A Multiphysics Analysis of Coupled Electromagnetic-Thermal Phenomena in Cable Lines

Abstract

:1. Introduction

1.1. General Remarks

- description of a laboratory stand for examination of current distribution in multi-strand lines,

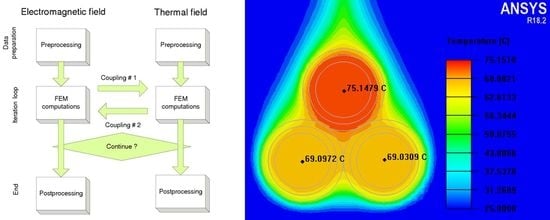

- development of a numerical model taking into account coupled electromagnetic-thermal phenomena,

- comparison of computation results from ICEPACK and MAXWELL-MECHANICAL codes for chosen geometries,

- variations of temperature and RMS current values during successive iterations using the coupled electromagnetic-thermal model.

1.2. Literature Review Concerning Ampacity Computation

2. Materials and Methods

3. Numerical Modeling

- modeling was carried out for 2D geometry. The full 3D modeling is possible in ANSYS, yet it is very time consuming; some tests carried out by the first author have shown that it may take several hours even for relatively simple geometries using a state-of-the-art desktop computer;

- individual strands twisted together to form a cable line (cf. Figure 2) are treated as a whole. This simplification may be called a geometric homogenization on the local scale. The proximity effects are accounted only between “clusters” of strands from the macroscopic standpoint. It can be remarked that this approach is a typical one; yet a recent publication on the wiring system for electrical vehicles focused on a more detailed scale [53];

- the cables are cooled by natural convection. It is assumed that their distance from the floor is sufficient to neglect the floor heating due to radiation emitted from the cables.

Determination of Free Convection Coefficient and Modeling

- the working strand—79.0 °C

- insulation—69.8 °C

- outer coating (measurement point below the strand)—62.0 °C

- outer coating (measurement point above the strand)—67.1 °C

- −

- unit loss per 1 cm length was calculated in Maxwell using the 3D model, it was equal to 0.557 W;

- −

- the values of thermal conductivity coefficients were taken from relevant materials science publications. They were as follows: PVC = 0.17 W/(m K), XPLE = 0.52 W/(m K) and ALU = 237 W/(m K). The radiation coefficient was 0.94. The ambient temperature was assumed as 26.1 °C.

4. Conclusions

- further validation of the barycenter criterion for optimal ampacity of multi-strand cable lines, outlined in Reference [7], considering the effect of harmonics and the presence of conducting shelves for placement of cables; a comparison of results obtained with the aforementioned criterion and with the VIS algorithm shall be carried out; and

- FEM-based studies of more complicated cases (distorted current waveforms, chosen three phase configurations, consideration of conducting power cable tray, forced air flow etc.).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Piątek, Z. Modelowanie Linii, Kabli i Torów Wielkoprądowych (Modeling of Lines, Cables and High-Current Busducts); Politechniki Częstochowskiej: Częstochowa, Poland, 2007. (In Polish) [Google Scholar]

- Szczegielniak, T. Analiza Elektromagnetycznych i Termicznych Pól Sprzężonych w Jednobiegunowych Torach Wielkoprądowych (An Analysis of Coupled Electromagnetic and Thermal Fields in Single-Duct High-Current Busducts); Politechniki Częstochowskiej: Częstochowa, Poland, 2019. (In Polish) [Google Scholar]

- Xiong, L.; Chen, Y.; Jiao, Y.; Wang, J.; Hu, X. Study on the Effect of Cable Group Laying Mode on Temperature Field Distribution and Cable Ampacity. Energies 2019, 12, 3397. [Google Scholar] [CrossRef] [Green Version]

- Lammeraner, J.; Štafl, M. Eddy Currents; Iliffe Books: London, UK, 1966. [Google Scholar]

- Jabłoński, P.; Szczegielniak, T.; Kusiak, D.; Piątek, Z. Analytical–Numerical Solution for the Skin and Proximity Effects in Two Parallel Round Conductors. Energies 2019, 12, 3584. [Google Scholar] [CrossRef] [Green Version]

- Jabłoński, P.; Szczegielniak, T.; Kusiak, D. Analytical-Numerical Approach to the Skin and Proximity Effect in Lines with Round Parallel Wires. Energies 2020, 13, 6716. [Google Scholar] [CrossRef]

- Cywiński, A.; Chwastek, K.; Kusiak, D.; Jabłoński, P. Optimization of Spatial Configuration of Multi-Strand Cable Lines. Energies 2020, 13, 5923. [Google Scholar] [CrossRef]

- Canova, A.; Freschi, F.; Tartaglia, M. Multiobjective Optimization of Parallel Cable Layout. IEEE Trans. Magn. 2007, 43, 3914–3920. [Google Scholar] [CrossRef]

- Moutassem, W.; Anders, G.J. Configuration Optimization of Underground Cables for Best Ampacity. IEEE Trans. Power Deliv. 2010, 25, 2037–2045. [Google Scholar] [CrossRef]

- Freschi, F.; Tartaglia, M. Power Lines Made of Many Parallel Single-Core Cables: A Case Study. IEEE Trans. Ind. Appl. 2013, 49, 1744–1750. [Google Scholar] [CrossRef]

