Developing a Polypropylene Fabric, Silica Fume, and Redispersible Emulsion Powder Cementitious Composite for Dynamic Water Environment

Abstract

:1. Introduction

2. Materials and Testing Design

2.1. Raw Materials

2.2. Testing Procedure and Testing Design

- (1)

- The w/c ratio with 0.8, 1.0, and 1.2 by weight; SF proportion with 5%, 10%, and 15% of cement quality; and PP fiber proportion with 0.1%, 0.3%, and 0.5% of cement volume were selected to carry out various tests.

- (2)

- Gel times (initial and final) were investigated by conducting Vicat needle tests according to the standard GB/T1346-2011 of China. Specimens for Vicat needle tests were formed by placing the needle in the suspension, immediately after preparation.

- (3)

- Fluidity was evaluated using a fluidity test apparatus, which consisted of a mixer, a truncated cone model, and a glass plate according to the standard GB/T8077-2000 of China. First, the truncated cone model was placed in the center of the glass plate. Then, the prepared fresh mixtures were put into a truncated cone model immediately. After that, truncated cone model was lifted and the diameter of the mixture flow in the glass plate was measured for 30 s. The average value of the maximum diameter at the mutual vertical directions was defined as the fluidity.

- (4)

- Bleeding rate was investigated by conducting sedimentation tests. Immediately after fresh mixtures preparation, 1000 mL of the mixtures were placed in a capacity cylinder (namely graduated beaker) and the volume of sediment was recorded as a function of time. Measurements were taken at predetermined time intervals for a period of up to 24 h to ensure that sedimentation had been completed. The bleeding rate is a function of time and is defined as the volume of bleed water above the slurry, ΔV, expressed as a percentage of the total volume of the initial slurry, V0. The value of ΔV/V0 (after the end of sedimentation) is defined as the bleed capacity of the mixtures.

- (5)

- After 7 days standard curing, specimens with the size of 40 × 40 × 160 mm3 were prepared for the static mechanical strength tests. Flexural strength and compressive strength were measured using rock and concrete mechanics test system (RMT-201) according to the standard GB/T50081 of China. First, the three-point bending test was performed to investigate flexural strength. Six samples were tested for each mix. The average value was served as the final flexural strength after removing the maximum and minimum values in the six samples. After the bending test, the broken two parts were used to conduct the compressive test. Three samples were tested for each mix. The average value was obtained as the final compressive strength.

- (6)

- The anti-washout properties were evaluated by a self-design testing apparatus, as shown in Figure 1. The apparatus was composed of a sink, flow valve, and slurry collection equipment. The length, width, and height of the sink was 200, 10, and 5 cm, respectively. The flow valve was used to adjust the flow velocity. Three water velocities, namely 0.2, 0.4, and 0.6 m/s, were considered in the tests. Furthermore, the procedure of the anti-washout test was illustrated as follows. First, the slurry with mass M0 (380 g in all the tests) was poured into the sink under the designed dynamic-water velocity. When the water in outlet changed to clean, the water inlet was closed, the residual slurry in the sink was collected and the mass M1 was recorded. Then, the anti-washout properties were evaluated using the index of grout retention ratio (GRR), which was defined by the ratio of M1/M0.

3. Result and Analysis

3.1. Influence of PP Fiber and Silica Fume on Cement Slurry

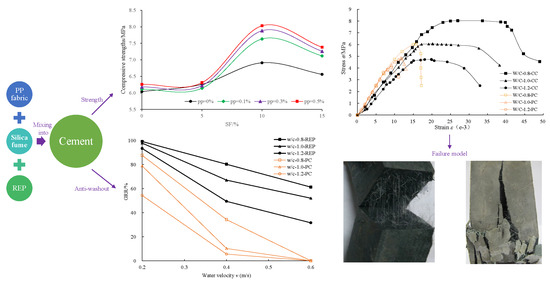

3.1.1. Strength Properties of Composite Material

- (1)

- Compared with the plain cement mixture, the maximum increase ratios of flexural strength and compressive strength after mixing the PP fiber individually reached 11.0% and 9.7% (at w/c = 1.0 and pp = 0.5). Meanwhile, those ratios after mixing SF individually increased to 13.2% and 14.4% (at w/c = 0.8 and SF = 10%), which are shown in Table 4. This indicates that SF had a greater influence than PP fiber on slurry strength.

