1. Introduction

Electrophilic substitution reactions of aromatics are very effective ways of producing valuable industrial materials [

1,

2,

3,

4,

5]. However, the commercial production of these materials often still uses methodologies developed many years ago. Many traditional processes for producing substituted aromatics involve the substantial generation of waste, the production of isomers that require separation and purification, low yields, and poor selectivity [

6,

7,

8,

9]. Dibromonaphthalenes are important intermediates in the organic syntheses of a range of valuable compounds [

10,

11]. Two main direct routes are available for the production of dibromonaphthalenes; either from further bromination of a monobromonaphthalene or by direct dibromination of naphthalene.

The bromination of 1-bromonaphthalene using bromine (Br

2; 1.5 mole equivalents) has been reported to give 1,4-dibromonaphthalene as the major product (73%) along with 1,5-dibromonaphthalene (21%) [

12]. However, a high temperature (120 °C) was needed for the reaction to proceed. A higher yield of 1,4-dibromonaphthalene (90%) was produced by the bromination of 1-bromonaphthalene using Br

2 in dichloromethane (DCM) at a very low temperature (−30 °C), but a long reaction time (48 h) was required [

13]. Under those conditions, 1,5-dibromonapthalene was a minor (2%) side product. On the other hand, 1,5-dibromonaphthalene was the major product (80% yield) from the photo-bromination (250 W lamp) of 1-bromonaphthalene using Br

2 (1.5 mole equivalents) in carbon tetrachloride (CCl

4) at 77 °C [

13]. The

1H NMR spectrum also showed the presence of 1,3,5-tribromonaphthalene (8%) in the reaction mixture.

The dibromination of naphthalene using dioxane dibromide (two mole equivalents) at 40 °C gave a mixture of 1,4-dibromonaphthalene, 2-bromonaphthalene and 1,5-dibromonaphthalene [

14]. The bromination of naphthalene using copper(II) bromide in chlorobenzene over alumina at 130 °C gave 1,4-dibromonaphthalene in 92% yield [

15]. Ionic liquids have been tested in the bromination of naphthalene, but early attempts were not successful at providing dibromonaphthalenes [

16,

17,

18]. For example, the use of

N-bromosuccinimide in the presence of an ionic liquid at 28 °C for 5 min was not effective in the bromination of naphthalene [

16], while 3-methylimidazolium tribromide, acting as both solvent and brominating agent, at 70 °C for 23 h, resulted only in monobromination, with the production of 1-bromonaphthalene in quantitative yield [

17]. The dibromination of naphthalene using Br

2 in a mixture of ionic liquid and water at 70 °C has been reported to give a quantitative yield of 1,4-dibromonaphthalene, but the reaction was conducted on a small scale (0.4 mmol) and required a high temperature, the use of an autoclave, a large excess of Br

2 (7.5 mole equivalents), and a series of crystallizations for purification [

18]. None of these dibromination procedures is attractive for large-scale application.

The photolytic (150 W lamp) bromination of tetralin using Br

2 (4.5 mole equivalents) in CCl

4 gave 1,1,4,4-tetrabromotetralin in 92% yield, which was debrominated using potassium

tert-butoxide (two mole equivalents) in tetrahydrofuran to give 1,4-dibromonaphthalene in 95% yield [

19]. However, such a method is wasteful of bromine atoms, requires two steps and is not convenient for commercial use.

Clearly, there are many limitations associated with the existing processes for the production of dibromonaphthalenes, including the generation of excessive waste and the use of expensive reagents, inconvenient temperatures, or special equipment. Therefore, instead of dibromonaphthalenes being reagents of choice for the synthesis of other disubstituted naphthalenes, many such compounds have been synthesized from the corresponding derivatives containing nitro, amino, or other groups. Therefore, there is still room for a convenient method for the production of dibromonaphthalenes selectively and in high yields by the direct bromination of naphthalene. We have previously developed several simple, efficient, and high yielding synthetic procedures for the production of substituted aromatics [

20,

21,

22,

23,

24,

25,

26,

27,

28] and in particular halogenated derivatives [

29,

30,

31,

32,

33]. Many of the procedures involved the use of solid additives to catalyze or control the regioselectivity of reactions. Therefore, we became interested in studying the dibromination of naphthalene to produce dibromonaphthalenes using Br

2 over various structured solids, and we now report our results.

