Research on Impact Resistance of Reinforced Concrete Beams Strengthened with Carbon Fiber Reinforced Polymer Grid and Engineered Cementitious Composites

Abstract

:1. Introduction

2. Experimental Content

2.1. Material Preparation

2.2. Material Properties

2.3. Design of Specimen

2.4. Test Equipment and Measurement Scheme

3. Analysis of Experimental Results

3.1. Crack Development

3.1.1. Crack Development in L1 Beam

3.1.2. Crack Development in L2 Beam

3.1.3. Crack Development in L3 Beam

3.1.4. Crack Development in L4 Beam

3.2. Damage Pattern

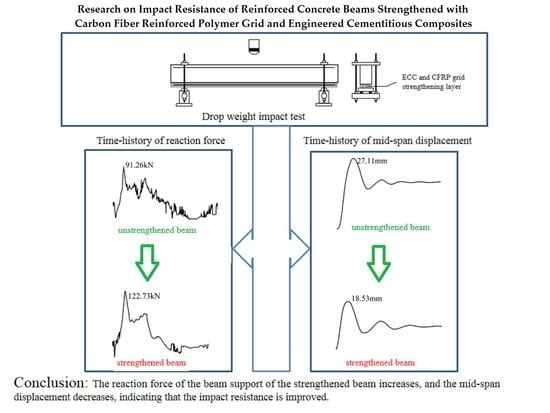

3.3. Support Reaction and Mid-Span Displacement

3.3.1. Time-History Curve of Support Reaction

3.3.2. Time-History Curve of Mid-Span Displacement

3.3.3. Discussion

3.4. Time-History Curve of Strain

3.4.1. Time-History Curve of CFRP Grid Strain

3.4.2. Time-History Curve of Carbon Fiber Sheet Strain

3.4.3. Time-History Curve of ECC Strain

4. Finite Element Modeling

4.1. Establishment of Finite Element Models

4.2. Comparative Analysis of Numerical Simulation and Experimental Results

4.2.1. Final Crack Pattern

4.2.2. Support Reaction Force Time-History Curve

4.2.3. Mid-Span Displacement Time-History Curve

4.3. Finite Element Parametric Analysis

4.3.1. Thickness of CFRP Grid

4.3.2. Longitudinal Reinforcement Rate of Tensile Steel

5. Simplified TDOF Model Analysis of Strengthened Beam

5.1. Parameter and Solution of Simplified TDOF Model

5.1.1. Mass Mechanical Model

5.1.2. Spring Mechanical Model

5.1.3. Damping Mechanical Model

5.1.4. Spring Mechanical Model

5.1.5. Damping Mechanical Model

5.1.6. Computational Solution

5.2. Comparison Analysis of Simplified Model and Experimental Results

5.3. Parameter Analysis with Simplified Model

5.3.1. Shear Span Ratio

5.3.2. Drop Hammer Impact Velocity

5.3.3. Drop Weight

6. Conclusions

- When the ECC and CFRP grid were used, the crack development was inhibited after the concrete cracked in the tensile area, and the tensile force was conducted to the uncracked concrete area, avoiding the brittle damage of RC beams with one crack to the end. CFRP grid reinforced ECC strengthened layer could improve the impact resistance of RC beams. The support reaction force was improved by 16.2%~34.5%, maximum mid-span displacement was reduced by 16.3%~31.6%, and mid-span residual displacement was reduced by 36.02%~49.53%. Too many layers of CFRP grid might lead to uneven ECC pouring and reduce the strengthening effect. The increase of ECC thickness could increase the peak of support reaction force and reduce the mid-span displacement. The 2% admixture of PE fibers in the ECC layer had a more significant effect on the lifting of the beam support reaction force and the reduction of the mid-span displacement than the 1% admixture. CFRP grid and ECC strengthened beams were close to the strengthening effect in the case where the nominal cross-sectional area of carbon fiber was much smaller than that of carbon fiber sheet and ECC strengthened beams.