- (2)

- As shown in Figure 2, the strength increased first and then decreased with the increase of SF, indicating a proper mixing amount existed for the modification of strength. Otherwise, the strength will in turn decrease with the further increase of SF, particularly, the flexural strength, which decreased to 0.46 MPa when SF = 15% at w/c = 1.2. This may have been due to the fact that the proper mixing amount of SF could fill the pore of cement powder, and then increase the strength. However, with the significant increase of SF, the number of cement particles will in turn decrease and weaken the hydration reaction, which will lead to the decrease of strength.

- (3)

- As shown in Figure 2, it can be observed that w/c possessed a negative influence on the strength. As the w/c increased, the strength decreased significantly. While the PP fiber possessed a positive influence on the strength at a low w/c (i.e., 0.8), this influence significantly reduced at a high w/c, or even transferred into the side effect with the increasing fiber amount. This may due to the fact that the interfacial bonding between the fiber and cement can increase the slurry strength at a low w/c. However, the porosity of slurry will increase with the increase of w/c, and the high amount of fiber will decrease the interfacial bonding and decrease the strength. Similarly, at the low w/c (i.e., 0.8), the suitable SF content was beneficial for the strength growth, while at a high w/c (i.e., 1.2), the strength decreased with the increase of SF, and the lower SF content was more beneficial for strength growth.

- (4)

- Table 4 indicates that there is an optimal proportion of SF and PP fiber content to maximize the strength for various w/c ratios. In addition, when w/c = 0.8, the optimum proportion (OP) of SF and PP fiber was 10% and 0.5%, respectively. Furthermore, when w/c = 1.0, the OP was 5% and 0.5%, respectively, while when w/c = 1.2, the OP was 5% and 0.1%, respectively.

3.1.2. Gel Time

3.1.3. Bleeding Rate

3.1.4. Fluidity of Fiber-SF Composite Slurry at the Optimal Proportion

3.1.5. Anti-Washout Performance of Fiber-SF Composite Slurry at the Optimal Proportion

3.2. Modification of PP Fiber-SF Cementitious Composite by Adding REP

4. Conclusions

- (1)

- A certain admixture amount of SF could significantly improve the strength and bleeding rate of the cement slurry, and the admixture of fiber could significantly modify the brittle fracture into ductile characteristics of the cement slurry.

- (2)

- After mixing with SF and fiber simultaneously, the flexural strength and compressive strength could be significantly increased by more than 30%. In addition, the slurry fluidity could reach 132 mm, at least with the decrease of no more than 30%, which could satisfy the pumpability in the practical engineering.

- (3)

- When the flow velocity was relatively small (v ≤ 0.4 m/s), the anti-washout properties could be significantly increased by mixing the fiber and SF and the maximum GRR could be up to 98.7%. However, the maximum GRR at the high flow velocity (v = 0.6m/s) was a mere 31.3%. After adding the REP material, the anti-washout property of the composite slurry was further improved, especially in the high flow velocity environment, where the maximum GRR at v = 0.6m/s could be up to more than 60%. Simultaneously, the admixture of REP could further increase the other performance such as strength, fluidity, and bleeding rate. The developed composite slurry possessed favorable performance in the dynamic water environment, which can be used as a reference for the engineers.

Author Contributions

Funding

Conflicts of Interest

References

- Ayazi, M.H.A.; Pirasteh, S.; Pili, A.K.A.; Biswajeet, P.; Nikouravan, B.; Mansor, S. Disasters and risk reduction in groundwater: Zagros Mountain, Southwest Iran using geoinformatics techniques. Disaster Adv. 2010, 3, 51–57. [Google Scholar]

- Mirmehrabi, H. Hazards of mechanized tunnel excavation in H2S bearing ground in Aspar tunnel, Iran. Environ. Earth Sci. 2012, 66, 529–535. [Google Scholar] [CrossRef]

- Liu, J.; Chen, W.; Nie, W.; Yuan, J.; Dong, J. Experimental research on the mass transfer and flow properties of water inrush in completely weathered granite under different particle size distributions. Rock Mech Rock Eng. 2018. [Google Scholar] [CrossRef]

- Liu, J.; Chen, W.; Yang, D.; Yuan, J.; Li, X.; Zhang, Q. Nonlinear seepage-erosion coupled water inrush model for completely weathered granite. Mar. Georesour. Geotechnol. 2018, 36, 484–493. [Google Scholar] [CrossRef]