2. Results and Discussion

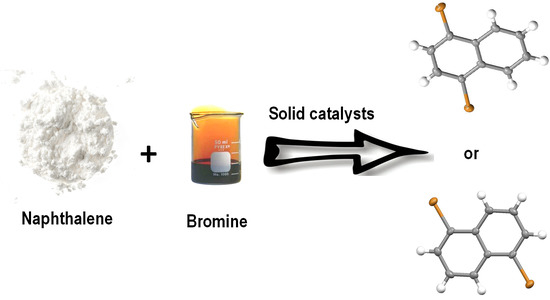

The dibromination of naphthalene (

1) using bromine (Br

2; two mole equivalents) at 25 °C in dichloromethane (DCM) was attempted (

Scheme 1) in the absence of any added catalyst to provide a baseline result. The reaction time was varied from 1 to 72 h (

Table 1). Under the conditions attempted, the main products were 1-bromonaphthalene (

2), 1,4-dibromonaphthane (

3), and 1,5-dibromonaphthalene (

4) based on quantitative gas chromatography (GC) analysis. 1-Bromonaphthalene (

2; 63%) was produced as the only product when the reaction time was 1 h. The highest yield obtained for

3 was 20% when the reaction was carried out for a long reaction time (72 h). No evidence was found for the formation of

4 when the reaction time was 1–6 h. In addition, unreacted naphthalene (14–35%) was identified when the reaction time was less than 6 h.

It appeared that a reaction time of 6 h at 25 °C could be suitable to test the effect of various catalysts on the yield and selectivity of brominated naphthalenes. Therefore, several different kinds of additives were tested as catalysts. They included a traditional Brønsted mineral acid (sulfuric acid), a traditional Lewis acid (AlBr

3) and a range of different kinds of commercial solids available in our laboratories following earlier research. The solids included amorphous materials (silicic acid, silica 60A, and two different “Synclysts”—silica–aluminas with different alumina content), lamella materials (two different commercial clays), and a range of zeolites with different pore and channel characteristics. Some features of the zeolites are listed

Table 2. Zeolite lattices are negatively charged because they incorporate 4-coordinate aluminum atoms, the number of which determines how many counter cations are required to preserve neutrality, so in some cases zeolites with the same pore-channel structure but different Si/Al ratios were used. The counter cations can be protons, in which case the zeolite will be acidic (the strength depending on several factors), or can be a metal cation, the nature of which can affect the acid-base properties and available pore aperture/volume of the zeolite. For example, in molecular sieve 3A the predominant counter cation is K

+, while in molecular sieve 5A the predominant counter cation is Ca

2+. Both are zeolite A. For other zeolites used, the nature of the major counter cation is indicated by a prefix to the zeolite type designation (so NaY means zeolite Y with predominantly Na

+ counter cations). The molecular sieves have a Si/Al ratio of around 1, but for the other zeolites the Si/Al ratio is given in parentheses after the zeolite designation when relevant.

In order to ensure consistency, all solids were calcined in an identical manner by heating at 550 °C in air for 6 h prior to use. Reactions were conducted under identical conditions. The results obtained are shown in

Table 3.

