Study of Photocatalytic Oxidation of Micropollutants in Water and Intensification Case Study

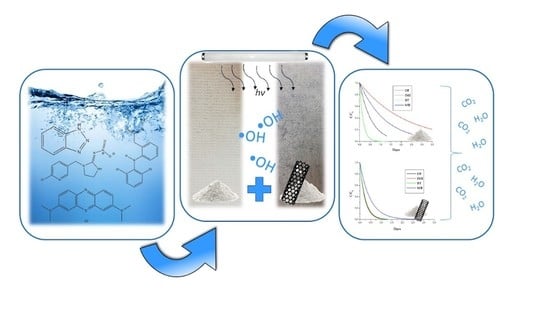

Abstract

:1. Introduction

2. Results and Discussion

2.1. Intensification by Photocatalyst Formulation

2.2. Photolytic and Photocatalytic Degradation of Selected Pollutants

2.2.1. Intensification of Photocatalytic Degradation

2.2.2. Modeling of Photocatalytic Degradation

3. Materials and Methods

3.1. Model Pollutants

3.2. Photocatalysts Preparation

3.3. Reaction Set Up

3.4. Mathematical Modeling of Intensification Factors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ameta, R.; Solanki, M.S.; Benjamin, S.; Ameta, S.C. Photocatalysis. In Advanced Oxidation Processes for Waste Water Treatment; Elsevier: Amsterdam, The Netherlands, 2018; pp. 135–175. ISBN 9780128105252. [Google Scholar]

- Martínez, C.; Canle, L.M.; Fernández, M.I.; Santaballa, J.A.; Faria, J. Aqueous degradation of diclofenac by heterogeneous photocatalysis using nanostructured materials. Appl. Catal. B Environ. 2011, 107, 110–118. [Google Scholar] [CrossRef]

- Ribeiro, A.R.L.; Moreira, N.F.F.; Puma, G.L.; Silva, A.M.T. Impact of water matrix on the removal of micropollutants by advanced oxidation technologies. Chem. Eng. J. 2019, 363, 155–173. [Google Scholar] [CrossRef] [Green Version]

- Kosek, K.; Luczkiewicz, A.; Fudala-Książek, S.; Jankowska, K.; Szopińska, M.; Svahn, O.; Tränckner, J.; Kaiser, A.; Langas, V.; Björklund, E. Implementation of advanced micropollutants removal technologies in wastewater treatment plants (WWTPs)—Examples and challenges based on selected EU countries. Environ. Sci. Policy 2020, 112, 213–226. [Google Scholar] [CrossRef]

- Bustos, E.B.; Sandoval-González, A.; Martínez-Sánchez, C. Detection and Treatment of Persistent Pollutants in Water: General Review of Pharmaceutical Products. ChemElectroChem 2022, 9, e202200188. [Google Scholar] [CrossRef]

- Espíndola, J.C.; Vilar, V.J.P. Innovative light-driven chemical/catalytic reactors towards contaminants of emerging concern mitigation: A review. Chem. Eng. J. 2020, 394, 124865. [Google Scholar] [CrossRef]

- Arany, E.; Láng, J.; Somogyvári, D.; Láng, O.; Alapi, T.; Ilisz, I.; Gajda-Schrantz, K.; Dombi, A.; Kőhidai, L.; Hernádi, K. Vacuum ultraviolet photolysis of diclofenac and the effects of its treated aqueous solutions on the proliferation and migratory responses of Tetrahymena pyriformis. Sci. Total Environ. 2014, 468–469, 996–1006. [Google Scholar] [CrossRef] [PubMed]

- Bi, L.; Chen, Z.; Li, L.; Kang, J.; Zhao, S.; Wang, B.; Yan, P.; Li, Y.; Zhang, X.; Shen, J. Selective adsorption and enhanced photodegradation of diclofenac in water by molecularly imprinted TiO2. J. Hazard. Mater. 2021, 407, 124759. [Google Scholar] [CrossRef]

- Diaz-Angulo, J.; Porras, J.; Mueses, M.; Torres-Palma, R.A.; Hernandez-Ramirez, A.; Machuca-Martinez, F. Coupling of heterogeneous photocatalysis and photosensitized oxidation for diclofenac degradation: Role of the oxidant species. J. Photochem. Photobiol. A Chem. 2019, 383, 112015. [Google Scholar] [CrossRef]

