1. Introduction

Log structures are unquestionably attractive and architecturally interesting structures for human occupancy, year-round lodging and other purposes. Historically, log walls have been designed as a single layer made of lumber, with a width of 200 to 400 mm. Joints of log walls and joinery details were sealed to prevent thermal loss of the building due to air leakage. They were erected in various ways with various effects on air tightness. Significant thermal loss results from a heat transfer through the log wall. Design of these structures became insufficient in terms of increasing thermal performance demands due to energy saving and environment impact.

In order to decrease the heat transfer, a multilayer log wall is designed using various insulations on the interior wall side, leading to improvement of the thermal performance of the log wall. Application of the vapor barrier layers of various effectivity can prevent interior air humidity transfer into the structure and water vapor condensation inside the structure, thus eliminating conditions favorable for the lumber biodegradation. Thermal insulation applied between the studs and in the service cavity can be organic or inorganic based, with various heat transfer, diffusion and other properties. The interior is finished with a timber cladding or mineral board and drywall. Design aim of multilayer log wall is to achieve required thermal performance properties such as heat transfer coefficient, superficial temperature excluding the risk of mold growth and superficial temperature in the wall excluding or limiting water vapor condensation and others.

Thermal performance properties are determined by calculations of various methods based on a fundamental material physical property. However, methods of calculation cannot reliably cover other essential complex material properties, e.g., processes of moisture transfer, material moisture content in the structure, critical dew points in loadbearing structures. Moreover, these methods do not describe complex influence of climate-related nonstationary conditions affecting a structure. Therefore, experimental verifying under in-situ conditions using a measuring tool to record the climate conditions and an oven-dry method to verify the moisture content of the materials must be performed for measurement accuracy verification of material moisture content and critical dew points in multilayer loadbearing walls.

Research on the thermal performance properties is conducted simultaneously in specific software and experimentally in-situ. The influence of vapor barrier equivalent diffuse thickness and the width of an insulation on mold growth risk in log structures was investigated in Alev et al. [

1]. The paper published by Conroy et al. [

2] verified the hygrothermal performance of a post and beam building designed to meet the International Passive House Standard both in-situ and via software WUFI

®. Geving et al. [

3] investigated the moisture conditions in several samples of the wood frame wall insulated with loose-fill and batt wood fiber as well as batt glass wool in variations with wind barrier, vapor barrier, vapor retarder or no barrier. Moreover, Glass et al. [

4] verified the interior vapor retarder on the performance of six configurations of energy efficient walls at elevated levels of interior relative humidity, Goodhew et al. [

5] verified the moisture content of the wood-discs placed in external straw-bale walls of a case study building. Volf et al. [

6] investigated physical properties of the selected natural insulating materials and tested possible mold growth risk in laboratory conditions. The vapor barrier influence on the materials moisture content and water vapor condensation in timber structures is also verified in [

7,

8,

9,

10,

11,

12,

13]. Materials biodegradation in timber structures is verified in [

14,

15,

16].

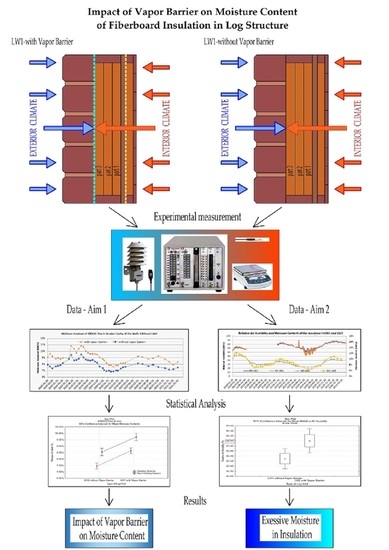

The aim of this paper is medium-term experimental moisture content verification of the fiberboard insulations in the two samples of multilayer loadbearing log walls, including and excluding vapor barrier.

