Poly (Lactic Acid)/Ground Tire Rubber Blends Using Peroxide Vulcanization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Composition

2.2. Materials Processing

2.3. GTR Size Distribution

2.4. Scanning Electron Microscopy (SEM)

2.5. Thermogravimetric Analysis (TGA)

2.6. Swelling

2.7. Thermoporosimetry

2.8. Uniaxial Tensile Stretching (UTS)

2.9. Impact-Tensile Tests

3. Results

3.1. Ground Tire Rubber (GTR) Properties

3.2. Tensile Properties of PLA/GTR Blends: Effect of the GTR Size

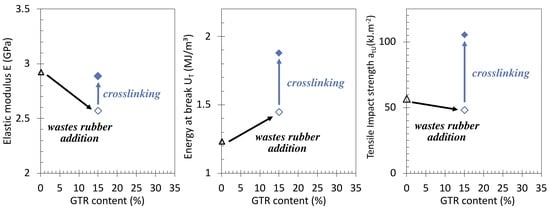

3.3. Tensile Properties of PLA-GTR Blends: Effect of the GTR Content

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- A European Strategy for Plastics in a Circular Economy. 2018. Report of the European Commission. Available online: https://ec.europa.eu/info/research-and-innovation/research-area/environment/circular-economy/plastics-circular-economy_en (accessed on 10 March 2021).

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Janik, H.; Borzędowska-Labuda, K.; Kucińska-Lipka, J. Environmentally friendly polymer-rubber composites obtained from waste tyres: A review. J. Clean. Prod. 2017, 147, 560–571. [Google Scholar] [CrossRef]

- Spierling, S.; Knüpffer, E.; Behnsen, H.; Mudersbach, M.; Krieg, H.; Springer, S.; Albrecht, S.; Herrmann, C.; Endres, H.J. Bio-based plastics—A review of environmental, social and economic impact assessments. J. Clean. Prod. 2018, 185, 476–491. [Google Scholar] [CrossRef]

- Iwata, T. Biodegradable and bio-based polymers: Future prospects of eco-friendly plastics. Angewandte Chem. Int. Ed. 2015, 54, 3210–3215. [Google Scholar] [CrossRef] [PubMed]

- Ikeda, Y.; Kato, A.; Kohjiya, S.; Nakajima, Y. Rubber Sci.: A Modern Approach; Springer: Singapore, 2018. [Google Scholar]

- Kikuchi, Y.; Fukui, T.; Okada, T.; Inoue, T. Elastic-plastic analysis of the deformation mechanism of PP-EPDM thermoplastic elastomer: Origin of rubber elasticity. Polym. Eng. Sci. 1991, 31, 1029–1032. [Google Scholar] [CrossRef]

- Abdou-Sabet, S.; Puydak, R.C.; Rader, C.P. Dynamically vulcanized thermoplastic elastomers. Rubber Chem. Technol. 1996, 69, 476–494. [Google Scholar] [CrossRef]

- Tanrattanakul, V.; Kosonmetee, K.; Laokijcharoen, P. Polypropylene/natural rubber thermoplastic elastomer: Effect of phenolic resin as a vulcanizing agent on mechanical properties and morphology. J. Appl. Polym. Sci. 2009, 112, 3267–3275. [Google Scholar] [CrossRef]

- Nakason, C.; Jamjinno, S.; Kaesaman, A.; Kiatkamjornwong, S. Thermoplastic elastomer based on high-density polyethylene/natural rubber blends: Rheological, thermal, and morphological properties. Polym. Adv. Technol. 2008, 19, 85–98. [Google Scholar] [CrossRef]

- Oguz, O.; Candau, N.; Citak, M.K.; Cetin, F.N.; Seven, S.A.; Menceloglu, Y.Z. A sustainable approach to produce stiff, super-tough, and heat-resistant poly (lactic acid)-based green materials. ACS Sust. Chem. Eng. 2019, 7, 7869–7877. [Google Scholar] [CrossRef]

- Yang, D.D.; Wu, C.; Wu, G.; Chen, S.C.; Wang, Y.Z. Toughening of polylactide with high tensile strength via constructing an integrative physical crosslinking network based on ionic interactions. Macromolecules 2020. [Google Scholar] [CrossRef]

