Effect of Iignocellulosic Nanoparticles Extracted from Yerba Mate (Ilex paraguariensis) on the Structural, Thermal, Optical and Barrier Properties of Mechanically Recycled Poly(lactic acid)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Nanoparticle Extraction from Yerba Mate Residues

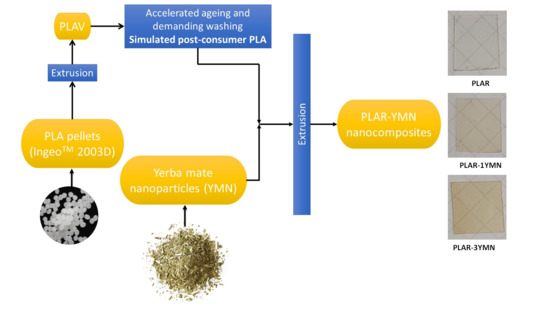

2.3. Preparation of the Samples

2.4. Characterization Techniques

3. Results and Discussion

3.1. Yerba Mate Nanoparticles’ Characterization

3.2. Structure and Morphology of the PLA-YMN Bionanocomposites

3.3. Properties of the PLA-YMN Bionanocomposites

3.3.1. Effect of the Addition of YMNs on the Intrinsic Viscosity

3.3.2. Thermal Properties

3.3.3. Optical Properties

3.3.4. Barrier Properties

3.3.5. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Castro-Aguirre, E.; Iniguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—mass production, processing, industrial applications, and end of life. Adv. Drug Deliver Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliver Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beltrán, F.R.; Gaspar, G.; Chomachayi, M.D.; Jalali-Arani, A.; Lozano-Pérez, A.A.; Cenis, J.L.; María, U.; Pérez, E.; Urreaga, J.M.M. Influence of addition of organic fillers on the properties of mechanically recycled PLA. Environ. Sci. Pollut. Res. 2020, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Chinthapalli, R.; Skoczinski, P.; Carus, M.; Baltus, W.; de Guzman, D.; Käb, H.; Raschka, A.; Ravenstijn, J. Biobased building blocks and polymers—global capacities, production and trends, 2018–2023. Ind. Biotechnol. 2019, 15, 237–241. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the use of PLA-PHB blends for sustainable food packaging applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef]

- Kale, G.; Auras, R.; Singh, S.P. Comparison of the degradability of poly (lactide) packages in composting and ambient exposure conditions. Packag. Technol. Sci. 2007, 20, 49–70. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the future? The impact of biodegradable polymers on the environment and on society. Angew. Chem.–Int. Edit. 2019, 58, 50–62. [Google Scholar] [CrossRef] [Green Version]

- Niaounakis, M. Recycling of biopolymers–the patent perspective. Eur. Polym. J. 2019, 114, 464–475. [Google Scholar] [CrossRef]

- Bourguignon, D. Plastics in a Circular Economy. European Parliamentary Research Service, 2018. Available online: http://www.europarl.europa.eu/RegData/etudes/ATAG/2018/625163/EPRS_ATA(2018)625163_EN.pdf (accessed on 20 March 2020).

- European Commission. A European Strategy for Plastics in a Circular Economy. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Brussels 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52018DC0028&from=EN (accessed on 20 March 2020).

- European Commission. Directive (eu) 2019/904 of the european parliament and of the council of 5 june 2019 on the reduction of the impact of certain plastic products on the environment. Off. J. Eur. Union 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019L0904&from=EN (accessed on 20 March 2020).