2. Materials and Methods

2.1. Materials—Loadbearing Log Structures

Two samples of multilayer loadbearing log walls were designed for the experimental moisture content verification of the fiberboard insulation:

Wall LW1 with paper vapor barrier—

Figure 1.

Wall LW2 without paper vapor barrier—

Figure 2.

Thermal performance properties of the walls are shown in

Table 1.

2.2. Fiberboard Insulation Used in Verification

The moisture content of the fiberboard insulations was verified in the walls LW1 and LW2 in

Figure 1 and

Figure 2:

STEICO Flex with a width of 40 mm, thermal conductivity coefficient λ = 0.038 W·m−1·K−1

STEICO Universal with a width of 22 mm, λ = 0.05 W·m−1·K−1·

STEICO Flex with a width of 140 mm, λ = 0.038 W·m−1·K−1, divided into 3 parts, part 1 width 45 mm, part 2 width 45 mm, part 3 width 50 mm, for more accurate measurement of the moisture distribution.

2.3. Water Vapor Barrier and House Wrap Used for the Verification

Paper water vapor barrier ISOCELL Oko Natur was used, the value of equivalent diffuse thickness Sd = 6.45 m, diffusion resistance factor µ = 32,250.

House wrap OMEGA 180 was used with the value of equivalent diffuse thickness Sd = 0.025 m, diffusion resistance factor µ = 28.

2.4. In-Situ Conditions and Period of Verification

LW1 and LW2 walls were installed into the north-facing wall of the research timber structure as shown in

Figure 3 and exposed to an exterior weather. Interior conditions simulated human occupancy. Interior side of the walls is shown in

Figure 4. In-situ conditions were recorded by measuring tools: air temperature and relative air humidity at 1-h intervals. The recorded conditions are shown in

Figure 5 and

Figure 6.

The experiment is in Zvolen, Slovak Republic, altitude 300 MSL, with a temperature inversion frequently occurring in spring and autumn. The period of verification was 2 years and 3 months, from 30 January 2019, to 3 May 2021.

Interior conditions for human occupancy were set at the air temperature of 20 ± 3 °C and relative air humidity 50 ± 10%. Higher relative air humidity, 60 to 80% was reached in humid rooms such as bathrooms, laundries, kitchen, etc. During the period from May 7 to December 12, 2019, an outage occurred causing data to be rewritten and deleted. Similar outages happened during the year 2020 as well.

2.5. Climatic Conditions in the Multilayer Loadbearing Log Structures

Climatic conditions in the walls were recorded by the measuring tool AHLBORN ALMEMO 5690 and sensors AHLBORN FHAD46C2 recording air temperature, relative air humidity and air pressure at 1-h intervals. The layout of the sensors is shown in

Figure 7.

2.6. Method of the Moisture Content Verification

The oven-dry method was used to verify moisture content of the insulations in the walls in accordance with the standard EN 322:1995[

18]. Weighing intervals were 2 to 4 weeks. Scale used for weighing method was RADWAG WLC 2/A2.

2.7. Evaluation Method of the Aims of the Paper

Firstly, verification of the vapor barrier effectivity on the moisture content of fiber-board insulation based on the results comparison of the oven-dry method during the heating season and rest of the year. The first hypothesis: it is assumed that the average fiberboard insulation moisture content in the wall with the vapor barrier will be different (percentual change by 5% or higher) during the heating season and the rest of the year compared to fiber-board insulation without the vapor barrier. Thus, the effect of the vapor barrier will be significant.

Verification of the vapor barrier effectivity on the insulation moisture content was evaluated by specifying the heating season and the result comparison of percentual change of the oven-dry method.

The heating season is a period of the year during which it is necessary to provide heating in buildings due to colder weather. The heating season was set:

The heating season 2019 (HS19): from 30 January 2019 to 30 April 2019

The heating season 2020 (HS20): from 1 November 2019 to 30 April 2020

The heating season 2021 (HS21): from 1 November 2020 to 30 April 2021

The non-heating season is a period of the year during which it is not necessary to provide heating in building.