- Náfrádi, M.; Hlogyik, T.; Farkas, L.; Alapi, T. Comparison of the heterogeneous photocatalysis of imidacloprid and thiacloprid—reaction mechanism, ecotoxicity, and the effect of matrices. J. Environ. Chem. Eng. 2021, 9, 106684. [Google Scholar] [CrossRef]

- Ding, T.; Jacobs, D.; Lavine, B.K. Liquid chromatography-mass spectrometry identification of imidacloprid photolysis products. Microchem. J. 2011, 99, 535–541. [Google Scholar] [CrossRef]

- Mikolić, A.; Karačonji, I.B. Imidacloprid as reproductive toxicant and endocrine disruptor: Investigations in laboratory animals. Arch. Ind. Hyg. Toxicol. 2018, 69, 103–108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Minella, M.; De Laurentiis, E.; Pellegrino, F.; Prozzi, M.; Dal Bello, F.; Maurino, V.; Minero, C. Photocatalytic Transformations of 1H-Benzotriazole and Benzotriazole Derivates. Nanomaterials 2020, 10, 1835. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.-Q.; Liu, Y.-S.; Xiong, Q.; Cai, W.-W.; Ying, G.-G. Occurrence, toxicity and transformation of six typical benzotriazoles in the environment: A review. Sci. Total Environ. 2019, 661, 407–421. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-E.; Kim, M.-K.; Lee, J.-Y.; Lee, Y.-M.; Zoh, K.-D. Degradation kinetics and pathway of 1H-benzotriazole during UV/chlorination process. Chem. Eng. J. 2019, 359, 1502–1508. [Google Scholar] [CrossRef]

- Weidauer, C.; Davis, C.; Raeke, J.; Seiwert, B.; Reemtsma, T. Sunlight photolysis of benzotriazoles—Identification of transformation products and pathways. Chemosphere 2016, 154, 416–424. [Google Scholar] [CrossRef] [PubMed]

- Bahnmüller, S.; Loi, C.H.; Linge, K.L.; von Gunten, U.; Canonica, S. Degradation rates of benzotriazoles and benzothiazoles under UV-C irradiation and the advanced oxidation process UV/H2O2. Water Res. 2015, 74, 143–154. [Google Scholar] [CrossRef] [PubMed]

- Reemtsma, T.; Miehe, U.; Duennbier, U.; Jekel, M. Polar pollutants in municipal wastewater and the water cycle: Occurrence and removal of benzotriazoles. Water Res. 2010, 44, 596–604. [Google Scholar] [CrossRef]

- Dai, Q.; Chen, W.; Luo, J.; Luo, X. Abatement kinetics of highly concentrated 1H-Benzotriazole in aqueous solution by ozonation. Sep. Purif. Technol. 2017, 183, 327–332. [Google Scholar] [CrossRef]

- Alotaibi, M.D.; McKinley, A.J.; Patterson, B.M.; Reeder, A.Y. Benzotriazoles in the Aquatic Environment: A Review of Their Occurrence, Toxicity, Degradation and Analysis. Water Air Soil Pollut. 2015, 226, 226. [Google Scholar] [CrossRef]

- Yin, W.; Shao, H.; Huo, Z.; Wang, S.; Zou, Q.; Xu, G. Degradation of anticorrosive agent benzotriazole by electron beam irradiation: Mechanisms, degradation pathway and toxicological analysis. Chemosphere 2022, 287, 132133. [Google Scholar] [CrossRef]

- Cancilla, D.A.; Martinez, J.; van Aggelen, G.C. Detection of Aircraft Deicing/Antiicing Fluid Additives in a Perched Water Monitoring Well at an International Airport. Environ. Sci. Technol. 1998, 32, 3834–3835. [Google Scholar] [CrossRef]

- Loos, R.; Locoro, G.; Comero, S.; Contini, S.; Schwesig, D.; Werres, F.; Balsaa, P.; Gans, O.; Weiss, S.; Blaha, L.; et al. Pan-European survey on the occurrence of selected polar organic persistent pollutants in ground water. Water Res. 2010, 44, 4115–4126. [Google Scholar] [CrossRef] [PubMed]