- Payne, J.; McKeown, P.; Jones, M.D. A circular economy approach to plastic waste. Polym. Degrad. Stabil. 2019, 165, 170–181. [Google Scholar] [CrossRef]

- Beltrán, F.; Lorenzo, V.; Acosta, J.; de la Orden, M.; Urreaga, J.M. Effect of simulated mechanical recycling processes on the structure and properties of poly(lactic acid). J. Environ. Manag. 2018, 216, 25–31. [Google Scholar] [CrossRef] [Green Version]

- Botta, L.; Scaffaro, R.; Sutera, F.; Mistretta, M.C. Reprocessing of PLA/graphene nanoplatelets nanocomposites. Polymers 2018, 10, 18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Scaffaro, R.; Sutera, F.; Mistretta, M.; Botta, L.; La Mantia, F. Structure-properties relationships in melt reprocessed PLA/hydrotalcites nanocomposites. Express. Polym. Lett. 2017, 11, 555. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Climent-Pascual, E.; de la Orden, M.U.; Martínez Urreaga, J. Effect of solid-state polymerization on the structure and properties of mechanically recycled poly(lactic acid). Polym. Degrad. Stabil. 2020, 171, 109045. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Infante, C.; de la Orden, M.U.; Martínez Urreaga, J. Mechanical recycling of poly(lactic acid): Evaluation of a chain extender and a peroxide as additives for upgrading the recycled plastic. J. Clean. Prod. 2019, 219, 46–56. [Google Scholar] [CrossRef]

- Tuna, B.; Ozkoc, G. Effects of diisocyanate and polymeric epoxidized chain extenders on the properties of recycled poly(lactic acid). J. Polym. Environ. 2017, 25, 983–993. [Google Scholar] [CrossRef]

- Beltrán, F.R.; de la Orden, M.U.; Martínez Urreaga, J. Amino-modified halloysite nanotubes to reduce polymer degradation and improve the performance of mechanically recycled poly(lactic acid). J. Polym. Environ. 2018, 26, 4046–4055. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, F.; Liu, X.; Tang, M.; Zeng, Z.; Liang, J.; Guan, X.; Wang, J.; Mu, X. Surface modified palygorskite nanofibers and their applications as reinforcement phase in cis-polybutadiene rubber nanocomposites. Appl. Clay Sci. 2016, 132–133, 175–181. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J.M. Multifunctional PLA-PHB/cellulose nanocrystal films: Processing, structural and thermal properties. Carbohydr. Polym. 2014, 107, 16–24. [Google Scholar] [CrossRef] [PubMed]

- Arrieta, M.P.; Garrido, L.; Faba, S.; Guarda, A.; Galotto, M.J.; Dicastillo, C.L.d. Cucumis metuliferus fruit extract loaded acetate cellulose coatings for antioxidant active packaging. Polymers 2020, 12, 1248. [Google Scholar] [CrossRef] [PubMed]

- Berglund, L.; Noël, M.; Aitomäki, Y.; Öman, T.; Oksman, K. Production potential of cellulose nanofibers from industrial residues: Efficiency and nanofiber characteristics. Ind. Crop. Prod. 2016, 92, 84–92. [Google Scholar] [CrossRef]

- Fajardo, J.; Valarezo, L.; López, L.; Sarmiento, A. Experiencies in obtaining polymeric composites reinforced with natural fiber from ecuador. Ingenius 2013, 28–35. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; López, J.; Kenny, J.M. Bionanocomposite films based on plasticized PLA–PHB/cellulose nanocrystal blends. Carbohydr. Polym. 2015, 121, 265–275. [Google Scholar] [CrossRef] [Green Version]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crop. Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Dominici, F.; Kenny, J.M.; Puglia, D. Effect of processing conditions and lignin content on thermal, mechanical and degradative behavior of lignin nanoparticles/polylactic(acid) bionanocomposites prepared by melt extrusion and solvent casting. Eur. Polym. J. 2015, 71, 126–139. [Google Scholar] [CrossRef]

- Fortunati, E.; Luzi, F.; Puglia, D.; Petrucci, R.; Kenny, J.M.; Torre, L. Processing of PLA nanocomposites with cellulose nanocrystals extracted from Posidonia oceanica waste: Innovative reuse of coastal plant. Ind. Crop. Prod. 2015, 67, 439–447. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Dominici, F.; Giovanale, G.; Mazzaglia, A.; Balestra, G.M.; Kenny, J.M.; Puglia, D. Synergic effect of cellulose and lignin nanostructures in PLA based systems for food antibacterial packaging. Eur. Polym. J. 2016, 79, 1–12. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Peponi, L.; López, D.; Fernández-García, M. Recovery of yerba mate (Ilex paraguariensis) residue for the development of PLA-based bionanocomposite films. Ind. Crop. Prod. 2018, 111, 317–328. [Google Scholar] [CrossRef]

