Characterization and Parametric Study on Mechanical Properties Enhancement in Biodegradable Chitosan-Reinforced Starch-Based Bioplastic Film

Abstract

:1. Introduction

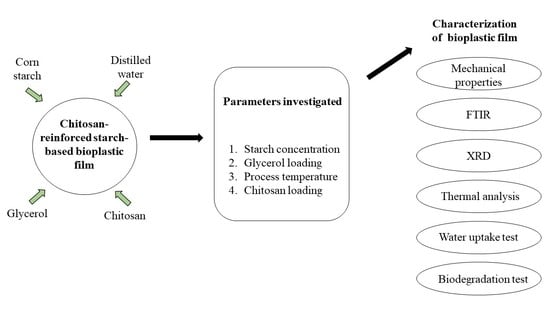

2. Materials and Methods

2.1. Materials

2.2. Preparation of Corn Starch Bioplastic Film

2.3. ANN Modeling

2.4. Data Verification

2.5. Characterization of Bioplastic Film

2.5.1. Mechanical Properties

2.5.2. Fourier-Transform Infrared (FTIR) Analysis

2.5.3. X-ray Diffraction (XRD)

2.5.4. Thermal Analysis

2.5.5. Water Uptake Test

2.5.6. Biodegradation Test

2.6. Statistical Analysis

3. Results and Discussion

3.1. Mechanical Properties

3.1.1. Effect of Starch Concentration

3.1.2. Effect of Glycerol Loading

3.1.3. Effect of Process Temperature

3.1.4. Effect of Chitosan Loading

3.2. ANN Modeling Results

3.3. FTIR

3.4. XRD

3.5. Thermal Analysis

3.6. Water Uptake Test

3.7. Biodegradation Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pathak, S.; Sneha, C.; Mathew, B.B. Bioplastics: Its timeline based scenario & challenges. J. Polym. Biopolym. Phys. Chem. 2014, 2, 84–90. [Google Scholar] [CrossRef]

- Zeller, M.A.; Hunt, R.; Jones, A.; Sharma, S. Bioplastics and their thermoplastic blends from Spirulina and Chlorella microalgae. J. Appl. Polym. Sci. 2013, 130, 3263–3275. [Google Scholar] [CrossRef]

- Thiruchelvi, R.; Das, A.; Sikdar, E. Bioplastics as better alternative to petro plastic. Mater. Today Proc. 2021, 37, 1634–1639. [Google Scholar] [CrossRef]

- Hasan, M.; Rahmayani, R. Bioplastic from Chitosan and Yellow Pumpkin Starch with Castor Oil as Plasticizer. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2018, 333, 012087. [Google Scholar] [CrossRef]

- Jiménez-Rosado, M.; Bouroudian, E.; Perez-Puyana, V.; Guerrero, A.; Romero, A. Evaluation of different strengthening methods in the mechanical and functional properties of soy protein-based bioplastics. J. Clean. Prod. 2020, 262, 121517. [Google Scholar] [CrossRef]

- Ginting, M.H.S.; Hasibuan, R.; Lubis, M.; Tanjung, D.; Iqbal, N. Effect of Hydrochloric Acid Concentration as Chitosan Solvent on Mechanical Properties of Bioplastics from Durian Seed Starch (Durio Zibethinus) with Filler Chitosan and Plasticizer Sorbitol. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2017, 180, 012126. [Google Scholar] [CrossRef] [Green Version]

- Ginting, M.H.S.; Tarigan, F.R.; Singgih, A.M. Effect of gelatinization temperature and chitosan on mechanical properties of bioplastics from avocado seed starch (Persea Americana mill) with plasticizer glycerol. Int. J. Eng. Sci. 2015, 4, 36–43. [Google Scholar]

- de Azêvedo, L.C.; Rovani, S.; Santos, J.J.; Dias, D.B.; Nascimento, S.S.; Oliveira, F.F.; Silva, L.G.; Fungaro, D.A. Study of Renewable Silica Powder Influence in the Preparation of Bioplastics from Corn and Potato Starch. J. Polym. Environ. 2021, 29, 707–720. [Google Scholar] [CrossRef]

- Nissa, R.; Fikriyyah, A.; Abdullah, A.; Pudjiraharti, S. Preliminary study of biodegradability of starch-based bioplastics using ASTM G21-70, dip-hanging, and Soil Burial Test methods. Proc. IOP Conf. Ser. Earth Environ. Sci. 2019, 277, 012007. [Google Scholar] [CrossRef]

