Moment Redistribution in Continuous Externally CFRP Prestressed Beams with Steel and FRP Rebars

Abstract

:1. Introduction

2. Numerical Program

3. Numerical Investigation

3.1. Support Reaction and Bending Moment

3.2. Reaction Ratio and Moment Ratio

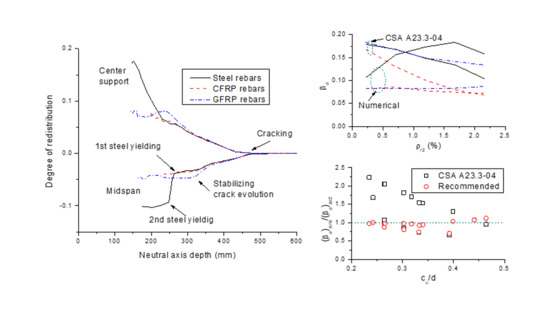

3.3. Degree of Moment Redistribution

4. Theoretical Consideration

4.1. Current Design Codes for Calculating Moment Redistribution

4.2. Evaluation of Design Codes

4.3. Recommended Equation

5. Conclusions

- Moment redistribution in the beams with FRP rebars was contributed by concrete cracking, and tended to stabilize after the stabilization of crack evolution. For the beams with steel rebars, apart from the contribution by concrete cracking, steel yielding led to further development of moment redistribution;

- Steel rebars led to significantly higher redistribution of moments than FRP rebars. The redistribution difference between the beams with steel and FRP rebars enlarged with increasing ρr2 up to 1.67% and decreased thereafter;

- The current codes of practice investigated (Eurocode 2, CSA A23.3-04 and ACI 318-19) could not reflect the influence of both the amount, and type, of rebars on moment redistribution in PCBs with external tendons. In addition, it was found that the codes may lead to unsafe predictions in moment redistribution in beams with FRP rebars;

- A simplified equation was recommended to predict moment redistribution in externally PCBs with steel and FRP rebars. It was shown that the recommended equation yields accurate and conservative predictions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ACI Committee. Prestressing Concrete Structures with FRP Tendons. ACI 440.4R-04; ACI Committee: Farmington Hills, MI, USA, 2004. [Google Scholar]

- Le, T.D.; Pham, T.M.; Hao, H.; Li, H. Behavior of Precast Segmental Concrete Beams Prestressed with External Steel and CFRP Tendons. J. Compos. Constr. 2020, 24, 04020053. [Google Scholar] [CrossRef]

- Tan, K.H.; Tjandra, R.A. Strengthening of RC Continuous Beams by External Prestressing. J. Struct. Eng. 2007, 133, 195–204. [Google Scholar] [CrossRef]

- ElMesalami, N.; Abed, F.; El Refai, A. Concrete Columns Reinforced with GFRP and BFRP Bars under Concentric and Eccentric Loads: Experimental Testing and Analytical Investigation. J. Compos. Constr. 2021, 25, 04021003. [Google Scholar] [CrossRef]

- Zhou, A.; Chow, C.L.; Lau, D. Structural behavior of GFRP reinforced concrete columns under the influence of chloride at casting and service stages. Compos. Part B Eng. 2018, 136, 1–9. [Google Scholar] [CrossRef]

- Sun, W.; Lou, T.; Achintha, M. A novel strong and durable near-surface mounted (NSM) FRP method with cost-effective fillers. Compos. Struct. 2021, 255, 112952. [Google Scholar] [CrossRef]

- Sun, W.; He, T.; Wang, X.; Zhang, J.; Lou, T. Developing an anchored near-surface mounted (NSM) FRP system for fuller use of FRP material with less epoxy filler. Compos. Struct. 2019, 226, 111251. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Hosseini, S.M.; Tehrani, B.N.; Eftekhar, M.R.; Dyari, M. Innovative warp and woof strap (WWS) method to anchor the FRP sheets in strengthened concrete beams. Constr. Build. Mater. 2019, 218, 351–364. [Google Scholar] [CrossRef]