- Yuan, D.; Chen, Z.; Xu, C.; Chen, K.; Chen, Y. Fully biobased shape memory material based on novel cocontinuous structure in poly(lactic acid)/natural rubber tpvs fabricated via peroxide-induced dynamic vulcanization and in situ interfacial compatibilization. ACS Sust. Chem. Eng. 2015, 3, 2856–2865. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, C.; Liang, M. Preparation of thermoplastic vulcanizates based on waste crosslinked polyethylene and ground tire rubber through dynamic vulcanization. J. Appl. Polym. Sci. 2011, 122, 2110–2120. [Google Scholar] [CrossRef]

- Nevatia, P.; Banerjee, T.S.; Dutta, B.; Jha, A.; Naskar, A.K.; Bhowmick, A.K. Thermoplastic elastomers from reclaimed rubber and waste plastics. J. Appl. Polym. Sci. 2002, 83, 2035–2042. [Google Scholar] [CrossRef]

- Radheshkumar, C.; Karger-Kocsis, J. Thermoplastic dynamic vulcanisates containing LDPE, rubber, and thermochemically reclaimed ground tyre rubber. Plast. Rubber Compos. 2002, 31, 99–105. [Google Scholar] [CrossRef]

- Al-Malaika, S.; Amir, E.J. Thermoplastic elastomers: Part III—Ageing and mechanical properties of natural rubber-reclaimed rubber/polypropylene systems and their role as solid phase dispersants in polypropylene/polyethylene blends. Polym. Degrad. Stab. 1989, 26, 31–41. [Google Scholar] [CrossRef]

- Colom, X.; Cañavate, J.; Carrillo, F.; Suñol, J.J. Effect of the particle size and acid pretreatments on compatibility and properties of recycled HDPE plastic bottles filled with ground tyre powder. J. Appl. Polym. Sci. 2009, 112, 1882–1890. [Google Scholar] [CrossRef]

- Sonnier, R.; Leroy, E.; Clerc, L.; Bergeret, A.; Lopez-Cuesta, J.M. Compatibilisation of polyethylene/ground tyre rubber blends by γ irradiation. Polym. Degrad. Stab. 2006, 91, 2375–2379. [Google Scholar] [CrossRef]

- Tantayanon, S.; Juikham, S. Enhanced toughening of poly(propylene) with reclaimed-tire rubber. J. Appl. Polym. Sci. 2004, 91, 510–515. [Google Scholar] [CrossRef]

- Mujal-Rosas, R.; Orrit-Prat, J.; Ramis-Juan, X.; Marin-Genesca, M.; Rahhali, A. Study on dielectric, thermal, and mechanical properties of the ethylene vinyl acetate reinforced with ground tire rubber. J. Reinf. Plast. Compos. 2011, 30, 581–592. [Google Scholar] [CrossRef]

- Awang, M.; Ismail, H.; Hazizan, M.A. Polypropylene-based blends containing waste tire dust: Effects of trans-polyoctylene rubber (TOR) and dynamic vulcanization. Polym. Test. 2007, 26, 779–787. [Google Scholar] [CrossRef]

- Lima, P.; Oliveira, J.; Costa, V. Partial replacement of EPDM by GTR in thermoplastic elastomers based on PP/EPDM: Effects on morphology and mechanical properties. J. Appl. Polym. Sci. 2014, 131, 40160. [Google Scholar] [CrossRef]

- Ramarad, S.; Khalid, M.; Ratnam, C.T.; Chuah, A.L.; Rashmi, W. ‘Waste tire rubber in polymer blends: A review on the evolution, properties and future. Progr. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Hel, C.L.; Bounor-Legaré, V.; Catherin, M.; Lucas, A.; Thèvenon, A.; Cassagnau, P. TPV: A new insight on the rubber morphology and mechanic/elastic properties. Polymers 2020, 12, 2315. [Google Scholar] [CrossRef] [PubMed]

- Sonnier, R.; Leroy, E.; Clerc, L.; Bergeret, A.; Lopez-Cuesta, J.M. Compatibilizing thermoplastic/ground tyre rubber powder blends: Efficiency and limits. Polym. Test. 2008, 27, 901–907. [Google Scholar] [CrossRef]

