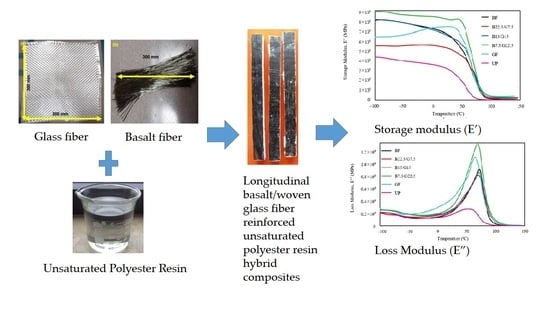

Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of B/G/UP Hybrid Composites

2.3. Chemical Structure of Composites

2.4. Dynamic Mechanical Analysis

2.5. Thermomechanical Analysis

3. Results and Discussion

3.1. Chemical Structure of Composites

3.2. Dynamic Mechanical Properties

3.2.1. Storage Modulus

3.2.2. Loss Modulus

3.2.3. Tan δ

3.3. Thermomechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ballo, A.; Närhi, T. 3-Biocompatibility of fiber-reinforced composites for dental applications. In Biocompatibility of Dental Biomaterials; Woodhead Publishing Series in Biomaterials; Shelton, R., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 23–39. ISBN 9780081008843. [Google Scholar]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun nanofiber: Emerging reinforcing filler in polymer matrix composite materials. Prog. Polym. Sci. 2017, 75, 73–107. [Google Scholar] [CrossRef]

- Suhot, M.A.; Hassan, M.Z.; Aziz, S.A.A.; Md Daud, M.Y. Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymers 2021, 13, 2391. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.Z.; Sapuan, S.M.; Roslan, S.A.; Aziz, S.A.; Sarip, S. Optimization of tensile behavior of banana pseudo-stem (Musa acuminate) fiber reinforced epoxy composites using response surface methodology. J. Mater. Res. Technol. 2019, 8, 3517–3528. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Roslan, S.A.; Sapuan, S.M.; Rasid, Z.A.; Mohd Nor, A.F.; Md Daud, M.Y.; Dolah, R.; Mohamed Yusoff, M.Z. Mercerization Optimization of Bamboo (Bambusa vulgaris) Fiber-Reinforced Epoxy Composite Structures Using a Box–Behnken Design. Polymers 2020, 12, 1367. [Google Scholar] [CrossRef]

- Nor, A.F.M.; Hassan, M.Z.; Rasid, Z.A.; Aziz, S.A.; Sarip, S.; Md Daud, M.Y. Optimization on Tensile Properties of Kenaf/Multi-walled CNT Hybrid Composites with Box-Behnken Design. Appl. Compos. Mater. 2021, 28, 607–632. [Google Scholar] [CrossRef]

- Prasad, V.; Suresh, D.; Joseph, M.A.; Sekar, K.; Ali, M. Development of Flax Fibre Reinforced Epoxy Composite with Nano Tio2 Addition Into Matrix To Enhance Mechanical Properties. Mater. Today Proc. 2018, 5, 11569–11575. [Google Scholar] [CrossRef]

- Adesina, O.T.; Jamiru, T.; Sadiku, E.R.; Ogunbiyi, O.F.; Beneke, L.W. Mechanical evaluation of hybrid natural fibre–reinforced polymeric composites for automotive bumper beam: A review. Int. J. Adv. Manuf. Technol. 2019, 103, 1781–1797. [Google Scholar] [CrossRef]

- Norhasnan, N.H.; Hassan, M.Z.; Nor, A.F.; Zaki, S.A.; Dolah, R.; Jamaludin, K.R.; Aziz, S.A. Physicomechanical Properties of Rice Husk/Coco Peat Reinforced Acrylonitrile Butadiene Styrene Blend Composites. Polymers 2021, 13, 1171. [Google Scholar] [CrossRef]

- Shioya, M.; Kikutani, T. Chapter 7—Synthetic textile fibres: Non-polymer fibres. In Textiles and Fashion; Woodhead Publishing Series in Textiles; Sinclair, R., Ed.; Woodhead Publishing: Sawston, UK, 2015; pp. 139–155. ISBN 9781845699314. [Google Scholar]

- Sanjay, M.R.; Yogesha, B. Studies on Natural/Glass Fiber Reinforced Polymer Hybrid Composites: An Evolution. Mater. Today Proc. 2017, 4, 2739–2747. [Google Scholar] [CrossRef]

- Chawla, K.K. Glass fibers. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9780128035818. [Google Scholar]