Secondly, verification of the undesirable excessive moisture due to the risk of biodegradation in fiberboard insulations in both fragments of the log walls. The second hypothesis: it is assumed that the critical average moisture content exceeding 20% causing the risk of biodegradation with mold and wood decaying fungi will not be reached in the fiberboard insulations of the log wall with and the wall without vapor barrier.

Verification of the undesirable excessive moisture increasing the risk of insulation biodegradation was evaluated based on the average moisture content of the fiberboard insulation STECO Flex part 3 as shown in

Figure 1 (3.3) and

Figure 2 (3.3), near the loadbearing log. The average moisture content was compared in the periods when relative air humidity in the walls reached 70% or more.

2.8. Statistical Method for Evaluation of the Aims of the Paper

The analyses were carried out using statistical software STATISTICA 12. The fact whether the variability of the outcomes is due to chance or to effect of factors (or their interaction) was tested applying a two-way ANOVA. This technique enables researchers to estimate how the mean of a quantitative (dependent) variable is changed according to the levels of two categorical (independent) variables called factors. One sample T-test was used to test population mean against a “limit value”, which is a known value from industry standards. In all tests, a 5% level of significance was used.

3. Results

Outdoor air temperature and the relative air humidity values were recorded during the monitored period as shown in

Figure 5.

Interior air temperature was maintained at 20 ± 3 °C, and the relative air humidity at 50 ± 10%, conditions matching human occupancy in accordance with the national standard as shown in

Figure 6.

During the period from May 7 to December 12, a power cut caused reset of the settings in measuring instrument without indication of error, which caused data to be rewritten and ultimately deleted. A similar short-term outage happened during the year 2020.

The insulation STEICO Flex situated in a service cavity in the wall LW1 with the vapor barrier reached higher moisture content than the same insulation situated in the wall without vapor barrier. The vapor barrier preventing the vapor transfer from the interior to the wall can be considered the reason. This humidity was accumulated in the service cavity in front of the barrier.

Statistics analysis was done in STATISTICA

® software, results shown in

Table 2 and

Figure 9.

Statistical analysis was done in STATISTICA

® software, results shown in

Table 3 and

Figure 11.

Statistical analysis of STEICO Flex part 1 was done in STATISTICA

® software, results shown in

Table 4 and

Figure 14.

Statistical analysis of STEICO Flex part 2 was done in STATISTICA

® software, results shown in

Table 5 and

Figure 15.

Statistical analysis of STEICO Flex part 3 was done in STATISTICA

® software, results shown in

Table 6 and

Figure 16.

Statistical analysis of factor analyzed influence on insulation moisture content was done in STATISTICA

® software, results shown in

Table 7.

Figure 17 shows moisture content of the STEICO Flex part 3 and relative air humidity in the walls.

4. Discussion

The significance of the vapor barrier effectivity on the moisture content of fiberboard insulations in the walls LW1 and LW2 during the season of the year is proved if the percentual change in the average moisture content is 5% or higher. The significant differences were tested on the alpha level 0.05. Subsequently, 95% confidence intervals for means of moisture content were calculated. The results of statistics analysis are shown in

Table 7. The moisture content of the insulations in the walls LW1 and LW2 are shown in

Figure 8,

Figure 10,

Figure 12,

Figure 13. The results of comparison are:

The results indicate that the vapor barrier effectivity on the insulation moisture content was significant, and the insulation moisture content in the service cavity of the wall LW1 is higher than that of the wall LW2.

The results in

Table 2 and

Figure 9 confirm the significance of differences of the vapor barrier effectivity on the insulation moisture content and at the same time confirm the significance of the effect of heating and non-heating season on the insulation moisture content.

The results indicate that the vapor barrier effectivity on the insulation moisture content was significant in HS19; otherwise, the effectivity proved not significant.