- Liu, J.; Chen, W.; Liu, T.; Yu, J.; Dong, J.; Nie, W. Effects of Initial Porosity and Water Pressure on Seepage-Erosion Properties of Water Inrush in Completely Weathered Granite. Geofluids 2018, 2018, 4103645. [Google Scholar]

- Zhao, Y.; Li, P.; Tian, S. Prevention and treatment technologies of railway tunnel water inrush and mud gushing in China. J. Rock Mech. Geotech. Eng. 2013, 5, 468–477. [Google Scholar] [CrossRef]

- Liu, J.; Chen, W.; Yuan, J.; Li, C.; Zhang, Q.; Li, X. Groundwater control and curtain grouting for tunnel construction in completely weathered granite. Bull. Eng. Geol. Environ. 2018, 77, 515–531. [Google Scholar] [CrossRef]

- Li, L.P.; Li, S.C.; Cui, J.S.; Li, Z. Plugging performance optimization tests of grouting material for sudden water inflow of underground engineering construction. Adv. Mater. Res. 2011, 306–307, 722–726. [Google Scholar] [CrossRef]

- Liu, J.; Chen, W.; Yuan, J. Test on anti-scouring property of grouting reinforced body in completely weathered granite. Chin. J. Rock Mech. Eng. 2016, 35, 1767–1775. (In Chinese) [Google Scholar]

- Li, X.F.; Sun, J.T.; Chen, W.Z.; Yuan, J.Q.; Liu, J.Q.; Zhang, Q.Y. Strength and anti-washout property of fibre silica fume cement grout. Rock Soil Mech. 2018, 39, 3157–3164. [Google Scholar]

- Liu, R.; Shucai, L.I.; Zhang, Q.; Yuan, X.; Han, W. Experiment and application research on a new type of dynamic water grouting material. Chin. J. Rock Mech. Eng. 2011, 1, 247–265. [Google Scholar]

- Li, X.F. Grouting Reinforcement Mechanism for Completely Weathered Granite with Rich Water and Its Application in Engineering. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2017. [Google Scholar]

- Yahia, A.; Khayat, K.H. Experiment design to evaluate interaction of high-range water-reducer and antiwashout admixture in high-performance cement grout. Cem. Concr. Res. 2001, 31, 749–757. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S.; Wei, J.; Zhang, Q.; Liu, R.; Zhang, X.; Yin, H. Grouting rock fractures with cement and sodium silicate grout. Carbonates Evaporites 2017, 2, 1–12. [Google Scholar] [CrossRef]

- Yuan, J.Q.; Chen, W.Z.; Tan, X.J.; Zheng, P.Q.; Yu, J.X. Experimental study of anti-washout property and gelling performance of fast-gelling grout. Chin. J. Rock Mech. Eng. 2015, 34, 960–967. [Google Scholar]

- Yang, X.H.; Xi, A. Application of cement-silicate double solution grouting in loess tunnel construction. Chin. J. Highw. Transp. 2004, 17, 68–72. [Google Scholar]

- Li, G.; Dai, T.; Lv, F.; Liu, H. Research and application on new type grouting material and control technology. Int. Symp. Water Resour. Environ. Prot. 2011, 4, 2624–2627. [Google Scholar]

- Vik, E.A.; Sverdrup, L.; Kelley, A.; Storhaug, R.; Beitnes, A.; Boge, K.; Grepstad, G.K.; Tveiten, V. Experiences from environmental risk management of chemical grouting agents used during construction of the romeriksporten tunnel. Tunn. Undergr. Space Technol. 2000, 15, 369–378. [Google Scholar] [CrossRef]

- Wang, D.; Jiang, Z. Characteristics of water inflow and chemical grouting treatment of a Liu Yuanzi coal mine shaft in the ordos basin. Int. J. Min. Sci. Technol. 2010, 20, 607–610. [Google Scholar] [CrossRef]

- Jiang, S.Z.; Chang, L.I.; Tan, R.S.; Xue, X.L. Chemical grouting and environmental protection. J. Yangtze River Sci. Res. Inst. 2000, 17, 45–46. [Google Scholar]

- Jiang, S.Z. Rewiew on green chemical grouting technology study. J. Yangtze River Sci. Res. Inst. 2006, 23, 33–35. [Google Scholar]

- Han, T.Y.; Lin, W.T.; Cheng, A.; Huang, R.; Huang, C.C. Influence of polyolefin fibers on the engineering properties of cement-based composites containing silica fume. Mater. Des. 2012, 37, 569–576. [Google Scholar] [CrossRef]

