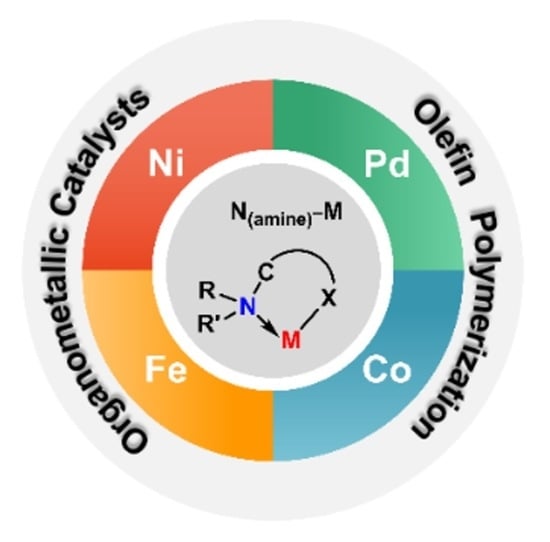

Late Transition Metal Catalysts with Chelating Amines for Olefin Polymerization

Abstract

:1. Introduction

2. Late Transition Metal Catalysts with Amine Donors

2.1. Nickel and Palladium Catalysts with Amine–Imine Ligands

2.2. Nickel, Palladium, and Iron Catalysts with Amine–Pyridine Ligands

2.3. Nickel and Palladium Complexes with α-Diamine Ligands

2.4. Nickel, Iron, and Cobalt Catalysts Bearing [N, N, N] Tridentate Ligands with Amine Donors

3. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MAO | Methylaluminoxane |

| CGC | Constrained geometry catalyst |

| POE | Polyolefin elastomers |

| OBCs | Olefin block copolymers |

| SHOP | Shell higher olefin process |

| DFT | Density functional theory |

| TMA | Trimethylaluminum |

| PE | Polyethylene |

| PH | Polyhexene |

| NB | Norbornene |

| PNB | Polynorbornene |

| PE–OH | Hydroxyl-terminated polyethylene |

| ROP | Ring-opening polymerization |

| PE–NH2 | Amino-terminated polyethylene |

| BLG–NCA | γ-Benzyl-L-glutamate-N-carboxyanhydride |

| NaBArF | Sodium tetrakis (3,5-bis(trifluoromethyl)phenyl)borate |

| MA | Methyl acrylate |

| BPE–(OH)n | Branched polyethylenes with multiple hydroxyls |

| NIPAM | N-isopropylacrylamide |

| PNIPAM | Poly (N-isopropylacrylamide) |

| Macro-CTAs | Macro–chain transfer agents |

| COC | Cyclic olefin copolymer |

| DME | Ethylene glycol dimethyl ether |

References

- Stürzel, M.; Mihan, S.; Mülhaupt, R. From multisite polymerization catalysis to sustainable materials and all-polyolefin composites. Chem. Rev. 2016, 116, 1398–1433. [Google Scholar] [CrossRef] [PubMed]

- Chadwick, J.C. Polyolefins—Catalyst and process innovations and their impact on polymer properties. Macromol. React. Eng. 2009, 3, 428–432. [Google Scholar] [CrossRef]

- Qiao, J.; Guo, M.; Wang, L.; Liu, D.; Zhang, X.; Yu, L.; Song, W.; Liu, Y. Recent advances in polyolefin technology. Polym. Chem. 2011, 2, 1611–1623. [Google Scholar] [CrossRef]

- Bahri-Laleh, N.; Hanifpour, A.; Mirmohammadi, S.A.; Poater, A.; Nekoomanesh-Haghighi, M.; Talarico, G.; Cavallo, L. Computational modeling of heterogeneous Ziegler-Natta catalysts for olefins polymerization. Prog. Polym. Sci. 2018, 84, 89–114. [Google Scholar] [CrossRef]

- Pelletier, J.D.A.; Basset, J.M. Catalysis by design: Well-defined single-site heterogeneous catalysts. Acc. Chem. Res. 2016, 49, 664–677. [Google Scholar] [CrossRef] [Green Version]

- Jehanno, C.; Alty, J.W.; Roosen, M.; De Meester, S.; Dove, A.P.; Chen, E.Y.X.; Leibfarth, F.A.; Sardon, H. Critical advances and future opportunities in upcycling commodity polymers. Nature 2022, 603, 803–814. [Google Scholar] [CrossRef]

- Kaminsky, W. The discovery of metallocene catalysts and their present state of the art. J. Polym. Sci. Part A Polym. Chem. 2004, 42, 3911–3921. [Google Scholar] [CrossRef]

- Batistini, A. New polyolefin plastomers and elastomers made with Insite™ technology: Structure-property relationship and benefits in flexible thermoplastic applications. Macromol. Symp. 1995, 100, 137–142. [Google Scholar] [CrossRef]

- Boussie, T.R.; Diamond, G.M.; Goh, C.; Hall, K.A.; LaPointe, A.M.; Leclerc, M.K.; Murphy, V.; Shoemaker, J.A.W.; Turner, H.; Rosen, R.K.; et al. Nonconventional catalysts for isotactic propene polymerization in solution developed by using high-throughput-screening technologies. Angew. Chem. 2006, 118, 3356–3361. [Google Scholar] [CrossRef]

- Arriola, D.J.; Carnahan, E.M.; Hustad, P.D.; Kuhlman, R.L.; Wenzel, T.T. Catalytic production of olefin block copolymers via chain shuttling polymerization. Science 2006, 312, 714–721. [Google Scholar] [CrossRef]

