Tribological, Mechanical and Thermal Properties of Fluorinated Ethylene Propylene Filled with Al-Cu-Cr Quasicrystals, Polytetrafluoroethylene, Synthetic Graphite and Carbon Black

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

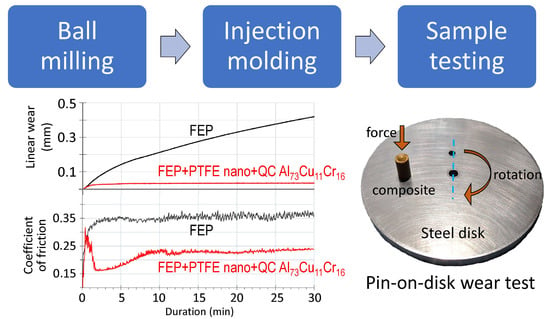

2.2. Composites Formation

2.3. Characterization of the Samples Structures

2.4. Density Measurements

2.5. Hardness Measurements

2.6. Mechanical Tests

2.7. Thermal Conductivity Tests

2.8. Thermo-Mechanical Tests

2.9. Tribological Tests

3. Results and Discussion

3.1. Thermal Analysis

3.2. Mechanical and Thermo-Mecahnical Properties

3.3. Tribological Test Results

4. Conclusions

- -

- Self-lubricating wear-resistant FEP/2 wt.% PTFE-nano/5 wt.% QC Al73Cu11Cr16 composite with excellent mechanical properties was produced by ball milling and injection molding;

- -

- Addition of 5 wt.% fine dispersed QC Al73Cu11Cr16 powder enhances the wear resistance of FEP by 50 times in dry sliding wear;

- -

- Addition of 2 wt.% nano-PTFE filler allows for a more efficient reduction of the friction as compared to regular PTFE without degradation of the plasticity of the composite;

- -

- Addition of 15 wt.% fine graphite powder enhances the thermal conductivity up to 0.65 W/mK and also enhances the antifriction properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Teng, H.X. Overview of the development of the fluoropolymer industry. Appl. Sci. 2012, 2, 496–512. [Google Scholar] [CrossRef]

- Chen, B.; Wang, J.; Yan, F. Friction and wear behaviors of several polymers sliding against GCr15 and 316 steel under the lubrication of sea water. Tribol. Lett. 2011, 42, 17–25. [Google Scholar] [CrossRef]

- Liang, J.Z.; Peng, W.; Wang, K.J. Dynamic rheological behavior of polyfluorinated ethylene propylene/polypropylene blend melts. J. Thermoplast. Compos. Mater. 2017, 30, 273–285. [Google Scholar] [CrossRef]

- Crosby, J.M.; Carreno, C.A.; Talley, K.L. Melt processible fluoropolymer composites. Polym. Compos. 1982, 3, 97–101. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, H.Y.; Oh, S.M.; Kim, B.C.; Bang, D.; Han, J.T.; Woo, J.S. Structural optimization of graphite for high performance fluorinated ethylene—Propylene composites as bipolar plates. Int. J. Hydrogen Energy 2018, 43, 21918–21927. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, H.Y.; Kim, J.; Han, J.T.; Lee, Y.S.; Woo, J.S. Influence of oxyfluorinated graphite on fluorinated ethylene–propylene composites as bipolar plates. Carbon Lett. 2020, 30, 345. [Google Scholar] [CrossRef]

- Pan, J.; Xiao, C.; Huang, Y.; Zhu, Z. Preparation and properties of melt-spun poly(fluorinated ethylene-propylene)/graphene composite fibers. Polym. Compos. 2020, 41, 233–243. [Google Scholar] [CrossRef]

- Ma, H.; Chu, B.; Hsiao, B.S. Modification of carbon nanotubes with fluorinated ionic liquid for improving processability of fluoro-ethylene-propylene. Eur. Polym. J. 2017, 87, 398–405. [Google Scholar] [CrossRef] [Green Version]