- De Araújo, M. 1—Natural and man-made fibres: Physical and mechanical properties. In Fibrous and Composite Materials for Civil Engineering Applications; Woodhead Publishing Series in Textiles; Fangueiro, R., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 3–28. ISBN 9781845695583. [Google Scholar]

- Fan, Y.; Guo, J.; Wang, X.; Xia, Y.; Han, P.; Shangguan, L.; Zhang, M. Comparative Failure Study of Different Bonded Basalt Fiber-Reinforced Polymer (BFRP)-AL Joints in a Humid and Hot Environment. Polymers 2021, 13, 2593. [Google Scholar] [CrossRef]

- Ogrodowska, K.; Łuszcz, K.; Garbacz, A. Nanomodification, Hybridization and Temperature Impact on Shear Strength of Basalt Fiber-Reinforced Polymer Bars. Polymers 2021, 13, 2585. [Google Scholar] [CrossRef]

- Ricciardi, M.R.; Papa, I.; Coppola, G.; Lopresto, V.; Sansone, L.; Antonucci, V. Effect of Plasma Treatment on the Impact Behavior of Epoxy/Basalt Fiber-Reinforced Composites: A Preliminary Study. Polymers 2021, 13, 1293. [Google Scholar] [CrossRef]

- Le, C.H.; Louda, P.; Buczkowska, K.E.; Dufkova, I. Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite. Polymers 2021, 13, 751. [Google Scholar] [CrossRef] [PubMed]

- Motoc, D.L.; Ferri, J.M.; Ferrandiz-Bou, S.; Garcia-Garcia, D.; Balart, R. Dynamic–Mechanical and Decomposition Properties of Flax/Basalt Hybrid Laminates Based on an Epoxidized Linseed Oil Polymer. Polymers 2021, 13, 479. [Google Scholar] [CrossRef]

- Glaskova-Kuzmina, T.; Zotti, A.; Borriello, A.; Zarrelli, M.; Aniskevich, A. Basalt Fibre Composite with Carbon Nanomodified Epoxy Matrix under Hydrothermal Ageing. Polymers 2021, 13, 532. [Google Scholar] [CrossRef] [PubMed]

- Barczewski, M.; Matykiewicz, D.; Mysiukiewicz, O.; Maciejewski, P. Evaluation of polypropylene hybrid composites containing glass fiber and basalt powder. J. Polym. Eng. 2018, 38, 281–289. [Google Scholar] [CrossRef]

- Babu, S.M.; Rao, M.V. Effect of basalt powder on mechanical properties and dynamic mechanical thermal analysis of hybrid epoxy composites reinforced with glass fiber. J. Chin. Adv. Mater. Soc. 2018, 6, 311–328. [Google Scholar] [CrossRef]

- El-Wazery, M.S. Mechanical Characterization of Glass-Basalt-Carbon/Polyester Hybrid Composites. Int. J. Eng. 2018, 31, 1139–1145. [Google Scholar] [CrossRef]

- Patel, N.I.; Patel, K.; Gohil, P.; Chaudhry, V. Investigations on Mechanical Strength of Hybrid Basalt/Glass Polyester Composites. Int. J. Appl. Eng. Res. 2018, 16, 4083–4088. [Google Scholar]

- Bozkurt, Ö.Y.; Erkliğ, A.; Bozkurt, Y.T. Influence of basalt fiber hybridization on the vibration-damping properties of glass fiber reinforced epoxy laminates. Mater. Res. Express 2018, 6, 15301. [Google Scholar] [CrossRef]

- El-Baky, M.A.A.; Attia, M.A.; Abdelhaleem, M.M.; Hassan, M.A. Flax/basalt/E-glass Fibers Reinforced Epoxy Composites with Enhanced Mechanical Properties. J. Nat. Fibers 2020, 1–15. [Google Scholar] [CrossRef]

- Özbek, Ö.; Bozkurt, Ö.Y.; Erkliğ, A. Effect of glass fiber hybridization on low velocity impact behaviors of basalt fiber reinforced composites laminates. Int. J. Mater. Eng. Technol. 2020, 3, 21–29. [Google Scholar]

- Jain, A.; Singh, B.; Sharma, K.; Shrivastava, Y. Fabrication, Testing and Machining of Hybrid Basalt-Glass Fiber Reinforced Plastic composite. Indian J. Pure Appl. Phys. 2021, 59, 258–262. [Google Scholar]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical Properties of Longitudinal Basalt/Woven-Glass-Fiber-reinforced Unsaturated Polyester-Resin Hybrid Composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef]

- Patel, N.; Patel, K.; Chaudhary, V.; Gohil, P. Investigations on drilling of hybrid basalt/glass polyester composites. Aust. J. Mech. Eng. 2020, 1–10. [Google Scholar] [CrossRef]

- ASTM E831-19 Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis; Techstreet: Pennsylvania, PA, USA, 2019.