- Deladino, L.; Teixeira, A.S.; Navarro, A.S.; Alvarez, I.; Molina-García, A.D.; Martino, M. Corn starch systems as carriers for yerba mate (Ilex paraguariensis) antioxidants. Food Bioprod. Process. 2015, 94, 463–472. [Google Scholar] [CrossRef]

- Dahlem, M.A.; Borsoi, C.; Hansen, B.; Catto, A.L. Evaluation of different methods for extraction of nanocellulose from yerba mate residues. Carbohydr. Polym. 2019, 218, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Pagliosa, C.M.; de Simas, K.N.; Amboni, R.D.; Murakami, A.N.N.; Petkowicz, C.L.; de Deus Medeiros, J.; Rodrigues, A.C.; Amante, E.R. Characterization of the bark from residues from mate tree harvesting (Ilex paraguariensis st. Hil.). Ind. Crop. Prod. 2010, 32, 428–433. [Google Scholar] [CrossRef]

- Burris, K.P.; Harte, F.M.; Davidson, P.M.; Stewart Jr, C.N.; Zivanovic, S. Composition and bioactive properties of yerba mate (Ilex paraguariensis a. St.-hil.): A review. Chil. J. Agricl. Res. 2012, 72, 268. [Google Scholar] [CrossRef] [Green Version]

- Medina Jaramillo, C.; Gutiérrez, T.J.; Goyanes, S.; Bernal, C.; Famá, L. Biodegradability and plasticizing effect of yerba mate extract on cassava starch edible films. Carbohydr. Polym. 2016, 151, 150–159. [Google Scholar] [CrossRef] [PubMed]

- González de Mejía, E.; Song, Y.S.; Heck, C.I.; Ramírez-Mares, M. Yerba mate tea (Ilex paraguariensis): Phenolics, antioxidant capacity and in vitro inhibition of colon cancer cell proliferation. J. Funct. Food 2010, 2, 23–34. [Google Scholar] [CrossRef]

- Instituto Brasileiro de Geografia e Estatística—IBGE. 2018. Available online: Https://sidra.Ibge.Gov.Br/tabela/289#resultado (accessed on 20 March 2020).

- Instituto Nacional de Yerba Mate (INYM). 2020. Available online: Https://www.Inym.Org.Ar/aumentaron-la-produccion-y-el-consumo-de-yerba-mate-en-la-argentina/ (accessed on 20 March 2020).

- Nunes Ferraz Junior, A.D.; Etchelet, M.I.; Braga, A.F.M.; Clavijo, L.; Loaces, I.; Noya, F.; Etchebehere, C. Alkaline pretreatment of yerba mate (Ilex paraguariensis) waste for unlocking low-cost cellulosic biofuel. Fuel 2020, 266, 117068. [Google Scholar] [CrossRef]

- Pinheiro Bruni, G.; dos Santos Acunha, T.; de Oliveira, J.P.; Martins Fonseca, L.; Tavares da Silva, F.; Martins Guimarães, V.; da Rosa Zavareze, E. Electrospun protein fibers loaded with yerba mate extract for bioactive release in food packaging. J. Sci. Food Agric. 2020, 100, 3341–3350. [Google Scholar] [CrossRef]

- Meaurio, E.; López-Rodríguez, N.; Sarasua, J.R. Infrared spectrum of poly(l-lactide): Application to crystallinity studies. Macromolecules 2006, 39, 9291–9301. [Google Scholar] [CrossRef]

- Fortunati, E.; Armentano, I.; Zhou, Q.; Iannoni, A.; Saino, E.; Visai, L.; Berglund, L.A.; Kenny, J.M. Multifunctional bionanocomposite films of poly(lactic acid), cellulose nanocrystals and silver nanoparticles. Carbohydr. Polym. 2012, 87, 1596–1605. [Google Scholar] [CrossRef]