- Akter, N.; Khan, R.A.; Tuhin, M.O.; Haque, M.E.; Nurnabi, M.; Parvin, F.; Islam, R. Thermomechanical, barrier, and morphological properties of chitosan-reinforced starch-based biodegradable composite films. J. Thermoplast. Compos. Mater. 2014, 27, 933–948. [Google Scholar] [CrossRef]

- Talón, E.; Trifkovic, K.T.; Nedovic, V.A.; Bugarski, B.M.; Vargas, M.; Chiralt, A.; González-Martínez, C. Antioxidant edible films based on chitosan and starch containing polyphenols from thyme extracts. Carbohydr. Polym. 2017, 157, 1153–1161. [Google Scholar] [CrossRef] [PubMed]

- Dome, K.; Podgorbunskikh, E.; Bychkov, A.; Lomovsky, O. Changes in the Crystallinity Degree of Starch Having Different Types of Crystal Structure after Mechanical Pretreatment. Polymers 2020, 12, 641. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Souza, A.; Benze, R.; Ferrão, E.; Ditchfield, C.; Coelho, A.; Tadini, C. Cassava starch biodegradable films: Influence of glycerol and clay nanoparticles content on tensile and barrier properties and glass transition temperature. LWT-Food Sci. Technol. 2012, 46, 110–117. [Google Scholar] [CrossRef]

- Jakubowska, E.; Gierszewska, M.; Nowaczyk, J.; Olewnik-Kruszkowska, E. Physicochemical and storage properties of chitosan-based films plasticized with deep eutectic solvent. Food Hydrocoll. 2020, 108, 106007. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Jędrzejewski, R.; Pilawka, R. Deep eutectic solvents as simultaneous plasticizing and crosslinking agents for starch. Int. J. Biol. Macromol. 2019, 129, 1040–1046. [Google Scholar] [CrossRef]

- Chan, Y.; Phang, S.; Tee, T.; Lee, T.; Soo, T. Preliminary Study of Mechanical Properties in Thermoplastic Starch (TPS)/Coffee-Waste-Derived Fillers Composites. In Proceedings of the Engineering Undergraduate Research Catalyst Conference (EURECA), Selangor, Malaysia, 1–2 July 2015; pp. 1–14. [Google Scholar]

- Mallakpour, S. Fructose functionalized MWCNT as a filler for starch nanocomposites: Fabrication and characterizations. Prog. Org. Coat. 2018, 114, 244–249. [Google Scholar] [CrossRef]

- de Azevedo, L.C.; Rovani, S.; Santos, J.J.; Dias, D.B.; Nascimento, S.S.; Oliveira, F.F.; Silva, L.G.; Fungaro, D.A. Biodegradable films derived from corn and potato starch and study of the effect of silicate extracted from sugarcane waste ash. ACS Appl. Polym. Mater. 2020, 2, 2160–2169. [Google Scholar] [CrossRef]

- Agustin, M.B.; Ahmmad, B.; Alonzo, S.M.M.; Patriana, F.M. Bioplastic based on starch and cellulose nanocrystals from rice straw. J. Reinf. Plast. Compos. 2014, 33, 2205–2213. [Google Scholar] [CrossRef]

- Méité, N.; Konan, L.K.; Tognonvi, M.T.; Doubi, B.I.H.G.; Gomina, M.; Oyetola, S. Properties of hydric and biodegradability of cassava starch-based bioplastics reinforced with thermally modified kaolin. Carbohydr. Polym. 2020, 254, 117322. [Google Scholar] [CrossRef]

- Anggraini, T.; Ulfimarjan, A.F.; Yenrina, R. The effect of chitosan concentration on the characteristics of sago (metroxylon sp) starch bioplastics. Res. J. Pharm. Biol. Chem. Sci. 2017, 8, 1339–1351. [Google Scholar] [CrossRef]

- Lopez, O.; Garcia, M.A.; Villar, M.A.; Gentili, A.; Rodriguez, M.; Albertengo, L. Thermo-compression of biodegradable thermoplastic corn starch films containing chitin and chitosan. LWT-Food Sci. Technol. 2014, 57, 106–115. [Google Scholar] [CrossRef]