In the absence of any catalyst under such conditions, both 2 (82%) and 3 (14%) were produced, but an insignificant quantity of 4 was seen. The reaction involving the use of H2SO4 led to a very low mass balance because the reaction was very messy and some products could not be identified. However, the only dibromonaphthalene observed in significant quantity was 3. The use of the Lewis acid AlBr3 led to a faster reaction than that involving no catalyst, and a significant amount of 4 was also observed in this case, but the conversion into dibromonaphthalenes was still only 49%. Several of the solid materials (notably silicic acid, 3A molecular sieve, NaY (Si/Al = 7.5) and NaY (Si/Al = 55)) gave low yields of dibromonaphthalenes (≤30%) involving little or no improvement compared to the reaction in the absence of a catalyst. In all of these cases, the amount of 4 recorded was very low (≤4%), but since the yield of 3 was also not large it is difficult to be confident about the precise ratio of 3:4 in these cases.

Some apparently quite similar solids gave rather higher yields of dibromonaphthalenes. For example, silica 60A gave more than silicic acid, molecular sieve 5A gave more than molecular sieve 3A, and samples of NaY with Si/Al ratios of 12.5 and 28 gave more than samples of NaY with Si/Al ratios of 7.5 and 55. In the reactions over NaY zeolites, there appeared to be a trend towards a higher conversion to dibromonaphthalenes with higher Si/Al ratio (lower number of Na+ cations), until the highest Si/Al ratio, when there may have been insufficient active sites available to have a great effect. However, the modest improvements in rates of reaction in all of these cases may be due to nothing more than differences in accessible surface area, particle size, stirring effectiveness or some other such physical factor. Differences in selectivity for the formation of 3 or 4 are more interesting. Apart from the case of silica 60A, which is a mild Brønsted acid, the other solids in this group all gave a much higher proportion of 4 than their apparently similar counterparts from the lower rate group. The solids concerned are not significantly acidic in the Brønsted sense, but neither are their counterparts, which gave lower proportions of 4. HZSM-5 (a medium pore zeolite) and H-mordenite (a large pore zeolite, but with linear channels that are therefore less accessible than more open three-dimensional channels) also led to modest rate enhancements but to a low proportion of 4. Both are fairly strong Brønsted acids.

The most interesting group of solids comprises those that led to a substantial increase in the yield of dibromonaphthalenes. This group included the two “Synclysts” (strongly acidic, amorphous silica–aluminas with different Si/Al ratios), two types of proton-exchanged zeolites (Hβ and HY) with large, three-dimensional pores, and the two commercial clays (K10 and KSF), one of which (K10) was strongly acidic. Most of the solids in this group not only led to a significantly higher yield of dibromonaphthalenes, but also gave a very high proportion of 1,4-dibromonaphthalene (ratio 3:4 ≥17). The exceptions were KSF clay and HY (Si/Al = 15), which both gave very high conversion into dibromonaphthalenes and a much higher proportion of 1,5-dibromonaphthalene (3:4 ratio of about 3:2). Interestingly, the dibromination reaction over HY (Si/Al = 15) was somewhat faster than any of those carried out over NaY zeolites.

From all of the above results, it seemed that it would be possible to provide access to

3 in a synthetically useful way by use of one of the Synclyst solids and possibly to

4 by use of KSF clay. However, the role played by the solids in influencing the regioselectivity was not very clear. In an attempt to increase the yields of

3 and

4 in some cases, and hopefully gain more insight into the regioselectivity of some of the reactions, a longer reaction time (72 h) was employed with some of the solids under otherwise identical conditions. The results achieved are presented in

Table 4. The conversion into dibromonaphthalenes generally increased compared to that at 6 h, but in the case of HY (Si/Al = 15) the conversion was actually less. The major product was again

3 in all cases, but with the longer reaction time, some

4 was seen in all cases. The proportion of

4 in the cases that had previously given quite a lot of it was usually somewhat lower. For example, the yield of

4 over KSF clay decreased from 40% (6 h reaction) to 11% when the reaction time was 72 h, which was a surprise. It seems likely that

4 was isomerized to

3 over time. In the case of HY (Si/Al = 15), the reduction in the quantity of

4 from 35% at 6 h to 27% at 72 h was accompanied by a rise in the amount of 1-bromonaphthalene (

2), suggesting that the further bromination of

2 was reversible, and that this could also be the mechanism by which

3 and

4 could be interconverted.

