Mechanical, Thermal, and Electrical Properties of BN–Epoxy Composites Modified with Carboxyl-Terminated Butadiene Nitrile Liquid Rubber

Abstract

:1. Introduction

2. Materials

2.1. Preparation of Composite Materials

2.2. Characterization

3. Results and Discussion

3.1. Fracture Morphology of Composite Materials

3.2. Mechanical Properties of Composites

3.3. Dynamic Mechanical Properties

3.4. Thermogravimetric Analysis

3.5. Thermal Conductivity of Composite Materials

3.6. Dielectric Properties

3.7. Breakdown Strength

4. Conclusions

- (1)

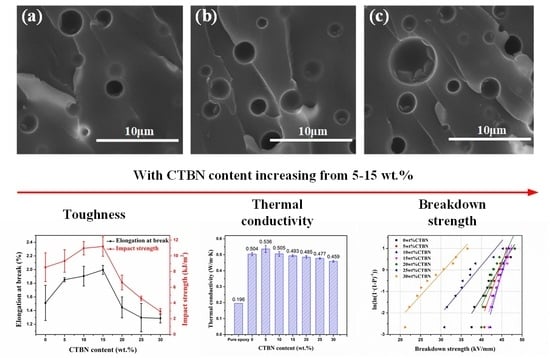

- When the amount of CTBN added was 5–15 wt.%, a dispersed sea–island structure was formed after the curing system was solidified, and the toughness of the composite material was improved. The impact strength and elongation at break of the composite containing 15 wt.% CTBN were both increased by about 32%, and the tensile strength was only slightly decreased.

- (2)

- The addition of CTBN reduced the crosslink density of the epoxy resin, the glass transition temperature of the composite decreased, and the thermal stability decreased. However, when the content of CTBN was low (5–15 wt.%), the decrease in thermal performance was within an acceptable range.

- (3)

- The composite containing 5 wt.% CTBN had the highest thermal conductivity, which was about 173% higher than that of pure epoxy resin. The dielectric constant of the composite increased with the addition of CTBN, and a peak appeared in the dielectric loss curve due to the influence of dielectric relaxation. At the same time, the addition of CTBN had a certain improvement effect on the breakdown strength of the composite.

- (4)

- The composite material with 10–15 wt.% CTBN content showed the best performance balance, good toughness, high glass transition temperature and thermal stability, high breakdown strength, but in practical application, the working conditions of high-voltage equipment should be fully considered to avoid excessive dielectric loss caused by dielectric relaxation.

Author Contributions

Funding

Conflicts of Interest

References

- Huang, X.; Jiang, P.; Tanaka, T. A review of dielectric polymer composites with high thermal conductivity. IEEE Electr. Insul. Mag. 2011, 27, 8–16. [Google Scholar] [CrossRef]

- Xiao, M.; Du, B. Review of high thermal conductivity polymer dielectrics for electrical insulation. High Volt. 2016, 1, 34–42. [Google Scholar] [CrossRef]

- Li, S.; Yu, S.; Feng, Y. Progress in and prospects for electrical insulating materials. High Volt. 2016, 1, 122–129. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, H.; Haque, A.; Chen, L.; Jackson, T.N.; Wang, Q. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Huang, X.; Chen, J.; Jiang, P. Epoxy thermoset resins with high pristine thermal conductivity. High Volt. 2017, 2, 139–146. [Google Scholar] [CrossRef]

- Yu, J.; Mo, H.; Jiang, P. Polymer/boron nitride nanosheet composite with high thermal conductivity and sufficient dielectric strength. Polym. Adv. Technol. 2015, 26, 514–520. [Google Scholar] [CrossRef]

- Zhou, W.; Zuo, J.; Zhang, X.; Zhou, A. Thermal, electrical, and mechanical properties of hexagonal boron nitride-reinforced epoxy composites. J. Compos. Mater. 2014, 48, 2517–2526. [Google Scholar] [CrossRef]

- Chen, C.; Jian, J.; Yen, F. Preparation and characterization of epoxy/γ-aluminum oxide nanocomposites. Compos. Part A Manuf. 2009, 40, 463–468. [Google Scholar] [CrossRef]

