Preparation of Biomorphic Porous SiC Ceramics from Bamboo by Combining Sol–Gel Impregnation and Carbothermal Reduction

Abstract

:1. Introduction

2. Materials and Methods

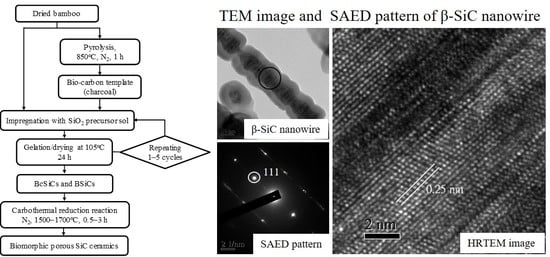

2.1. Experimental Materials and Procedure

2.2. Characterization

3. Results and Discussion

3.1. Effect of Sintering Temperature on the Properties of Porous Biomorphic Silicon Carbide (Bio-SiC) Ceramics

3.2. Effect of Sintering Duration on the Properties of Porous Bio-SiC Ceramics

3.3. Effect of Sol–Gel Impregnation Cycle on the Properties of Porous Bio-SiC Ceramics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qian, J.M.; Wang, J.P.; Jin, Z.H. Preparation of biomorphic SiC ceramic by carbothermal reduction of oak wood charcoal. Mat. Sci. Eng. A Struct. 2004, 371, 229–235. [Google Scholar] [CrossRef]

- Amaral-Labat, G.; Zollfrank, C.; Ortona, A.; Pusterla, S.; Pizzi, A.; Fierro, V.; Celzard, A. Structure and oxidation resistance of micro-cellular Si-SiC foams derived from natural resins. Ceram. Int. 2013, 39, 1841–1851. [Google Scholar] [CrossRef]

- Gordic, M.; Bucevac, D.; Ruzic, J.; Gavrilovic, S.; Hercigonja, R.; Stankovic, M.; Mtovic, B. Biomimetic synthesis and properties of cellular SiC. Ceram. Int. 2014, 40, 3699–3705. [Google Scholar] [CrossRef]

- Pizzi, A.; Zollfrank, C.; Li, X.; Cangemi, M.; Celzard, A. A SEM record of Proteins-derived microcellular silicon carbide foams. J. Renew. Mat. 2014, 2, 230–234. [Google Scholar] [CrossRef]

- Mao, W.G.; Chen, J.; Si, M.S.; Zhang, R.F.; Ma, Q.S.; Fang, D.N.; Chen, X. High temperature digital image correlation evaluation of in-situ failure mechanism: An experimental framework with application to C/SiC composites. Mat. Sci. Eng. A Struct. 2016, 665, 26–34. [Google Scholar] [CrossRef] [Green Version]

- Locs, J.; Berzina-Cimdina, L.; Zhurinsh, A.; Loca, D. Effect of processing on the microstructure and crystalline phase composition of wood derived porous SiC ceramics. J. Eur. Ceram. Soc. 2011, 31, 183–188. [Google Scholar] [CrossRef]

- Locs, J.; Berzina-Cimdina, L.; Zhurinsh, A.; Loca, D. Optimized vaccum/pressure sol impregnation processing of wood for the synthesis of porous, biomorphic SiC ceramics. J. Eur. Ceram. Soc. 2009, 29, 1513–1519. [Google Scholar] [CrossRef]

- Sun, D.; Hao, X.; Yu, X.; Chen, X.; Liu, M. Preparation and characterisation of carbon fibre-reinforced laminated woodceramics. Wood Sci. Technol. 2016, 50, 581–597. [Google Scholar] [CrossRef]

- Zollfrank, C.; Siebera, H. Microstructure and phase morphology of wood derived biomorphous SiSiC-ceramics. J. Eur. Ceram. Soc. 2004, 24, 495–506. [Google Scholar] [CrossRef]

- Esposito, L.; Sciti, D.; Pinacastelli, A.; Bellosi, A. Microstructure and properties of porous β-SiC template from soft woods. J. Eur. Ceram. Soc. 2004, 24, 533–540. [Google Scholar] [CrossRef]

