Effect of Manufacturing on the Transverse Response of Polymer Matrix Composites

Abstract

:1. Introduction

- (a)

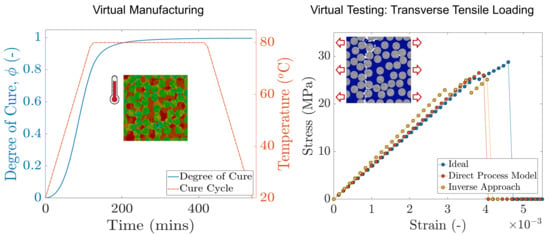

- Direct process modeling: FE-based approach that predicts the instantaneous in situ matrix property evolution and residual stress generation as a function of the processing conditions and the degree of cure . Its implementation is detailed in Section 2.2.1.

- (b)

- Inverse approach: experiment-based approach that extracts the process-induced, nonlinear in situ matrix properties from the uniaxial tensile response of a ±45 laminate. The detailed procedure is reported by [42], its summary is presented in Section 2.2.2.

2. Virtual Analysis Procedure

2.1. Microscale Computational Model

2.2. Virtual Manufacturing

2.2.1. Direct Process Modeling

2.2.2. Inverse Approach

2.3. Virtual Mechanical Loading

3. Results and Discussion

3.1. 100-Fiber RVE

3.2. Size Effect Study

3.3. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Galos, J. Thin-ply composite laminates: A review. Compos. Struct. 2020, 236, 111920. [Google Scholar] [CrossRef]

- Lu, Z.; Li, J.; Xie, J.; Huang, P.; Xue, L. Durability of flexurally strengthened RC beams with prestressed CFRP sheet under wet–dry cycling in a chloride-containing environment. Compos. Struct. 2021, 255, 112869. [Google Scholar] [CrossRef]

- Li, C.; Xian, G.; Li, H. Combined effects of temperature, hydraulic pressure and salty concentration on the water uptake and mechanical properties of a carbon/glass fibers hybrid rod in salty solutions. Polym. Test. 2019, 76, 19–32. [Google Scholar] [CrossRef]

- Li, C.; Xian, G.; Li, H. Tension-tension fatigue performance of a large-diameter pultruded carbon/glass hybrid rod. Int. J. Fatigue 2019, 120, 141–149. [Google Scholar] [CrossRef]

- Baran, I.; Cinar, K.; Ersoy, N.; Akkerman, R.; Hattel, J.H. A Review on the Mechanical Modeling of Composite Manufacturing Processes. Arch. Comput. Methods Eng. 2017, 24, 365–395. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shah, S.; Plaka, E.; Schey, M.; Hu, J.; Liu, F.; Beke, T.; Stapleton, S.E.; Maiaru, M. Quantification of Thermoset Composite Microstructures for Process Modeling. In Proceedings of the AIAA Scitech 2021 Forum, AIAA SciTech Forum, San Diego, CA, USA, 3–7 January 2021. [Google Scholar]

- Shah, S.; Schey, M.; Hu, J.; Liu, F.; Beke, T.; Stapleton, S.E.; Maiaru, M. Microstructural Quantification and Virtual Reconstruction of Polymer Matrix Composites. In Proceedings of the AIAA Scitech 2020 Forum, AIAA SciTech Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Shah, S.; Plaka, E.; Schey, M.; Hu, J.; Liu, F.; Beke, T.; Stapleton, S.E.; Maiaru, M. In-Situ Characterization of Polymer Matrix Composites and Progressive Damage Analysis of Virtually Reconstructed Microstructures. In Proceedings of the American Society for Composites—Thirty-Fifth Technical Conference, Online, 14–17 September 2020. [Google Scholar]

- Maragoni, L.; Carraro, P.A.; Quaresimin, M. Development, validation and analysis of an efficient micro-scale representative volume element for unidirectional composites. Compos. Part Appl. Sci. Manuf. 2018, 110, 268–283. [Google Scholar] [CrossRef]

- Ghayoor, H.; Hoa, S.V.; Marsden, C.C. A micromechanical study of stress concentrations in composites. Compos. Part B Eng. 2018, 132, 115–124. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Cao, D.; Pavier, M.; Zhong, Y.; Zu, L.; Liu, L.; Li, S. Investigation of non-uniform gelation effects on residual stresses of thick laminates based on tailed FBG sensor. Compos. Struct. 2018, 202, 1361–1372. [Google Scholar] [CrossRef] [Green Version]