- Park, H.J.; Woo, J.S.; Kim, S.H.; Park, K.S.; Park, S.H.; Park, S.Y. High-performance fluorinated ethylene-propylene/graphite composites interconnected with single-walled carbon nanotubes. Macromol. Res. 2019, 27, 1161–1166. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, X.; Nie, R.; Mi, C.; Zhou, Y. Properties of graphite modified FEP thermal conductive composite. J. Beijing Univ. Technol. 2018, 44, 933–939. [Google Scholar]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Jenks, C.J.; Thiel, P.A. Surface properties of quasicrystals. MRS Bull. 1997, 22, 55–58. [Google Scholar] [CrossRef]

- Bloom, P.D.; Baikerikar, K.G.; Anderegg, J.W.; Shereas, V.V. Fabrication and wear resistance of Al-Cu-Fe quasicrystal-epoxy composite materials. Mater. Sci. Eng. A 2003, 360, 46–57. [Google Scholar] [CrossRef]

- Sakly, A.; Kenzari, S.; Bonina, D.; Gorbel, S.; Fournee, V. A novel quasicrystal-resin composite for stereolithography. Mater. Design. 2014, 56, 280–285. [Google Scholar] [CrossRef]

- Altidis, J.D.; Lima, S.J.G.; Gomes, R.M.; Sampaio, E.M.; Torres, S.M.; De Barros, S. Adhesion tests using epoxy quasicrystal composites. J. Adh. Sci. Technol. 2012, 26, 1443–1451. [Google Scholar] [CrossRef]

- Barros, T.P.D.S.; Cavalcante, D.G.D.L.; De Oliveira, D.F.; Caluête, R.E.; De Lima, S.J.G. Study of the surface properties of the epoxy/quasicrystal composite. J. Mater. Res. Technol. 2019, 8, 590–598. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Drogan, E.G.; Burlakova, V.E.; Kydralieva, K.A.; Shershneva, I.N.; Dzhardimalieva, G.I. Testing the mechanical and tribological properties of new metal-polymer nanocomposite materials based on linear low-density polyethylene and Al65Cu22Fe13 quasicrystals. Polym. Test. 2019, 74, 178–186. [Google Scholar] [CrossRef]

- Kothalkar, A.; Sharma, A.S.; Biswas, K.; Basu, B. Novel HDPE-quasicrystal composite fabricated for wear resistance. Philos. Mag. 2011, 91, 2944–2953. [Google Scholar] [CrossRef]

- Anderson, B.C.; Bloom, P.D.; Baikerikar, K.G.; Sheares, V.V.; Mallapragada, S.K. Al-Cu-Fe quasicrystal/ultra-high molecular weight polyethylene composites as biomaterials for acetabular cup prosthetics. Biomaterials 2002, 23, 1761–1768. [Google Scholar] [CrossRef]

- Kaloshkin, S.D.; Tcherdyntsev, V.V.; Danilov, V.D. Preparation of Al-Cu-Fe quasicrystalline powdered alloys and related materials by mechanical activation. Cryst. Rep. 2007, 52, 953–965. [Google Scholar] [CrossRef]

- Kaloshkin, S.D.; Vandi, L.J.; Tcherdyntsev, V.V.; Shelekhov, E.V.; Danilov, V.D. Multi-scaled polymer-based composite materials synthesized by mechanical alloying. J. Alloys Compd. 2009, 483, 195–199. [Google Scholar] [CrossRef]

- Schwartz, C.J.; Bahadur, S.; Mallapragada, S.K. Effect of crosslinking and Pt-Zr quasicrystal fillers on the mechanical properties and wear resistance of UHMWPE for use in artificial joints. Wear 2007, 263, 1072–1080. [Google Scholar] [CrossRef]

- Tsetlin, M.B.; Teplov, A.A.; Belousov, S.I.; Chvalun, S.N.; Golovkova, E.A.; Krasheninnikov, S.V.; Golubev, E.K.; Presnyakov, M.Y.; Orekhov, A.S.; Vasiliev, A.L. Effect of a quasicrystalline filler on the tribological properties of a composite based on ultrahigh-molecular-weight polyethylene. J. Surf. Investig. 2015, 9, 1077–1084. [Google Scholar] [CrossRef]

- Olifirov, L.K.; Kaloshkin, S.D.; Tcherdyntsev, V.V.; Danilov, V.D. Development of antifriction composites based on polypyromellitimide matrix. J. Alloys Compd. 2014, 586, S446–S450. [Google Scholar] [CrossRef]