- The finite element model could effectively predict the crack distribution of CFRP grid reinforced ECC strengthened RC beams. The parameters analysis with the finite element model revealed that the peak bearing reaction force increased with the increase of CFRP grid thickness, and the maximum displacement in the mid-span decreased with the increase of CFRP grid thickness. The peak bearing reaction force increased with the increase of longitudinal reinforcement rate, and the maximum displacement in the mid-span decreased with the increase of longitudinal reinforcement rate.

- The simplified TDOF model could simulate the impact response of the reinforced beam accurately. The parameter analysis with the simplified TDOF model showed that the maximum mid-span displacement of the beam increased first and then decreased slightly with the increase of the shear span ratio. The maximum mid-span displacement increased monotonically with the increase of the falling hammer speed and the growth rate increased gradually. With the increase of the falling hammer quality, the maximum mid-span displacement increased linearly and monotonically.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rizkalla, S.; Hassan, T.; Hassan, N. Design recommendations for the use of FRP for reinforcement and strengthening of concrete structures. Prog. Struct. Eng. Mater. 2003, 5, 16–28. [Google Scholar]

- Mohamed, O.A.; Al Hawat, W.; Keshawarz, M. Durability and Mechanical Properties of Concrete Reinforced with Basalt Fiber-Reinforced Polymer (BFRP) Bars: Towards Sustainable Infrastructure. Polymers 2021, 13, 1402. [Google Scholar] [CrossRef] [PubMed]

- Tin, H.X.; Thuy, N.T.; Seo, S.Y. Structural Behavior of RC Column Confined by FRP Sheet under Uniaxial and Biaxial Load. Polymers 2021, 14, 75. [Google Scholar] [PubMed]

- Jahani, Y.; Baena, M.; Gómez, J.; Barris, C.; Torres, L. Experimental study of the effect of high service temperature on the flexural performance of near-surface mounted (NSM) carbon fiber-reinforced polymer (CFRP)-strengthened concrete beams. Polymers 2021, 13, 920. [Google Scholar] [CrossRef]

- Pan, J.; Wang, X.; Dong, H. Strengthening of Precast RC Frame to Mitigate Progressive Collapse by Externally Anchored Carbon Fiber Ropes. Polymers 2021, 13, 1306. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.X. Flexural behaviors of glass fiber-reinforced polymer (GFRP) reinforced engineered cementitious composite beams. ACI Mater. J. 2002, 99, 11–21. [Google Scholar]

- Hu, B.; Zhou, Y.; Xing, F.; Sui, L.; Luo, M. Experimental and theoretical investigation on the hybrid CFRP-ECC flexural strengthening of RC beams with corroded longitudinal reinforcement. Eng. Struct. 2019, 200, 109717. [Google Scholar]

- Yuan, F.; Pan, J.; Leung, C.K.Y. Flexural behaviors of ECC and concrete/ECC composite beams reinforced with basalt fiber-reinforced polymer. J. Compos. Constr. 2013, 17, 591–602. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Zhou, X. Flexural behavior of basalt FRP reinforced ECC and concrete beams. Constr. Build. Mater. 2017, 142, 423–430. [Google Scholar] [CrossRef]

- Afefy, H.M.; Kassem, N.; Hussein, M. Enhancement of flexural behavior of CFRP-strengthened reinforced concrete beams using engineered cementitious composites transition layer. Struct. Infrastruct. Eng. 2015, 11, 1042–1053. [Google Scholar]

- Maalej, M.; Leong, K.S. Engineered cementitious composites for effective FRP-strengthening of RC beams. Compos. Sci. Technol. 2005, 65, 1120–1128. [Google Scholar] [CrossRef]

- Wu, C.; Li, V.C. CFRP-ECC hybrid for strengthening of the concrete structures. Compos. Struct. 2017, 178, 372–382. [Google Scholar] [CrossRef]

- Erki, M.A.; Meier, U. Impact loading of concrete beams externally strengthened with CFRP laminates. J. Compos. Constr. 1999, 3, 117–124. [Google Scholar] [CrossRef]