- Zakaria, N.; Muhammad, N.; Sandu, A.; Abdullah, M. Effect of Mixing Temperature on Characteristics of Thermoplastic Potato Starch Film. Drug Deliv. Syst. 2018, 5, 7. [Google Scholar] [CrossRef]

- Yusof, Y.; Shukur, M.; Illias, H.; Kadir, M. Conductivity and electrical properties of corn starch–chitosan blend biopolymer electrolyte incorporated with ammonium iodide. Phys. Scr. 2014, 89, 035701. [Google Scholar] [CrossRef]

- Fakhouri, F.M.; Costa, D.; Yamashita, F.; Martelli, S.M.; Jesus, R.C.; Alganer, K.; Collares-Queiroz, F.P.; Innocentini-Mei, L.H. Comparative study of processing methods for starch/gelatin films. Carbohydr. Polym. 2013, 95, 681–689. [Google Scholar] [CrossRef]

- Kartika, T.; Harahap, M.B.; Ginting, M.H.S. Utilization of mango seed starch in manufacture of bioplastic reinforced with microparticle clay using glycerol as plasticizer. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2018, 309, 012068. [Google Scholar]

- Lubis, M.; Harahap, M.; Manullang, A.; Ginting, M.; Sartika, M. Utilization starch of jackfruit seed (Artocarpus heterophyllus) as raw material for bioplastics manufacturing using sorbitol as plasticizer and chitosan as filler. Proc. J. Phys. Conf. Ser. 2017, 801, 012014. [Google Scholar] [CrossRef] [Green Version]

- Lubis, M.; Harahap, M.B.; Ginting, M.H.S.; Sartika, M.; Azmi, H. Production of bioplastic from avocado seed starch reinforced with microcrystalline cellulose from sugar palm fibers. J. Eng. Sci. Technol. 2018, 13, 381–393. [Google Scholar]

- Maulida, S.M.; Tarigan, P. Production of starch based bioplastic from cassava peel reinforced with microcrystalline celllulose avicel PH101 using sorbitol as plasticizer. Proc. J. Phys. Conf. Ser. 2016, 710, 012012. [Google Scholar] [CrossRef] [Green Version]

- Salehudin, M.H.; Salleh, E.; Mamat, S.N.H.; Muhamad, I.I. Starch based active packaging film reinforced with empty fruit bunch (EFB) cellulose nanofiber. Procedia Chem. 2014, 9, 23–33. [Google Scholar] [CrossRef] [Green Version]

- Maran, J.P.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Artificial neural network and response surface methodology modeling in mass transfer parameters predictions during osmotic dehydration of Carica papaya L. Alex. Eng. J. 2013, 52, 507–516. [Google Scholar] [CrossRef] [Green Version]

- Abral, H.; Basri, A.; Muhammad, F.; Fernando, Y.; Hafizulhaq, F.; Mahardika, M.; Sugiarti, E.; Sapuan, S.; Ilyas, R.; Stephane, I. A simple method for improving the properties of the sago starch films prepared by using ultrasonication treatment. Food Hydrocoll. 2019, 93, 276–283. [Google Scholar] [CrossRef]

- Wu, C.-S. Renewable resource-based green composites of surface-treated spent coffee grounds and polylactide: Characterisation and biodegradability. Polym. Degrad. Stab. 2015, 121, 51–59. [Google Scholar] [CrossRef]

- Sapei, L.; Padmawijaya, K.S.; Sijayanti, O.; Wardhana, P.J. The effect of banana starch concentration on the properties of chitosan-starch bioplastics. J. Chem. Pharm. Res. 2015, 7, 101–105. [Google Scholar]

- Sultan, N.F.K.; Johari, W.L.W. The development of banana peel/corn starch bioplastic film: A preliminary study. Bioremediation Sci. Technol. Res. 2017, 5, 12–17. [Google Scholar]

- Samer, M.; Khalefa, Z.; Abdelall, T.; Moawya, W.; Farouk, A.; Abdelaziz, S.; Soliman, N.; Salah, A.; Gomaa, M.; Mohamed, M. Bioplastics production from agricultural crop residues. Agric. Eng. Int. CIGR J. 2019, 21, 190–194. [Google Scholar]

- Almeida, C.M.; Magalhães, J.M.; Souza, H.K.; Gonçalves, M.P. The role of choline chloride-based deep eutectic solvent and curcumin on chitosan films properties. Food Hydrocoll. 2018, 81, 456–466. [Google Scholar] [CrossRef]