- Arrieta, J.S.; Richaud, E.; Fayolle, B.; Nizeyimana, F. Thermal oxidation of vinyl ester and unsaturated polyester resins. Polym. Degrad. Stab. 2016, 129, 142–155. [Google Scholar] [CrossRef] [Green Version]

- Koto, N.; Soegijono, B. Effect of Rice Husk Ash Filler of Resistance Against of High-Speed Projectile Impact on Polyester-Fiberglass Double Panel Composites. J. Phys. Conf. Ser. 2019, 1191, 12058. [Google Scholar] [CrossRef]

- Chukwu, M.; Madueke, C.; Ekebafe, L. Effects of Snail Shell as Filler on the Mechanical Properties of Terephthalic Unsaturated Polyester Resin. Niger. Res. J. Chem. Sci. 2019, 6, 21–32. [Google Scholar]

- Prakash, V.A.; Rajadurai, A. Inter laminar shear strength behavior of acid, base and silane treated E-glass fibre epoxy resin composites on drilling process. Def. Technol. 2017, 13, 40–46. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M. On the impact of flax fibers as an internal layer on the properties of basalt-epoxy composites modified with silanized basalt powder. Compos. Commun. 2020, 20, 100360. [Google Scholar] [CrossRef]

- Seghini, M.C.; Touchard, F.; Sarasini, F.; Cech, V.; Chocinski-Arnault, L.; Mellier, D.; Tirillò, J.; Bracciale, M.P.; Zvonek, M. Engineering the interfacial adhesion in basalt/epoxy composites by plasma polymerization. Compos. Part A Appl. Sci. Manuf. 2019, 122, 67–76. [Google Scholar] [CrossRef]

- Alothman, O.Y.; Jawaid, M.; Senthilkumar, K.; Chandrasekar, M.; Alshammari, B.A.; Fouad, H.; Hashem, M.; Siengchin, S. Thermal characterization of date palm/epoxy composites with fillers from different parts of the tree. J. Mater. Res. Technol. 2020, 9, 15537–15546. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R.; Alothman, O.Y. Thermal properties of sugar palm/glass fiber reinforced thermoplastic polyurethane hybrid composites. Compos. Struct. 2018, 202, 954–958. [Google Scholar] [CrossRef]

- Manoharan, S.; Suresha, B.; Ramadoss, G.; Bharath, B. Effect of Short Fiber Reinforcement on Mechanical Properties of Hybrid Phenolic Composites. J. Mater. 2014, 2014, 478549. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A.; Rafiqah, S.A.; Hanafee, Z.M. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 2020, 9, 1606–1618. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R. Thermoplastic composites for fused deposition modeling filament: Challenges and applications. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780128035818. [Google Scholar]

- Vinu Kumar, S.M.; Senthil Kumar, K.L.; Siddhi Jailani, H.; Rajamurugan, G. Mechanical, DMA and Sound Acoustic behaviour of Flax woven fabric reinforced Epoxy composites. Mater. Res. Express 2020, 7, 085302. [Google Scholar] [CrossRef]

- Gupta, M.; Deep, V. Effect of Stacking Sequence on Flexural and Dynamic Mechanical Properties of Hybrid Sisal/Glass Polyester Composite. Am. J. Polym. Sci. Eng. 2017, 5, 53–6253. [Google Scholar]

- Negawo, T.A.; Polat, Y.; Buyuknalcaci, F.N.; Kilic, A.; Saba, N.; Jawaid, M. Mechanical, morphological, structural and dynamic mechanical properties of alkali treated Ensete stem fibers reinforced unsaturated polyester composites. Compos. Struct. 2019, 207, 589–597. [Google Scholar] [CrossRef]

- Arulmurugan, M.; Prabu, K.; Rajamurugan, G.; Selvakumar, A.S. Impact of BaSO4 filler on woven Aloevera/Hemp hybrid composite: Dynamic mechanical analysis. Mater. Res. Express 2019, 6, 45309. [Google Scholar] [CrossRef]