- Sorrentino, L.; Esposito, L.; Bellini, C. A new methodology to evaluate the influence of curing overheating on the mechanical properties of thick FRP laminates. Compos. Part Eng. 2017, 109, 187–196. [Google Scholar] [CrossRef]

- Rabearison, N.; Jochum, C.; Grandidier, J.C. A FEM coupling model for properties prediction during the curing of an epoxy matrix. Comput. Mater. Sci. 2009, 45, 715–724. [Google Scholar] [CrossRef]

- Parlevliet, P.P.; Bersee, H.E.N.; Beukers, A. Residual stresses in thermoplastic composites—A study of the literature. Part III: Effects of thermal residual stresses. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1581–1596. [Google Scholar] [CrossRef]

- Chekanov, Y.; Korotkov, V.; Rozenberg, B.; Dhzavadyan, E.; Bogdanova, L. Cure shrinkage defects in epoxy resins. Polymer 1995, 36, 2013–2017. [Google Scholar] [CrossRef]

- Shah, S.; Maiaru, M. Microscale Analysis of Virtually Cured Polymer Matrix Composites Accounting for Uncertainty in Matrix Properties During Manufacturing. In Proceedings of the American Society for Composites—Thirty-Third Technical Conference, Seattle, WA, USA, 24–27 September 2018. [Google Scholar]

- Maiarù, M.; D’Mello, R.J.; Waas, A.M. Characterization of intralaminar strengths of virtually cured polymer matrix composites. Compos. Part B Eng. 2018, 149, 285–295. [Google Scholar] [CrossRef]

- Maiaru, M. Effect of uncertainty in matrix fracture properties on the transverse strength of fiber reinforced polymer matrix composites. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- D’Mello, R.J.; Maiarù, M.; Waas, A.M. Virtual manufacturing of composite aerostructures. Aeronaut. J. 2016, 120, 61–81. [Google Scholar] [CrossRef] [Green Version]

- D’Mello, R.J.; Maiarù, M.; Waas, A.M. Effect of the curing process on the transverse tensile strength of fiber-reinforced polymer matrix lamina using micromechanics computations. Integr. Mater. Manuf. Innov. 2015, 4, 119–136. [Google Scholar] [CrossRef] [Green Version]

- Mesogitis, T.S.; Skordos, A.A.; Long, A.C. Uncertainty in the manufacturing of fibrous thermosetting composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 57, 67–75. [Google Scholar] [CrossRef] [Green Version]

- D’Mello, R.J.; Waas, A.M. Virtual curing of textile polymer matrix composites. Compos. Struct. 2017, 178, 455–466. [Google Scholar] [CrossRef]

- Danzi, F.; Fanteria, D.; Panettieri, E.; Mancino, M.C. A numerical micro-mechanical study on damage induced by the curing process in carbon/epoxy unidirectional material. Compos. Struct. 2019, 210, 755–766. [Google Scholar] [CrossRef]

- Hui, X.; Xu, Y.; Wang, J.; Zhang, W. Microscale viscoplastic analysis of unidirectional CFRP composites under the influence of curing process. Compos. Struct. 2021, 266, 113786. [Google Scholar] [CrossRef]

- Hui, X.; Xu, Y.; Zhang, W. An integrated modeling of the curing process and transverse tensile damage of unidirectional CFRP composites. Compos. Struct. 2021, 263, 113681. [Google Scholar] [CrossRef]

- He, C.; Ge, J.; Qi, D.; Gao, J.; Chen, Y.; Liang, J.; Fang, D. A multiscale elasto-plastic damage model for the nonlinear behavior of 3D braided composites. Compos. Sci. Technol. 2019, 171, 21–33. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Ma, J.; Liu, B. Effects of inter-fiber spacing and thermal residual stress on transverse failure of fiber-reinforced polymer–matrix composites. Comput. Mater. Sci. 2013, 68, 255–262. [Google Scholar] [CrossRef]

- Lorca, J.L.; González, C.; Molina-Aldareguía, J.M.; Segurado, J.; Seltzer, R.; Sket, F.; Rodríguez, M.; Sádaba, S.; Muñoz, R.; Canal, L.P. Multiscale Modeling of Composite Materials: A Roadmap Towards Virtual Testing. Adv. Mater. 2011, 23, 5130–5147. [Google Scholar] [CrossRef]

- Zhao, L.G.; Warrior, N.A.; Long, A.C. A micromechanical study of residual stress and its effect on transverse failure in polymer–matrix composites. Int. J. Solids Struct. 2006, 43, 5449–5467. [Google Scholar] [CrossRef] [Green Version]