- Usman, F.; Shaharudin, S.; Abd Ghani, M.F. Effect of polypropylene fiber on the flexural strength of ferrocement. Appl. Mech. Mater. 2014, 554, 199–202. [Google Scholar] [CrossRef]

- Lin, W.T.; Cheng, A.; Huang, R.; Chen, Y.C.; Zhou, X.G. Effect of polyolefin fiber on the engineered properties of cement-based composites containing silica fume. Mater. Des. 2011, 37, 569–576. [Google Scholar]

- Sanjuán, M.Á.; Argiz, C.; Gálvez, J.C.; Moragues, A. Effect of silica fume fineness on the improvement of portland cement strength performance. Constr. Build. Mater. 2015, 96, 55–64. [Google Scholar] [CrossRef]

- Lei, D.Y.; Guo, L.P.; Sun, W.; Liu, J.; Shu, X.; Guo, X.L. A new dispersing method on silica fume and its influence on the performance of cement-based materials. Constr. Build. Mater. 2016, 115, 716–726. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Z.P.; Wang, P.M. Effects of polymers on properties of underwater antiwashout self-compacting concrete. In The SCC’2005-China: 1st International Symposium on Design, Performance and Use of Self-Consolidating Concrete; RILEM Publications SARL: Paris, France, 2005; pp. 153–160. [Google Scholar]

- Han, B.; Zhang, L.; Ou, J. Non-Dispersible Underwater Concrete. Smart and Multifunctional Concrete toward Sustainable Infrastructures; Springer: Singapore, 2017. [Google Scholar]

- Dong, X.; Wang, S.; Gong, C.; Lu, L. Effects of aggregate gradation and polymer modifiers on properties of cement-eps/vitrified microsphere mortar. Construct. Build. Mater. 2014, 73, 255–260. [Google Scholar] [CrossRef]

- Teng, Z.H. Study on mechanism and application of redispersible emulsion powder. Chin. Adhes. 2008, 17, 43–45. [Google Scholar]

- Tao, W.H.; Wu, B.; Fu, X.H.; Liu, C. Influence of polymer on properties of sulphoaluminate cement waterproof mortar. Appl. Mech. Mater. 2015, 740, 43–46. [Google Scholar] [CrossRef]

- Zhao, H.X.; Hua, T.F.; Ma, X.J.; Zhou, H. Study of the effects of redisperable emulsion powder on the properties of concert structure. Concrete 2015, 6, 121–123. [Google Scholar]

| Type | SiO2 | AL2O3 | Fe2O3 | Ca O + MgO2 | K2O + Na2O | Loss | Water |

|---|---|---|---|---|---|---|---|

| Cement | 21.28 | 5.32 | 3.37 | 70.15 | - | 0.74 | - |

| SF | ≥90 | ≤1.5 | ≤2 | ≤2 | ≤2 | - | ≤5 |

| Density (g·cm−3) | Diameter (μm) | Length (mm) | Fracture Strength (MPa) | Fracture Elongation (%) | Young‘s Modulus (GPa) | Melting Point (°C) |

|---|---|---|---|---|---|---|

| 0.91 | 31 | 9 | ≥400 | ≤2 | ≥3.5 | 160 |

| Bulk Density (g·cm−3) | Diameter (μm) | Viscosity of 50% Aqueous Solution (mm) | Solid Content (%) | Ash Content (1000 °C) (%) |

|---|---|---|---|---|

| 0.4–0.6 | 80 | ≥10 | 98 | 15 ± 2 |

| w/c | PP (%) | SF (%) | Compressive Strength (MPa) | Flexural Strength (MPa) | Bleeding Rate (%) | Gel Time (min) | |