- Wang, S.; Wang, L.; Zhong, L.; Xu, R.; Wang, X.; Kang, W.; Gao, H.Y. C1-Symmetric tert-butyl substituted pyridylamido hafnium complex for ethylene, α-olefin, and styrene polymerizations. Eur. Polym. J. 2020, 131, 109709. [Google Scholar] [CrossRef]

- Wang, L.; Li, D.; Ren, H.; Wang, Y.; Wu, W.; Gao, Y.; Wang, X.; Gao, H.Y. Isoselective 4-methylpentene polymerization by pyridylamido hafnium catalysts. Polym. Chem. 2021, 12, 3556–3563. [Google Scholar] [CrossRef]

- Wang, L.Z.; Ni, X.Q.; Ren, H.; Gao, Y.X.; Gao, H.Y. Homo- and copolymerization of 4-methyl-1-pentene and 1-hexene with pyridylamido hafnium catalyst. Acta Polym. Sin. 2021, 52, 1481–1487. [Google Scholar]

- Kuhn, P.; Semeril, D.; Matt, D.; Chetcuti, M.J.; Lutz, P. Structure-reactivity relationships in SHOP-type complexes: Tunable catalysts for the oligomerisation and polymerisation of ethylene. Dalton Trans. 2007, 5, 515–528. [Google Scholar] [CrossRef]

- Johnson, L.K.; Killian, C.M.; Brookhart, M. New Pd(II)- and Ni(II)-based catalysts for polymerization of ethylene and α-olefins. J. Am. Chem. Soc. 1995, 117, 6414–6415. [Google Scholar] [CrossRef]

- Liu, F.S.; Hu, H.B.; Xu, Y.; Guo, L.H.; Zai, S.B.; Song, K.M.; Gao, H.Y.; Zhang, L.; Zhu, F.M.; Wu, Q. Thermostable α-diimine nickel(II) catalyst for ethylene polymerization: Effects of the substituted backbone structure on catalytic properties and branching structure of polyethylene. Macromolecules 2009, 42, 7789–7796. [Google Scholar] [CrossRef]

- Gao, H.Y.; Liu, X.; Tang, Y.; Pan, J.; Wu, Q. Living/controlled polymerization of 4-methyl-1-pentene with α-diimine nickel-diethylaluminium chloride: Effect of alkylaluminium cocatalysts. Polym. Chem. 2011, 2, 1398–1403. [Google Scholar] [CrossRef]

- Gao, H.Y.; Pan, J.; Guo, L.H.; Xiao, D.; Wu, Q. Polymerization of 4-methyl-1-pentene catalyzed by α-diimine nickel catalysts: Living/controlled behavior, branch structure, and mechanism. Polymer 2011, 52, 130–137. [Google Scholar] [CrossRef]

- Guo, L.H.; Gao, H.Y.; Li, L.; Wu, Q. Complex branched polyolefin generated from quasi-living polymerization of 4-methyl-1-pentene catalyzed by α-diimine palladium catalyst. Macromol. Chem. Phys. 2011, 212, 2029–2035. [Google Scholar] [CrossRef]

- Guo, L.H.; Gao, H.Y.; Guan, Q.R.; Hu, H.B.; Deng, J.; Liu, J.; Liu, F.S.; Wu, Q. Substituent effects of the backbone in α-diimine palladium catalysts on homo- and copolymerization of ethylene with methyl acrylate. Organometallics 2012, 31, 6054–6062. [Google Scholar] [CrossRef]

- Liu, F.S.; Gao, H.Y.; Hu, Z.; Hu, H.B.; Zhu, F.M.; Wu, Q. Poly(1-hexene) with long methylene sequences and controlled branches obtained by a thermostable α-diimine nickel catalyst with bulky camphyl backbone. J. Polym. Sci. Part A Polym. Chem. 2012, 50, 3859–3866. [Google Scholar] [CrossRef]

- Shi, X.; Zhao, Y.; Gao, H.Y.; Zhang, L.; Zhu, F.M.; Wu, Q. Synthesis of hyperbranched polyethylene amphiphiles by chain walking polymerization in tandem with RAFT polymerization and supramolecular self-assembly vesicles. Macromol. Rapid Commun. 2012, 33, 374–379. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.Y.; Liu, F.S.; Hu, H.B.; Zhu, F.M.; Wu, Q. Synthesis of bimodal polyethylene with unsymmetrical α-diimine nickel complexes: Influence of ligand backbone and unsym-substituted aniline moiety. Chin. J. Polym. Sci. 2013, 31, 563–573. [Google Scholar] [CrossRef]

- Lian, K.; Zhu, Y.; Li, W.; Dai, S.; Chen, C. Direct synthesis of thermoplastic polyolefin elastomers from nickel catalyzed ethylene polymerization. Macromolecules 2017, 50, 6074–6080. [Google Scholar] [CrossRef]

- Liu, J.; Chen, D.; Wu, H.; Xiao, Z.; Gao, H.Y.; Zhu, F.M.; Wu, Q. Polymerization of α-olefins using a camphyl α-diimine nickel catalyst at elevated temperature. Macromolecules 2014, 47, 3325–3331. [Google Scholar] [CrossRef]

- Zhong, L.; Li, G.L.; Liang, G.D.; Gao, H.Y.; Wu, Q. Enhancing thermal stability and living fashion in α-diimine–nickel-catalyzed (co)polymerization of ethylene and polar monomer by increasing the steric bulk of ligand backbone. Macromolecules 2017, 50, 2675–2682. [Google Scholar] [CrossRef]

- Zhong, S.H.; Tan, Y.X.; Zhong, L.; Gao, J.; Liao, H.; Jiang, L.; Gao, H.Y.; Wu, Q. Precision synthesis of ethylene and polar monomer copolymers by palladium-catalyzed living coordination copolymerization. Macromolecules 2017, 50, 5661–5669. [Google Scholar] [CrossRef]