- Loos, R.; Tavazzi, S.; Mariani, G.; Suurkuusk, G.; Paracchini, B.; Umlauf, G. Analysis of emerging organic contaminants in water, fish and suspended particulate matter (SPM) in the Joint Danube Survey using solid-phase extraction followed by UHPLC-MS-MS and GC–MS analysis. Sci. Total Environ. 2017, 607–608, 1201–1212. [Google Scholar] [CrossRef]

- LeFevre, G.H.; Müller, C.E.; Li, R.J.; Luthy, R.G.; Sattely, E.S. Rapid Phytotransformation of Benzotriazole Generates Synthetic Tryptophan and Auxin Analogs in Arabidopsis. Environ. Sci. Technol. 2015, 49, 10959–10968. [Google Scholar] [CrossRef] [PubMed]

- LeFevre, G.H.; Lipsky, A.; Hyland, K.C.; Blaine, A.C.; Higgins, C.P.; Luthy, R.G. Benzotriazole (BT) and BT plant metabolites in crops irrigated with recycled water. Environ. Sci. Water Res. Technol. 2017, 3, 213–223. [Google Scholar] [CrossRef]

- Yao, L.; Zhao, J.-L.; Liu, Y.-S.; Yang, Y.-Y.; Liu, W.-R.; Ying, G.-G. Simultaneous determination of 24 personal care products in fish muscle and liver tissues using QuEChERS extraction coupled with ultra pressure liquid chromatography-tandem mass spectrometry and gas chromatography-mass spectrometer analyses. Anal. Bioanal. Chem. 2016, 408, 8177–8193. [Google Scholar] [CrossRef]

- Yao, L.; Lv, Y.-Z.; Zhang, L.-J.; Liu, W.-R.; Zhao, J.-L.; Liu, Y.-S.; Zhang, Q.-Q.; Ying, G.-G. Determination of 24 personal care products in fish bile using hybrid solvent precipitation and dispersive solid phase extraction cleanup with ultrahigh performance liquid chromatography-tandem mass spectrometry and gas chromatography-mass spectrometry. J. Chromatogr. A 2018, 1551, 29–40. [Google Scholar] [CrossRef]

- Yao, L.; Zhao, J.-L.; Liu, Y.-S.; Zhang, Q.-Q.; Jiang, Y.-X.; Liu, S.; Liu, W.-R.; Yang, Y.-Y.; Ying, G.-G. Personal care products in wild fish in two main Chinese rivers: Bioaccumulation potential and human health risks. Sci. Total Environ. 2018, 621, 1093–1102. [Google Scholar] [CrossRef]

- Asimakopoulos, A.G.; Wang, L.; Thomaidis, N.S.; Kannan, K. Benzotriazoles and benzothiazoles in human urine from several countries: A perspective on occurrence, biotransformation, and human exposure. Environ. Int. 2013, 59, 274–281. [Google Scholar] [CrossRef]

- Pillard, D.A.; Cornell, J.S.; DuFresne, D.L.; Hernandez, M.T. Toxicity of Benzotriazole and Benzotriazole Derivatives to Three Aquatic Species. Water Res. 2001, 35, 557–560. [Google Scholar] [CrossRef]

- Samuel, J.J. Photocatalytic degradation of methylene blue under visible light by dye sensitized titania Photocatalytic degradation of methylene blue under visible light by dye sensitized titania. Mater. Res. Express 2020, 7, 015051. [Google Scholar] [CrossRef]

- Islam, M.T.; Dominguez, A.; Turley, R.S.; Kim, H.; Sultana, K.A.; Shuvo, M.A.I.; Alvarado-Tenorio, B.; Montes, M.O.; Lin, Y.; Gardea-Torresdey, J.; et al. Development of photocatalytic paint based on TiO2 and photopolymer resin for the degradation of organic pollutants in water. Sci. Total Environ. 2020, 704, 135406. [Google Scholar] [CrossRef] [PubMed]