- Yang, W.; Owczarek, J.; Fortunati, E.; Kozanecki, M.; Mazzaglia, A.; Balestra, G.; Kenny, J.; Torre, L.; Puglia, D. Antioxidant and antibacterial lignin nanoparticles in polyvinyl alcohol/chitosan films for active packaging. Ind. Crop. Prod. 2016, 94, 800–811. [Google Scholar] [CrossRef]

- Mondragon, G.; Fernandes, S.; Retegi, A.; Peña, C.; Algar, I.; Eceiza, A.; Arbelaiz, A. A common strategy to extracting cellulose nanoentities from different plants. Ind. Crop. Prod. 2014, 55, 140–148. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 864. [Google Scholar] [CrossRef]

- Badia, J.; Santonja-Blasco, L.; Martínez-Felipe, A.; Ribes-Greus, A. Hygrothermal ageing of reprocessed polylactide. Polym. Degrad. Stabil. 2012, 97, 1881–1890. [Google Scholar] [CrossRef] [Green Version]

- Beltrán, F.; de la Orden, M.; Lorenzo, V.; Pérez, E.; Cerrada, M.; Urreaga, J.M. Water-induced structural changes in poly(lactic acid) and PLLA-clay nanocomposites. Polymer 2016, 107, 211–222. [Google Scholar] [CrossRef]

- Chen, X.; Han, L.; Zhang, T.; Zhang, J. Influence of crystal polymorphism on crystallinity calculation of poly (l-lactic acid) by infrared spectroscopy. Vib. Spectrosc. 2014, 70, 1–5. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J.M. PLA-PHB/cellulose based films: Mechanical, barrier and disintegration properties. Polym. Degrad. Stabil. 2014, 107, 139–149. [Google Scholar] [CrossRef]

- Way, C.; Dean, K.; Wu, D.Y.; Palombo, E. Biodegradation of sequentially surface treated lignocellulose reinforced polylactic acid composites: Carbon dioxide evolution and morphology. Polym. Degrad. Stabil. 2012, 97, 430–438. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L. Calorimetric analysis of the multiple melting behavior of poly (l-lactic acid). J. App Polym. Sci. 2006, 100, 3145–3151. [Google Scholar] [CrossRef]

- Lizundia, E.; Fortunati, E.; Dominici, F.; Vilas, J.L.; León, L.M.; Armentano, I.; Torre, L.; Kenny, J.M. PLLA-grafted cellulose nanocrystals: Role of the CNC content and grafting on the PLA bionanocomposite film properties. Carbohydr. Polym. 2016, 142, 105–113. [Google Scholar] [CrossRef]

- Burgos, N.; Martino, V.P.; Jiménez, A. Characterization and ageing study of poly(lactic acid) films plasticized with oligomeric lactic acid. Polym. Degrad. Stabil. 2013, 98, 651–658. [Google Scholar] [CrossRef]

- Chariyachotilert, C.; Joshi, S.; Selke, S.E.; Auras, R. Assessment of the properties of poly (L-lactic acid) sheets produced with differing amounts of postconsumer recycled poly(L-lactic acid). J. Plast. Film Sheeting 2012, 28, 314–335. [Google Scholar] [CrossRef]

- Yang, W.; Weng, Y.; Puglia, D.; Qi, G.; Dong, W.; Kenny, J.M.; Ma, P. Poly(lactic acid)/lignin films with enhanced toughness and anti-oxidation performance for active food packaging. Int. J. Biol. Macromol. 2020, 144, 102–110. [Google Scholar] [CrossRef]

- Shogren, R. Water vapor permeability of biodegradable polymers. J. Environ. Polym. Degrad. 1997, 5, 91–95. [Google Scholar] [CrossRef]

- Kim, Y.; Suhr, J.; Seo, H.-W.; Sun, H.; Kim, S.; Park, I.-K.; Kim, S.-H.; Lee, Y.; Kim, K.-J.; Nam, J.-D. All biomass and UV protective composite composed of compatibilized lignin and poly(lactic-acid). Sci. Rep. 2017, 7, 43596. [Google Scholar] [CrossRef] [Green Version]