- Hou, J.; Li, G.; Yang, N.; Qin, L.; Grami, M.E.; Zhang, Q.; Wang, N.; Qu, X. Preparation and characterization of surface modified boron nitride epoxy composites with enhanced thermal conductivity. RSC Adv. 2014, 4, 44282–44290. [Google Scholar] [CrossRef]

- Huang, X.; Iizuka, T.; Jiang, P.; Ohki, Y.; Tanaka, T. Role of Interface on the Thermal Conductivity of Highly Filled Dielectric Epoxy/AlN Composites. J. Phys. Chem. C 2012, 116, 13629–13639. [Google Scholar] [CrossRef]

- Jeong, S.H.; Song, J.; Kim, K.L.; Choi, Y.H.; Lee, H. Enhanced thermal properties of epoxy composite containing cubic and hexagonal boron nitride fillers for superconducting magnet applications. Compos. Part B Eng. 2016, 107, 22–28. [Google Scholar] [CrossRef]

- Jiang, Y.; Shi, X.; Feng, Y.; Li, S.; Zhou, X.; Xie, X. Enhanced thermal conductivity and ideal dielectric properties of epoxy composites containing polymer modified hexagonal boron nitride. Compos. Part A Manuf. 2018, 107, 657–664. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, W.; Li, Y.; Zhao, D.; Yin, H. Hybrid fillers of hexagonal and cubic boron nitride in epoxy composites for thermal management applications. RSC Adv. 2019, 9, 7388–7399. [Google Scholar] [CrossRef] [Green Version]

- Atif, R.; Shyha, I.; Inam, F. Mechanical, Thermal, and Electrical Properties of Graphene-Epoxy Nanocomposites—A Review. Polymers 2016, 8, 281. [Google Scholar] [CrossRef] [PubMed]

- Johnsen, B.B.; Kinloch, A.J.; Taylor, A.C. Toughness of syndiotactic polystyrene/epoxy polymer blends: Microstructure and toughening mechanisms. Polymer 2005, 46, 7352–7369. [Google Scholar] [CrossRef]

- Feng, Y.; Fang, Z.; Gu, A. Toughening of cyanate ester resin by carboxyl terminated nitrile rubber. Polym. Adv. Technol. 2004, 15, 628–631. [Google Scholar] [CrossRef]

- Ramos, V.D.; Costa, H.M.D.; Soares, V.L.P.; Nascimento, R.S.V. Modification of epoxy resin: A comparison of different types of elastomer. Polym. Test. 2005, 24, 387–394. [Google Scholar] [CrossRef]

- Zhao, K.; Song, X.; Liang, C.; Wang, J.; Xu, S. Morphology and properties of nanostructured epoxy blends toughened with epoxidized carboxyl-terminated liquid rubber. Iran. Polym. J. 2015, 24, 425–435. [Google Scholar] [CrossRef]

- Tripathi, G.; Srivastava, D. Effect of carboxyl-terminated poly(butadiene-co-acrylonitrile) (CTBN) concentration on thermal and mechanical properties of binary blends of diglycidyl ether of bisphenol-A (DGEBA) epoxy resin. Mater. Sci. Eng. A 2007, 443, 262–269. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Friedrich, K. Microstructure-related fracture toughness and fatigue crack growth behaviour in toughened, anhydride-cured epoxy resins. Compos. Sci. Technol. 1993, 48, 263–272. [Google Scholar] [CrossRef]

- Pan, H.; Xu, M.; Lei, X.; Jia, K.; Liu, X. Curing behaviors and performance of a carboxyl-terminated butadiene acrylonitrile rubber/bisphthalonitrile resin system. High. Perform. Polym. 2016, 28, 581–590. [Google Scholar] [CrossRef]

- Grishchuk, S.; Sorochynska, L.; Vorster, O.C.; Karger-Kocsis, J. Structure, thermal, and mechanical properties of DDM-hardened epoxy/benzoxazine hybrids: Effects of epoxy resin functionality and ETBN toughening. J. Appl. Polym. Sci. 2013, 127, 5082–5093. [Google Scholar] [CrossRef]

- Auad, M.L.; Aranguren, M.I.; Borrajo, J. Quasibinary and quasiternary styrene, dimethacrylate resin, and CTBN (or VTBN) liquid rubber systems: Phase diagrams, interaction parameters and cured materials morphologies. Polymer 2001, 42, 6503–6513. [Google Scholar] [CrossRef]