- Chen, X.L.; Gao, J.; Liao, H.; Gao, H.Y.; Wu, Q. Synthesis, characterization, and catalytic ethylene oligomerization of pyridine-imine palladium complexes. Chin. J. Polym. Sci. 2018, 36, 176–184. [Google Scholar] [CrossRef]

- Gao, J.; Ying, Z.H.; Zhong, L.; Liao, H.; Gao, H.Y.; Wu, Q. Regioselective living polymerization of allylcyclohexane and precise synthesis of hydrocarbon block copolymers with cyclic units. Polym. Chem. 2018, 9, 1109–1115. [Google Scholar] [CrossRef]

- Pei, L.X.; Liu, F.S.; Liao, H.; Gao, J.; Zhong, L.; Gao, H.Y.; Wu, Q. Synthesis of polyethylenes with controlled branching with α-diimine nickel catalysts and revisiting formation of long-chain branching. ACS Catal. 2018, 8, 1104–1113. [Google Scholar] [CrossRef]

- Xiao, Z.F.; Zheng, H.D.; Du, C.; Zhong, L.; Liao, H.; Gao, J.; Gao, H.Y.; Wu, Q. Enhancement on alternating copolymerization of carbon monoxide and styrene by dibenzobarrelene-based α-diimine palladium catalysts. Macromolecules 2018, 51, 9110–9121. [Google Scholar] [CrossRef]

- Du, C.; Zhong, L.; Gao, J.; Zhong, S.H.; Liao, H.; Gao, H.Y.; Wu, Q. Living (co)polymerization of ethylene and bio-based furfuryl acrylate using dibenzobarrelene derived α-diimine palladium catalysts. Polym. Chem. 2019, 10, 2029–2038. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, L.; Zhong, L.; Du, C.; Liao, H.; Gao, H.Y.; Wu, Q. Living isomerization polymerizations of alkenylcyclohexane with camphyl α-diimine nickel catalysts. Polymer 2019, 164, 26–32. [Google Scholar] [CrossRef]

- Zhong, L.; Du, C.; Liao, G.F.; Liao, H.; Zheng, H.D.; Wu, Q.; Gao, H.Y. Effects of backbone substituent and intra-ligand hydrogen bonding interaction on ethylene polymerizations with α-diimine nickel catalysts. J. Catal. 2019, 375, 113–123. [Google Scholar] [CrossRef]

- Du, C.; Chu, H.; Xiao, Z.F.; Zhong, L.; Zhou, Y.S.; Qin, W.; Liang, G.D.; Gao, H.Y. Alternating vinylarene–carbon monoxide copolymers: Simple and efficient nonconjugated luminescent macromolecules. Macromolecules 2020, 53, 9337–9344. [Google Scholar] [CrossRef]

- Liao, G.F.; Xiao, Z.F.; Chen, X.L.; Du, C.; Zhong, L.; Cheung, C.S.; Gao, H.Y. Fast and regioselective polymerization of para-alkoxystyrene by palladium catalysts for precision production of high-molecular-weight polystyrene derivatives. Macromolecules 2020, 53, 256–266. [Google Scholar] [CrossRef]

- Zhong, L.; Zheng, H.D.; Du, C.; Du, W.B.; Liao, G.F.; Cheung, C.S.; Gao, H.Y. Thermally robust α-diimine nickel and palladium catalysts with constrained space for ethylene (co)polymerizations. J. Catal. 2020, 384, 208–217. [Google Scholar] [CrossRef]

- Du, C.; Cheung, C.S.; Zheng, H.D.; Li, D.H.; Du, W.B.; Gao, H.; Liang, G.D.; Gao, H.Y. Bathochromic-shifted emissions by postfunctionalization of nonconjugated polyketones. ACS Appl. Mater. Interfaces 2021, 13, 59288–59297. [Google Scholar] [CrossRef]

- Ruan, J.J.; Zheng, H.D.; Jiang, Y.; Wang, L.B.; Wang, S.H.; Gao, H.Y. Synthesis and catalytic performance of α-diimine nickel and palladium complexes for oligomerization of decene mixture. Acta Polym. Sin. 2021, 52, 1603–1610. [Google Scholar]

- Xiao, Z.F.; Zhong, L.; Du, C.; Du, W.B.; Zheng, H.D.; Cheung, C.S.; Wang, L.B.; Gao, H.Y. Unprecedented steric and positioning effects of comonomer substituents on α-diimine palladium-catalyzed vinyl arene/co copolymerization. Macromolecules 2021, 54, 687–695. [Google Scholar] [CrossRef]

- Zheng, H.D.; Zhong, L.; Du, C.; Du, W.B.; Cheung, C.S.; Ruan, J.J.; Gao, H.Y. Combining hydrogen bonding interactions with steric and electronic modifications for thermally robust α-diimine palladium catalysts toward ethylene (co)polymerization. Catal. Sci. Technol. 2021, 11, 124–135. [Google Scholar] [CrossRef]

- Du, W.B.; Zheng, H.D.; Li, Y.W.; Cheung, C.S.; Li, D.H.; Gao, H.; Deng, H.Y.; Gao, H.Y. Neutral tridentate α-sulfonato-β-diimine nickel catalyst for (co)polymerizations of ethylene and acrylates. Macromolecules 2022, 55, 3096–3105. [Google Scholar] [CrossRef]

- Zheng, H.D.; Li, Y.W.; Du, W.B.; Cheung, C.S.; Li, D.H.; Gao, H.; Deng, H.Y.; Gao, H.Y. Unprecedented square-planar α-diimine dibromonickel complexes and their ethylene polymerizations modulated by Ni–phenyl interactions. Macromolecules 2022, 55, 3533–3540. [Google Scholar] [CrossRef]