- Tschirch, J.; Dillert, R.; Bahnemann, D.; Proft, B.; Biedermann, A.; Goer, B. Photodegradation of methylene blue in water, a standard method to determine the activity of photocatalytic coatings? Res. Chem. Intermed. 2008, 34, 381–392. [Google Scholar] [CrossRef]

- Gao, B.; Chen, G.Z.; Puma, G.L. Carbon nanotubes/titanium dioxide (CNTs/TiO2) nanocomposites prepared by conventional and novel surfactant wrapping sol-gel methods exhibiting enhanced photocatalytic activity. Appl. Catal. B Environ. 2009, 89, 503–509. [Google Scholar] [CrossRef]

- Kwon, C.H.; Shin, H.; Kim, J.H.; Choi, W.S.; Yoon, K.H. Degradation of methylene blue via photocatalysis of titanium dioxide. Mater. Chem. Phys. 2004, 86, 78–82. [Google Scholar] [CrossRef]

- Ono, Y.; Rachi, T.; Okuda, T.; Yokouchi, M.; Kamimoto, Y.; Nakajima, A.; Okada, K. Kinetics study for photodegradation of methylene blue dye by titanium dioxide powder prepared by selective leaching method. J. Phys. Chem. Solids 2012, 73, 343–349. [Google Scholar] [CrossRef]

- Ertuş, E.B.; Vakifahmetoglu, C.; Öztürk, A. Enhanced methylene blue removal efficiency of TiO2 embedded porous glass. J. Eur. Ceram. Soc. 2020, 41, 1530–1536. [Google Scholar] [CrossRef]

- Shidpour, R.; Simchi, A.; Ghanbari, F.; Vossoughi, M. Photo-degradation of organic dye by zinc oxide nanosystems with special defect structure: Effect of the morphology and annealing temperature. Appl. Catal. A Gen. 2014, 472, 198–204. [Google Scholar] [CrossRef]

- Yang, C.; Dong, W.; Cui, G.; Zhao, Y.; Shi, X.; Xia, X.; Tang, B.; Wang, W. Highly efficient photocatalytic degradation of methylene blue by P2ABSA-modified TiO2 nanocomposite due to the photosensitization synergetic effect of TiO2 and P2ABSA. RSC Adv. 2017, 7, 23699–23708. [Google Scholar] [CrossRef] [Green Version]

- National Center for Biotechnology Information PubChem Compound Summary for CID 6099, Methylene blue. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Methylene-blue#section=Use-and-Manufacturing (accessed on 15 November 2020).

- Anwar, D.I.; Mulyadi, D. Synthesis of Fe-TiO2 Composite as a Photocatalyst for Degradation of Methylene Blue. Procedia Chem. 2015, 17, 49–54. [Google Scholar] [CrossRef]

- Savić, T.D.; Carević, M.V.; Mitrić, M.N.; Kuljanin-Jakovljević, J.Ž.; Abazović, N.D.; Čomor, M.I. Simulated solar light driven performance of nanosized ZnIn2S4/dye system: Decolourization vs. photodegradation. J. Photochem. Photobiol. A Chem. 2020, 388, 112154. [Google Scholar] [CrossRef]

- Zhang, T.; Oyama, T.; Aoshima, A.; Hidaka, H.; Zhao, J.; Serpone, N. Photooxidative N-demethylation of methylene blue in aqueous TiO2 dispersions under UV irradiation. J. Photochem. Photobiol. A Chem. 2001, 140, 163–172. [Google Scholar] [CrossRef]

- Mahmoud, W.M.M.; Rastogi, T.; Kümmerer, K. Application of titanium dioxide nanoparticles as a photocatalyst for the removal of micropollutants such as pharmaceuticals from water. Curr. Opin. Green Sustain. Chem. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Khan, M.M.; Pradhan, D.; Sohn, Y. Springer Series on Polymer and Composite Materials Nanocomposites for Visible Light-induced Photocatalysis. In Nanocomposites Visible Light. Photocatal; Springer: Cham, Switzerland, 2017; pp. 19–40. [Google Scholar] [CrossRef]