- Ginting, M.H.S.; Kristiani, M.; Amelia, Y.; Hasibuan, R. The effect of chitosan, sorbitol, and heating temperature bioplastic solution on mechanical properties of bioplastic from durian seed starch (Durio zibehinus). Int. J. Eng. Res. Appl. 2015, 6, 33–38. [Google Scholar]

- Santana, R.F.; Bonomo, R.C.F.; Gandolfi, O.R.R.; Rodrigues, L.B.; Santos, L.S.; dos Santos Pires, A.C.; de Oliveira, C.P.; Fontan, R.d.C.I.; Veloso, C.M. Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. J. Food Sci. Technol. 2018, 55, 278–286. [Google Scholar] [CrossRef]

- Haryanti, P.; Setyawati, R.; Wicaksono, R. Pengaruh Suhu dan Lama Pemanasan Suspensi Pati serta Konsentrasi Butanol terhadap Karakteristik Fisikokimia Pati Tinggi Amilosa dari Tapioka. Agritech 2014, 34, 308–315. [Google Scholar] [CrossRef]

- Zhao, Y.; Saldaña, M.D. Hydrolysis of cassava starch, chitosan and their mixtures in pressurized hot water media. J. Supercrit. Fluids 2019, 147, 293–301. [Google Scholar] [CrossRef]

- Wojciechowska, P. The effect of concentration and type of plasticizer on the mechanical properties of cellulose acetate butyrate organic-inorganic hybrids. In Recent Advances in Plasticizers; IntechOpen: London, UK, 2012; pp. 141–164. [Google Scholar]

- Shi, A.-M.; Wang, L.-J.; Li, D.; Adhikari, B. Characterization of starch films containing starch nanoparticles: Part 1: Physical and mechanical properties. Carbohydr. Polym. 2013, 96, 593–601. [Google Scholar] [CrossRef]

- Bourtoom, T.; Chinnan, M.S. Preparation and properties of rice starch–chitosan blend biodegradable film. LWT-Food Sci. Technol. 2008, 41, 1633–1641. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Johansson, C. Mechanical and barrier properties of starch-based films plasticized with two-or three component deep eutectic solvents. Carbohydr. Polym. 2016, 151, 103–112. [Google Scholar] [CrossRef]

- Silitonga, A.; Masjuki, H.; Ong, H.C.; Yusaf, T.; Kusumo, F.; Mahlia, T. Synthesis and optimization of Hevea brasiliensis and Ricinus communis as feedstock for biodiesel production: A comparative study. Ind. Crops Prod. 2016, 85, 274–286. [Google Scholar] [CrossRef]

- Minakawa, A.F.; Faria-Tischer, P.C.; Mali, S. Simple ultrasound method to obtain starch micro-and nanoparticles from cassava, corn and yam starches. Food Chem. 2019, 283, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Pereira, P.F.; Andrade, C.T. Optimized pH-responsive film based on a eutectic mixture-plasticized chitosan. Carbohydr. Polym. 2017, 165, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Valodkar, M.; Thakore, S. Isocyanate crosslinked reactive starch nanoparticles for thermo-responsive conducting applications. Carbohydr. Res. 2010, 345, 2354–2360. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Kim, K.; Hanna, M.; Nag, D. Chitosan-starch composite film: Preparation and characterization. Ind. Crops Prod. 2005, 2, 185–192. [Google Scholar] [CrossRef]

- Namazi, H.; Dadkhah, A. Convenient method for preparation of hydrophobically modified starch nanocrystals with using fatty acids. Carbohydr. Polym. 2010, 79, 731–737. [Google Scholar] [CrossRef]

- Jiugao, Y.; Ning, W.; Xiaofei, M. The effects of citric acid on the properties of thermoplastic starch plasticized by glycerol. J. Starch-Stärke 2005, 57, 494–504. [Google Scholar] [CrossRef]

- Liu, H.; Adhikari, R.; Guo, Q.; Adhikari, B. Preparation and characterization of glycerol plasticized (high-amylose) starch–chitosan films. J. Food Eng. 2013, 116, 588–597. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Rodrigues, P.F.; Lopes, A.; Silva, R.J.; Caldeira, J.; Duarte, M.P.; Fernandes, F.B.; Coelhoso, I.M.J.C. Physical and morphological characterization of chitosan/montmorillonite films incorporated with ginger essential oil. Coatings 2019, 9, 700. [Google Scholar] [CrossRef] [Green Version]