- Tan, C.; Chen, C. Emerging palladium and nickel catalysts for copolymerization of olefins with polar monomers. Angew. Chem. Int. Ed. 2019, 58, 7192–7200. [Google Scholar] [CrossRef]

- Wang, F.; Chen, C. A continuing legend: The Brookhart-type α-diimine nickel and palladium catalysts. Polym. Chem. 2019, 10, 2354–2369. [Google Scholar] [CrossRef] [Green Version]

- Mu, H.; Zhou, G.; Hu, X.; Jian, Z. Recent advances in nickel mediated copolymerization of olefin with polar monomers. Coord. Chem. Rev. 2021, 435, 213802. [Google Scholar] [CrossRef]

- Qasim, M.; Bashir, M.S.; Iqbal, S.; Mahmood, Q. Recent advancements in α-diimine-nickel and -palladium catalysts for ethylene polymerization. Eur. Polym. J. 2021, 160, 110783. [Google Scholar] [CrossRef]

- Zhou, G.; Cui, L.; Mu, H.; Jian, Z. Custom-made polar monomers utilized in nickel and palladium promoted olefin copolymerization. Polym. Chem. 2021, 12, 3878–3892. [Google Scholar] [CrossRef]

- Ittel, S.D.; Johnson, L.K.; Brookhart, M. Late-metal catalysts for ethylene homo- and copolymerization. Chem. Rev. 2000, 100, 1169–1204. [Google Scholar] [CrossRef]

- Gibson, V.C.; Redshaw, C.; Solan, G.A. Bis(imino)pyridines: Surprisingly reactive ligands and a gateway to new families of catalysts. Chem. Rev. 2007, 107, 1745–1776. [Google Scholar] [CrossRef]

- Wang, Z.; Solan, G.A.; Zhang, W.; Sun, W.H. Carbocyclic-fused N,N,N-pincer ligands as ring-strain adjustable supports for iron and cobalt catalysts in ethylene oligo-/polymerization. Coord. Chem. Rev. 2018, 363, 92–108. [Google Scholar] [CrossRef] [Green Version]

- Han, M.; Zhang, Q.; Oleynik, I.I.; Suo, H.; Oleynik, I.V.; Solan, G.A.; Ma, Y.; Liang, T.; Sun, W.H. Adjusting ortho-cycloalkyl ring size in a cycloheptyl-fused N,N,N-iron catalyst as means to control catalytic activity and polyethylene properties. Catalysts 2020, 10, 1002. [Google Scholar] [CrossRef]

- Zhang, J.; Ke, Z.F.; Bao, F.; Long, J.M.; Gao, H.Y.; Zhu, F.M.; Wu, Q. Ethylene polymerization and oligomerization catalyzed by bulky β-diketiminato Ni(II) and β-diimine Ni(II) complexes/methylaluminoxane systems. J. Mol. Catal. A Chem. 2006, 249, 31–39. [Google Scholar] [CrossRef]

- Azoulay, J.D.; Rojas, R.S.; Serrano, A.V.; Ohtaki, H.; Galland, G.B.; Wu, G.; Bazan, G.C. Nickel α-keto-beta-diimine initiators for olefin polymerization. Angew. Chem. Int. Ed. Engl. 2009, 48, 1089–1092. [Google Scholar] [CrossRef]

- Azoulay, J.D.; Schneider, Y.; Galland, G.B.; Bazan, G.C. Living polymerization of ethylene and α-olefins using a nickel α-keto-beta-diimine initiator. Chem. Commun. 2009, 41, 6177–6179. [Google Scholar] [CrossRef]

- Eckert, N.A.; Bones, E.M.; Lachicotte, R.J.; Holland, P.L. Nickel complexes of a bulky β-diketiminate ligand. Inorg. Chem. 2003, 42, 1720–1725. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, H.Y.; Ke, Z.F.; Bao, F.; Zhu, F.M.; Wu, Q. Investigation of 1-hexene isomerization and oligomerization catalyzed with β-diketiminato Ni(II) bromide complexes/methylaluminoxane system. J. Mol. Catal. A Chem. 2005, 231, 27–34. [Google Scholar] [CrossRef]

- Matsui, S.; Mitani, M.; Saito, J.; Tohi, Y.; Makio, H.; Tanaka, H.; Fujita, T. Post-metallocenes: A new bis(salicylaldiminato) zirconium complex for ethylene polymerization. Chem. Lett. 1999, 28, 1263–1264. [Google Scholar] [CrossRef]

- Matsui, S.; Tohi, Y.; Mitani, M.; Saito, J.; Makio, H.; Tanaka, H.; Nitabaru, M.; Nakano, T.; Fujita, T. New bis(salicylaldiminato) titanium complexes for ethylene polymerization. Chem. Lett. 1999, 28, 1065–1066. [Google Scholar] [CrossRef]

- Bianchini, C.; Giambastiani, G.; Luconi, L.; Meli, A. Olefin oligomerization, homopolymerization and copolymerization by late transition metals supported by (imino)pyridine ligands. Coord. Chem. Rev. 2010, 254, 431–455. [Google Scholar] [CrossRef]

- Small, B.L.; Brookhart, M.; Bennett, A.M.A. Highly active iron and cobalt catalysts for the polymerization of ethylene. J. Am. Chem. Soc. 1998, 120, 4049–4050. [Google Scholar] [CrossRef]

- Gao, H.Y.; Pei, L.X.; Song, K.; Wu, Q. Styrene polymerization with novel anilido–imino nickel complexes/MAO catalytic system: Catalytic behavior, microstructure of polystyrene and polymerization mechanism. Eur. Polym. J. 2007, 43, 908–914. [Google Scholar] [CrossRef]