- Kantar, E.; Anil, Ö. Low velocity impact behavior of concrete beam strengthened with CFRP strip. Steel Compos. Struct. Int. J. 2012, 12, 207–230. [Google Scholar] [CrossRef]

- Tang, T. Behavior of Concrete Beams Retrofitted with Composite Laminates under Impact Loading. Ph.D. Thesis, University of Arizona, Tucson, AZ, USA, 2002. [Google Scholar]

- Soleimani, S. Sprayed Glass Fiber Reinforced Polymers in Shear Strengthening and Enhancement of Impact Resistance of Reinforced Concrete Beams. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2006. [Google Scholar]

- Al-Rousan, R.; Al-Saraireh, S. Impact of anchored holes technique on behavior of reinforced concrete beams strengthened with different CFRP sheet lengths and widths. Case Stud. Constr. Mater. 2020, 13, e00405. [Google Scholar] [CrossRef]

- Min, K.H.; Kwon, K.Y.; Lee, J.Y.; Yoon, Y.-S. Effects of steel fibre and shear reinforcement on static and impact load resistances of concrete beams. Mag. Concr. Res. 2014, 66, 998–1006. [Google Scholar] [CrossRef]

- Ulzurrun, G.S.D.; Zanuy, C. Enhancement of impact performance of reinforced concrete beams without stirrups by adding steel fibers. Constr. Build. Mater. 2017, 145, 166–182. [Google Scholar] [CrossRef]

- Liew, J.Y.R.; Sohel, K.M.A.; Koh, C.G. Impact tests on steel–concrete–steel sandwich beams with lightweight concrete core. Eng. Struct. 2009, 31, 2045–2059. [Google Scholar] [CrossRef]

- Li, F.Y. Experimental Study on Bond Behavior between RC Beam and Steel Plate under Impact Loading. Master’s Thesis, School of Civil and Hydraulic Engineering, Huazhong University of Science and Technology, Wuhan, China, 2018; pp. 42–73. [Google Scholar]

- Liao, W.; Zhang, W. Experimental Research on Impact and Flexural Behavior of RC Beams Strengthened with High Strength Steel Wire Mesh and High Performance Mortar. In Challenges and Advances in Sustainable Transportation Systems; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 246–254. [Google Scholar]

- Liao, W.; Li, M.; Zhang, W.; Tian, Z. Experimental studies and numerical simulation of behavior of RC beams retrofitted with HSSWM-HPM under impact loading. Eng. Struct. 2017, 149, 131–146. [Google Scholar] [CrossRef]

- Al-Fakher, U.; Manalo, A.; Ferdous, W.; Aravianthan, T.; Zhuge, Y.; Bai, Y.; Edoo, A. Bending behaviour of precast concrete slab with externally flanged hollow FRP tubes. Eng. Struct. 2021, 241, 112433. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.V.; Pettigrew, J. Experimental and numerical evaluations on the behaviour of structures repaired using prefabricated FRP composites jacket. Eng. Struct. 2020, 210, 110358. [Google Scholar] [CrossRef]

- Ding, Y.; Chen, X.; Chen, W. The flexural behavior of beams strengthened with FRP grid and ECC. In Proceedings of the 5th International Conference on FRP Composites in Civil Engineering, Beijing, China, 27–29 September 2010; pp. 668–671. [Google Scholar]

- Zheng, Y.; Wang, W.; Brigham, J.C. Flexural behavior of reinforced concrete beams strengthened with a composite reinforcement layer: BFRP grid and ECC. Constr. Build. Mater. 2016, 115, 424–437. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.Y.; Chen, X.B.; Yi, D. The shear behavior of beams strengthened with FRP grid. In Proceedings of the 5th International Conference on FRP Composites in Civil Engineering, Beijing, China, 27–29 September 2010; pp. 772–775. [Google Scholar]

- Wang, W.; Zheng, U. Experimental research on shear capacity of concrete beams strengthened with BFRP grid reinforced ECC. In Proceedings of the Ninth National Academic Exchange Conference on FRP Application in Construction Engineering, Chongqing, China, 31 October 2014–28 February 2015; pp. 317–322. [Google Scholar]