- Singh, V.; Ali, S.; Somashekar, R.; Mukherjee, P. Nature of crystallinity in native and acid modified starches. Int. J. Food Prop. 2006, 9, 845–854. [Google Scholar] [CrossRef]

- Muñoz, L.A.; Pedreschi, F.; Leiva, A.; Aguilera, J.M. Loss of birefringence and swelling behavior in native starch granules: Microstructural and thermal properties. J. Food Eng. 2015, 152, 65–71. [Google Scholar] [CrossRef]

- Ren, L.; Yan, X.; Zhou, J.; Tong, J.; Su, X. Influence of chitosan concentration on mechanical and barrier properties of corn starch/chitosan films. Int. J. Biol. Macromol. 2017, 105, 1636–1643. [Google Scholar] [CrossRef] [PubMed]

- Syafri, E.; Kasim, A.; Abral, H.; Sulungbudi, G.T.; Sanjay, M.; Sari, N.H. Synthesis and characterization of cellulose nanofibers (CNF) ramie reinforced cassava starch hybrid composites. Int. J. Biol. Macromol. 2018, 120, 578–586. [Google Scholar] [CrossRef] [PubMed]

- Wahyuningtyas, N.E.; Suryanto, H.; Rudianto, E.; Sukarni, S.; Puspitasari, P. Thermogravimetric and Kinetic Analysis of Cassava Starch Based Bioplastic. J. Mech. Eng. Sci. 2017, 1, 69–77. [Google Scholar] [CrossRef] [Green Version]

- Krishnamurthy, A.; Amritkumar, P.J.S.A.S. Synthesis and characterization of eco-friendly bioplastic from low-cost plant resources. SN Appl. Sci. 2019, 1, 1432. [Google Scholar] [CrossRef] [Green Version]

- Mathew, S.; Brahmakumar, M.; Abraham, T.E. Microstructural imaging and characterization of the mechanical, chemical, thermal, and swelling properties of starch–chitosan blend films. Biopolym. Orig. Res. Biomol. 2006, 82, 176–187. [Google Scholar] [CrossRef]

- Zuraida, A.; Anuar, H.; Yusof, Y. The study of biodegradable thermoplastics sago starch. Proc. Key Eng. Mater. 2011, 471, 397–402. [Google Scholar] [CrossRef]

- McKeen, L. Introduction to the physical, mechanical, and thermal properties of plastics and elastomers. In The Effect of Sterilization Methods on Plastics and Elastomers; Elsevier: Amsterdam, The Netherlands, 2012; pp. 57–84. [Google Scholar]

- Klinmalai, P.; Srisa, A.; Laorenza, Y.; Katekhong, W.; Harnkarnsujarit, N. Antifungal and plasticization effects of carvacrol in biodegradable poly (lactic acid) and poly (butylene adipate terephthalate) blend films for bakery packaging. LWT 2021, 152, 112356. [Google Scholar] [CrossRef]

- Luchese, C.L.; Pavoni, J.M.F.; dos Santos, N.Z.; Quines, L.K.; Pollo, L.D.; Spada, J.C.; Tessaro, I.C. Effect of chitosan addition on the properties of films prepared with corn and cassava starches. J. Food Sci. Technol. 2018, 55, 2963–2973. [Google Scholar] [CrossRef] [PubMed]

- Wadaugsorn, K.; Panrong, T.; Wongphan, P.; Harnkarnsujarit, N. Plasticized hydroxypropyl cassava starch blended PBAT for improved clarity blown films: Morphology and properties. Ind. Crops Prod. 2022, 176, 114311. [Google Scholar] [CrossRef]

- Raspo, M.A.; Gomez, C.G.; Andreatta, A.E. Optimization of antioxidant, mechanical and chemical physical properties of chitosan-sorbitol-gallic acid films by response surface methodology. Polym. Test. 2018, 70, 180–187. [Google Scholar] [CrossRef] [Green Version]

| Starch Concentration (wt.%) | Gelatinized Duration (h) | Film Appearance |

|---|---|---|

| 2.5 | 5.5 | Film free of air bubbles. |

| 5 | 2 | Film free of air bubbles. |

| 7.5 | 1.5 | Film with tiny air bubbles. |

| 10 | 1 | Brittle film. |

| Experimental Run | Starch Concentration (wt.%) | Glycerol Loading (wt.%) | Process Temperature (°C) | Chitosan Loading (wt.%) | Experimental Tensile Strength (MPa) | Predicted Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 1 | 2.5 | 40 | 70 | 0 | 3.22 | 3.22 |