- Vogli, E.; Mukerji, J.; Hoffmann, C.; Klandy, R.; Sieber, H.; Greil, P. Conversion of oak to cellular silicon carbide ceramic by gas-phase reaction with silicon monoxide. J. Am. Ceram. Soc. 2001, 84, 1236–1240. [Google Scholar] [CrossRef]

- Vogli, E.; Sieber, H.; Greil, P. Biomorphic SiC-ceramic perpetrated by Si-vapor phase infiltration of wood. J. Eur. Ceram. Soc. 2002, 22, 2663–2668. [Google Scholar] [CrossRef]

- Qian, J.M.; Wang, J.P.; Jin, Z.H. Preparation and properties of porous microcellular SiC ceramics by reactive infiltration of Si vapor into carbonized basswood. Mater. Chem. Phys. 2003, 82, 648–653. [Google Scholar] [CrossRef]

- Greil, P.; Vogli, E.; Fey, T.; Bezold, A.; Popovska, N.; Gerhard, H.; Siebera, H. Effect of microstructure on the fracture behaviour of biomorphous silicon carbide ceramics. J. Eur. Ceram. Soc. 2002, 22, 2697–2707. [Google Scholar] [CrossRef]

- Klinger, R.; Sell, J.; Zimmermann, T.; Herzog, A.; Vogt, U.; Graule, T.; Thurner, P.; Beckmann, F.; Muller, B. Wood-delivered porous ceramics via infiltration of SiO2-sol and carbothermal reduction. Holzforschung 2003, 57, 440–446. [Google Scholar] [CrossRef]

- Furuno, T.; Fujitsawa, M. Carbonization of wood-silica composites and formation of silicon carbide in the cell wall. Wood Fiber Sci. 2004, 36, 269–277. [Google Scholar]

- Herzog, A.; Klingner, R.; Vogt, U.; Graule, T. Wood-derived porous SiC ceramics by sol infiltration and carbothermal reduction. J. Am. Ceram. Soc. 2004, 87, 784–793. [Google Scholar] [CrossRef]

- Qian, J.M.; Wang, J.P.; Qiao, G.J.; Jin, Z.H. Preparation of porous SiC ceramic with a woodlike microstructure by sol-gel and carbothermal reduction processing. J. Eur. Ceram. Soc. 2004, 24, 3251–3259. [Google Scholar] [CrossRef]

- Shin, Y.; Wang, C.; Exarhos, G.J. Synthesis of SiC ceramics by the carbothermal reduction of mineralized wood with silica. Adv. Mater. 2005, 17, 73–77. [Google Scholar] [CrossRef]

- Sieber, H. Biomimetic synthesis of ceramics and ceramic composites. Mat. Sci. Eng. A Struct. 2005, 412, 43–47. [Google Scholar] [CrossRef]

- Qian, J.M.; Jin, Z.H. Preparation and characterization of porous, biomorphic SiC ceramic with hybrid pore structure. J. Eur. Ceram. Soc. 2006, 26, 1311–1316. [Google Scholar] [CrossRef]

- Egelja, A.; Gulickovski, J.; Devečerski, A.; Ninić, M.; Radoslavljević-Mihaljović, A.; Matović, B. Preparation of biomorphic SiC ceramics. Sci. Sinter. 2008, 40, 141–145. [Google Scholar] [CrossRef]

- Sakka, S.; Miyafuji, H. Handbook of Sol-Gel Science and Technology: Processing, Characterization and Applications. Volume III: Applications of Sol-Gel Technology; Kluwer Academic Publishers: Boston, MA, USA, 2005. [Google Scholar]

- Scurlock, J.M.O.; Dayton, D.C.; Hames, B. Bamboo: An overlooked biomass resource? Biomass Bioenerg. 2000, 19, 229–244. [Google Scholar] [CrossRef]

- Liu, Z.; Fei, B.; Jiang, Z.; Cai, Z.; Liu, X. Important properties of bamboo pellets to be used as commercial solid fuel in China. Wood Sci. Technol. 2014, 48, 903–917. [Google Scholar] [CrossRef]

- Mori, Y.; Kuwano, Y.; Tomokiyo, S.; Kuroyanagi, N.; Odahara, K. Inhibitory effects of Moso bamboo (Phyllostachys heterocycla f. pubescens) extracts on phytopathogenic bacterial and fungal growth. Wood Sci. Technol. 2019, 53, 135–150. [Google Scholar] [CrossRef]