- Tcherdyntsev, V.V.; Stepashkin, A.A.; Chukov, D.I.; Olifirov, L.K.; Senatov, F.S. Formation of ethylene-vinyl acetate composites filled with Al-Cu-Fe and Al-Cu-Cr quasicrystallline particles. J. Mater. Res. Technol. 2019, 8, 572–589. [Google Scholar] [CrossRef]

- Kenzari, S.; Bonina, D.; Dubois, J.M.; Fournee, V. Quasicrystal-polymer composites for selective laser sintering technology. Mater. Design. 2012, 35, 691–695. [Google Scholar] [CrossRef]

- Wang, X.L.; Li, X.S.; Zhang, Z.J.; Zhang, S.S.; Liu, W.Q.; Wang, L.M. Preparation and wear resistance of Ti-Zr-Ni quasicrystal and polyamide composite materials. Philos. Mag. 2011, 91, 2929–2936. [Google Scholar] [CrossRef]

- Liu, H.; Liu, W.Q.; Sun, Y.; Chen, P.; Zhao, J.X.; Guo, X.; Su, Z.M. Preparation and electrochemical hydrogen storage properties of Ti49Zr26Ni25 alloy covered with porous polyaniline. Int. J. Hydrogen Energy 2020, 45, 11675–11685. [Google Scholar] [CrossRef]

- Chukov, D.I.; Stepashkin, A.A.; Tcherdyntsev, V.V.; Olifirov, L.K.; Kaloshkin, S.D. Structure and properties of composites based on polyphenylene sulfide reinforced with Al-Cu-Fe quasicrystalline particles. J. Thermoplast. Compos. Mater. 2018, 31, 882–895. [Google Scholar] [CrossRef]

- Bloom, P.D.; Baikerikar, K.G.; Otaigbe, J.U.; Sheares, V.V. Development of novel polymer/quasicrystal composite materials. Mater. Sci. Eng. A 2000, 294–296, 156–159. [Google Scholar] [CrossRef]

- Golovkova, E.A.; Teplov, A.A.; Tsetlin, M.B.; Tikhomirov, S.A.; Belousov, S.I. Effect of friction on the degree of crystallinity of composite materials based on ultra-high-molecular-weight polyethylene and polytetrafluoroethylene with quasicrystalline filler Al-Cu-Fe. Cryst. Rep. 2020, 65, 622–626. [Google Scholar] [CrossRef]

- Tsetlin, M.B.; Teplov, A.A.; Belousov, S.I.; Chvalun, S.N.; Golovkova, E.A.; Krasheninnikov, S.V.; Golubev, E.K.; Pichkur, E.B.; Dmitryakov, P.V.; Buzin, A.I. composite material based on polytetrafluoroethylene and Al-Cu-Fe quasi-crystal filler with ultralow wear: Morphology, tribological, and mechanical properties. J. Surf. Investig. 2018, 12, 277–285. [Google Scholar] [CrossRef]

- Tsetlin, M.B.; Teplov, A.A.; Belousov, S.I.; Chvalun, S.N.; Golovkova, Y.A.; Krasheninnikov, S.V.; Golubev, E.K.; Vasilyev, A.L.; Presnyakov, M.Y.; Dmitryakov, P.V. Tribological and mechanical properties of composites based on ethylene-tetrafluoroethylene and quasicrystalline Al-Cu-Fe Filler. J. Surf. Investig. 2017, 11, 315–321. [Google Scholar] [CrossRef]

- Olifirov, L.K.; Kaloshkin, S.D.; Ergin, K.S.; Tcherdyntsev, V.V.; Danilov, V.D. Solid-state recycling of polyimide film waste. J. Appl. Polym. Sci. 2013, 127, 2960–2968. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E. Microstructure, fabrication and properties of quasicrystalline Al-Cu-Fe alloys: A review. J. Alloys Compd. 2004, 363, 150–174. [Google Scholar] [CrossRef]

- Rudiger, A.; Koster, U. Corrosion behavior of Al-Cu-Fe quasicrystals. Mater. Sci. Eng. A 2000, 294–296, 890–893. [Google Scholar] [CrossRef]

- Lee, K.; Chen, E.; Naugle, D.; Liang, H. Corrosive behavior of multi-phased quasicrystal alloys. J. Alloys Compd. 2021, 851, 156862. [Google Scholar] [CrossRef]

