Copolyamide-Imide Membrane with Low CTE and CME for Potential Space Optical Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Copolyamide-Imide Membrane

2.3. Characterization

3. Results and Discussion

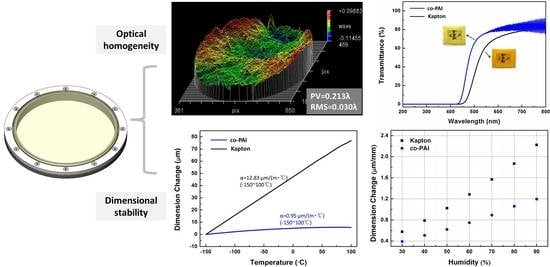

3.1. Optical Properties

3.2. Dimensional Stability

3.3. Thermal and Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sroog, C. Polyimides. Prog. Polym. Sci. 1991, 16, 561–694. [Google Scholar] [CrossRef]

- Cheng, S.Z.; Wu, Z.; Eashoo, M.; Hsu, S.L.C.; Harris, F.W. A high-performance aromatic polyimide fibre: 1. Structure, properties and mechanical-history dependence. Polymer 1991, 32, 1803–1810. [Google Scholar] [CrossRef]

- Kimura, K.; Kohama, S.-I.; Yamazaki, S. Morphology Control of Aromatic Polymers in Concert with Polymerization. Polym. J. 2006, 38, 1005–1022. [Google Scholar] [CrossRef]

- Feltz, J.C. Development of the modulation transfer function and contrast transfer function for discrete systems, particularly charge-coupled devices [also Comment 35(7), 2105-2106 (July 1996)]. Opt. Eng. 1990, 29, 893–904. [Google Scholar] [CrossRef]

- Barton, I.M.; Britten, J.A.; Dixit, S.N.; Summers, L.J.; Thomas, I.M.; Rushford, M.C.; Lu, K.; Hyde, R.A.; Perry, M.D. Fabrication of large-aperture lightweight diffractive lenses for use in space. Appl. Opt. 2001, 40, 447–451. [Google Scholar] [CrossRef] [PubMed]

- Meinel, A.; Meinel, M. Large sparse aperture space optical systems. Opt. Eng. 2002, 41, 1983–1994. [Google Scholar] [CrossRef]

- Domber, J.L.; Atcheson, P.D.; Kommers, J. MOIRE: Ground Test Bed Results for a Large Membrane Telescope. In Proceedings of the Spacecraft Structures Conference, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar] [CrossRef]

- Paul Atcheson, J.D.; Kevin, W. MOIRE—Ground Demonstration of a Large Aperture Diffractive Transmissive Telescope. In Proceedings of the SPIE Astronomical Telescopes + Instrumentation, Montréal, QC, Canada, 28 August 2014; pp. 1–15. [Google Scholar]

- Rahlves, M.; Rezem, M.; Boroz, K.; Schlangen, S.; Reithmeier, E.; Roth, B. Flexible, fast, and low-cost production process for polymer based diffractive optics. Opt. Express. 2015, 23, 3614–3622. [Google Scholar] [CrossRef] [PubMed]

- Tracy, L.; Copp, J.L.D.; Paul, A.; Bill, T.; Jeff, K. MOIRE: Membrane Material Property Characterizations, Testing and Lessons Learned. In Proceedings of the Spacecraft Structures Conference, National Harbor, MD, USA, 13–17 January 2014; pp. 1–16. [Google Scholar] [CrossRef]

- Huang, S.B.; Jiang, Z.Y.; Ma, X.Y.; Qiu, X.P.; Men, Y.; Gao, L.X.; Ding, M.X. Properties, morphology and structure of BPDA/PPD/ODA polyimide fibres. Plast. Rubber Compos. 2013, 42, 407–415. [Google Scholar] [CrossRef]

- Aguilar-Lugo, C.; Santiago-García, J.L.; Loría-Bastarrachea, M.I.; Guzmán-Lucero, D.; Alexandrova, L.; Aguilar-Vega, M. Synthesis, characterization, and structure-property relationships of aromatic polyimides containing 4,4′-diaminotriphenylmethane. J. Polym. Res. 2016, 23, 49. [Google Scholar] [CrossRef]

- Kuang, L.; Zhong, M.; Sang, X.-Y.; Huang, Z.-Z. Synthesis and characterization of novel polyimides based on 10,10-bis[4-(4-aminophenoxy)-3-methylphenyl]-9(10H)-anthrone. J. Macromol. Sci. Part A 2020, 57, 734–742. [Google Scholar] [CrossRef]

- Chen, W.J.; Chen, W.; Zhang, B.Q.; Yang, S.Y.; Liu, C.Y. Thermal imidization process of polyimide fi lm: Interplay between solvent evaporation and imidization. Polymer 2017, 109, 205–215. [Google Scholar] [CrossRef]