The reactions carried out over all zeolites (including molecular sieves) had not quite given complete conversion to dibromonaphthalenes even after 72 h. This could be due to the segregation between naphthalene, intermediates and bromine because of differential absorption within the zeolite pores. In particular, some molecular bromine could have been removed from availability for reaction either by possible absorption within zeolite small cavities or perhaps by evaporation over the long reaction time. In support of the former possibility, the overall yield of dibromonaphthalenes over zeolites could be improved by the addition of excess bromine, while the latter reason may be responsible for the reaction not going to completion in the case of silicic acid. Only the use of K10 and KSF clays led to the complete conversion of naphthalene to dibromonaphthalenes, along with 1,4,6-tribromonaphthalene as a minor product (2%). Both reactions had or had almost gone to completion even after 6 h, but the proportions of 3 and 4 after 6 h were very different for the two different clays, whereas after 72 h the proportions were almost the same. Again, this suggested that isomerization must be possible under the reaction conditions.

Since KSF clay (40%) and zeolite HY (Si/Al = 15; 35%) led to the highest yield of

4 in a 6 h reaction, the two catalysts were chosen for further investigation. A shorter reaction time (3 h) was employed to test if

4 could be produced in higher yields at the early stages of the reaction before its possible isomerization to

3. The quantity of catalyst was also varied from 0.5 g to 8.0 g for 7.64 mmol of

1 to test the effect of quantity on the yields and selectivity of the products (

Table 5).

Table 5 shows that the total yield of dibromonaphthalenes

3 and

4 increased broadly in line with the quantity of solid used until the largest quantities of solids were used, where stirring efficiency may have been affected. However, the ratio between

3 and

4 remained almost constant. The period of 3 h was clearly not long enough for the complete conversion of

2 into

3 and

4 with up to 8 g of solid. Nevertheless, some interesting observations can be made. Even allowing for the fact that these heterogeneous reaction mixtures are more difficult to regulate, in terms of ensuring equal dispersion of materials, etc., it was clear that the proportion of

4 within the dibromonaphthalene portion of the products was higher than for the 6 h reactions over both solids, and that KSF clay gave a faster conversion into dibromonaphthalenes than HY (Si/Al = 15). In view of these findings, a broader study of the effect of reaction time on the yields and proportions of dibromonaphthalenes over 4 g of KSF clay was undertaken (

Table 6). Due to difficulty in taking representative samples of the whole reaction mixture from such heterogeneous reactions, each time point relates to a separate reaction mixture, set up in an identical manner, rather than to samples of the same mixture taken at different times. This may account for some of the variability in the extent of reaction with time.

A high yield of dibromonaphthalenes was attained even after a short reaction time, and the reaction proportion of 4 was greater than the proportion of 3 in the early stages. Interestingly, the proportion changed with longer reaction times, and by 72 h 3 was easily the more abundant isomer. For example, the yield of 4 was 49% after 45 min and decreased to only 11% after 72 h. This confirmed the isomerization of 4 to 3 under the conditions. It appears that the higher selectivity for 4 in the early stages may be under kinetic control, while over a prolonged reaction time the thermodynamic proportions may be established. In an attempt to check whether the presence of HBr produced as a side product was responsible for catalyzing the isomerization, a reaction was conducted in which a stream of nitrogen was passed through the mixture. Unfortunately, it appeared that molecular bromine was also removed, so that the yields of both 3 and 4 suffered and no conclusion could be drawn.