|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | ||||||

| 0.8 | 0.0 | 0 | 6.04 | 1.67 | 10.80 | 682 | 1293 |

| 0.0 | 5 | 6.26 | 1.78 | 6.67 | 630 | 1212 | |

| 0.0 | 10 | 6.91 | 1.89 | 2.92 | 605 | 1185 | |

| 0.0 | 15 | 6.56 | 1.51 | 0.00 | 600 | 1170 | |

| 0.1 | 0 | 6.11 | 1.68 | 10.50 | 683 | 1295 | |

| 0.1 | 5 | 6.14 | 1.68 | 6.45 | 635 | 1212 | |

| 0.1 | 10 | 7.63 | 1.98 | 2.63 | 605 | 1185 | |

| 0.1 | 15 | 7.12 | 1.87 | 0.00 | 600 | 1170 | |

| 0.3 | 0 | 6.18 | 1.72 | 10.16 | 683 | 1295 | |

| 0.3 | 5 | 6.22 | 1.78 | 5.87 | 635 | 1215 | |

| 0.3 | 10 | 7.88 | 2.12 | 2.43 | 605 | 1185 | |

| 0.3 | 15 | 7.26 | 1.98 | 0.00 | 600 | 1170 | |

| 0.5 | 0 | 6.26 | 1.81 | 10.02 | 685 | 1295 | |

| 0.5 | 5 | 6.31 | 1.88 | 5.65 | 635 | 1210 | |

| 0.5 | 10 | 8.03 | 2.23 | 1.68 | 600 | 1185 | |

| 0.5 | 15 | 7.38 | 2.08 | 0.00 | 600 | 1180 | |

| 1.0 | 0.0 | 0 | 4.84 | 1.45 | 20.40 | 713 | 1320 |

| 0.0 | 5 | 5.56 | 1.62 | 11.67 | 695 | 1300 | |

| 0.0 | 10 | 4.76 | 1.39 | 5.00 | 655 | 1260 | |

| 0.0 | 15 | 4.79 | 1.06 | 2.92 | 625 | 1230 | |

| 0.1 | 0 | 5.08 | 1.53 | 18.58 | 713 | 1320 | |

| 0.1 | 5 | 5.92 | 1.59 | 10.23 | 685 | 1300 | |

| 0.1 | 10 | 5.41 | 1.24 | 4.87 | 660 | 1260 | |

| 0.1 | 15 | 5.09 | 1.15 | 2.79 | 655 | 1230 | |

| 0.3 | 0 | 5.25 | 1.59 | 18.33 | 713 | 1320 | |

| 0.3 | 5 | 6.03 | 1.61 | 10.10 | 685 | 1295 | |

| 0.3 | 10 | 5.52 | 1.28 | 4.65 | 665 | 1255 | |

| 0.3 | 15 | 4.95 | 1.08 | 2.67 | 655 | 1255 | |

| 0.5 | 0 | 5.31 | 1.61 | 18.92 | 712 | 1320 | |

| 0.5 | 5 | 6.07 | 1.68 | 5.12 | 685 | 1295 | |

| 0.5 | 10 | 5.62 | 1.35 | 4.21 | 660 | 1255 | |

| 0.5 | 15 | 4.82 | 0.99 | 2.73 | 650 | 1255 | |

| 1.2 | 0.0 | 0 | 4.06 | 1.05 | 31.25 | 745 | 1360 |

| 0.0 | 5 | 4.21 | 1.11 | 25.83 | 715 | 1330 | |

| 0.0 | 10 | 3.67 | 0.55 | 17.50 | 680 | 1305 | |

| 0.0 | 15 | 2.56 | 0.46 | 5.00 | 660 | 1290 | |

| 0.1 | 0 | 4.45 | 1.09 | 30.83 | 745 | 1360 | |

| 0.1 | 5 | 4.74 | 1.16 | 25 | 715 | 1330 | |

| 0.1 | 10 | 3.88 | 0.59 | 16.70 | 680 | 1305 | |

| 0.1 | 15 | 2.64 | 0.48 | 4.63 | 660 | 1290 | |

| 0.3 | 0 | 4.21 | 1.06 | 29.92 | 745 | 1360 | |

| 0.3 | 5 | 4.66 | 1.13 | 23.83 | 715 | 1330 | |

| 0.3 | 10 | 3.82 | 0.55 | 15.84 | 680 | 1305 | |

| 0.3 | 15 | 2.52 | 0.42 | 4.22 | 660 | 1290 | |

| 0.5 | 0 | 4.13 | 0.61 | 29.58 | 745 | 1360 | |

| 0.5 | 5 | 4.57 | 1.11 | 22.76 | 715 | 1330 | |

| 0.5 | 10 | 3.75 | 0.45 | 14.35 | 680 | 1305 | |

| 0.5 | 15 | 2.38 | 0.35 | 3.43 | 660 | 1290 | |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 77.729 a | 8 | 9.716 | 26.750 | 0.000 |