The results in

Table 3 and

Figure 11 do not confirm the significance of differences of the vapor barrier effectivity on the insulation moisture content but confirm the significance of the effect of heating and non-heating season on the insulation moisture content.

The results indicate that the vapor barrier effectivity on the insulation moisture content was not significant in HS19; otherwise, the effectivity proved significant.

The results in

Table 4 and

Figure 14 confirm the significance of differences of the vapor barrier effectivity on the insulation moisture content and at the same time confirm the significance of the effect of heating and non-heating season on the insulation moisture content.

The results indicate that the vapor barrier effectivity on the insulation moisture content was not significant in HS19; otherwise, the effectivity proved significant.

The results in

Table 5 and

Figure 15 do not confirm the significance of differences of the vapor barrier effectivity on the insulation moisture content but confirm the significance of the effect of heating and non-heating season on the insulation moisture content.

The results indicate that the vapor barrier effectivity on the insulation moisture content is undetermined.

The results in

Table 6 and

Figure 16 do not confirm the significance of differences of the vapor barrier effectivity on the insulation moisture content and at the same time confirm the significance of the effect of heating and non-heating season on the insulation moisture content.

The vapor barrier effectivity on the fiberboard insulations moisture content in the walls LW1 and LW2:

Is significant in the insulation STECO Flex, shown in

Figure 1 (5) and

Figure 2 (5), the vapor barrier prevents and slows down the moisture transfer from the interior into the wall

In general, is not significant in the insulation STEICO Universal, shown in

Figure 1 (4) and

Figure 2 (4),

In general, is significant in the insulation STEICO Flex part 1, shown in

Figure 1 (3.1) and

Figure 2 (3.1); the moisture content of the insulation in the wall LW1 is generally higher than the wall LW2,

In general, is significant in the insulation STEICO Flex part 2, shown in

Figure 1 (3.2) and

Figure 2 (3.2); the moisture content of the insulation in the wall LW1 decreases in time compared to the insulation in the wall LW2,

In general, the significance in the insulation STEICO Flex part 3, shown in

Figure 1 (3.3) and

Figure 2 (3.3), cannot be determined; the moisture content of the insulation in the wall LW1 and LW2 oscillates depending on the weather conditions, probably caused by imperfect airtightness of the gaps in the loadbearing log wall.

Undesirable excessive moisture is considered for the average moisture content of 20% lasting more than 2 weeks continuously. The verification of the undesirable excessive moisture increasing the risk of biodegradation is done at the border of the insulations STEICO Flex part 3 and the loadbearing log wall. The recorded values of the relative air humidity, shown in

Figure 17, presuppose conditions favorable for the mold growth and wood decaying fungi at this border, particularly when relative air humidity reaches 70% or more. The statistics analysis results are shown in

Table 8 and

Figure 18. Average moisture content of the insulation STEICO Flex part 3 in the wall LW1 and LW2 reached during this period are compared below.

The relative air humidity in the walls reached 70% or more:

from 29 January to 16 April 2019, the insulation in LW1 reached the average moisture content of 10.98% and the insulation in LW2 reached the average moisture content of 11.23%;

from 10 December 2019 to 15 June 2020, the insulation in LW1 reached the average moisture content of 8.51% and the insulation in LW2 reached the average moisture content of 8.90%;

from 1 October 2020 to 29 March 2021, the insulation in LW1 reached the average moisture content of 9.05%, and the insulation in LW2 reached the average moisture content of 10.38%.

The results indicate that average moisture content of the insulations STEICO Flex part 3 in both walls LW1 and LW2, under the recorded weather and indoor conditions did not exceed MC = 20%, and thus, no risk of the biodegradation appeared in the walls. The insulation in the wall LW2 had in general insignificantly higher average moisture content compared to the wall LW1.