- Kamal, M.R.; Sourour, S. Kinetics and thermal characterization of thermoset cure. Polym. Eng. Sci. 1973, 13, 59–64. [Google Scholar] [CrossRef]

- Plepys, A.; Vratsanos, M.S.; Farris, R.J. Determination of residual stresses using incremental linear elasticity. Compos. Struct. 1994, 27, 51–56. [Google Scholar] [CrossRef]

- Plepys, A.R.; Farris, R.J. Evolution of residual stresses in three-dimensionally constrained epoxy resins. Polymer 1990, 31, 1932–1936. [Google Scholar] [CrossRef]

- Bogetti, T.A.; Gillespie, J.J.W. Process-Induced Stress and Deformation in Thick-Section Thermoset Composite Laminates. J. Compos. Mater. 2016. [Google Scholar] [CrossRef]

- Zhang, J.T.; Zhang, M.; Li, S.X.; Pavier, M.J.; Smith, D.J. Residual stresses created during curing of a polymer matrix composite using a viscoelastic model. Compos. Sci. Technol. 2016, 130, 20–27. [Google Scholar] [CrossRef] [Green Version]

- Ding, A.; Li, S.; Wang, J.; Zu, L. A three-dimensional thermo-viscoelastic analysis of process-induced residual stress in composite laminates. Compos. Struct. 2015, 129, 60–69. [Google Scholar] [CrossRef]

- Adolf, D.B.; Chambers, R.S. A thermodynamically consistent, nonlinear viscoelastic approach for modeling thermosets during cure. J. Rheol. 2007, 51, 23–50. [Google Scholar] [CrossRef]

- Lange, J.; Toll, S.; Månson, J.-A.E.; Hult, A. Residual stress build-up in thermoset films cured below their ultimate glass transition temperature. Polymer 1997, 38, 809–815. [Google Scholar] [CrossRef]

- White, S.; Hahn, H. Process Modeling of Composite Materials: Residual Stress Development during Cure. Part I. Model Formulation. J. Compos. Mater. 1992, 26, 2402–2422. [Google Scholar] [CrossRef]

- Heinrich, C.; Aldridge, M.; Wineman, A.S.; Kieffer, J.; Waas, A.M.; Shahwan, K.W. The role of curing stresses in subsequent response, damage and failure of textile polymer composites. J. Mech. Phys. Solids 2013, 61, 1241–1264. [Google Scholar] [CrossRef]

- Heinrich, C.; Aldridge, M.; Wineman, A.S.; Kieffer, J.; Waas, A.M.; Shahwan, K.W. Generation of heat and stress during the cure of polymers used in fiber composites. Int. J. Eng. Sci. 2012, 53, 85–111. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, D. A micromechanics-based processing model for predicting residual stress in fiber-reinforced polymer matrix composites. Compos. Struct. 2018, 204, 153–166. [Google Scholar] [CrossRef]

- Ng, W.H.; Salvi, A.G.; Waas, A.M. Characterization of the in-situ non-linear shear response of laminated fiber-reinforced composites. Compos. Sci. Technol. 2010, 70, 1126–1134. [Google Scholar] [CrossRef]

- Song, S.; Waas, A.M.; Shahwan, K.W.; Faruque, O.; Xiao, X.S. Compression response, strength and post-peak response of an axial fiber reinforced tow. Int. J. Mech. Sci. 2009, 51, 491–499. [Google Scholar] [CrossRef]

- Yerramalli, C.S.; Waas, A.M. In Situ Matrix Shear Response Using Torsional Test Data of Fiber Reinforced Unidirectional Polymer Composites. J. Eng. Mater. Technol. 2002, 124, 152–159. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Xin, L.-M. In situ strengths of matrix in a composite. Acta Mech. Sin. 2017, 33, 120–131. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Liu, L. Assessment of composite failure and ultimate strength without experiment on composite. Acta Mech. Sin. 2014, 30, 569–588. [Google Scholar] [CrossRef]

- Liu, L.; Huang, Z.-M. Stress concentration factor in matrix of a composite reinforced with transversely isotropic fibers. J. Compos. Mater. 2014, 48, 81–98. [Google Scholar] [CrossRef]

- Sanei, S.H.R.; Barsotti, E.J.; Leonhardt, D.; Fertig, R.S. Characterization, synthetic generation, and statistical equivalence of composite microstructures. J. Compos. Mater. 2017, 51, 1817–1829. [Google Scholar] [CrossRef]

