet chemical | Pad-dry-cure | Antibacterial | [77] 2020 |

| ZnONPs | n.a | - | Spin coating & Pad-dry-cure | Antibacterial | [78] 2020 |

| ZnONPs | 26 nm | liquid precipitation | Dip and curing | Antibacterial, antifungal and UV protection | [79] 2020 |

| ZnONPs | 70 (±5) nm | Wet chemical | Mechanical thermo-fixation (Pad-dry-cure) | Antibacterial and UV protection | [80] 2021 |

| ZnONPs | n.a | Sonosynthesis | Coating | Antibacterial | [81] 2021 |

| Nanomaterials | NPs Size | Synthesis Method | Application Method | Functionality | Ref Year |

|---|---|---|---|---|---|

| CuNPs | Less than 100 nm | - | Immersion, drying | Antibacterial | [85] 2018 |

| CuNPs | 130 ± 20 nm | ATRP and electroless deposition | Immersion, drying | Antibacterial | [86] 2018 |

| CuONPs | 40–100 nm | Green synthesis (Cassia alata leaf extract) | Dip coating Shaking+ | Antibacterial | [87] 2018 |

| CuONPs | 11–47 nm | Green synthesis (Biomass Filtrate of Aspergillus terreus AF-1) | Immersion, pad-dry-cure | Antibacterial | [88] 2021 |

| CuONPs | 10–100 nm | In situ synthesis | Pad-dry-cure | Antibacterial and Antifungal | [89] 2021 |

| CuONPs | n.a | - | Ultrasonic irradiation | Antibacterial and antiviral | [90] 2021 |

| Nanomaterials | NPs Size | Synthesis Method | Application Method | Functionality | Ref Year |

|---|---|---|---|---|---|

| AuNPs | 8–30 nm Average size 14 nm | Chemical reduction | Padding | Antibacterial | [92] 2018 |

| AuNPs | Less than 100 nm | Green method (extract of Acoruscalamusrhizome) | Pad-dry-cure | Antibacterial and UV protection | [93] 2019 |

| AuNPs | 18.5 ± 2.8 nm | Chemical reduction | Dip coating | Photocatalysis | [94] 2019 |

| AuNPs | Different sizes (<20 nm) | Biological reduction | Pad-dry-cure | Antibacterial and UV protection | [95] 2019 |

| AuNPs | 16.6–17 nm | Green synthesis | Pad-dry-cure | Antibacterial, anticancer, and UV protection | [96] 2020 |

| AuNPs | 19 nm | Green synthesis (Acalypha indica extract) | Pad-dry-cure | Antibacterial | [97] 2020 |

| AuNPs | 15–30 nm | Biological reduction (Pergulariadaemia leaves extract) | Pad-dry-cure | Antibacterial, anticancer, and UV protection | [98] 2022 |

| Nanomaterial | NPs Size | Synthesis Method | Application Method | Functionality | Applications | Ref Year |

|---|---|---|---|---|---|---|

| ZnO/TiO2NPs | n.a | Sol-gel | Pad-dry-cure | Antimicrobial activity, UV protection, and self-cleaning | Various household industrial and medical applications | [99] 2018 |

| Ag/CuNPs | 61 nm | In situ generation using Aloe vera leaf extract | Immersion, drying | Antibacterial activity | Dressing, wound healing, packaging, and medical applications | [100] 2018 |

| Ag/CuNPs | 80–90 nm Average size 100 nm | In situ method using aqueous red sand extracts | Dip coating | Antibacterial activity | Antibacterial bed and dressing materials | [101] 2019 |

| Ag/TiO2NPs | Anatase 34 nm and rutile 39 nm for Ag/TiO2 | Photo-assisted deposition (PAD) | Dip coating | Antimicrobial activity and self-cleaning | Footwear application | [102] 2019 |

| Ag/ZnO/CuNPs | FPEI 50 nm PMC 24 nm | Chemical synthesis | Immersion, Pad-dry-cure | Antibacterial activity, UV protection, and conductivity properties | Upholster beds, underwear, and protective clothing | [103] 2019 |

| Ag/ZnO/TiO2NPs | Silver colloidal (15.79–97.75 nm) TiO2 (9–14 nm) ZnO (13–20 nm) | Chemical synthesis | Immersion | Photocatalytic and antibacterial activities | Hospital and sportswear | [104] 2020 |

| Ag/ZnONPs | Ag 15 nm ZnO 30 nm | Chemical precipitation | Immersion, drying | Hydrophobicity, UV resistance, antibacterial, and anti-mildew activity | Protective clothing | [105] 2020 |

| TiO2/SiO2NPs | n.a | - | Immersion, pad-dry-cure | Self-cleaning | Self-cleaning textile | [106] 2020 |

| Ag/TiO2NPs | 1.3 ± 0.4 nm and 27.6 ± 9.9 nm | Sonochemistry method | - | Antimicrobial and antiviral activities | Protective and medical applications | [107] 2021 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abou Elmaaty, T.M.; Elsisi, H.; Elsayad, G.; Elhadad, H.; Plutino, M.R. Recent Advances in Functionalization of Cotton Fabrics with Nanotechnology. Polymers 2022, 14, 4273. https://doi.org/10.3390/polym14204273

Abou Elmaaty TM, Elsisi H, Elsayad G, Elhadad H, Plutino MR. Recent Advances in Functionalization of Cotton Fabrics with Nanotechnology. Polymers. 2022; 14(20):4273. https://doi.org/10.3390/polym14204273

Chicago/Turabian StyleAbou Elmaaty, Tarek M., Hanan Elsisi, Ghada Elsayad, Hagar Elhadad, and Maria Rosaria Plutino. 2022. "Recent Advances in Functionalization of Cotton Fabrics with Nanotechnology" Polymers 14, no. 20: 4273. https://doi.org/10.3390/polym14204273