- Bennitz, A.; Schmidt, J.W.; Nilimaa, J.; Taljsten, B.; Goltermann, P.; Ravn, D.L. Reinforced Concrete T-Beams Externally Prestressed with Unbonded Carbon Fiber-Reinforced Polymer Tendons. ACI Struct. J. 2012, 109, 521–530. [Google Scholar] [CrossRef]

- Lou, T.; Karavasilis, T.L. Numerical evaluation of prestressed steel-concrete composite girders with external FRP or steel tendons. J. Constr. Steel Res. 2019, 162, 105698. [Google Scholar] [CrossRef]

- Xue, W.; Tan, Y.; Peng, F. Experimental Study on Damaged Prestressed Concrete Beams Using External Post-Tensioned Tendons. ACI Struct. J. 2019, 117, 159–168. [Google Scholar] [CrossRef]

- Aravinthan, T.; Witchukreangkrai, E.; Mutsuyoshi, H. Flexural Behavior of Two-Span Continuous Prestressed Concrete Girders with Highly Eccentric External Tendons. ACI Struct. J. 2005, 102, 402–411. [Google Scholar] [CrossRef] [Green Version]

- Lou, T.; Lopes, S.M.R.; Lopes, A.V. Flexural Response of Continuous Concrete Beams Prestressed with External Tendons. J. Bridg. Eng. 2013, 18, 525–537. [Google Scholar] [CrossRef]

- Chan, K.E.; Au, F.T. Behaviour of continuous prestressed concrete beams with external tendons. Struct. Eng. Mech. 2015, 55, 1099–1120. [Google Scholar] [CrossRef]

- Lou, T.; Lopes, S.M.R.; Lopes, A.V. Factors affecting moment redistribution at ultimate in continuous beams prestressed with external CFRP tendons. Compos. Part B Eng. 2014, 66, 136–146. [Google Scholar] [CrossRef]

- Lou, T.; Peng, C.; Karavasilis, T.L.; Min, D.; Sun, W. Moment redistribution versus neutral axis depth in continuous PSC beams with external CFRP tendons. Eng. Struct. 2020, 209, 109927. [Google Scholar] [CrossRef]

- Lou, T.; Lopes, S.M.; Lopes, A.V. Effect of linear transformation on nonlinear behavior of continuous prestressed beams with external FRP cables. Eng. Struct. 2017, 147, 410–424. [Google Scholar] [CrossRef]

- ACI Committee. Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary (ACI 318R-19); American Concrete Institute: Farmington Hills, MI, USA, 2019; p. 519. [Google Scholar]

- ACI Committee. Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars. ACI 440.1R-06; ACI Committee: Farmington Hills, MI, USA, 2006. [Google Scholar]

- El Refai, A.; Abed, F.; Altalmas, A. Bond durability of basalt fiber–reinforced polymer bars embedded in concrete under direct pullout conditions. ASCE J. Compos. Constr. 2015, 19, 04014078. [Google Scholar] [CrossRef]

- Altalmas, A.; El Refai, A.; Abed, F. Bond degradation of basalt fiber-reinforced polymer (BFRP) bars exposed to accelerated aging conditions. Constr. Build. Mater. 2015, 81, 162–171. [Google Scholar] [CrossRef]

- Al-Tamimia, A.; Abed, F.H.; Al-Rahmani, A. Effects of harsh environmental exposures on the bond capacity between concrete and GFRP reinforcing bars. Adv. Concr. Constr. 2014, 2, 1–11. [Google Scholar] [CrossRef]

- Alkhraisha, H.; Mhanna, H.; Tello, N.; Abed, F. Serviceability and Flexural Behavior of Concrete Beams Reinforced with Basalt Fiber-Reinforced Polymer (BFRP) Bars Exposed to Harsh Conditions. Polymer 2020, 12, 2110. [Google Scholar] [CrossRef]