- Romanov, V.; Lomov, S.V.; Swolfs, Y.; Orlova, S.; Gorbatikh, L.; Verpoest, I. Statistical analysis of real and simulated fibre arrangements in unidirectional composites. Compos. Sci. Technol. 2013, 87, 126–134. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Zhang, J.; Liang, W.; Zhou, L. Automatic generation of random distribution of fibers in long-fiber-reinforced composites and mesomechanical simulation. Mater. Des. 2011, 32, 885–891. [Google Scholar] [CrossRef]

- Vaughan, T.J.; McCarthy, C.T. A combined experimental—Numerical approach for generating statistically equivalent fibre distributions for high strength laminated composite materials. Compos. Sci. Technol. 2010, 70, 291–297. [Google Scholar] [CrossRef] [Green Version]

- Melro, A.R.; Camanho, P.P.; Pinho, S.T. Generation of random distribution of fibres in long-fibre reinforced composites. Compos. Sci. Technol. 2008, 68, 2092–2102. [Google Scholar] [CrossRef]

- Trias, D.; Costa, J.; Turon, A.; Hurtado, J.E. Determination of the critical size of a statistical representative volume element (SRVE) for carbon reinforced polymers. Acta Mater. 2006, 54, 3471–3484. [Google Scholar] [CrossRef]

- Wongsto, A.; Li, S. Micromechanical FE analysis of UD fibre-reinforced composites with fibres distributed at random over the transverse cross-section. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1246–1266. [Google Scholar] [CrossRef]

- Buryachenko, V.A.; Pagano, N.J.; Kim, R.Y.; Spowart, J.E. Quantitative description and numerical simulation of random microstructures of composites and their effective elastic moduli. Int. J. Solids Struct. 2003, 40, 47–72. [Google Scholar] [CrossRef]

- Byström, J. Influence of the inclusions distribution on the effective properties of heterogeneous media. Compos. Part B Eng. 2003, 34, 587–592. [Google Scholar] [CrossRef]

- Zeman, J.; Šejnoha, M. Numerical evaluation of effective elastic properties of graphite fiber tow impregnated by polymer matrix. J. Mech. Phys. Solids 2001, 49, 69–90. [Google Scholar] [CrossRef]

- Gusev, A.A.; Hine, P.J.; Ward, I.M. Fiber packing and elastic properties of a transversely random unidirectional glass/epoxy composite. Compos. Sci. Technol. 2000, 60, 535–541. [Google Scholar] [CrossRef]

- Yang, S.; Tewari, A.; Gokhale, A.M. Modeling of Non-Uniform Spatial Arrangements of Fibers in a Ceramic Matrix Composite. Acta Mater. 1997, 45, 3059–3069. [Google Scholar] [CrossRef]

- Carey, E.; Maiaru, M. Randomization algorithm for the micromechanical modeling of fiber-reinforced Polymer Matrix Composites. In Proceedings of the American Society for Composites—Technical Conference, West Lafayette, IN, USA, 23–25 October 2017. [Google Scholar]

- Simulia Corp Dassault Systemes. Abaqus 6.16 Documentation; Simulia Corp.: Providence, RI, USA, 2016. [Google Scholar]

- Bažant, Z.P.; Oh, B.H. Crack band theory for fracture of concrete. MatéRiaux Constr. 1983, 16, 155–177. [Google Scholar] [CrossRef] [Green Version]

- Pineda, E.J.; Bednarcyk, B.A.; Waas, A.M.; Arnold, S.M. Progressive failure of a unidirectional fiber-reinforced composite using the method of cells: Discretization objective computational results. Int. J. Solids Struct. 2013, 50, 1203–1216. [Google Scholar] [CrossRef] [Green Version]

- Hui, X.; Xu, Y.; Zhang, W. Multiscale model of micro curing residual stress evolution in carbon fiber-reinforced thermoset polymer composites. Front. Mech. Eng. 2020, 15, 475–483. [Google Scholar] [CrossRef]

- Sanei, S.H.R.; Fertig, R.S. Uncorrelated volume element for stochastic modeling of microstructures based on local fiber volume fraction variation. Compos. Sci. Technol. 2015, 117, 191–198. [Google Scholar] [CrossRef]

- Liu, K.C.; Ghoshal, A. Validity of random microstructures simulation in fiber-reinforced composite materials. Compos. Part B Eng. 2014, 57, 56–70. [Google Scholar] [CrossRef]

- Melro, A.R.; Camanho, P.P.; Pinho, S.T. Influence of geometrical parameters on the elastic response of unidirectional composite materials. Compos. Struct. 2012, 94, 3223–3231. [Google Scholar] [CrossRef]