- Gao, H.Y.; Chen, Y.; Zhu, F.M.; Wu, Q. Copolymerization of norbornene and styrene catalyzed by a novel anilido–imino nickel complex/methylaluminoxane system. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 5237–5246. [Google Scholar] [CrossRef]

- Gao, H.Y.; Wang, G.; Bao, F.; Gui, G.Q.; Zhang, J.K.; Zhu, F.M.; Wu, Q. Synthesis, molecular structure, and solution-dependent behavior of nickel complexes chelating anilido-imine donors and their catalytic activity toward olefin polymerization. Organometallics 2004, 23, 6273–6280. [Google Scholar] [CrossRef]

- Gao, H.Y.; Ke, Z.F.; Pei, L.X.; Song, K.; Wu, Q. Drastic ligand electronic effect on anilido–imino nickel catalysts toward ethylene polymerization. Polymer 2007, 48, 7249–7254. [Google Scholar] [CrossRef]

- Gao, H.Y.; Zhang, J.; Chen, Y.; Zhu, F.M.; Wu, Q. Vinyl-polymerization of norbornene with novel anilido–imino nickel complexes/methylaluminoxane: Abnormal influence of polymerization temperature on molecular weight of polynorbornenes. J. Mol. Catal. A Chem. 2005, 240, 178–185. [Google Scholar] [CrossRef]

- Hu, W.Q.; Sun, X.L.; Wang, C.; Gao, Y.; Tang, Y.; Shi, L.P.; Xia, W.; Sun, J.; Dai, H.L.; Li, X.Q.; et al. Synthesis and characterization of novel tridentate [NOP] titanium complexes and their application to copolymerization and polymerization of ethylene. Organometallics 2004, 23, 1684–1688. [Google Scholar] [CrossRef]

- Lamberti, M.; Bortoluzzi, M.; Paolucci, G.; Pellecchia, C. Synthesis and olefin polymerization activity of (quinolin-8-ylamino)phenolate and (quinolin-8-ylamido)phenolate Group 4 metal complexes. J. Mol. Catal. A Chem. 2011, 351, 112–119. [Google Scholar] [CrossRef]

- Press, K.; Cohen, A.; Goldberg, I.; Venditto, V.; Mazzeo, M.; Kol, M. Salalen titanium complexes in the highly isospecific polymerization of 1-hexene and propylene. Angew. Chem. Int. Ed. 2011, 50, 3529–3532. [Google Scholar] [CrossRef]

- Tshuva, E.Y.; Goldberg, I.; Kol, M.; Weitman, H.; Goldschmidt, Z. Novel zirconium complexes of amine bis(phenolate) ligands. Remarkable reactivity in polymerization of hex-1-ene due to an extra donor arm. Chem. Commun. 2000, 5, 379–380. [Google Scholar] [CrossRef]

- Bisz, E.; Białek, M.; Zarychta, B. Synthesis, characterization and catalytic properties for olefin polymerization of two new dimeric zirconium(IV) complexes having diamine-bis(phenolate) and chloride ligands. Appl. Catal. A 2015, 503, 26–33. [Google Scholar] [CrossRef]

- Tshuva, E.Y.; Goldberg, I.; Kol, M.; Goldschmidt, Z. Living polymerization and block copolymerization of α-olefins by an amine bis(phenolate) titanium catalyst. Chem. Commun. 2001, 20, 2120–2121. [Google Scholar] [CrossRef] [PubMed]

- Zai, S.B.; Gao, H.Y.; Huang, Z.; Hu, H.B.; Wu, H.; Wu, Q. Substituent effects of pyridine-amine nickel catalyst precursors on ethylene polymerization. ACS Catal. 2012, 2, 433–440. [Google Scholar] [CrossRef]

- Hu, H.B.; Zhang, L.; Gao, H.Y.; Zhu, F.M.; Wu, Q. Design of thermally stable amine-imine nickel catalyst precursors for living polymerization of ethylene: Effect of ligand substituents on catalytic behavior and polymer properties. Chem. Eur. J. 2014, 20, 3225–3233. [Google Scholar] [CrossRef]

- Nomura, K.; Fukuda, H.; Katao, S.; Fujiki, M.; Kim, H.J.; Kim, D.H.; Zhang, S. Effect of ligand substituents in olefin polymerisation by half-sandwich titanium complexes containing monoanionic iminoimidazolidide ligands-MAO catalyst systems. Dalton. Trans. 2011, 40, 7842–7849. [Google Scholar] [CrossRef]

- Wang, W.; Yamada, J.; Fujiki, M.; Nomura, K. Effect of aryloxo ligand for ethylene polymerization by (arylimido)(aryloxo)vanadium(V) complexes–MAO catalyst systems: Attempt for polymerization of styrene. Catal. Commun. 2003, 4, 159–164. [Google Scholar] [CrossRef]

- Qian, J.; Comito, R.J. A robust vanadium(v) tris(2-pyridyl)borate catalyst for long-lived high-temperature ethylene polymerization. Organometallics 2021, 40, 1817–1821. [Google Scholar] [CrossRef]

- Kim, Y.; Han, Y.; Do, Y. New half-sandwich metallocene catalysts for polyethylene and polystyrene. J. Organomet. Chem. 2001, 634, 19–24. [Google Scholar] [CrossRef]

- Yuan, S.F.; Yan, Y.; Solan, G.A.; Ma, Y.; Sun, W.H. Recent advancements in N-ligated Group 4 molecular catalysts for the (co)polymerization of ethylene. Coord. Chem. Rev. 2020, 411, 213254. [Google Scholar] [CrossRef]