It was of interest to test the effect of different solvents on the yields of dibromonaphthalenes

3 and

4 and their proportions over KSF clay for a short reaction time (1 h). The results obtained are recorded in

Table 7. The reaction proceeded readily in

n-pentane,

n-hexane, chloroform and DCM, while the yields of dibromonaphthalenes were much lower when 1,2-dichloroethane, tetrachloroethylene, and especially more polar solvents were used. Indeed, with the latter group unreacted naphthalene (

1) was present at the end of the reaction time, possibly because much of the bromine introduced into the reaction mixture was consumed by reaction with the solvent. The highest yield (82%) of

3 was obtained when

n-hexane was used. Therefore, this reaction was attempted for a prolonged duration. The 24 h reaction in

n-hexane led to the formation of a mixture of

2 (16%),

3 (67%), and

4 (13%). This may again be indicative of the reversibility of the reaction and some loss of bromine by other means.

As a result of all the above studies, Synclyst 13 was identified as a useful catalyst for highly regioselective synthesis of 1,4-dibromonaphthalene (

3) and KSF clay was identified as a useful catalyst for regioselective synthesis of 1,5-dibromonaphthalene (

4). Reactions were conducted for periods of 6 h (Synclyst) or 45 min (KSF) (4 g solid for 7.54 mmol reactions; for the Synclyst 13 reaction the bromine was added dropwise over 45 min, but for the KSF reaction involving a shorter reaction time, the bromine was added all at once) and worked up as for the analytical reactions, and then the products were simply recrystallized. The Synclyst 13 reaction gave 91% isolated yield of pure

3, while the KSF reaction gave 40% of pure

4. Each of these preparative reactions was performed on the same scale (using 0.98 g of naphthalene) as the analytical reactions. However, we also carried out reactions under identical conditions on a larger scale (7.83 g of naphthalene) and obtained virtually identical results. As explained earlier, the added solids were samples left over from earlier research. Unfortunately, neither of these materials is now commercially available and our supplies were limited, so conducting the reactions on an even larger scale was not considered. However, Synclyst 13 is just an amorphous silica–alumina with 13% alumina content and the preparation of such material is well documented [

34,

35], so it is expected that similar results could be reproduced with prepared materials.

The exact identity of KSF clay, on the other hand, was a commercial confidence, although it was believed to be based on bentonite. Therefore, we decided to investigate the dibromination of naphthalene (1) over readily available bentonite clay. In the early stages of this project, we had decided to treat all of the solids used in the same way, involving calcination at 550 °C, and so we again treated the bentonite clay in the same way. However, this is not the normal way to prepare clays before using them because such treatment can lead to irreversible loss of water and collapse of the lamellar structure of a clay. It is more usual simply to dry them at 100–120 °C, so we also treated a sample of bentonite in this way and compared the effects of the two samples of bentonite with that of KSF in reactions of 1 with two equivalents of bromine. The results suggested that the effect of calcined bentonite was qualitatively similar to that of calcined KSF. The formation of dibromo compounds was perhaps somewhat slower, so that at 3 h there was still a substantial amount of 2 remaining, but after 1 day the product was almost entirely a mixture of 3 and 4 with a 3:4 ratio of ca. 70:30. Additional experimentation would be required to identify the optimal conditions for the reaction, but it is clear that calcined bentonite could provide an alternative to calcined KSF for the synthesis of 4. Bentonite that had just been dried at 120 °C, however, behaved quite differently, giving a product that was almost entirely 3 after 1 day.

In order to try to gain some information about the differences between the samples of bentonite treated in the two different ways (drying or calcination), we subjected them to atomic force microscopy (AFM). The major physical differences between the two samples were that the calcined sample showed greater core roughness depth (difference between the minimum and maximum heights of the surface), surface roughness average (mean deviation from the arithmetical mean surface plane), and surface area ratio (percentage additional area contributed by the texture compared to that of the arithmetical mean surface plane), but smaller average diameter of granules (both mean and median) than the non-calcined sample (

Table 8 and

Supplementary Materials). More work would be required to characterize any chemical changes in the materials.

The pure samples of

3 and

4 obtained following the crystallizations reported above were used to confirm their structures using various spectroscopic techniques (see experimental section). In addition, their molecular structures were confirmed using X-ray crystallography (

Figure 1) and were found to be consistent with those reported [

36,

37].