- Chugunov, D.B.; Meshkov, L.L.; Osipov, A.K.; Balandina, A.B. Corrosion behavior of quasi-crystalline alloys of the Al-Cu-Fe-Cr system in alkaline media. Russ. J. Electrochem. 2020, 56, 754–759. [Google Scholar] [CrossRef]

- Salimon, A.I.; Shevchukov, A.P.; Stepashkin, A.A.; Tcherdyntsev, V.V.; Olifirov, L.K.; Kaloshkin, S.D. Mechanical alloying as a solid state route for fabrication of Al-Cu-M(=Fe, Cr) quasicrystalline phases. J. Alloys Compd. 2017, 707, 315–320. [Google Scholar] [CrossRef]

- Pucciariello, R.; Angioletti, C. Phase behavior of crystalline blends of poly(tetrafluoroethylene) and of random fluorinated copolymers of tetrafluoroethylene. J. Polym. Sci. B Polym Phys. 1999, 37, 679–689. [Google Scholar] [CrossRef]

- Endo, M.; Ohnishi, A.; Kutsumizu, S.; Shimizu, T.; Yano, S. Crystallization in binary blends of polytetrafluoroethylene with perfluorinated tetrafluoroethylene copolymer. Polym. J. 2004, 36, 716–727. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Yang, J.; Tan, B.L.; Tang, B.; Li, E.Z.; Zhang, S.R. Preparation, characterization and properties of FEP modified PTFE/glass fiber composites for microwave circuit application. J. Mater. Sci. Mater. Electron. 2017, 28, 6015–6021. [Google Scholar] [CrossRef]

- Kurose, T.; Takahashi, T.; Koyama, K. Uniaxial elongational viscosity of FEP—A small amount of PTFE blends. J. Soc. Rheol. Jap. 2003, 31, 195–200. [Google Scholar] [CrossRef] [Green Version]

- Oshima, A.; Mutou, F.; Hyuga, T.; Asano, S.; Ichizuri, S.; Li, J.Y.; Miura, T.; Washio, M. Synthesis of per-fluorinated polymer-alloy based on PTFE by high temperature EB-irradiation. Nucl. Instr. Meth. Phys. Res. B 2005, 236, 172–178. [Google Scholar] [CrossRef]

- Hong, M.H.; Pyun, S.I. Effect of fluorinated ethylene propylene copolymer on the wear behaviour of polytetrafluoroethylene. Wear 1991, 143, 87–97. [Google Scholar]

- Menzel, B.; Blanchet, T.A. Effect of particle size and volume fraction of irradiated FEP filler on the transfer wear of PTFE. Lubr. Eng. 2002, 58, 29–35. [Google Scholar]

- Chen, B.B.; Wang, J.Z.; Yan, F.Y. Microstructure of PTFE-based polymer blends and their tribological behaviors under aqueous environment. Tribol. Lett. 2012, 45, 387–395. [Google Scholar] [CrossRef]

- Saravanan, P.; Satyanarayana, N.; Sinha, S.K. Self-lubricating SU-8 nanocomposites for microelectromechanical systems applications. Tribol. Lett. 2013, 49, 169–178. [Google Scholar] [CrossRef]

- Agrawal, N.; Parihar, A.S.; Singh, J.P.; Goswami, T.H.; Tripathi, D.N. Efficient nanocomposite formation of acyrlo nitrile rubber by incorporation of graphite and graphene layers: Reduction in friction and wear rate. Proc. Mater. Sci. 2015, 10, 139–148. [Google Scholar] [CrossRef] [Green Version]

- Pan, J.M.; Yan, X.H.; Cheng, X.N.; Xu, D.; Lu, Q.B. Preparation and tribological properties of hierarchical porous SiOC/BN composites from wood powder and polysiloxane precursor. Ceram. Int. 2015, 41, 1012–1019. [Google Scholar] [CrossRef]

- Xu, Y.K.; Qi, H.M.; Li, G.T.; Guo, X.P.; Wan, Y.; Zhang, G. Significance of an in-situ generated boundary film on tribocorrosion behavior of polymer-metal sliding pair. J. Colloid Interface Sci. 2018, 518, 263–276. [Google Scholar] [CrossRef] [PubMed]