| Intercept | 1339.431 | 1 | 1339.431 | 3687.640 | 0.000 |

| wc | 72.143 | 2 | 36.072 | 99.311 | 0.000 |

| PP | 1.124 | 3 | 0.375 | 1.032 | 0.389 |

| SF | 4.461 | 3 | 1.487 | 4.094 | 0.013 |

| Error | 14.166 | 39 | 0.363 | ||

| Total | 1431.325 | 48 | |||

| Corrected Total | 91.894 | 47 |

| w/c | Strength of Portland Cement (MPa) | Strength of Composite Slurry (MPa) | Strength Increase Rate (%) | |||

|---|---|---|---|---|---|---|

| Compressive Strength | Flexural Strength | Compressive Strength | Flexural Strength | Compressive Strength | Flexural Strength | |

| 0.8 | 6.04 | 1.67 | 8.03 | 2.23 | 32.9 | 33.5 |

| 1.0 | 4.84 | 1.45 | 6.07 | 1.68 | 25.4 | 15.9 |

| 1.2 | 4.06 | 1.05 | 4.74 | 1.16 | 16.7 | 10.5 |

| w/c | Bleeding Rate of the Portland Cement (%) | Bleeding Rate of the Composite Slurry (%) | Change Rate of Bleeding (%) |

|---|---|---|---|

| 0.8 | 10.80 | 1.68 | 84.40 |

| 1.0 | 20.40 | 7.88 | 61.37 |

| 1.2 | 31.25 | 25.00 | 20.00 |

| w/c | Fluidity of Portland Cement (mm) | Fluidity of Composite Slurry (mm) | Change Rate of Fluidity (%) |

|---|---|---|---|

| 0.8 | 180 | 132 | 26.7 |

| 1.0 | 340 | 265 | 22.1 |

| 1.2 | 400 | 335 | 16.3 |

| w/c | v (m/s) | GRR (%) | Growth Rate of GRR (%) | |||

|---|---|---|---|---|---|---|

| Plain Cement Slurry | Fiber-SF Slurry | Fiber-SF-REP Slurry | Fiber-SF Slurry Compared to Portland Cement | Fiber-SF-REP Slurry Compared to Fiber-SF Slurry | ||

| 0.8 | 0.2 | 87.7 | 98.7 | 99.2 | 12.5 | 0.5 |

| 0.8 | 0.4 | 34.3 | 63.1 | 80.3 | 84.3 | 27.2 |

| 0.8 | 0.6 | 0.0 | 31.3 | 61.3 | / | 96.2 |

| 1.0 | 0.2 | 78.9 | 92.8 | 97.9 | 17.7 | 5.5 |

| 1.0 | 0.4 | 10.3 | 42.0 | 67.1 | 309.4 | 59.9 |

| 1.0 | 0.6 | 0.0 | 18.6 | 52.1 | / | 180.1 |

| 1.2 | 0.2 | 54.4 | 89.4 | 93.4 | 64.4 | 4.5 |

| 1.2 | 0.4 | 5.6 | 25.1 | 49.5 | 347.8 | 96.9 |

| 1.2 | 0.6 | 0.0 | 7.4 | 31.6 | / | 326.7 |

| w/c | Strength (MPa) | Bleeding Rate (%) | Fluidity (mm) | Gel Time (min) | ||

|---|---|---|---|---|---|---|

| Compressive Strength | Flexural Strength | Initial Setting | Final Setting | |||

| 0.8 | 10.66 | 2.32 | 1.42 | 139 | 645 | 1230 |

| 1.0 | 8.25 | 1.78 | 4.26 | 287 | 715 | 1325 |

| 1.2 | 6.34 | 1.37 | 21.3 | 372 | 735 | 1365 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Li, X.; Saffari, P.; Liang, Q.; Li, L.; Chen, W. Developing a Polypropylene Fabric, Silica Fume, and Redispersible Emulsion Powder Cementitious Composite for Dynamic Water Environment. Polymers 2019, 11, 47. https://doi.org/10.3390/polym11010047

Liu J, Li X, Saffari P, Liang Q, Li L, Chen W. Developing a Polypropylene Fabric, Silica Fume, and Redispersible Emulsion Powder Cementitious Composite for Dynamic Water Environment. Polymers. 2019; 11(1):47. https://doi.org/10.3390/polym11010047

Chicago/Turabian StyleLiu, Jinquan, Xiaofei Li, Pooya Saffari, Qichao Liang, Ling Li, and Weizhong Chen. 2019. "Developing a Polypropylene Fabric, Silica Fume, and Redispersible Emulsion Powder Cementitious Composite for Dynamic Water Environment" Polymers 11, no. 1: 47. https://doi.org/10.3390/polym11010047