- Wu, N.; Zhang, H. Mechanical properties and phase morphology of super-tough PLA/PBAT/EMA-GMA multicomponent blends. Mater. Lett. 2017, 192, 17–20. [Google Scholar] [CrossRef]

- Kamaal, M.; Anas, M.; Rastogi, H.; Bhardwaj, N.; Rahaman, A. Effect of FDM process parameters on mechanical properties of 3D-printed carbon fibre–PLA composite. Prog. Addit. Manuf. 2021, 6, 63–69. [Google Scholar] [CrossRef]

- Oguz, O.; Candau, N.; Demongeot, A.; Citak, M.K.; Cetin, F.N.; Stoclet, G.; Michaud, V.; Menceloglu, Y.Z. Poly(lactide)/cellulose nanocrystal nanocomposites by high-shear mixing. Polym. Eng. Sci. 2021, 61, 1028–1040. [Google Scholar] [CrossRef]

- Oguz, O.; Bilge, K.; Simsek, E.; Citak, M.K.; Wis, A.A.; Ozkoc, G.; Menceloglu, Y.Z. High-performance green composites of poly(lactic acid) and waste cellulose fibers prepared by high-shear thermokinetic mixing. Ind. Eng. Chem. Res. 2017, 56, 8568–8579. [Google Scholar] [CrossRef]

- Ma, P.; Hristova-Bogaerds, D.G.; Goossens, J.G.P.; Spoelstra, A.B.; Zhang, Y.; Lemstra, P.J. Toughening of poly(lactic acid) by ethylene-co-vinyl acetate copolymer with different vinyl acetate contents. Eur. Polym. J. 2012, 48, 146–154. [Google Scholar] [CrossRef]

- Cailloux, J.; Abt, T.M.; García Masabet, V.D.V.; Santana Pérez, O.O.; Sánchez Soto, M.; Carrasco Alonso, F.Á.; Maspoch Rulduà, M. Effect of the viscosity ratio on the PLA/PA10.10 bioblends morphology and mechanical properties. Exp. Polym. Lett. 2018, 12, 569–582. [Google Scholar] [CrossRef]

- Harada, M.; Iida, K.; Okamoto, K.; Hayashi, H.; Hirano, K. Reactive compatibilization of biodegradable poly(lactic acid)/poly(ε-caprolactone) blends with reactive processing agents. Polym. Eng. Sci. 2008, 48, 1359–1368. [Google Scholar] [CrossRef]

- Feng, Y.; Hu, Y.; Yin, J.; Zhao, G.; Jiang, W. High impact poly (lactic acid)/poly (ethylene octene) blends prepared by reactive blending. Polym. Eng. Sci. 2013, 53, 389–396. [Google Scholar] [CrossRef]

- Huang, J.; Fan, J.; Cao, L.; Xu, C.; Chen, Y. A novel strategy to construct co-continuous PLA/NBR thermoplastic vulcanizates: Metal-ligand coordination-induced dynamic vulcanization, balanced stiffness-toughness and shape memory effect. Chem. Eng. J. 2020, 385, 123828. [Google Scholar] [CrossRef]

- Wang, R.; Wang, S.; Zhang, Y.; Wan, C.; Ma, P. Toughening modification of PLLA/PBS blends via in situ compatibilization. Polym. Eng. Sci. 2009, 49, 26–33. [Google Scholar] [CrossRef]

- Zhao, Q.; Ding, Y.; Yang, B.; Ning, N.; Fu, Q. Highly efficient toughening effect of ultrafine full-vulcanized powdered rubber on poly (lactic acid) (PLA). Polym. Test. 2013, 32, 299–305. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic acid (pla) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sust. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Oliveira, M.; Santos, E.; Araújo, A.; Fechine, G.J.M.; Machado, A.V.; Botelho, G. The role of shear and stabilizer on PLA degradation. Polym. Test. 2016, 51, 109–116. [Google Scholar] [CrossRef]

- Rabiei, S.; Shojaei, A. Vulcanization kinetics and reversion behavior of natural rubber/styrene-butadiene rubber blend filled with nanodiamond—The role of sulfur curing system. Eur. Polym. J. 2016, 81, 98–113. [Google Scholar] [CrossRef]

- Leroy, E.; Souid, A.; Deterre, R. A continuous kinetic model of rubber vulcanization predicting induction and reversion. Polym. Test. 2013, 32, 575–582. [Google Scholar] [CrossRef]