| 2 | 5 | 40 | 70 | 0 | 2.86 | 2.85 |

| 3 | 7.5 | 40 | 70 | 0 | 0.78 | 0.78 |

| 4 | 5 | 50 | 70 | 0 | 2.30 | 2.29 |

| 5 | 5 | 60 | 70 | 0 | 1.36 | 1.30 |

| 6 | 5 | 70 | 70 | 0 | 0.42 | 0.51 |

| 7 | 5 | 80 | 70 | 0 | 0.24 | 0.23 |

| 8 | 5 | 40 | 65 | 0 | 1.52 | 1.52 |

| 9 | 5 | 40 | 75 | 0 | 2.50 | 2.94 |

| 10 | 5 | 40 | 80 | 0 | 2.27 | 2.20 |

| 11 | 5 | 40 | 85 | 0 | 2.15 | 2.14 |

| 12 | 5 | 40 | 90 | 0 | 1.96 | 2.34 |

| 13 | 5 | 40 | 70 | 5 | 3.86 | 3.86 |

| 14 | 5 | 40 | 70 | 10 | 4.65 | 4.68 |

| 15 | 5 | 40 | 70 | 15 | 5.03 | 5.02 |

| 16 | 5 | 40 | 70 | 20 | 5.19 | 5.18 |

| R2 | 0.9955 |

| Experimental Run | Starch Concentration (wt.%) | Glycerol Loading (wt.%) | Process Temperature (°C) | Chitosan Loading (wt.%) | Experimental Elongation at Break (%) | Predicted Elongation at Break (%) |

|---|---|---|---|---|---|---|

| 1 | 2.5 | 40 | 70 | 0 | 53.6 | 54.3 |

| 2 | 5 | 40 | 70 | 0 | 51.5 | 48.6 |

| 3 | 7.5 | 40 | 70 | 0 | 41.6 | 41.4 |

| 4 | 5 | 50 | 70 | 0 | 53.8 | 56.2 |

| 5 | 5 | 60 | 70 | 0 | 64.8 | 63.7 |

| 6 | 5 | 70 | 70 | 0 | 68.2 | 69.9 |

| 7 | 5 | 80 | 70 | 0 | 76.1 | 74.3 |

| 8 | 5 | 40 | 65 | 0 | 39.8 | 38.7 |

| 9 | 5 | 40 | 75 | 0 | 52.6 | 53.5 |

| 10 | 5 | 40 | 80 | 0 | 53.2 | 55.3 |

| 11 | 5 | 40 | 85 | 0 | 67.1 | 65.4 |

| 12 | 5 | 40 | 90 | 0 | 70.8 | 75.1 |

| 13 | 5 | 40 | 70 | 5 | 47.9 | 48.2 |

| 14 | 5 | 40 | 70 | 10 | 49.8 | 47.5 |

| 15 | 5 | 40 | 70 | 15 | 46.1 | 46.4 |

| 16 | 5 | 40 | 70 | 20 | 44.6 | 45.1 |

| R2 | 0.9859 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.X.; Ong, H.C.; Andriyana, A.; Lim, S.; Pang, Y.L.; Kusumo, F.; Ngoh, G.C. Characterization and Parametric Study on Mechanical Properties Enhancement in Biodegradable Chitosan-Reinforced Starch-Based Bioplastic Film. Polymers 2022, 14, 278. https://doi.org/10.3390/polym14020278

Tan SX, Ong HC, Andriyana A, Lim S, Pang YL, Kusumo F, Ngoh GC. Characterization and Parametric Study on Mechanical Properties Enhancement in Biodegradable Chitosan-Reinforced Starch-Based Bioplastic Film. Polymers. 2022; 14(2):278. https://doi.org/10.3390/polym14020278

Chicago/Turabian StyleTan, Shiou Xuan, Hwai Chyuan Ong, Andri Andriyana, Steven Lim, Yean Ling Pang, Fitranto Kusumo, and Gek Cheng Ngoh. 2022. "Characterization and Parametric Study on Mechanical Properties Enhancement in Biodegradable Chitosan-Reinforced Starch-Based Bioplastic Film" Polymers 14, no. 2: 278. https://doi.org/10.3390/polym14020278