Effect of Glass Fibers Thermal Treatment on the Mechanical and Thermal Behavior of Polysulfone Based Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Sample Preparation

2.2. Characterization of the Samples’ Structures

2.3. Mechanical Tests

2.4. Thermo-Mechanical Tests

3. Results and Discussion

3.1. FTIR

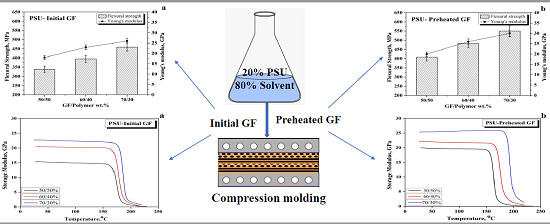

3.2. Mechanical Tests

3.3. Thermo-Mechanical Tests

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jose, A.J.; Wilson, R.; Jacob, G.; Alagar, M. Studies on thermo mechanical and surface properties of polysulfone/poly(ether imide ester) blends. Mater. Today Proc. 2019, 9, 279–294. [Google Scholar] [CrossRef]

- Zhao, J.; He, G.; Liu, G.; Pan, F.; Wu, H.; Jin, W.; Jiang, Z. Manipulation of interactions at membrane interfaces for energy and environmental applications. Prog. Polym. Sci. 2018, 80, 125–152. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D.; Zhang, H.; Huang, L.; Yao, Y.; Li, G.; Mobasher, B. Mechanical Characterization of the Tensile Properties of Glass Fiber and Its Reinforced Polymer (GFRP) Composite under Varying Strain Rates and Temperatures. Polymers 2016, 8, 196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chukov, D.; Nematulloev, S.; Zadorozhnyy, M.; Tcherdyntsev, V.; Stepashkin, A.; Zherebtsov, D. Structure, Mechanical and Thermal Properties of Polyphenylene Sulfide and Polysulfone Impregnated Carbon Fiber Composites. Polymers 2019, 11, 684. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moriana, R.; Vilaplana, F.; Karlsson, S.; Ribes-Greusa, A. Improved thermo-mechanical properties by the addition of natural fibres in starch-based sustainable biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 30–40. [Google Scholar] [CrossRef] [Green Version]

- Di Landro, R.; Lorenzi, W. Mechanical Properties and Dynamic Mechanical Analysis of Thermoplastic-Natural Fiber/Glass Reinforced Composites. Macromol. Symp. 2009, 286, 145–155. [Google Scholar] [CrossRef]

- Kim, N.; Kim, D.-Y.; Kim, Y.-J.; Jeong, K.-U. Enhanced thermomechanical properties of long and short glass fiber-reinforced polyamide 6,6/polypropylene mixtures by tuning the processing procedures. J. Mater. Sci. 2014, 49, 6333–6342. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Torokhov, V.; Stepashkin, A.; Sherif, G.; Tcherdyntsev, V.V. Effect of carbon fiber surface modification on their interfacial interaction with polysulfone. Results Phys. 2019, 15, 102634. [Google Scholar] [CrossRef]

- Stepashkin, A.A.; Chukov, D.I.; Gorshenkov, M.V.; Tcherdyntsev, V.V.; Kaloshkin, S.D. Electron microscopy investigation of interface between carbon fiber and ultra high molecular weight polyethylene. J. Alloys Compd. 2014, 586, S168–S172. [Google Scholar] [CrossRef]

- Obande, W.; Mamalis, D.; Ray, D.; Yang, L.; Brádaigh, C.M.O. Mechanical and thermomechanical characterisation of vacuum-infused thermoplastic- and thermoset-based composites. Mater. Des. 2019, 175, 107828. [Google Scholar] [CrossRef]

- Zhao, Z.K.; Du, S.S.; Li, F.; Xiao, H.M.; Li, Y.Q.; Zhang, W.G.; Hu, N.; Fu, S.Y. Mechanical and tribological properties of short glass fiber and short carbon fiber reinforced polyethersulfone composites: A comparative study. Compos. Commun. 2018, 8, 1–6. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A.; Schipper, G.; Krikor, H.G.L.T. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: Part 3. Strength and strain at failure. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1075–1084. [Google Scholar] [CrossRef]

- Laura, D.M.; Keskkula, H.; Barlow, J.W.; Paul, D.R. Effect of glass fiber surface chemistry on the mechanical properties of glass fiber reinforced, rubber-toughened nylon 6. Polymer 2002, 43, 4673–4687. [Google Scholar] [CrossRef]