- Espino-Pérez, E.; Bras, J.; Ducruet, V.; Guinault, A.; Dufresne, A.; Domenek, S. Influence of chemical surface modification of cellulose nanowhiskers on thermal, mechanical, and barrier properties of poly(lactide) based bionanocomposites. Eur. Polym. J. 2013, 49, 3144–3154. [Google Scholar] [CrossRef]

- Fortunati, E.; Peltzer, M.; Armentano, I.; Torre, L.; Jiménez, A.; Kenny, J.M. Effects of modified cellulose nanocrystals on the barrier and migration properties of pla nano-biocomposites. Carbohyd. Polym. 2012, 90, 948–956. [Google Scholar] [CrossRef]

- Pillin, I.; Montrelay, N.; Bourmaud, A.; Grohens, Y. Effect of thermo-mechanical cycles on the physico-chemical properties of poly (lactic acid). Polym. Degrad. Stabil. 2008, 93, 321–328. [Google Scholar] [CrossRef]

- Zaidi, L.; Bruzaud, S.; Bourmaud, A.; Médéric, P.; Kaci, M.; Grohens, Y. Relationship between structure and rheological, mechanical and thermal properties of polylactide/cloisite 30b nanocomposites. J. Appl. Polym. Sci. 2010, 116, 1357–1365. [Google Scholar] [CrossRef]

- Zaidi, L.; Kaci, M.; Bruzaud, S.; Bourmaud, A.; Grohens, Y. Effect of natural weather on the structure and properties of polylactide/cloisite 30b nanocomposites. Polym. Degrad. Stabil. 2010, 95, 1751–1758. [Google Scholar] [CrossRef]

| Sample | Description |

|---|---|

| PLAV | PLA obtained after the first extrusion and compression molding steps |

| PLAR | PLA obtained after the accelerated ageing, washing, and melt compounding of PLAV |

| PLAR-1YMN | PLAR with 1 wt. % of yerba mate nanoparticles |

| PLAR-3YMN | PLAR with 3 wt. % of yerba mate nanoparticles |

| Sample | Tg (°C) | Tcc (°C) | Tm (°C) | ∆Hcc (J/g) | ∆Hm (J/g) | T10 (°C) | Tmax (°C) |

|---|---|---|---|---|---|---|---|

| PLAV | 59.0 | 125.2 | 150.8 | 14.5 | 15.4 | 334.2 | 365.9 |

| PLAR | 58.6 | 110.5 | 147.3–153.9 | 27.1 | 27.7 | 316.1 | 355.9 |

| PLAR-1YMN | 58.6 | 108.9 | 146.9–153.7 | 26.7 | 27.8 | 318.1 | 354.6 |

| PLAR-3YMN | 58.1 | 107.7 | 146.5–153.7 | 28.2 | 28.3 | 307.3 | 349.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beltrán, F.R.; Arrieta, M.P.; Gaspar, G.; de la Orden, M.U.; Martínez Urreaga, J. Effect of Iignocellulosic Nanoparticles Extracted from Yerba Mate (Ilex paraguariensis) on the Structural, Thermal, Optical and Barrier Properties of Mechanically Recycled Poly(lactic acid). Polymers 2020, 12, 1690. https://doi.org/10.3390/polym12081690

Beltrán FR, Arrieta MP, Gaspar G, de la Orden MU, Martínez Urreaga J. Effect of Iignocellulosic Nanoparticles Extracted from Yerba Mate (Ilex paraguariensis) on the Structural, Thermal, Optical and Barrier Properties of Mechanically Recycled Poly(lactic acid). Polymers. 2020; 12(8):1690. https://doi.org/10.3390/polym12081690

Chicago/Turabian StyleBeltrán, Freddys R., Marina P. Arrieta, Gerald Gaspar, María U. de la Orden, and Joaquín Martínez Urreaga. 2020. "Effect of Iignocellulosic Nanoparticles Extracted from Yerba Mate (Ilex paraguariensis) on the Structural, Thermal, Optical and Barrier Properties of Mechanically Recycled Poly(lactic acid)" Polymers 12, no. 8: 1690. https://doi.org/10.3390/polym12081690