To confirm these results, relative air humidity in the walls was further investigated from 1 December 2020 to 30 April 2021. Borderline relative air humidity favorable for biodegradation was set to RH = 84% in accordance with the national standard in this period, and Student’s T-test was done. The results shown in

Table 9 and

Figure 19 confirm mean relative air humidity in the LW1 of 84.29% and in the LW2 of 85.18%. The insulation STEICO Flex part 3 in LW1 reached the average moisture content of 9.6% and the insulation in LW2 reached the average moisture content of 10.2%. The average moisture content of the insulation STEICO Flex part 3 in both walls LW1 and LW2 did not exceed 20%, and no risk of biodegradation appeared in the walls.

Moisture contents of the materials in timber structures under in-situ conditions are described in the paper of Conroy [

2]. In the paper, the authors verified hygrothermal performance of a post and beam building designed to meet the International Passive House Standard both in-situ and via WUFI

® software. Thicker walls dry out slower, and humidity could accumulate according to the paper conclusions. However, the in-situ results show no accumulation of the humidity in the wall and no risk of biodegradation. Similar conditions of slow drying out of the walls could appear in the walls LW1 due to the combined effect of the house wrap and the thickness of the log and in LW2 due to the thickness of the log. However, gaps between logs are filled with the insulation STEICO Flex with a width of 30 mm, which is vapor permeable, thus allowing the walls to dry out more intensively. It supports the results of the moisture content of STEICO Flex part 3 in the non-heating season when the moisture content is lower than in the heating season and the humidity does not accumulate in the insulation. Results of Geving et al. [

3] indicate slightly better performance of the loose fill fiber insulation compared to batt fiber insulation and positive influence on the moisture conditions when 50 mm wood fiber board was used as a wind barrier. Positive influence was proven using so-called smart vapor barrier. The results are comparable to this work, specifically in measured values of relative air humidity in the samples. In the paper of Glass [

4], interior vapor retarder effect on the performance of six configurations of energy efficient walls at elevated levels of interior relative humidity is verified. The results prove that oriented strand board used in configuration of the wall without vapor retarder and interior drywall with latex paint had higher moisture content compared to the configuration with vapor retarder. The consequence of the higher moisture content resulted in mold growth on the OSB, which is undesirable. Volf et al. [

6] investigated physical properties of the selected natural insulating materials and tested possible mold growth risk in laboratory conditions and determined that natural insulation has comparable thermal properties to common building insulation materials. Although there was no mold growth observed in samples, fungi spores could be present in natural insulation; therefore, proper and safe constructing design is extremely important. Volf et al. [

6] used fiberboard with a density of 51.5 kg·m

−3 and measured relative air humidity of 85%, and the moisture content was approximately 8.5%. Fiberboard used in this work had a density of 60 kg·m

−3, and the average moisture content of the insulation in LW2 was 10.2%. It is assumed that higher moisture content in the insulation was caused by higher density and higher relative air humidity in the wall of 89% in HS21. In comparison with this work, there is no mold growth in the wall LW2 because of redistribution of the moisture in the insulation. Alev [

1] simulated the risk of mold growth in log structure using software WUFI. The results are principles for designing log structures, such as appropriate choice of vapor barrier and width of the insulation. Due to different timber structures, verified materials, weather and geographical conditions and the period of verification in the papers of Conroy [

2] and Glass [

4], these results cannot be compared. Moisture content verifying methods and climate conditions both outdoors and indoors are identical.

The research of the fiberboard insulation moisture content in log walls LW1 and LW2 brought interesting new knowledge, for example the initial assumption that the vapor barrier effect would be significant for every insulation in the wall proved wrong, the vapor barrier effect proved significant in STEICO Flex in the service cavity and STEICO Flex part 1 and part 2, while the effect proved not significant in STEICO Universal and STEICO Flex part 3. Research into vapor barrier effect on the insulation based on the type and physical properties of insulation and different position of the vapor barrier in the wall is suggested.