- Mitchell, N.E.; Long, B.K. Recent advances in thermally robust, late transition metal-catalyzed olefin polymerization. Polym. Int. 2019, 68, 14–26. [Google Scholar] [CrossRef] [Green Version]

- Chirik, P.J. Iron- and cobalt- catalyzed alkene hydrogenation: Catalysis with both redox-active and strong field ligands. Acc. Chem. Res. 2015, 48, 1687–1695. [Google Scholar] [CrossRef] [Green Version]

- Makio, H.; Kashiwa, N.; Fujita, T. FI Catalysts: A new family of high performance catalysts for olefin polymerization. Adv. Synth. Catal. 2002, 344, 477–493. [Google Scholar] [CrossRef]

- Matsui, S.; Mitani, M.; Saito, J.; Tohi, Y.; Makio, H.; Matsukawa, N.; Takagi, Y.; Tsuru, K.; Nitabaru, M.; Nakano, T.; et al. A family of zirconium complexes having two phenoxy-imine chelate ligands for olefin polymerization. J. Am. Chem. Soc. 2001, 123, 6847–6856. [Google Scholar] [CrossRef]

- Soshnikov, I.E.; Bryliakov, K.P.; Antonov, A.A.; Sun, W.H.; Talsi, E.P. Ethylene polymerization of nickel catalysts with α-diimine ligands: Factors controlling the structure of active species and polymer properties. Dalton Trans. 2019, 48, 7974–7984. [Google Scholar] [CrossRef]

- Hu, H.B.; Gao, H.Y.; Wu, Q. Recent progress in late transition metal catalysts for controlled/living olefin polymerization. Acta Polym. Sin. 2011, 9, 965–972. [Google Scholar] [CrossRef]

- Hu, H.B.; Gao, H.Y.; Zhu, F.M.; Wu, Q. Olefin polymerization catalyzed by nickel complexes bearing [N,N]-bidentate ligands. Sci.China Chem. 2012, 42, 628–635. [Google Scholar]

- Zheng, H.D.; Gao, H.Y.; Du, C.; Wang, L.; Zhong, L.; Gao, H.Y.; Wu, Q. Bulky backbone strategy in α-diimine nickel and palladium catalyzed-olefin polymerization. Polym. Bull. 2021, 6, 81–93. [Google Scholar]

- Cheung, C.S.; Shi, X.; Pei, L.X.; Du, C.; Gao, H.Y.; Qiu, Z.L.; Gao, H.Y. Alternating copolymerization of carbon monoxide and vinyl arenes using [N,N] bidentate palladium catalysts. J. Polym. Sci. 2022, 60, 1448–1467. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Q.; Solan, G.A.; Sun, W.H. Recent advances in Ni-mediated ethylene chain growth: Nimine-donor ligand effects on catalytic activity, thermal stability and oligo-/polymer structure. Coord. Chem. Rev. 2017, 350, 68–83. [Google Scholar] [CrossRef]

- Tan, C.; Zou, C.; Chen, C. Material properties of functional polyethylenes from transition-metal-catalyzed ethylene–polar monomer copolymerization. Macromolecules 2022, 55, 1910–1922. [Google Scholar] [CrossRef]

- Guo, L.; Dai, S.; Sui, X.; Chen, C. Palladium and nickel catalyzed chain walking olefin polymerization and copolymerization. ACS Catal. 2016, 6, 428–441. [Google Scholar] [CrossRef] [Green Version]

- Berkefeld, A.; Mecking, S. Coordination copolymerization of polar vinyl monomers H2C=CHX. Angew. Chem. Int. Ed. 2008, 47, 2538–2542. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Brookhart, M. Exploring ethylene/polar vinyl monomer copolymerizations using Ni and Pd α-diimine catalysts. Acc. Chem. Res. 2018, 51, 1831–1839. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.J.; Yang, F.Z.; Lin, Y.F.; Chang, Y.C.; Yu, K.H.; Chang, M.C.; Lee, G.H.; Liu, Y.H.; Wang, Y.; Liu, S.T.; et al. Unsymmetrical bidentate ligands of α-aminoaldimines leading to sterically controlled selectivity of geometrical isomerism in square planar coordination. Dalton Trans. 2008, 43, 5945–5956. [Google Scholar] [CrossRef]

- Yang, F.Z.; Chen, Y.C.; Lin, Y.F.; Yu, K.H.; Liu, Y.H.; Wang, Y.; Liu, S.T.; Chen, J.T. Nickel catalysts bearing bidentate α-aminoaldimines for ethylene polymerization—independent and cooperative structure/reactivity relationship resulting from unsymmetric square planar coordination. Dalton Trans. 2009, 7, 1243–1250. [Google Scholar] [CrossRef]

- Yang, F.Z.; Wang, Y.H.; Chang, M.C.; Yu, K.H.; Huang, S.L.; Liu, Y.H.; Wang, Y.; Liu, S.T.; Chen, J.T. Kinetic and mechanistic studies of geometrical isomerism in neutral square-planar methylpalladium complexes bearing unsymmetrical bidentate ligands of α-aminoaldimines. Inorg. Chem. 2009, 48, 7639–7644. [Google Scholar] [CrossRef]

- Gao, H.Y.; Hu, H.B.; Zhu, F.M.; Wu, Q. A thermally robust amine-imine nickel catalyst precursor for living polymerization of ethylene above room temperature. Chem. Commun. 2012, 48, 3312–3314. [Google Scholar] [CrossRef]

- Mundil, R.; Hermanová, S.; Peschel, M.; Lederer, A.; Merna, J. On the topology of highly branched polyethylenes prepared by amine−imine nickel and palladium complexes: The effect of ortho-aryl substituents. Polym. Int. 2018, 67, 946–956. [Google Scholar] [CrossRef]