- Atiqah, A.; Ansari, M.N.M.; Jawaid, M.; Hamdan, A. Viscoelastic Properties of Kenaf/Basalt Reinforced Epoxy Hybrid Composites through Vacuum Infusion Methods. Test Eng. Manag. 2020, 83, 1226–1231. [Google Scholar]

- Zhang, D.; He, M.; He, W.; Zhou, Y.; Qin, S.; Yu, J. Influence of Thermo-Oxidative Ageing on the Thermal and Dynamical Mechanical Properties of Long Glass Fibre-Reinforced Poly(Butylene Terephthalate) Composites Filled with DOPO. Materials 2017, 10, 500. [Google Scholar] [CrossRef] [Green Version]

- Norizan, M.N.; Abdan, K.; Ilyas, R.A.; Zin, M.; Muthukumar, C.; Rafiqah, S.; Aisyah, H. Effect of fiber orientation and fiber loading on the mechanical and thermal properties of sugar palm yarn fiber reinforced unsaturated polyester resin composites. Polim. Warsaw 2019, 64, 34–43. [Google Scholar] [CrossRef]

- Amuthakkannan, P.; Manikandan, V. Free vibration and dynamic mechanical properties of basalt fiber reinforced polymer composites. Indian J. Eng. Mater. Sci. 2018, 25, 265–270. [Google Scholar]

- Das, S.C.; Paul, D.; Grammatikos, S.A.; Siddiquee, M.A.B.; Papatzani, S.; Koralli, P.; Islam, J.M.M.; Khan, M.A.; Shauddin, S.M.; Khan, R.A.; et al. Effect of stacking sequence on the performance of hybrid natural/synthetic fiber reinforced polymer composite laminates. Compos. Struct. 2021, 276, 114525. [Google Scholar] [CrossRef]

- James, J. Chapter 7—Thermomechanical analysis and its applications. In Thermal and Rheological Measurement Techniques for Nanomaterials Characterization; Micro and Nano Technologies; Thomas, S., Thomas, R., Zachariah, A.K., Mishra, R.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 159–171. ISBN 9780323461399. [Google Scholar]

- Espinach, F.X.; Boufi, S.; Delgado-Aguilar, M.; Julián, F.; Mutjé, P.; Méndez, J.A. Composites from poly(lactic acid) and bleached chemical fibres: Thermal properties. Compos. Part B Eng. 2018, 134, 169–176. [Google Scholar] [CrossRef]

- Vinod, A.; Yashas Gowda, T.G.; Vijay, R.; Sanjay, M.R.; Gupta, M.K.; Jamil, M.; Kushvaha, V.; Siengchin, S. Novel Muntingia Calabura bark fiber reinforced green-epoxy composite: A sustainable and green material for cleaner production. J. Clean. Prod. 2021, 294, 126337. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Paridah, M.T.; Saba, N.; Nasir, M.; Shahroze, R.M. Dynamic and thermo-mechanical properties of hybridized kenaf/PALF reinforced phenolic composites. Polym. Compos. 2019, 40, 3814–3822. [Google Scholar] [CrossRef]

| No. | Resin | Hybrid | Fabrication Method | Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Strength (kJ/m2) | Remark | Ref. |

|---|---|---|---|---|---|---|---|---|

| 1 | PP | Filler | Extrusion | 31 | - | - | Increasing basalt content led to a decrease in tensile strength. | [20] |

| 2 | Epoxy | Filler | Hand layup | 273 | 497 | 426 | The addition of a large amount of basalt reduced the impact strength. | [21] |

| 3 | Polyester | Laminate | Hand layup | 78 | 175 | - | Mechanical properties of BGRP composite are lower than BCRP laminates. | [22] |

| 4 | Epoxy | Laminate | Vacuum begging | 448 | - | - | The tensile strength of BGRP composite was lower than GFRP laminates. | [24] |

| 5 | Polyester | Laminate | Hand layup | 293 | 302 | 192 | The stacking sequence of BGRP improved mechanical properties. | [23] |

| 6 | Epoxy | Laminate | Vacuum begging | 225 | 195 | 212 | Increased glass fiber increased the tensile strength (BGRP < GFRP composite). | [25] |

| 7 | Epoxy | Laminate | Vacuum begging | - | - | 4 | Hybrid BGRP had a lower impact strength than the BFRP composite. | [26] |

| 8 | Polyester | Laminate | Hand layup | 270 | - | 946 | Hybrid BGRP offered the highest value of mechanical properties compared to GFRP and BFRP laminates. | [28] |

| 9 | Polyester | Laminate | Hand layup | 246 | - | 204 | Hybrid BGRP laminate had the highest tensile strength. | [29] |