- Chen, J.; Xu, H.; Liu, C.; Mi, L.; Shen, C. The effect of double grafted interface layer on the properties of carbon fiber reinforced polyamide 66 composites. Compos. Sci. Technol. 2018, 168, 20–27. [Google Scholar] [CrossRef]

- Qu, M.; Nilsson, F.; Qin, Y.; Yang, G.; Pan, Y.; Liu, X.; Rodriguez, G.H.; Chen, J.; Zhang, C.; Schubert, D.H. Electrical conductivity and mechanical properties of melt-spun ternary composites comprising PMMA, carbon fibers and carbon black. Compos. Sci. Technol. 2017, 150, 24–31. [Google Scholar] [CrossRef]

- Lv, G.; Zhang, N.; Huang, M.; Shen, C.; Castro, J.; Tan, K.; Liu, X.; Liu, C. The remarkably enhanced particle erosion resistance and toughness properties of glass fiber/epoxy composites via thermoplastic polyurethane nonwoven fabric. Polym. Test. 2018, 69, 470–477. [Google Scholar] [CrossRef]

- Liao, M.; Yang, Y.; Hamada, H. Mechanical performance of glass woven fabric composite: Effect of different surface treatment agents. Compos. Part B Eng. 2016, 86, 17–26. [Google Scholar] [CrossRef]

- Hwang, D.; Cho, D. Fiber aspect ratio effect on mechanical and thermal properties of carbon fiber/ABS composites via extrusion and long fiber thermoplastic processes. J. Ind. Eng. Chem. 2019, 80, 335–344. [Google Scholar] [CrossRef]

- Nikforooz, M.; Montesano, J.; Golzar, M.; Shokrieh, M.M. Assessment of the thermomechanical performance of continuous glass fi ber-reinforced thermoplastic laminates. Polym. Test. 2018, 67, 457–467. [Google Scholar] [CrossRef]

- Cen-Puc, M.; Pool, G.; Oliva-Avilés, A.I.; May-Pat, A.; Avilés, F. Experimental investigation of the thermoresistive response of multiwall carbon nanotube/polysulfone composites under heating-cooling cycles. Compos. Sci. Technol. 2017, 151, 34–43. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Karsli, N.G.; Demirkol, S.; Yilmaz, T. Thermal aging and reinforcement type effects on the tribological, thermal, thermomechanical, physical and morphological properties of poly(ether ether ketone) composites. Compos. Part B Eng. 2016, 88, 253–263. [Google Scholar] [CrossRef]

- Ficai, D.; Ficai, A.; Trusca, R.; Vasile, B.S.; Voicu, G.; Guran, C.; Andronescu, E. Synthesis and Characterization of Magnetite-Polysulfone Micro- and Nanobeads with Improved Chemical Stability in Acidic Media. Curr. Nanosci. 2013, 9, 271–277. [Google Scholar] [CrossRef]

- Mhatre, A.M.; Chappa, S.; Ojha, S.; Pandey, A.K. Functionalized glass fiber membrane for extraction of iodine species. Sep. Sci. Technol. 2019, 54, 1469–1477. [Google Scholar] [CrossRef]

- Nair, K.C.M.; Thomas, S.; Groeninckx, G. Thermal and dynamic mechanical analysis of polystyrene composites reinforced with short sisal fibres. Compos. Sci. Technol. 2001, 61, 2519–2529. [Google Scholar] [CrossRef]

- Mouhmid, B.; Imad, A.; Benseddiq, N.; Benmedakhene, S.; Maazouz, A. A study of the mechanical behaviour of a glass fibre reinforced polyamide 6,6: Experimental investigation. Polym. Test. 2006, 25, 544–552. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects. Polym. Test. 2016, 51, 151–164. [Google Scholar] [CrossRef]

- Senturk, O.; Senturk, A.E.; Palabiyik, M. Evaluation of hybrid effect on the thermomechanical and mechanical properties of calcite/SGF/PP hybrid composites. Compos. Part B Eng. 2018, 140, 68–77. [Google Scholar] [CrossRef]

- Tábi, T.; Hajba, S.; Kovács, J.G. Effect of crystalline forms (α′ and α) of poly(lactic acid) on its mechanical, thermo-mechanical, heat deflection temperature and creep properties. Eur. Polym. J. 2016, 82, 232–243. [Google Scholar] [CrossRef] [Green Version]