- Rios-Soberanis, C.R.; Wakayama, S.; Sakai, T.; Rodriguez-Laviada, J.D.; Pérez-Pacheco, E. Manufacture of partially biodegradable composite materials based on PLA-tires powder: Process and characterization. Int. J. Polym. Sci. 2013, 14951. [Google Scholar] [CrossRef]

- Sakai, T.; Morikiyo, T.; Rios-Soberanis, C.R.; Yoneyama, S.; Wakayama, S. Effect of crushing method of wasted tire on mechanical behavior on PLA composites. In Challenges in Mech. of Time-Dependent Materials and Processes in Conventional and Multifunctional Materials; Springer: New York, NY, USA, 2013; pp. 85–91. [Google Scholar] [CrossRef]

- Yang, J.; Nie, S.; Zhu, J. A comparative study on different rubbery modifiers: Effect on morphologies, mechanical, and thermal properties of PLA blends. J. Appl. Polym. Sci. 2016, 133, 43340. [Google Scholar] [CrossRef]

- Yang, J.; Nie, S.B.; Ding, G.X.; Wang, Z.F.; Gao, J.S.; Zhu, J.B. Mechanical properties, morphologies and thermal decomposition kinetics of poly (lactic acid) toughened by waste rubber powder. Int. Polym. Process. 2015, 30, 467–475. [Google Scholar] [CrossRef]

- Nematollahi, M.; Jalali-Arani, A.; Modarress, H. High-performance bio-based poly(lactic acid)/natural rubber/epoxidized natural rubber blends: Effect of epoxidized natural rubber on microstructure, toughness and static and dynamic mechanical properties. Polym. Int. 2019, 68, 439–446. [Google Scholar] [CrossRef]

- Lu, X.; Wei, X.; Huang, J.; Yang, L.; Zhang., G.; He, G.; Wang, M.; Qu, J. Supertoughened poly (lactic acid)/polyurethane blend material by in situ reactive interfacial compatibilization via dynamic vulcanization. Ind. Eng. Chem. Res. 2014, 53, 17386–17393. [Google Scholar] [CrossRef]

- Chen, Y.; Yuan, D.; Xu, C. Dynamically vulcanized biobased polylactide/natural rubber blend material with continuous cross-linked rubber phase. ACS Appl. Mater. Interf. 2014, 6, 3811–3816. [Google Scholar] [CrossRef]

- Cailloux, J. Modified Poly (Lactic Acid) Sheets Manufactured by One-Step Reactive Extrusion-Calendering: Thermal, Rheological, Mechanical and Fracture Behaviours. Ph.D. Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2016. [Google Scholar]

- Kraus, G. Swelling of filler-reinforced vulcanizates. J. Appl. Polym. Sci. 1963, 7, 861–871. [Google Scholar] [CrossRef]

- Candau, N. Compréhension des mécanismes de cristallisation sous tension des élastomères en conditions quasi-statiques et dynamiques. Ph.D. Thesis, Institut National des Sciences Appliquées de Lyon (INSA), Lyon, France, 2014. [Google Scholar]

- Candau, N.; Chazeau, L.; Chenal, J.M.; Gauthier, C.; Munch, E. Complex dependence on the elastically active chains density of the strain induced crystallization of vulcanized natural rubbers, from low to high strain rate. Polymer 2016, 97, 158–166. [Google Scholar] [CrossRef]

- Candau, N.; Oguz, O.; Peuvrel-Disdier, E.; Bouvard, J.L.; Pradille, C.; Billon, N. Strain-induced network chains damage in carbon black filled EPDM. Polymer 2019, 175, 329–338. [Google Scholar] [CrossRef]

- Candau, N.; Oguz, O.; Peuvrel-Disdier, E.; Bouvard, J.L.; Pradille, C.; Billon, N. Strain and filler ratio transitions from chains network to filler network damage in EPDM during single and cyclic loadings. Polymer 2020, 197, 122435. [Google Scholar] [CrossRef]

- Zefeng, W.; Yong, K.; Zhao, W.; Yi, C. Recycling waste tire rubber by water jet pulverization: Powder characteristics and reinforcing performance in natural rubber composites. J. Polym. Eng. 2018, 38, 51–62. [Google Scholar] [CrossRef]