| Chemical Components | Composition (wt%) | |

|---|---|---|

| Basalt | E-Glass | |

| SiO2 (silica) | 57.5 | 55 |

| Al2O3 (alumina) | 16.9 | 15 |

| Fe2O3 (ferric oxide) | 9.5 | 0.3 |

| MgO | 3.7 | 3 |

| Na2O | 2.5 | 0.8 |

| TiO2 | 1.1 | - |

| K2O | 0.8 | 0.2 |

| B2O3 | - | 7 |

| F | - | 0.3 |

| Properties | Basalt | E-Glass |

|---|---|---|

| Density | 2.67 | 2.55–2.58 |

| Modulus (GPa) | 85–89 | 78–80 |

| Strength (MPa) | 2900–3100 | 2000–2500 |

| Moisture (%) | 0.008 | 0.1 |

| No. | Composites | Sample Designation | Composition (wt%) | ||

|---|---|---|---|---|---|

| Matrix | Basalt | Glass | |||

| 1 | Five layers BF | BF | 70 | 30 | 0 |

| 2 | Four layers BF + two layers woven GF | B22.5/G7.5 | 70 | 22.5 | 7.5 |

| 3 | Three layers woven GF + Three layers of BF | B15/G15 | 70 | 15 | 15 |

| 4 | Two layers woven BF + three layers of GF | B7.5/G22.5 | 70 | 7.5 | 22.5 |

| 5 | Five layers of woven GF | GF | 70 | 0 | 30 |

| 6 | UPE resin | UP | 100 | 0 | 0 |

| Weight Percentage (wt%) | |

| Glass Fiber (wt%) | = 15 wt% |

| Basalt Fiber (wt%) | = 15 wt% |

| Unsaturated Polyester Resin (wt%) | = 70 wt% |

| MEKP (wt%) to UP resin | = 0.5% to UP resin |

| Density | |

| Glass Fiber | = 2.2 kg/L |

| Basalt Fiber | = 2.65 kg/L |

| Unsaturated Polyester Resin | = 1.87 kg/L |

| MEKP | = 1.152 kg/L |

| Volume | |

| Steel Mould | = 300 × 300 × 5 mm3 = 0.45 L |

| Glass Fiber | = 15% × 0.45 L = 0.0675 L |

| Basalt Fiber | = 15% × 0.45 L = 0.0675 L |

| Unsaturated Polyester Resin | = 70% × 0.45 L = 0.315 L |

| MEKP | = 0.5% × 0.315 L = 0.001575 L |

| Weight | |

| Glass Fiber | = 0.00675 L × 2.2 kg/L = 0.01485 kg = 148.5 g |

| Basalt Fiber | = 0.00675 L × 2.65 kg/L = 0.01788 kg = 178.8 g |

| Unsaturated Polyester Resin | = 0.315 L × 1.87 kg/L = 0.589 kg = 589 g |

| MEKP | = 0.001575 L × 1.152 kg/L = 0.0018144 kg = 1.8144 g |

| Sample ID | Peak Height of Tan δ | Temperature (°C) | |

|---|---|---|---|

| Tg from Tan δ | Tg from Loss Modulus | ||

| BF | 0.49 | 81.37 | 71.48 |

| B22.5/G7.5 | 0.52 | 84.47 | 70.80 |

| B15/G15 | 0.46 | 83.36 | 69.85 |

| B7.5/G22.5 | 0.48 | 80.24 | 69.70 |

| GF | 0.44 | 76.98 | 66.17 |

| UP | 0.71 | 80.24 | 55.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haris, N.I.N.; Ilyas, R.A.; Hassan, M.Z.; Sapuan, S.M.; Afdzaluddin, A.; Jamaludin, K.R.; Zaki, S.A.; Ramlie, F. Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. Polymers 2021, 13, 3343. https://doi.org/10.3390/polym13193343

Haris NIN, Ilyas RA, Hassan MZ, Sapuan SM, Afdzaluddin A, Jamaludin KR, Zaki SA, Ramlie F. Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. Polymers. 2021; 13(19):3343. https://doi.org/10.3390/polym13193343

Chicago/Turabian StyleHaris, Nur Izzah Nabilah, R. A. Ilyas, Mohamad Zaki Hassan, S. M. Sapuan, Atiqah Afdzaluddin, Khairur Rijal Jamaludin, Sheikh Ahmad Zaki, and Faizir Ramlie. 2021. "Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites" Polymers 13, no. 19: 3343. https://doi.org/10.3390/polym13193343