- Mi, Y.; Chen, X.; Guo, Q. Bamboo fiber-reinforced polypropylene composites: Crystallization and interfacial morphology. J. Appl. Polym. Sci. 1997, 64, 1267–1273. [Google Scholar] [CrossRef]

- Lee, S.H.; Ohkita, T. Bamboo fiber (BF)-filled poly (butylenes succinate) bio-composite–Effect of BF-e-MA on the properties and crystallization kinetics. Holzforschung 2004, 58, 537–543. [Google Scholar] [CrossRef]

- Shao, S.; Wen, G.; Jin, Z. Changes in chemical characteristics of bamboo (Phyllostachys pubescens) components during steam explosion. Wood Sci. Technol. 2008, 42, 439–451. [Google Scholar] [CrossRef]

- Chang, S.T.; Wu, J.H. Stabilizing effect of chromated salt treatment on the green color of ma bamboo (Dendrocalamus latiflorus). Holzforschung 2000, 54, 327–330. [Google Scholar] [CrossRef]

- Wu, T.L.; Chien, Y.C.; Chen, T.Y.; Wu, J.H. The influence of hot-press temperature and cooling rate on thermal and physicomechanical properties of bamboo particle-polylactic acid composites. Holzforschung 2013, 67, 325–331. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, Z.; Fei, B.; Hse, C.; Sun, Z. Tensile behavior and fracture mechanism of moso bamboo (Phyllostachys pubescens). Holzforschung 2015, 69, 47–52. [Google Scholar] [CrossRef]

- Hung, K.C.; Wu, J.H. Characteristics and thermal decomposition kinetics of wood-SiO2 composites derived by the sol-gel process. Holzforschung 2017, 71, 233–240. [Google Scholar] [CrossRef]

- Ding, J.; Zhu, H.; Li, G.; Deng, C.; Li, J. Growth of SiC nanowires on wooden template surface using molten salt media. Appl. Surf. Sci. 2014, 320, 620–626. [Google Scholar] [CrossRef]

- Hata, T.; Castro, V.; Fujisawa, M.; Imamura, Y.; Bonnamy, S.; Bronsveld, P.; Kikuchi, H. Formation of silicon carbide nanorods from wood-based carbons. Fuller. Nanotub. Carbon Nano Struct. 2005, 13, 107–113. [Google Scholar] [CrossRef]

- Evbuomwan, B.O.; Abutu, A.S.; Ezeh, C.P. The effects of carbonization temperature on some physicochemical properties of bamboo based activated carbon by potassium hydroxide (KOH) activation. Greener J. Phys. Sci. 2013, 3, 187–191. [Google Scholar]

- Huang, P.H.; Jhan, J.W.; Cheng, Y.M.; Cheng, H.H. Effects of carbonization parameters of moso-bamboo-based porous charcoal on capturing carbon dioxide. Sci. World J. 2014, 2014, 937867. [Google Scholar] [CrossRef] [PubMed]

- Pastore, R.; Delfini, A.; Micheli, D.; Vricella, A.; Marchetti, M.; Santoni, F.; Piergentili, F. Carbon foam electromagnetic mm-wave absorption in reverberation chamber. Carbon 2019, 144, 63–71. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, K.-C.; Wu, T.-L.; Xu, J.-W.; Wu, J.-H. Preparation of Biomorphic Porous SiC Ceramics from Bamboo by Combining Sol–Gel Impregnation and Carbothermal Reduction. Polymers 2019, 11, 1442. https://doi.org/10.3390/polym11091442

Hung K-C, Wu T-L, Xu J-W, Wu J-H. Preparation of Biomorphic Porous SiC Ceramics from Bamboo by Combining Sol–Gel Impregnation and Carbothermal Reduction. Polymers. 2019; 11(9):1442. https://doi.org/10.3390/polym11091442

Chicago/Turabian StyleHung, Ke-Chang, Tung-Lin Wu, Jin-Wei Xu, and Jyh-Horng Wu. 2019. "Preparation of Biomorphic Porous SiC Ceramics from Bamboo by Combining Sol–Gel Impregnation and Carbothermal Reduction" Polymers 11, no. 9: 1442. https://doi.org/10.3390/polym11091442