- Kwon, E.E.; Yi, H.; Castaldi, M.J. Utilizing carbon dioxide as a reaction medium to mitigate production of polycyclic aromatic hydrocarbons from the thermal decomposition of styrene butadiene rubber. Environ. Sci. Technol. 2012, 46, 10752–10757. [Google Scholar] [CrossRef]

- Cheng, K.; Heidari, Z. Combined interpretation of NMR and TGA measurements to quantify the impact of relative humidity on hydration of clay minerals. Appl. Clay Sci. 2017, 143, 362–371. [Google Scholar] [CrossRef]

- Wang, H.; Li, C.; Peng, Z.; Zhang, S. Characterization and thermal behavior of kaolin. J. Ther. Anal. Calorim. 2011, 105, 157–160. [Google Scholar] [CrossRef]

- Gisbert, A.N.; Amorós, J.E.C.; Martínez, J.L.; Garcia, A.M. Study of thermal degradation kinetics of elastomeric powder (ground tire rubber). Polym. Plast. Technol. Eng. 2007, 47, 36–39. [Google Scholar] [CrossRef]

- Hamed, G.R. Molecular aspects of the fatigue and fracture of rubber. Rubber Chem. Technol. 1994, 67, 529–536. [Google Scholar] [CrossRef]

- Candau, N.; Oguz, O.; Peuvrel-Disdier, E.; Bouvard, J.-L.; Maspoch, M.L.; Corvec, G.; Pradille, C.; Billon, N. Effect of the strain rate on damage in filled EPDM during single and cyclic loadings. Polymers 2020, 12, 3021. [Google Scholar] [CrossRef] [PubMed]

- Candau, N.; Oguz, O.; Peuvrel-Disdier, E.; Bouvard, J.-L.; Maspoch, M.L.; Corvec, G.; Pradille, C.; Billon, N. Heat source and voiding signatures of Mullins damage in filled EPDM. Polym. Test. 2020, 91, 106838. [Google Scholar] [CrossRef]

- Valentín, J.L.; Fernández-Torres, A.; Posadas, P.; Marcos-Fernández, A.; Rodríguez, A.; González, L. Measurements of freezing-point depression to evaluate rubber network structure. Crosslinking of natural rubber with dicumyl peroxide. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 544–556. [Google Scholar] [CrossRef]

- Valentín, J.L.; Mora-Barrantes, I.; Carretero-González, J.; López-Manchado, M.A.; Sotta, P.; Long, D.R.; Saalwächter, K. Novel experimental approach to evaluate filler−elastomer interactions. Macromolecules 2010, 43, 334–346. [Google Scholar] [CrossRef]

- Myhre, M.; MacKillop, D.A. Rubber recycling. Rubber Chem. Technol. 2002, 75, 429–474. [Google Scholar] [CrossRef]

- Rulduà, M.L.M.; Santana Pérez, O.O.; Cailloux, J.; Franco Urquiza, E.; Rodríguez González, C.; Belzunce Varela, F.J.; Martínez, A.B. Ductile-brittle transition behaviour of PLA/o-MMT films during the physical aging process. Exp. Polym. Lett. 2015, 9, 185–195. [Google Scholar]

- Najafi, N.; Heuzey, M.C.; Carreau, P.J. Polylactide (PLA)-clay nanocomposites prepared by melt compounding in the presence of a chain extender. Compos. Sci. Technol. 2012, 72, 608–615. [Google Scholar] [CrossRef]

- Coppola, B.; Cappetti, N.; di Maio, L.; Scarfato, P.; Incarnato, L. 3D Printing of PLA/clay Nanocomposites: Influence of printing temperature on printed samples properties. Materials 2018, 11, 1947. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, S.; Wu, Z.H.; Yang, W.; Yang, M.B. Thermal and mechanical properties of chemical crosslinked polylactide (PLA). Polym. Test. 2008, 27, 957–963. [Google Scholar] [CrossRef]

- Stoclet, G.; Lefebvre, J.M.; Séguéla, R.; Vanmansart, C. In-Situ SAXS study of the plastic deformation behavior of polylactide upon cold-drawing. Polymer 2014, 55, 1817–1828. [Google Scholar] [CrossRef]