- Gao, H.Y.; Liu, Y.; Li, G.; Xiao, Z.F.; Liang, G.D.; Wu, Q. Catalytic synthesis of polyethylene-block-polynorbornene copolymers using a living polymerization nickel catalyst. Polym. Chem. 2014, 5, 6012–6018. [Google Scholar] [CrossRef]

- Gao, H.Y.; Tan, Y.; Guan, Q.; Cai, T.; Liang, G.D.; Wu, Q. Synthesis, characterization and micellization of amphiphilic polyethylene-b-polyphosphoester block copolymers. RSC Adv. 2015, 5, 49376–49384. [Google Scholar] [CrossRef]

- Gao, H.Y.; Li, G.; Hu, Z.; Xiao, Z.F.; Liang, G.D.; Wu, Q. Synthesis of amphiphilic polyethylene-b-poly(l-glutamate) block copolymers with vastly different solubilities and their stimuli-responsive polymeric micelles in aqueous solution. Polymer 2014, 55, 4593–4600. [Google Scholar] [CrossRef]

- Hu, H.B.; Gao, H.Y.; Chen, D.; Li, G.L.; Tan, Y.; Liang, G.D.; Zhu, F.M.; Wu, Q. Ligand-directed regioselectivity in amine–imine nickel-catalyzed 1-hexene polymerization. ACS Catal. 2014, 5, 122–128. [Google Scholar] [CrossRef]

- Hu, H.B.; Chen, D.; Gao, H.Y.; Zhong, L.; Wu, Q. Amine–imine palladium catalysts for living polymerization of ethylene and copolymerization of ethylene with methyl acrylate: Incorporation of acrylate units into the main chain and branch end. Polym. Chem. 2016, 7, 529–537. [Google Scholar] [CrossRef]

- Peng, D.; Chen, C. Photoresponsive palladium and nickel catalysts for ethylene polymerization and copolymerization. Angew. Chem. Int. Ed. 2021, 60, 22195–22200. [Google Scholar] [CrossRef]

- Huang, Z.F.; Song, K.; Liu, F.S.; Long, J.M.; Hu, H.B.; Gao, H.Y.; Wu, Q. Synthesis and characterization of a series of 2-aminopyridine nickel(II) complexes and their catalytic properties toward ethylene polymerization. J. Polym. Sci. Part A Polym. Chem. 2008, 46, 1618–1628. [Google Scholar] [CrossRef]

- Zai, S.B.; Liu, F.S.; Gao, H.Y.; Li, C.; Zhou, G.Y.; Cheng, S.; Guo, L.H.; Zhang, L.; Zhu, F.M.; Wu, Q. Longstanding living polymerization of ethylene: Substituent effect on bridging carbon of 2-pyridinemethanamine nickel catalysts. Chem. Commun. 2010, 46, 4321–4323. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, H.Y.; Liang, G.D.; Zhu, F.M.; Wu, Q. Synthesis of well-defined amphiphilic branched polyethylene-graft-poly (N-isopropylacrylamide) copolymers by coordination copolymerization in tandem with RAFT polymerization and their self-assembled vesicles. Polym. Chem. 2014, 5, 962–970. [Google Scholar] [CrossRef]

- Lovett, D.M.; Thierer, L.M.; Santos, E.E.P.; Hardie, R.L.; Dougherty, W.G.; Piro, N.A.; Kassel, W.S.; Cromer, B.M.; Coughlin, E.B.; Zubris, D.L. Structural analysis of imino- and amino-pyridine ligands for Ni(II):Precatalysts for the polymerization of ethylene. J. Organomet. Chem. 2018, 863, 44–53. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yu, K.H.; Lin, Y.F.; Lee, G.H.; Wang, Y.; Liu, S.T.; Chen, J.T. Synthesis, structures of (aminopyridine)nickel complexes and their use for catalytic ethylene polymerization. Dalton Trans. 2012, 41, 6661–6670. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yu, K.H.; Huang, S.L.; Liu, Y.H.; Wang, Y.; Liu, S.T.; Chen, J.T. Alternating ethylene-norbornene copolymerization catalyzed by cationic organopalladium complexes bearing hemilabile bidentate ligands of α-amino-pyridines. Dalton Trans. 2009, 41, 9058–9067. [Google Scholar] [CrossRef]

- Yu, K.H.; Huang, S.L.; Liu, Y.H.; Wang, Y.; Liu, S.T.; Cheng, Y.C.; Lin, Y.F.; Chen, J.T. Kinetics, Mechanism and theoretical studies of norbornene-ethylene alternating copolymerization catalyzed by organopalladium(II) complexes bearing hemilabile α-amino–pyridine. Molecules 2017, 22, 1095. [Google Scholar] [CrossRef] [Green Version]

- Jing, C.; Wang, L.; Mahmood, Q.; Zhao, M.; Zhu, G.; Zhang, X.; Wang, X.; Wang, Q. Synthesis and characterization of aminopyridine iron (II) chloride catalysts for isoprene polymerization: Sterically controlled monomer enchainment. Dalton Trans. 2019, 48, 7862–7874. [Google Scholar] [CrossRef]

- Jing, C.; Wang, L.; Zhu, G.; Hou, H.; Zhou, L.; Wang, Q. Enhancing thermal stability in aminopyridine iron(II)-catalyzed polymerization of conjugated dienes. Organometallics 2020, 39, 4019–4026. [Google Scholar] [CrossRef]

- Liao, H.; Zhong, L.; Xiao, Z.F.; Zheng, T.; Gao, H.Y.; Wu, Q. α-Diamine nickel catalysts with nonplanar chelate rings for ethylene polymerization. Chem. Eur.J. 2016, 22, 14048–14055. [Google Scholar] [CrossRef]