- Swaminathan, S.; Ghosh, S.; Pagano, N.J. Statistically Equivalent Representative Volume Elements for Unidirectional Composite Microstructures: Part I—Without Damage. J. Compos. Mater. 2006, 40, 583–604. [Google Scholar] [CrossRef]

- Shan, Z.; Gokhale, A.M. Representative volume element for non-uniform micro-structure. Comput. Mater. Sci. 2002, 24, 361–379. [Google Scholar] [CrossRef]

- Sabuncuoglu, B.; Orlova, S.; Gorbatikh, L.; Lomov, S.V.; Verpoest, I. Micro-scale finite element analysis of stress concentrations in steel fiber composites under transverse loading. J. Compos. Mater. 2015, 49, 1057–1069. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Ran, Z.; Liu, Y. A new method for generating random fibre distributions for fibre reinforced composites. Compos. Sci. Technol. 2013, 76, 14–20. [Google Scholar] [CrossRef]

- Naya, F.; González, C.; Lopes, C.S.; der Veen, S.V.; Pons, F. Computational micromechanics of the transverse and shear behavior of unidirectional fiber reinforced polymers including environmental effects. Compos. Part A Appl. Sci. Manuf. 2017, 92, 146–157. [Google Scholar] [CrossRef]

- González, C.; Lorca, J.L. Mechanical behavior of unidirectional fiber-reinforced polymers under transverse compression: Microscopic mechanisms and modeling. Compos. Sci. Technol. 2007, 67, 2795–2806. [Google Scholar] [CrossRef]

- Schey, M.J.; Beke, T.; Appel, L.; Zabler, S.; Shah, S.; Hu, J.; Liu, F.; Maiaru, M.; Stapleton, S. Identification and Quantification of 3D Fiber Clusters in Fiber-Reinforced Composite Materials. JOM 2021, 73, 2129–2142. [Google Scholar] [CrossRef]

| Property | Value | Unit | |

|---|---|---|---|

| Density | 1780 | [kg/m3] | |

| Axial Modulus | 276,000 | [MPa] | |

| Transverse Modulus | 19,500 | [MPa] | |

| In-plane Poisson’s ratio | 0.28 | [-] | |

| Out-of-plane Poisson’s ratio | 0.25 | [-] | |

| In-plane Shear Modulus | 70,000 | [MPa] | |

| Out-of-plane Shear Modulus | 7800 | [MPa] | |

| Axial Coefficient of Thermal Expansion | −0.54 × 10 | [K−1] | |

| Transverse Coefficient of Thermal Expansion | 10.08 × 10 | [K−1] | |

| Thermal Conductivity | 5.4 | [W/m-K] | |

| Specific Heat | 879 | [J/kg-K] | |

| Property | Value | Unit | |

|---|---|---|---|

| Density | 1200 | [kg/m3] | |

| Direct Process Modeling | |||

| Coefficient of Thermal Expansion | 61 × 10 | [K−1] | |

| Chemical Shrinkage Coefficient | 0.111 | [-] | |

| Thermal Conductivity | 0.245 | [W/m-K] | |

| Specific Heat | 1600 | [J/kg-K] | |

| Elastic Modulus | 2482 | [MPa] | |

| Poisson’s ratio | 0.37 | [-] | |

| Critical Strength | 64.1 | [MPa] | |

| Fracture Toughness | 0.001 | [J/m2] | |

| Inverse Approach | |||

| Elastic Modulus | 2956 | [MPa] | |

| Poisson’s ratio | 0.37 | [-] | |

| Hydrostatic Cutoff Stress | 43 | [MPa] | |

| Property | Value | Unit | |

|---|---|---|---|

| Exponents | m | 0.4 | [-] |

| n | 1.5 | [-] | |

| Rate Constants | 3.6 × 10 | [s−1] | |

| 0.01245 | [s−1] | ||

| Activation Energy | 85.3 | [kJ/mol] | |

| 11.1 | [kJ/mol] | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, S.P.; Maiarù, M. Effect of Manufacturing on the Transverse Response of Polymer Matrix Composites. Polymers 2021, 13, 2491. https://doi.org/10.3390/polym13152491

Shah SP, Maiarù M. Effect of Manufacturing on the Transverse Response of Polymer Matrix Composites. Polymers. 2021; 13(15):2491. https://doi.org/10.3390/polym13152491

Chicago/Turabian StyleShah, Sagar P., and Marianna Maiarù. 2021. "Effect of Manufacturing on the Transverse Response of Polymer Matrix Composites" Polymers 13, no. 15: 2491. https://doi.org/10.3390/polym13152491