- Kim, H.T.; Kim, S.-K.; Park, J.-K. Development of In-Plane Orientation in Pyromellitic Dianhydride-Oxydianiline Polyimide Film on Substrate during Thermal Imidization. Polym. J. 1999, 31, 154–159. [Google Scholar] [CrossRef]

- Kim, B.-H.; Park, H.; Park, H.; Moon, D.C. Degree of imidization for polyimide films investigated by evolved gas analysis-mass spectrometry. Thermochim. Acta 2013, 551, 184–190. [Google Scholar] [CrossRef]

- Fest, E. Chapter 4 Scattering from optical surface roughness and coatings. In Stray Light Analysis and Control; Society of Photo-Optical Instrumentation Engineers: Bellingham, WA, USA, 2013; pp. 61–122. [Google Scholar]

- Mao, D.; Lv, G.; Gao, G.; Fan, B. Fabrication of polyimide films with imaging quality using a spin-coating method for potential optical applications. J. Polym. Eng. 2019, 39, 917–925. [Google Scholar] [CrossRef]

- Ando, S.; Matsuura, T.; Sasaki, S. Coloration of Aromatic Polyimides and Electronic Properties of Their Source Materials. Polym. J. 1997, 29, 69–76. [Google Scholar] [CrossRef]

- Hasegawa, M.; Horie, K. Photophysics, photochemistry, and optical properties of polyimides. Prog. Polym. Sci. 2001, 26, 259–335. [Google Scholar] [CrossRef]

- Swanson, G.J.; Veldkamp, W.B. High-Efficiency Multilevel Diffractive Optical Elements. U.S. Patent 4,895,790, 23 January 1990. [Google Scholar]

- Rossi, M.; Hessler, T. Stray-light effects of diffractive beam-shaping elements in optical microsystems. Appl. Opt. 1999, 38, 3068–3076. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, H.; Lu, Z.; Zhang, H. Modified phase function model for kinoform lenses. Appl. Opt. 2008, 47, 4055–4060. [Google Scholar] [CrossRef] [PubMed]

- Ando, T.; Korenaga, T.; Suzuki, M.-A.; Tanida, J. Diffraction light analysis method for a diffraction grating imaging lens. Appl. Opt. 2014, 53, 2532–2538. [Google Scholar] [CrossRef] [PubMed]

- Garrett, D.; Poe, B.G.P. Zero CTE Polyimides for at Hermal Optical Membranes. In Proceedings of the SPIE 7061, Novel Optical Systems Design and Optimization XI, 706114, San Diego, CA, USA, 11 September 2008. [Google Scholar]

- Zhuang, Y.; Liu, X.; Gu, Y. Molecular packing and properties of poly(benzoxazole-benzimidazole-imide) copolymers. Polym. Chem. 2012, 3, 1517. [Google Scholar] [CrossRef]

- Yue, Z.; Cai, Y.-B.; Xu, S. Facile synthesis of a symmetrical diamine containing bis-benzimidazole ring and its thermally stable polyimides. J. Polym. Res. 2014, 21, 1–8. [Google Scholar] [CrossRef]

- Hu, J.; Li, R.; Chen, C.; Lu, Z.; Zeng, K.; Yang, G. New insights into mechanism of negative in-plane CTE based on bio-based adenine-containing polyimide film. Polymer 2018, 146, 133–141. [Google Scholar] [CrossRef]

- Wu, T.; Dong, J.; Gan, F.; Fang, Y.; Zhao, X.; Zhang, Q. Low dielectric constant and moisture-resistant polyimide aerogels containing trifluoromethyl pendent groups. Appl. Surf. Sci. 2018, 440, 595–605. [Google Scholar] [CrossRef]

| Sample | λ0 1 (nm) | T500 2 (%) | T800 3 (%) | Tav 4 (%) |

|---|---|---|---|---|

| co-PAI | 434 | 64 | 82 | 80 |

| Kapton | 454 | 29 | 79 | 69 |

| Sample | nTE 1 | nTM 2 | nav 3 |

|---|---|---|---|

| co-PAI | 1.8342 | 1.6099 | 1.7626 |

| Kapton | 1.7562 | 1.6169 | 1.7110 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Mao, D.; Fan, B. Copolyamide-Imide Membrane with Low CTE and CME for Potential Space Optical Applications. Polymers 2021, 13, 1001. https://doi.org/10.3390/polym13071001

Yin J, Mao D, Fan B. Copolyamide-Imide Membrane with Low CTE and CME for Potential Space Optical Applications. Polymers. 2021; 13(7):1001. https://doi.org/10.3390/polym13071001

Chicago/Turabian StyleYin, Jiajia, Danbo Mao, and Bin Fan. 2021. "Copolyamide-Imide Membrane with Low CTE and CME for Potential Space Optical Applications" Polymers 13, no. 7: 1001. https://doi.org/10.3390/polym13071001