- Daghigh, V.; Lacy, T.E., Jr.; Daghigh, H.; Gu, G.; Baghaei, K.T.; Horstemeyer, M.F.; Pittman, C.U., Jr. Heat deflection temperatures of bio-nano-composites using experiments and machine learning predictions. Mater. Today Commun. 2020, 22, 100789. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Feldmann, M. Polyoxymethylene composites with natural and cellulose fibres: Toughness and heat deflection temperature. Compos. Sci. Technol. 2012, 72, 1870–1874. [Google Scholar] [CrossRef]

- Sherif, G.; Chukov, D.; Tcherdyntsev, V.; Torokhov, V. Effect of Formation Route on the Mechanical Properties of the Polyethersulfone Composites Reinforced with Glass Fibers. Polymers 2019, 11, 1364. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thomason, J. A review of the analysis and characterisation of polymeric glass fibre sizings. Polym. Test. 2020, 85, 106421. [Google Scholar] [CrossRef]

- Jenkins, P.G. Investigation of the Strength Loss of Heat Treated Glass Fibre. Ph.D. Thesis, University of Strathclyde, Glasgow, Scotland, 2016. [Google Scholar]

- Mäder, E. Study of fibre surface treatments for control of interphase properties incomposites. Compos. Sci. Technol. 1997, 57, 1077–1088. [Google Scholar]

- Romanenko, K.V.; Lapina, O.B.; Simonova, L.G.; Fraissard, J. 1H and 29Si-MAS NMR characterization of silicate fiberglass supports. Phys. Chem. Chem. Phys. 2003, 5, 2686–2691. [Google Scholar] [CrossRef]

- Thomason, J.L.; Nagel, U.; Yang, L.; Bryce, D. A study of the thermal degradation of glass fibre sizings at composite processing temperatures. Compos. Part A Appl. Sci. Manuf. 2019, 121, 56–63. [Google Scholar] [CrossRef] [Green Version]

- Zhuravlev, L.T. Concentration of hydroxyl groups on the surface of amorphous silicas. Langmuir 1987, 3, 316–318. [Google Scholar] [CrossRef]

- Dizman, C.; Ates, S.; Torun, L.; Yagci, Y. Synthesis, characterization and photoinduced curing of polysulfones with (meth)acrylate functionalities. Beilstein J. Org. Chem. 2010, 6, 56. [Google Scholar] [CrossRef] [Green Version]

- Wei, X.; Wang, Z.; Wang, J.; Wang, S. A novel method of surface modification to polysulfone ultrafiltration membrane by preadsorption of citric acid or sodium bisulfite. Membr. Water Treat. 2012, 3, 35–49. [Google Scholar] [CrossRef] [Green Version]

- Thomason, J.L. Glass fibre sizing: A review. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105619. [Google Scholar] [CrossRef]

- Saha, N.; Basu, D.; Banerjee, A.N. Heat-distortion temperature of unidirectional polyethylene-glass fiber-PMMA hybrid composite laminates. J. Appl. Polym. Sci. 1999, 71, 541–545. [Google Scholar] [CrossRef]

| Fiber/Polymer | 50/50 | 60/40 | 70/30 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Property | Tg (°C) | Tan δ | HDT (°C) | Tg (°C) | Tan δ | HDT (°C) | Tg (°C) | Tan δ | HDT (°C) |

| Initial GF composites | 163 | 0.75 | 168 | 180 | 0.65 | 197 | 192 | 0.53 | 209 |

| Preheated GF composites | 170 | 0.81 | 181 | 187 | 0.7 | 202 | 198 | 0.56 | 214 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sherif, G.; Chukov, D.I.; Tcherdyntsev, V.V.; Torokhov, V.G.; Zherebtsov, D.D. Effect of Glass Fibers Thermal Treatment on the Mechanical and Thermal Behavior of Polysulfone Based Composites. Polymers 2020, 12, 902. https://doi.org/10.3390/polym12040902

Sherif G, Chukov DI, Tcherdyntsev VV, Torokhov VG, Zherebtsov DD. Effect of Glass Fibers Thermal Treatment on the Mechanical and Thermal Behavior of Polysulfone Based Composites. Polymers. 2020; 12(4):902. https://doi.org/10.3390/polym12040902

Chicago/Turabian StyleSherif, Galal, Dilyus I. Chukov, Victor V. Tcherdyntsev, Valerii G. Torokhov, and Dmitry D. Zherebtsov. 2020. "Effect of Glass Fibers Thermal Treatment on the Mechanical and Thermal Behavior of Polysulfone Based Composites" Polymers 12, no. 4: 902. https://doi.org/10.3390/polym12040902