- Liao, H.; Gao, J.; Zhong, L.; Gao, H.Y.; Wu, Q. Regioselective polymerizations of α-olefins with an α-diamine nickel catalyst. Chin. J. Polym. Sci. 2019, 37, 959–965. [Google Scholar] [CrossRef]

- Zheng, T.; Liao, H.; Gao, J.; Zhong, L.; Gao, H.Y.; Wu, Q. Synthesis and characterization of α-diamine palladium complexes and insight into hybridization effects of nitrogen donor atoms on norbornene (co)polymerizations. Polym. Chem. 2018, 9, 3088–3097. [Google Scholar] [CrossRef]

- Brooke, L.; Small, M.B. Polymerization of propylene by a new generation of iron catalysts: Mechanisms of chain initiation, propagation, and termination. Macromolecules 1999, 32, 2120–2130. [Google Scholar]

- Britovsek, G.; Gibson, V.; Mastroianni, S.; Oakes, D.; Redshaw, C.; Solan, G.; White, A.; Williams, D. Imine versus amine donors in iron-based ethylene polymerization catalysts. Eur. J. Inorg. Chem. 2001, 2001, 431–437. [Google Scholar] [CrossRef]

- Cariou, R.; Chirinos, J.J.; Gibson, V.C.; Jacobsen, G.; Tomov, A.K.; Britovsek, G.J.; White, A.J. The effect of the central donor in bis(benzimidazole)-based cobalt catalysts for the selective cis-1,4-polymerisation of butadiene. Dalton Trans. 2010, 39, 9039–9045. [Google Scholar] [CrossRef]

- Cowdell, R.; Davies, C.J.; Hilton, S.J.; Marechal, J.D.; Solan, G.A.; Thomas, O.; Fawcett, J. Flexible N,N,N-chelates as supports for iron and cobalt chloride complexes; synthesis, structures, DFT calculations and ethylene oligomerization studies. Dalton Trans. 2004, 20, 3231–3240. [Google Scholar] [CrossRef] [Green Version]

- Obuah, C.; Omondi, B.; Nozaki, K.; Darkwa, J. Solvent and co-catalyst dependent pyrazolylpyridinamine and pyrazolylpyrroleamine nickel(II) catalyzed oligomerization and polymerization of ethylene. J. Mol. Catal. A Chem. 2014, 382, 31–40. [Google Scholar] [CrossRef]

- Pinheiro, A.C.; Virgili, A.H.; Roisnel, T.; Kirillov, E.; Carpentier, J.F.; Casagrande, O.L. Ni(II) complexes bearing pyrrolide-imine ligands with pendant N-, O- and S-donor groups: Synthesis, structural characterization and use in ethylene oligomerization. RSC Adv. 2015, 5, 91524–91531. [Google Scholar] [CrossRef]

- Nyamato, G.S.; Ojwach, S.O.; Akerman, M.P. Ethylene oligomerization studies by nickel(II) complexes chelated by (amino)pyridine ligands: Experimental and density functional theory studies. Dalton Trans. 2016, 45, 3407–3416. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Xing, Q.; Sun, W.H. Frustratingly synergic effect of cobalt–nickel heterometallic precatalysts on ethylene reactivity: The cobalt and its heteronickel complexes bearing 2-methyl-2,4-bis(6-aryliminopyridin-2-yl)-1H-1,5-benzodiazepines. RSC Adv. 2016, 6, 72170–72176. [Google Scholar] [CrossRef]

- Zhang, S.; Vystorop, I.; Tang, Z.H.; Sun, W.H. Bimetallic (iron or cobalt) complexes bearing 2-methyl-2,4-bis (6-iminopyridin-2-yl)-1h-1,5-benzodiazepines for ethylene reactivity. Organometallics 2007, 26, 2456–2460. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, W.H.; Kuang, X.; Vystorop, I.; Yi, J. Unsymmetric bimetal(II) complexes: Synthesis, structures and catalytic behaviors toward ethylene. J. Organomet. Chem. 2007, 692, 5307–5316. [Google Scholar] [CrossRef]

| Ni | R1 | R2 | R3 | R4 |

|---|---|---|---|---|

| 11a | H | Me | i-Pr | H |

| 12a | Ph | Me | i-Pr | H |

| 12b | Naphthyl | Me | i-Pr | H |

| 12c | H | Ph | i-Pr | H |

| 12d | H | Me and Ph | i-Pr | H |

| 11b | H | 2,4,6-trimethylphenyl | i-Pr | H |

| 12e | H | H | H | H |

| 12e | H | H | Me | H |

| 12g | H | H | i-Pr | H |

| 12h | H | 2,4,6-trimethylphenyl | H | H |

| 12i | H | 2,4,6-trimethylphenyl | F | H |

| 12j | H | 2,4,6-trimethylphenyl | Me | H |

| 12k | H | 2,4,6-trimethylphenyl | Me | F |

| 12l | H | 2,4,6-trimethylphenyl | Me | Me |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, H.; Zheng, H.; Gao, H.; Pei, L.; Gao, H. Late Transition Metal Catalysts with Chelating Amines for Olefin Polymerization. Catalysts 2022, 12, 936. https://doi.org/10.3390/catal12090936

Deng H, Zheng H, Gao H, Pei L, Gao H. Late Transition Metal Catalysts with Chelating Amines for Olefin Polymerization. Catalysts. 2022; 12(9):936. https://doi.org/10.3390/catal12090936

Chicago/Turabian StyleDeng, Huiyun, Handou Zheng, Heng Gao, Lixia Pei, and Haiyang Gao. 2022. "Late Transition Metal Catalysts with Chelating Amines for Olefin Polymerization" Catalysts 12, no. 9: 936. https://doi.org/10.3390/catal12090936