- Grčić, I.; Marčec, J.; Radetić, L.; Radovan, A.-M.; Melnjak, I.; Jajčinović, I.; Brnardić, I. Ammonia and methane oxidation on TiO2 supported on glass fiber mesh under artificial solar irradiation. Environ. Sci. Pollut. Res. 2020, 28, 18354–18367. [Google Scholar] [CrossRef]

- Racovita, A.D. Titanium Dioxide: Structure, Impact, and Toxicity. Int. J. Environ. Res. Public Health 2022, 19, 5681. [Google Scholar] [CrossRef]

- Casado, C.; García-Gil, Á.; van Grieken, R.; Marugán, J. Critical role of the light spectrum on the simulation of solar photocatalytic reactors. Appl. Catal. B Environ. 2019, 252, 1–9. [Google Scholar] [CrossRef]

- Khalid, N.R.; Majid, A.; Tahir, M.B.; Niaz, N.A.; Khalid, S. Carbonaceous-TiO2 nanomaterials for photocatalytic degradation of pollutants: A review. Ceram. Int. 2017, 43, 14552–14571. [Google Scholar] [CrossRef]

- Woan, K.; Pyrgiotakis, G.; Sigmund, W. Photocatalytic carbon-nanotube-TiO2 composites. Adv. Mater. 2009, 21, 2233–2239. [Google Scholar] [CrossRef]

- Malinowski, S.; Presečki, I.; Jajčinović, I.; Brnardić, I.; Mandić, V.; Grčić, I. Intensification of Dihydroxybenzenes Degradation over Immobilized TiO2 Based Photocatalysts under Simulated Solar Light. Appl. Sci. 2020, 10, 7571. [Google Scholar] [CrossRef]

- Marques, R.R.N.; Sampaio, M.J.; Carrapiço, P.M.; Silva, C.G.; Morales-Torres, S.; Dražić, G.; Faria, J.L.; Silva, A.M.T. Photocatalytic degradation of caffeine: Developing solutions for emerging pollutants. Catal. Today 2013, 209, 108–115. [Google Scholar] [CrossRef]

- Sundar, K.P.; Kanmani, S. Progression of Photocatalytic reactors and it’s comparison: A Review. Chem. Eng. Res. Des. 2020, 154, 135–150. [Google Scholar] [CrossRef]

- Zhao, D.; Yang, X.; Chen, C.; Wang, X. Enhanced photocatalytic degradation of methylene blue on multiwalled carbon nanotubes–TiO2. J. Colloid Interface Sci. 2013, 398, 234–239. [Google Scholar] [CrossRef] [PubMed]

- Pava-Gómez, B.; Vargas-Ramírez, X.; Díaz-Uribe, C.; Romero, H.; Duran, F. Evaluation of copper-doped TiO2 film supported on glass and LDPE with the design of a pilot-scale solar photoreactor. Sol. Energy 2021, 220, 695–705. [Google Scholar] [CrossRef]

- Mani, S.S.; Rajendran, S.; Nalajala, N.; Mathew, T.; Gopinath, C.S. Electronically Integrated Mesoporous Ag–TiO2 Nanocomposite Thin films for Efficient Solar Hydrogen Production in Direct Sunlight. Energy Technol. 2022, 10, 2100356. [Google Scholar] [CrossRef]

- Rodriguez-Acosta, J.W.; Mueses, M.Á.; Machuca-Martínez, F. Mixing Rules Formulation for a Kinetic Model of the Langmuir-Hinshelwood Semipredictive Type Applied to the Heterogeneous Photocatalytic Degradation of Multicomponent Mixtures. Int. J. Photoenergy 2014, 2014, 817538. [Google Scholar] [CrossRef] [Green Version]

- Muñoz-Flores, P.; Poon, P.S.; Ania, C.O.; Matos, J. Performance of a C-containing Cu-based photocatalyst for the degradation of tartrazine: Comparison of performance in a slurry and CPC photoreactor under artificial and natural solar light. J. Colloid Interface Sci. 2022, 623, 646–659. [Google Scholar] [CrossRef] [PubMed]

- Marić, T. Aging of Photocatalysis Based on Titanium (IV) Oxide and Carbon Nanotubes. Master’s Thesis, University of Zagreb, Zagreb, Croatia, 2020. [Google Scholar]