- Al Rifai, M.; El-Hassan, H.; El-Maaddawy, T.; Abed, F. Durability of basalt FRP reinforcing bars in alkaline solution and moist concrete environments. Constr. Build. Mater. 2020, 243, 118258. [Google Scholar] [CrossRef]

- Pang, M.; Li, Z.; Lou, T. Numerical Study of Using FRP and Steel Rebars in Simply Supported Prestressed Concrete Beams with External FRP Tendons. Polymer 2020, 12, 2773. [Google Scholar] [CrossRef]

- Santos, P.; Laranja, G.; Franca, P.M.; Correia, J.R. Ductility and moment redistribution capacity of multi-span T-section concrete beams reinforced with GFRP bars. Constr. Build. Mater. 2013, 49, 949–961. [Google Scholar] [CrossRef]

- Mahroug, M.; Ashour, A.; Lam, D. Experimental response and code modelling of continuous concrete slabs reinforced with BFRP bars. Compos. Struct. 2014, 107, 664–674. [Google Scholar] [CrossRef]

- Dundar, C.; Tanrikulu, A.K.; Frosch, R.J. Prediction of load–deflection behavior of multi-span FRP and steel reinforced concrete beams. Compos. Struct. 2015, 132, 680–693. [Google Scholar] [CrossRef]

- Akiel, M.S.; El-Maaddawy, T.; El Refai, A. Serviceability and moment redistribution of continuous concrete members reinforced with hybrid steel-BFRP bars. Constr. Build. Mater. 2018, 175, 672–681. [Google Scholar] [CrossRef]

- Zinkaah, O.H.; Ashour, A.; Sheehan, T. Experimental tests of two-span continuous concrete deep beams reinforced with GFRP bars and strut-and-tie method evaluation. Compos. Struct. 2019, 216, 112–126. [Google Scholar] [CrossRef]

- Baša, N.; Vuković, N.K.; Ulićević, M.; Muhadinović, M. Effects of Internal Force Redistribution on the Limit States of Continuous Beams with GFRP Reinforcement. Appl. Sci. 2020, 10, 3973. [Google Scholar] [CrossRef]

- Abdallah, M.; Al Mahmoud, F.; Khelil, A.; Mercier, J.; Almassri, B. Assessment of the flexural behavior of continuous RC beams strengthened with NSM-FRP bars, experimental and analytical study. Compos. Struct. 2020, 242, 112127. [Google Scholar] [CrossRef]

- Lou, T.-J.; Xiang, Y.-Q. Finite element modeling of concrete beams prestressed with external tendons. Eng. Struct. 2006, 28, 1919–1926. [Google Scholar] [CrossRef]

- CEN. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. EN 1992-1-1; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- Lou, T.; Min, D.; Sun, W.; Chen, B. Numerical assessment of continuous prestressed NSC and HSC members with external CFRP tendons. Compos. Struct. 2020, 234, 111671. [Google Scholar] [CrossRef]

- CSA. Design of Concrete Structures. A23.3-04; Canadian Standards Association: Mississauga, ON, Canada, 2004. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, T.; Li, Z.; Pang, M. Moment Redistribution in Continuous Externally CFRP Prestressed Beams with Steel and FRP Rebars. Polymers 2021, 13, 1181. https://doi.org/10.3390/polym13081181

Lou T, Li Z, Pang M. Moment Redistribution in Continuous Externally CFRP Prestressed Beams with Steel and FRP Rebars. Polymers. 2021; 13(8):1181. https://doi.org/10.3390/polym13081181

Chicago/Turabian StyleLou, Tiejiong, Zhangxiang Li, and Miao Pang. 2021. "Moment Redistribution in Continuous Externally CFRP Prestressed Beams with Steel and FRP Rebars" Polymers 13, no. 8: 1181. https://doi.org/10.3390/polym13081181