- Vattikuti, S.V.; Byon, C.; Venkata, C.R.; Venkatesh, B.; Jaesool Shim, J. Synthesis and structural characterization of MoS2 nanospheres and nanosheets using solvothermal method. J. Mater. Sci. 2015, 50, 5024–5038. [Google Scholar] [CrossRef]

- Vattikuti, S.V.; Byon, C. Synthesis and characterization of molybdenum disulfide nanoflowers and nanosheets: Nanotribology. J. Nanomater. 2015, 2015, 11. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.S.; Wei, D.D.; Xu, R.S.; Mai, Y.J.; Zhang, L.Y.; Jie, X.H. Electroplated Co-Ni/WS2 composite coating with excellent tribological and anticorrosion performance. Tribol. Trans. 2020, 63, 856–866. [Google Scholar] [CrossRef]

- Gandi, A.N.; Schwingenschlogl, U. Thermal conductivity of bulk and monolayer MoS2. EPL 2016, 113, 36002. [Google Scholar] [CrossRef]

- Tando, K. The Synthesis and Characterisation of Fluorinated Ethylene Propylene (FEP) Copolymers. Master’s Thesis, University of Pretoria, Pretoria, South Africa, 2014. [Google Scholar]

- Bouznik, V.M.; Vopilov, Y.E.; Dedov, S.A.; Ignatieva, L.N.; Murin, A.S.; Slobodyuk, A.B. Structure of Ultrafine Polytetrafluoroethylene Powders Obtained from Industrial Wastes via Hydrothermal Method. Chem. Sustain. Develop. 2010, 18, 33–39. [Google Scholar]

| Composite | Components Content (wt.%) | Label |

|---|---|---|

| FEP unfilled | 100 | F0 |

| FEP-CB-QC Al73Cu11Cr16 | 97–1.25–1.25 | F1.25C1.25Q |

| FEP-nano PTFE-QC Al73Cu11Cr16 | 95.5–2–2.5 | F2nP2.5Q |

| 93–2–5 | F2nP5Q | |

| 88–2–10 | F2nP10Q | |

| 85–5–10 | F5nP10Q | |

| FEP-nano PTFE-QC Al73Cu11Cr16-Gr | 83–2–10–5 | F2nP10Q5G |

| 78–2–5–15 | F2nP5Q15G | |

| FEP-PTFE-QC Al73Cu11Cr16 | 93.75–5–1.25 | F5P1.25Q |

| 92.5–5–2.5 | F5P2.5Q | |

| 90–5–5 | F5P5Q | |

| 85–5–10 | F5P10Q |

| No. | Material | Thermal Diffusivity (mm2/s) | Density (g/cm3) | Specific Heat (J/g·K) |

|---|---|---|---|---|

| 1 | F0 | 0.107 ± 0.007 | 2.13 ± 0.004 | 1.06 |

| 2 | F1.25C1.25Q | 0.105 ± 0.003 | 2.157 ± 0.001 | 1.05 |

| 3 | F5P1.25Q | 0.103 ± 0.007 | 2.161 ± 0.005 | 1.05 |

| 4 | F5P2.5Q | 0.108 ± 0.001 | 2.178 ± 0.001 | 1.05 |

| 5 | F5P5Q | 0.108 ± 0.002 | 2.207 ± 0.001 | 1.03 |

| 6 | F5P10Q | 0.114 ± 0.001 | 2.249 ± 0.002 | 1 |

| 7 | F2nP2.5Q | 0.102 ± 0.003 | 2.173 ± 0.005 | 1.05 |

| 8 | F2nP5Q | 0.105 ± 0.001 | 2.199 ± 0.002 | 1.03 |

| 9 | F2nP10Q | 0.106 ± 0.001 | 2.243 ± 0.006 | 1 |

| 10 | F2nP10Q5G | 0.19 ± 0.006 | 2.251 ± 0.002 | 0.89 |

| 11 | F2nP5Q15G | 0.299 ± 0.009 | 2.209 ± 0.003 | 0.96 |

| No. | Material | Hardness (Shore D) | Young’s Modulus (GPa) | Tensile Strength (MPa) | Elongation (%) | VST (°C) |