- Zeng, M.; Sun, X.; Xiao, H.; Ji, G.; Jiang, X.; Wang, B.; Qi, C. Investigation of free volume and the interfacial, and toughening behavior for epoxy resin/rubber composites by positron annihilation. Radiat. Phys. Chem. 2008, 77, 245–251. [Google Scholar]

- Chen, S.; Wang, Q.; Wang, T. Hydroxy-terminated liquid nitrile rubber modified castor oil based polyurethane/epoxy IPN composites: Damping, thermal and mechanical properties. Polym. Test. 2011, 30, 726–731. [Google Scholar] [CrossRef]

- Okubo, H. Enhancement of electrical insulation performance in power equipment based on dielectric material properties. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 733–754. [Google Scholar] [CrossRef]

- Li, S.; Yin, G.; Chen, G.; Li, J.; Bai, S.; Zhong, L.; Zhang, Y.; Lei, Q. Short-term breakdown and long-term failure in nanodielectrics: A review. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1523–1535. [Google Scholar] [CrossRef]

- Ueta, G.; Wada, J.; Okabe, S.; Miyashita, M.; Nishida, C.; Kamei, M. Insulation performance of three types of micro-defects in inner epoxy insulators. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 947–954. [Google Scholar] [CrossRef]

- Akbari, R.; Beheshty, M.H.; Shervin, M. Toughening of dicyandiamide-cured DGEBA-based epoxy resins by CTBN liquid rubber. Iran. Polym. J. 2013, 22, 313–324. [Google Scholar] [CrossRef]

- Pearson, R.A.; Yee, A.F. Influence of particle size and particle size distribution on toughening mechanisms in rubber-modified epoxies. J. Mater. Sci. 1991, 26, 3828–3844. [Google Scholar] [CrossRef] [Green Version]

- Kinloch, A.J.; Shaw, S.J.; Tod, D.A.; Hunston, D.L. Deformation and fracture behaviour of a rubber-toughened epoxy: 1. Microstructure and fracture studies. Polymer 1983, 24, 1341–1354. [Google Scholar] [CrossRef]

- Shukla, S.K.; Srivastava, D. Blends of modified epoxy resin and carboxyl-terminated polybutadiene. I. J. Appl. Polym. Sci. 2006, 100, 1802–1808. [Google Scholar] [CrossRef]

- Zha, J.; Dang, Z.; Li, W.; Zhu, Y.; Chen, G. Effect of micro-Si3N4-nano-Al2O3 co-filled particles on thermal conductivity, dielectric and mechanical properties of silicone rubber composites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1989–1996. [Google Scholar] [CrossRef]

- Zheng, M.; Zha, J.; Yang, Y.; Han, P.; Hu, C.; Dang, Z. Enhanced breakdown strength of poly (vinylidene fluoride) utilizing rubber nanoparticles for energy storage application. Appl. Phys. Lett. 2016, 109, 072902. [Google Scholar] [CrossRef]

- Zhou, W.; Cai, J. Mechanical and dielectric properties of epoxy resin modified using reactive liquid rubber (HTPB). J. Appl. Polym. Sci. 2012, 124, 4346–4351. [Google Scholar] [CrossRef]

- Tan, J.; Wang, X.; Tai, J.; Luo, Y.; Jia, D. Novel blends of acrylonitrile butadiene rubber and polyurethane-silica hybrid networks. Express Polym Lett. 2012, 6, 588–600. [Google Scholar] [CrossRef]

- Tripathi, G.; Srivastava, D. Studies on the physico-mechanical and thermal characteristics of blends of DGEBA epoxy, 3,4 epoxy cyclohexylmethyl, 3’,4’-epoxycylohexane carboxylate and carboxyl terminated butadiene co-acrylonitrile (CTBN). Mater. Sci. Eng. A 2008, 496, 483–493. [Google Scholar] [CrossRef]

- Kishi, H.; Naitou, T.; Matsuda, S.; Murakami, A.; Muraji, Y.; Nakagawa, Y. Mechanical properties and inhomogeneous nanostructures of dicyandiamide-cured epoxy resins. J. Polym. Sci. Polym. Phys. 2007, 45, 1425–1434. [Google Scholar] [CrossRef]