- Anisuzzaman, S.M.; Joseph, C.G.; Pang, C.K.; Affandi, N.A.; Maruja, S.N.; Vijayan, V. Current Trends in the Utilization of Photolysis and Photocatalysis Treatment Processes for the Remediation of Dye Wastewater: A Short Review. ChemEngineering 2022, 6, 58. [Google Scholar] [CrossRef]

- Vaya, D.; Surolia, P.K. Semiconductor based photocatalytic degradation of pesticides: An overview. Environ. Technol. Innov. 2020, 20, 101128. [Google Scholar] [CrossRef]

- Kurwadkar, S.; Evans, A.; DeWinne, D.; White, P.; Mitchell, F. Modeling photodegradation kinetics of three systemic neonicotinoids-dinotefuran, imidacloprid, and thiamethoxam-in aqueous and soil environment. Environ. Toxicol. Chem. 2016, 35, 1718–1726. [Google Scholar] [CrossRef]

- Herrmann, J.-M. Photocatalysis. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; pp. 1–44. ISBN 9780128105252. [Google Scholar]

- Pérez-Estrada, L.A.; Maldonado, M.I.; Gernjak, W.; Agüera, A.; Fernández-Alba, A.R.; Ballesteros, M.M.; Malato, S. Decomposition of diclofenac by solar driven photocatalysis at pilot plant scale. Catal. Today 2005, 101, 219–226. [Google Scholar] [CrossRef]

- Shorgoli, A.A.; Shokri, M. Photocatalytic degradation of imidacloprid pesticide in aqueous solution by TiO2 nanoparticles immobilized on the glass plate. Chem. Eng. Commun. 2017, 204, 1061–1069. [Google Scholar] [CrossRef]

- Liang, R.; Tang, F.; Wang, J.; Yue, Y. Photo-degradation dynamics of five neonicotinoids: Bamboo vinegar as a synergistic agent for improved functional duration. PLoS ONE 2019, 14, e0223708. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ye, J.; Zhou, P.; Chen, Y.; Ou, H.; Liu, J.; Li, C.; Li, Q. Degradation of 1H-benzotriazole using ultraviolet activating persulfate: Mechanisms, products and toxicological analysis. Chem. Eng. J. 2018, 334, 1493–1501. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Xing, X.; Li, Q.; Yang, J. Visible light photocatalytic activities of carbon nanotube/titanic acid nanotubes derived-TiO2 composites for the degradation of methylene blue. Adv. Powder Technol. 2015, 26, 8–13. [Google Scholar] [CrossRef]

- Elghniji, K.; Ksibi, M.; Elaloui, E. Sol–gel reverse micelle preparation and characterization of N-doped TiO2: Efficient photocatalytic degradation of methylene blue in water under visible light. J. Ind. Eng. Chem. 2012, 18, 178–182. [Google Scholar] [CrossRef]

- de la Flor, M.P.; Camarillo, R.; Martínez, F.; Jiménez, C.; Quiles, R.; Rincón, J. Synthesis and characterization of TiO2/CNT/Pd: An effective sunlight photocatalyst for neonicotinoids degradation. J. Environ. Chem. Eng. 2021, 9, 106278. [Google Scholar] [CrossRef]

- Speltini, A.; Maraschi, F.; Sturini, M.; Contini, M.; Profumo, A. Dispersive multi-walled carbon nanotubes extraction of benzenesulfonamides, benzotriazoles, and benzothiazoles from environmental waters followed by microwave desorption and HPLC-HESI-MS/MS. Anal. Bioanal. Chem. 2017, 409, 6709–6718. [Google Scholar] [CrossRef]

- Martínez, C.; Canle, L.M.; Fernández, M.I.; Santaballa, J.A.; Faria, J. Kinetics and mechanism of aqueous degradation of carbamazepine by heterogeneous photocatalysis using nanocrystalline TiO2, ZnO and multi-walled carbon nanotubes–anatase composites. Appl. Catal. B Environ. 2011, 102, 563–571. [Google Scholar] [CrossRef]

- Cao, Q.; Yu, Q.; Connell, D.W.; Yu, G. Titania/carbon nanotube composite (TiO2/CNT) and its application for removal of organic pollutants. Clean Technol. Environ. Policy 2013, 15, 871–880. [Google Scholar] [CrossRef]