|---|---|---|---|---|---|---|

| 1 | F0 | 57.5 ± 1 | 0.59 ± 0.01 | 15.4 ± 0.4 | 295 ± 11 | 83.7 ± 0.5 |

| 2 | F1.25C1.25Q | 59 ± 1 | 0.6 ± 0.01 | 15.4 ± 0.1 | 295 ± 9 | − |

| 3 | F5P1.25Q | 55 ± 1 | 0.55 ± 0.01 | 14.1 ± 0.1 | 136 ± 9 | − |

| 4 | F5P2.5Q | 56 ± 1 | 0.57 ± 0.01 | 14.7 ± 0.1 | 48 ± 4 | 82.9 ± 0.4 |

| 5 | F5P5Q | 57.5 ± 1 | 0.6 ± 0.01 | 14.9 ± 0.2 | 44 ± 2 | 84.2 ± 0.5 |

| 6 | F5P10Q | 60 ± 1 | 0.66 ± 0.01 | 15.4 ± 0.1 | 34 ± 2 | 86.8 ± 0.5 |

| 7 | F2nP2.5Q | 58.5 ± 1 | 0.61 ± 0.01 | 14.7 ± 0.4 | 294 ± 16 | 87.1 ± 0.6 |

| 8 | F2nP5Q | 59.5 ± 1 | 0.64 ± 0.01 | 14.3 ± 0.2 | 280 ± 10 | 91.2 ± 0.7 |

| 9 | F2nP10Q | 61.5 ± 1 | 0.7 ± 0.01 | 14.4 ± 0.2 | 147 ± 7 | 97.2 ± 0.7 |

| 10 | F5nP10Q | 52 ± 1 | 0.69 ± 0.01 | 13.6 ± 0.8 | 55 ± 5 | − |

| No. | Material | Wear (mm3) | Coefficient of Friction |

|---|---|---|---|

| 1 | F0 | 1.038 ± 0.189 | 0.36 ± 0.03 |

| 2 | F1.25C1.25Q | 0.064 ± 0.019 | 0.27 ± 0.02 |

| 3 | F5P1,25Q | 0.064 ± 0.009 | 0.25 ± 0.02 |

| 4 | F5P2.5Q | 0.062 ± 0.019 | 0.27 ± 0.01 |

| 5 | F5P5Q | 0.029 ± 0.015 | 0.28 ± 0.02 |

| 6 | F5P10Q | 0.013 ± 0.002 | 0.28 ± 0.02 |

| 7 | F2nP2.5Q | 0.057 ± 0.008 | 0.24 ± 0.01 |

| 8 | F2nP5Q | 0.02 ± 0.006 | 0.24 ± 0.01 |

| 9 | F2nP10Q | 0.015 ± 0.006 | 0.25 ± 0.01 |

| 10 | F5nP10Q | 0.024 ± 0.007 | 0.24 ± 0.01 |

| 11 | F2nP5Q15G | 0.013 ± 0.005 | 0.23 ± 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olifirov, L.K.; Stepashkin, A.A.; Sherif, G.; Tcherdyntsev, V.V. Tribological, Mechanical and Thermal Properties of Fluorinated Ethylene Propylene Filled with Al-Cu-Cr Quasicrystals, Polytetrafluoroethylene, Synthetic Graphite and Carbon Black. Polymers 2021, 13, 781. https://doi.org/10.3390/polym13050781

Olifirov LK, Stepashkin AA, Sherif G, Tcherdyntsev VV. Tribological, Mechanical and Thermal Properties of Fluorinated Ethylene Propylene Filled with Al-Cu-Cr Quasicrystals, Polytetrafluoroethylene, Synthetic Graphite and Carbon Black. Polymers. 2021; 13(5):781. https://doi.org/10.3390/polym13050781

Chicago/Turabian StyleOlifirov, Leonid K., Andrey A. Stepashkin, Galal Sherif, and Victor V. Tcherdyntsev. 2021. "Tribological, Mechanical and Thermal Properties of Fluorinated Ethylene Propylene Filled with Al-Cu-Cr Quasicrystals, Polytetrafluoroethylene, Synthetic Graphite and Carbon Black" Polymers 13, no. 5: 781. https://doi.org/10.3390/polym13050781