- Phattarateera, S.; Pattamaprom, C. The effect of polylactic acid (PLA)/poly-d-lactide stereocomplex on the thermal and mechanical properties of various PLA/rubber blends. Polym. Int. 2020, 69, 41–49. [Google Scholar] [CrossRef]

- Zhang, L.; Hua, J.; Wang, Z. Dynamically vulcanized polylactide/nitrile butadiene rubber blends with continuous cross-linked rubber phase. J. Polym Res. 2018, 26, 11. [Google Scholar] [CrossRef]

- Maroufkhani, M.; Katbab, A.; Bizhani, H.; Zhang, J. Toward morphology development and impact strength of Co-continuous supertough dynamically vulcanized rubber toughened PLA blends: Effect of sulfur content. Polymer 2021, 217, 123439. [Google Scholar] [CrossRef]

- Bitinis, N.; Verdejo, R.; Cassagnau, P.; Lopez-Manchado, M.A. Structure and properties of polylactide/natural rubber blends. Mater. Chem. Phys. 2011, 129, 823–831. [Google Scholar] [CrossRef]

- Klinkajorn, J.; Tanrattanakul, V. The effect of epoxide content on compatibility of poly (lactic acid)/epoxidized natural rubber blends. J. Appl. Polym. Sci. 2020, 137, 48996. [Google Scholar] [CrossRef]

- Boonmahitthisud, A.; Mongkolvai, A.; Chuayjuljit, S. Toughness improvement in bio-based poly (lactic acid)/epoxidized natural rubber blend reinforced with nanosized silica. J. Polym. Environ. 2021. [Google Scholar] [CrossRef]

- Kawai, F. Polylactic acid (PLA)-degrading microorganisms and PLA depolymerases. In Green Polymer Chemistry: Biocatalysis and Biomaterials; American Chemical Society: Washington, DC, USA, 2010; pp. 405–414. [Google Scholar]

- Ghavipanjeh, F.; Rad, Z.Z.; Pazouki, M. Devulcanization of ground tires by different strains of bacteria: Optimization of culture condition by taguchi method. J. Polym. Environ. 2018, 26, 3168–3175. [Google Scholar] [CrossRef]

| Sample Code | GTR Weight Content (%) | DCP (per 100 g of GTR) | Pre-Treatment of the GTR Powder | Particles Mesh Size (µm) |

|---|---|---|---|---|

| PLA | 0 | - | - | - |

| PLA/GTRa 15% Y ’s | 15 | 0 | Ambient grinding | Y = 40 ’s; 80 ’s; 120 ’s |

| PLA/GTRa 15% Y ’s | 15 | 1.5 | Ambient grinding | Y = 40 ’s; 80 ’s; 120 ’s |

| PLA/GTRc 15% Y ’s | 15 | 1.5 | Cryogenic grinding | Y = 120 ’s; 230 ’s |

| PLA/GTRa X% 120 ’s | X = 7.5; 15; 22.5 | 0 | Ambient grinding | 120 ’s |

| PLA/GTRa X% 120 ’s | X = 7.5; 15; 22.5 | 1.5 | Ambient grinding | 120 ’s |

| PLA/GTRc X% 120 ’s | X = 3; 7.5; 15; 30 | 1.5 | Cryogenic grinding | 120 ’s |

| PLA/GTRc 15% 120 ’s | X = 15 | 0 | Cryogenic grinding | 120 ’s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candau, N.; Oguz, O.; León Albiter, N.; Förster, G.; Maspoch, M.L. Poly (Lactic Acid)/Ground Tire Rubber Blends Using Peroxide Vulcanization. Polymers 2021, 13, 1496. https://doi.org/10.3390/polym13091496

Candau N, Oguz O, León Albiter N, Förster G, Maspoch ML. Poly (Lactic Acid)/Ground Tire Rubber Blends Using Peroxide Vulcanization. Polymers. 2021; 13(9):1496. https://doi.org/10.3390/polym13091496

Chicago/Turabian StyleCandau, Nicolas, Oguzhan Oguz, Noel León Albiter, Gero Förster, and Maria Lluïsa Maspoch. 2021. "Poly (Lactic Acid)/Ground Tire Rubber Blends Using Peroxide Vulcanization" Polymers 13, no. 9: 1496. https://doi.org/10.3390/polym13091496