- Yao, Y.; Luan, J. Preparation, Property Characterization of Gd2YSbO7/ZnBiNbO5 Heterojunction Photocatalyst for Photocatalytic Degradation of Benzotriazole under Visible Light Irradiation. Catalysts 2022, 12, 159. [Google Scholar] [CrossRef]

- Čižmar, T.; Panžić, I.; Capan, I.; Gajović, A. Nanostructured TiO2 photocatalyst modified with Cu for improved imidacloprid degradation. Appl. Surf. Sci. 2021, 569, 151026. [Google Scholar] [CrossRef]

- Bohač, M.; Čižmar, T.; Kojić, V.; Marčec, J.; Juraić, K.; Grčić, I.; Gajović, A. Novel, Simple and Low-Cost Preparation of Ba-Modified TiO2 Nanotubes for Diclofenac Degradation under UV/Vis Radiation. Nanomaterials 2021, 11, 2714. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ye, J.; Li, C.; Zhou, P.; Liu, J.; Ou, H. Degradation of 1 H -benzotriazole by UV/H2O2 and UV/TiO2: Kinetics, mechanisms, products and toxicology. Environ. Sci. Water Res. Technol. 2018, 4, 1282–1294. [Google Scholar] [CrossRef]

- Nekouei, S.; Nekouei, F. Comparative procedure of photodegradation of methylene blue using N doped activated carbon loaded with hollow 3D flower like ZnS in two synergic phases of adsorption and catalytic. J. Photochem. Photobiol. A Chem. 2018, 364, 262–273. [Google Scholar] [CrossRef]

- Salavati, H.; Kohestani, T. Preparation, characterization and photochemical degradation of dyes under UV light irradiation by inorganic–organic nanocomposite. Mater. Sci. Semicond. Process. 2013, 16, 1904–1911. [Google Scholar] [CrossRef]

- Ji, K.H.; Jang, D.M.; Cho, Y.J.; Myung, Y.; Kim, H.S.; Kim, Y.; Park, J. Comparative Photocatalytic Ability of Nanocrystal-Carbon Nanotube and -TiO2 Nanocrystal Hybrid Nanostructures. J. Phys. Chem. C 2009, 113, 19966–19972. [Google Scholar] [CrossRef]

- Grčić, I.; Papić, S.; Brnardić, I. Photocatalytic Activity of TiO2 Thin Films: Kinetic and Efficiency Study. Int. J. Chem. React. Eng. 2018, 16, 20160153. [Google Scholar] [CrossRef]

| Ycat (-) | ||

|---|---|---|

| DF | 3.56 × 10−10 | 2.35 |

| IMI | 8.90 × 10−11 | 8.84 |

| BT | 1.20 × 10−09 | 0.64 |

| MB | 1.62 × 10−10 | 2.52 |

| TiO2 | TiO2/CNT | |||||||

|---|---|---|---|---|---|---|---|---|

| DF | IMI | BT | MB | DF | IMI | BT | MB | |

| 50% | 9 h | 37 h | 3 h | 21 h | 4 h | 4 h | 4 h | 8 h |

| 90% | 31 h | >84 h | 9 h | 67 h | 13 h | 14 h | 15 h | 27 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radetić, L.; Marčec, J.; Brnardić, I.; Čižmar, T.; Grčić, I. Study of Photocatalytic Oxidation of Micropollutants in Water and Intensification Case Study. Catalysts 2022, 12, 1463. https://doi.org/10.3390/catal12111463

Radetić L, Marčec J, Brnardić I, Čižmar T, Grčić I. Study of Photocatalytic Oxidation of Micropollutants in Water and Intensification Case Study. Catalysts. 2022; 12(11):1463. https://doi.org/10.3390/catal12111463

Chicago/Turabian StyleRadetić, Lucija, Jan Marčec, Ivan Brnardić, Tihana Čižmar, and Ivana Grčić. 2022. "Study of Photocatalytic Oxidation of Micropollutants in Water and Intensification Case Study" Catalysts 12, no. 11: 1463. https://doi.org/10.3390/catal12111463