- Zheng, Y. Experiment and Calculation Method Research on Reinforced Concrete (RC) Beams Strengthened with the Composite of FRP Grid and ECC. Ph.D. Thesis, Southeast University, Nanjing, China, 2018. [Google Scholar]

- Guo, R.; Ren, Y.; Gu, T.Y. Experimental study on the shear performance of fiber-reinforced composite mesh-engineered cementitious composites reinforced reinforced concrete beams. Ind. Constr. 2019, 49, 145–151. [Google Scholar]

- Yang, X.; Gao, W.-Y.; Dai, J.-G.; Lu, Z.-D.; Yu, K.-Q. Flexural strengthening of RC beams with CFRP grid-reinforced ECC matrix. Compos. Struct. 2018, 189, 9–26. [Google Scholar] [CrossRef]

- SCE. Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Cracks; Japan Society of Civil Engineers: Tokyo, Japan, 2008. [Google Scholar]

- Zhao, D.B. Response Characteristics and Design Method of Reinforced Concrete Beams under Impacting Load. Ph.D. Thesis, College of Civil Engineering, Hunan University, Changsha, China, 2017; pp. 57–63. [Google Scholar]

- Kishi, N.; Mikami, H.; Matsuoka, K.G.; Ando, T. Impact behavior of shear-failure-type RC beams without shear rebar. Int. J. Impact Eng. 2002, 27, 955–968. [Google Scholar] [CrossRef]

- Joshani, M.; Koloor, S.S.R.; Abdullah, R. Damage Mechanics Model for Fracture Process of Steel-concrete Composite Slabs. Appl. Mech. Mater. 2012, 165, 339–345. [Google Scholar] [CrossRef]

- Farokhi Nejad, A.; Rahimian Koloor, S.S.; Syed Hamzah, S.M.S.A.; Yahya, M.Y. Mechanical Behavior of Pin-Reinforced Foam Core Sandwich Panels Subjected to Low Impact Loading. Polymers 2021, 13, 3627. [Google Scholar] [CrossRef]

- Grassl, P.; Xenos, D.; Nystrom, U.; Rempling, R.; Gylltoft, K. CDPM2: A damage-plasticity approach to modelling the failure of concrete. Int. J. Solids Struct. 2013, 50, 3805–3816. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Wang, X. Numerical and experimental investigations on the axial crushing response of composite tube. Compos. Struct. 2009, 91, 222–228. [Google Scholar] [CrossRef]

- CAO W, F. The Research on Crushing Response and Crashworthiness under Axial Compression of Thin-walled CFRP Tubes. Master’s Thesis, College of Civil Engineering, Hunan University, Changsha, China, 2017; pp. 54–56. [Google Scholar]

- Guo, J.L. Research on Dynamic Response of Recycled Aggregate Concrete Beam under Impact Action. Ph.D. Thesis, School of Civil Engineering and Transportation, South China University of Technology, Guangzhou, China, 2016; pp. 72–74. [Google Scholar]

- Mays, G. Blast Effects on Buildings: Design of Buildings to Optimize Resistance to Blast Loading; Thomas Telford: London, UK, 1995. [Google Scholar]

- Mattock, A.H. Discussion of “Rotational capacity of reinforced concrete beams”. J. Struct. Div. 1967, 93, 519–522. [Google Scholar] [CrossRef]

- Fujikake, K.; Li, B.; Soeun, S. Impact response of reinforced concrete beam and its analytical evaluation. J. Struct. Eng. 2009, 135, 938–950. [Google Scholar] [CrossRef]