- Thomas, R.; Yumei, D.; Yuelong, H.; Le, Y.; Moldenaers, P.; Weimin, Y.; Czigany, T.; Thomas, S. Miscibility, morphology, thermal, and mechanical properties of a DGEBA based epoxy resin toughened with a liquid rubber. Polymer 2008, 49, 278–294. [Google Scholar] [CrossRef]

- Zha, J.; Zhu, T.; Wu, Y.; Wang, S.; Li, R.K.Y.; Dang, Z. Tuning of thermal and dielectric properties for epoxy composites filled with electrospun alumina fibers and graphene nanoplatelets through hybridization. J. Mater. Chem. C 2015, 3, 7195–7202. [Google Scholar] [CrossRef]

- Zha, J.; Zhu, Y.; Li, W.; Bai, J.; Dang, Z. Low dielectric permittivity and high thermal conductivity silicone rubber composites with micro-nano-sized particles. Appl. Phys. Lett. 2012, 101, 062905. [Google Scholar] [CrossRef]

- Choi, S.; Kim, J. Thermal conductivity of epoxy composites with a binary-particle system of aluminum oxide and aluminum nitride fillers. Compos. Part B Eng. 2013, 51, 140–147. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.; Zhang, H.; Wang, H.; Liu, L.; Xu, Z.; Liu, P.; Peng, Z. Influence of addition of hydroxyl-terminated liquid nitrile rubber on dielectric properties and relaxation behavior of epoxy resin. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2258–2269. [Google Scholar] [CrossRef]

- Yang, D.; Kong, X.; Ni, Y.; Ruan, M.; Huang, S.; Shao, P.; Guo, W.; Zhang, L. Improved Mechanical and Electrochemical Properties of XNBR Dielectric Elastomer Actuator by Poly(dopamine) Functionalized Graphene Nano-Sheets. Polymers 2019, 11, 218. [Google Scholar] [CrossRef]

| Sample | T10% (°C) | T50% (°C) | Tmax (°C) |

|---|---|---|---|

| 0 wt.%CTBN | 390 | 434 | 425 |

| 5 wt.%CTBN | 385 | 433 | 422 |

| 10 wt.%CTBN | 377 | 432 | 423 |

| 15 wt.%CTBN | 368 | 427 | 417 |

| 20 wt.%CTBN | 332 | 423 | 416 |

| 25 wt.%CTBN | 319 | 421 | 417 |

| 30 wt.%CTBN | 281 | 415 | 414 |

| Sample | Scale Parameter α (kV/mm) | Shape Parameter β |

|---|---|---|

| 0 wt.% CTBN | 44.1 | 13.1 |

| 5 wt.% CTBN | 44.4 | 22.8 |

| 10 wt.% CTBN | 45.1 | 30.7 |

| 15 wt.% CTBN | 45.3 | 24.0 |

| 20 wt.% CTBN | 44.0 | 18.5 |

| 25 wt.% CTBN | 39.7 | 6.4 |

| 30 wt.% CTBN | 29.4 | 5.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, X.; Tuo, R.; Yang, W.; Zhang, Y.; Xie, Q.; Zha, J.; Lin, J.; He, S. Mechanical, Thermal, and Electrical Properties of BN–Epoxy Composites Modified with Carboxyl-Terminated Butadiene Nitrile Liquid Rubber. Polymers 2019, 11, 1548. https://doi.org/10.3390/polym11101548

Bian X, Tuo R, Yang W, Zhang Y, Xie Q, Zha J, Lin J, He S. Mechanical, Thermal, and Electrical Properties of BN–Epoxy Composites Modified with Carboxyl-Terminated Butadiene Nitrile Liquid Rubber. Polymers. 2019; 11(10):1548. https://doi.org/10.3390/polym11101548

Chicago/Turabian StyleBian, Xingming, Rui Tuo, Wei Yang, Yiran Zhang, Qing Xie, Junwei Zha, Jun Lin, and Shaojian He. 2019. "Mechanical, Thermal, and Electrical Properties of BN–Epoxy Composites Modified with Carboxyl-Terminated Butadiene Nitrile Liquid Rubber" Polymers 11, no. 10: 1548. https://doi.org/10.3390/polym11101548