- Mathews, J.H.; Fink, K.D. Numerical Methods Using MATLAB; Prentice-Hall Inc.: Upper Saddle River, NJ, USA, 2004; pp. 497–499. [Google Scholar]

| Rebar Diameter (mm) | Model | Yield Strength (MPa) | Ultimate Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| 12 | HRB400 | 452 | 601 | 208 |

| 6 | HPB300 | 404 | 558 | 201 |

| Compressive Strength (MPa) | Flexural Strength (MPa) | Cracking Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| 55.16 | 16.45 | 5.05 | 6.66 |

| Tensile Strength (MPa) | Elastic Modulus (GPa) | Poisson Ratio | Nominal Thickness (m) |

|---|---|---|---|

| 3513 | 240 | 0.307 | 0.000167 |

| Material | Tensile Strength (MPa) | Elastic Modulus (GPa) | Poisson Ratio | Nominal Thickness (m) | Nominal Cross-Sectional Area (m2) |

|---|---|---|---|---|---|

| CFRP | 4900 | 230 | 0.307 | 0.0005 | 0.00009 |

| GFRP | 3430 | 73 | 0.22 | 0.0003 | 0.00005 |

| Number | Strengthening Method | Fiber Content | ECC Thickness(mm) | Impact Height (m) | Grid Layers |

|---|---|---|---|---|---|

| L1 | — | 0 | 0 | 1 | 0 |

| L2 | ECC | 2% | 20 | 1 | 0 |

| L3 | grid + ECC | 2% | 20 | 1 | 1 |

| L4 | carbon fiber sheet + ECC | 2% | 20 | 1 | 0 |

| L5 | grid + ECC | 2% | 20 | 1 | 2 |

| L6 | grid + ECC | 2% | 40 | 1 | 1 |

| L7 | grid + ECC | 2% | 20 | 0.5 | 1 |

| L8 | grid + ECC | 1% | 20 | 1 | 1 |

| Crack Pattern | 2–5 ms | 10–15 ms | 15–20 ms | 20–25 ms | |

|---|---|---|---|---|---|

| L1 | Main Crack | 2/5 h | 3/5 h | 4/5 h | - |

| Horizontal cracks | - | - | Appear | - | |

| L2 | Main Crack | 1/2 h | 3/5 h | - | 7/10 h |

| Horizontal cracks | - | Appear | - | - | |

| L3 | Main Crack | 2/5 h | 7/10 h | 4/5 h | - |

| Horizontal cracks | - | Appear | - | - | |

| L4 | Main Crack | 1/2 h | - | 3/5 h | - |

| Horizontal cracks | - | Appear | - | - |

| Number | v | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| L1 | 63.0 | 1.09 | 3.02 | 7.85 | 1.44 | 2.23 | 2.49 | 2.34 | 12.6 | 4.43 |

| L2 | 67.4 | 1.12 | 3.73 | 3.46 | 2.06 | 2.91 | 5.90 | 2.43 | 10.9 | 4.43 |

| L3 | 67.4 | 1.12 | 3.83 | 3.57 | 2.18 | 21.1 | 5.95 | 2.47 | 8.78 | 4.43 |

| L5 | 67.4 | 1.12 | 3.93 | 3.68 | 2.29 | 36.9 | 6.00 | 2.50 | 7.75 | 4.43 |

| L6 | 71.9 | 1.15 | 3.94 | 4.85 | 2.16 | 22.7 | 6.09 | 2.56 | 8.00 | 4.43 |

| L7 | 67.4 | 1.12 | 3.83 | 3.57 | 2.18 | 21.1 | 5.95 | 2.47 | 8.78 | 3.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Si, Z.; Liu, F.; Pan, J.; Dong, H. Research on Impact Resistance of Reinforced Concrete Beams Strengthened with Carbon Fiber Reinforced Polymer Grid and Engineered Cementitious Composites. Polymers 2022, 14, 1951. https://doi.org/10.3390/polym14101951

Si Z, Liu F, Pan J, Dong H. Research on Impact Resistance of Reinforced Concrete Beams Strengthened with Carbon Fiber Reinforced Polymer Grid and Engineered Cementitious Composites. Polymers. 2022; 14(10):1951. https://doi.org/10.3390/polym14101951

Chicago/Turabian StyleSi, Zhihao, Fan Liu, Jianwu Pan, and Hao Dong. 2022. "Research on Impact Resistance of Reinforced Concrete Beams Strengthened with Carbon Fiber Reinforced Polymer Grid and Engineered Cementitious Composites" Polymers 14, no. 10: 1951. https://doi.org/10.3390/polym14101951