- Zarchi, D.A.; Vahidi, B. Optimal placement of underground cables to maximise total ampacity considering cable lifetime. IET Gener. Transm. Distrib. 2016, 10, 263–269. [Google Scholar] [CrossRef]

- Giaccone, L. Optimal layout of parallel power cables to minimize the stray magnetic field. Electr. Power Syst. Res. 2016, 134, 152–157. [Google Scholar] [CrossRef]

- Huang, F.; Li, J. Optimization Research on Ampacity of Underground High Voltage Cable Based on Interior Point Method. IOP Conf. Ser. Mater. Sci. Eng. 2017, 274, 012123. [Google Scholar] [CrossRef]

- Perović, B.D.; Tasić, D.S.; Klimenta, D.O.; Radosavljević, J.N.; Jevtić, M.D.; Milovanović, M.J. Optimising the thermal environment and the ampacity of underground power cables using the gravitational search algorithm. IET Gener. Transm. Distrib. 2018, 12, 423–430. [Google Scholar] [CrossRef]

- Sun, B.; Makram, E. Configuration Optimization of Cables in Ductbank Based on Their Ampacity. J. Power Energy Eng. 2018, 6, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Rasoulpoor, M.; Mirzaie, M.; Mirimani, S.M. Arrangement Optimization of Power Cables in Harmonic Currents to Achieve the Maximum Ampacity Using ICA. Electr. Power Comp. Syst. 2019, 46, 1820–1833. [Google Scholar] [CrossRef]

- Shabani, H.; Vahidi, B. Co-optimization of ampacity and lifetime with considering harmonic and stochastic parameters by Imperialist Competition Algorithm. Appl. Soft Comput. J. 2020, 96, 106599. [Google Scholar] [CrossRef]

- Ocłoń, P.; Rerak, M.; Rao, R.V.; Cisek, P.; Vallati, A.; Jakubek, D.; Rozegnał, B. Multiobjective optimization of underground power cable systems. Energy 2021, 215, 119089. [Google Scholar] [CrossRef]

- Cywiński, A. Optymalizacja Rozkładu Przestrzennego Wielowiązkowych Linii Kablowych w Celu Minimalizacji Strat Energii (Optimization of Spatial Distribution of Multi-Bundle Cable Lines in Order to Minimize Energy Losses). Ph.D. Thesis, Faculty of Electrical Engineering, Częstochowa University of Technology, Częstochowa, Poland, September 2020. (In Polish). [Google Scholar]

- Driesen, J. Coupled Electromagnetic-Thermal Problems in Electrical Energy Transducers. Ph.D. Thesis, ESAT, KU Leuven, Leuven, Belgium, May 2000. [Google Scholar]

- Schneider, C.S.; Winchell, S.D. Hysteresis in conducting ferromagnets. Physical B 2006, 372, 269–272. [Google Scholar] [CrossRef]

- Jakubas, A.; Chwastek, K. A Simplified Sablik’s Approach to Model the Effect of Compaction Pressure on the Shape of Hysteresis Loops in Soft Magnetic Composite Cores. Materials 2020, 13, 170. [Google Scholar] [CrossRef] [Green Version]

- Schneider, C.S.; Gedney, S.D.; Ojeda-Ayala, N.; Travers, M. Dynamic exponential model of ferromagnetic hysteresis. Phys. B 2021, 607, 412802. [Google Scholar] [CrossRef]

- Zimmerman, W.B.J. Multiphysics Modeling with Finite Element Methods; World Scientific: London, UK, 2006. [Google Scholar]

- Suárez Arriaga, M.C.; Bundschuh, J.; Domínguez-Mota, F.J. (Eds.) Numerical Modeling of Coupled Phenomena in Science and Engineering: Practical Uses and Examples; CRC Press, Taylor Francis Group: Boca Raton, FL, USA, 2009. [Google Scholar]

- Pryor, R.W. Multiphysics Modeling Using COMSOL: A First Principles Approach; Jones and Bartlett Publishers: Sudbury, MA, USA, 2011. [Google Scholar]

- Keyes, D.E.; McInnes, L.C.; Woodward, C.; Gropp, W.; Myra, E.; Pernice, M.; Bell, J.; Brown, J.; Clo, A.; Connors, J.; et al. Multiphysics simulations. Int. J. High Perform. Comput. Appl. 2013, 27, 4–83. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Guo, Y.; Cheng, G.; Li, D. Performance Study of Hybrid Magnetic Coupler Based on Magneto Thermal Coupled Analysis. Energies 2017, 10, 1148. [Google Scholar] [CrossRef] [Green Version]

- Barański, M. FE analysis of coupled electromagnetic-thermal phenomena in the squirrel cage motor working at high ambient temperature. COMPEL 2019, 38, 1120–1132. [Google Scholar] [CrossRef]

- Cheng, X.; Liu, W.; Tan, Z.; Zhou, Z.; Yu, B.; Wang, W.; Zhang, Y.; Liu, S. Thermal Analysis Strategy for Axial Permanent Magnet Coupling Combining FEM with Lumped-Parameter Thermal Network. Energies 2020, 13, 5019. [Google Scholar] [CrossRef]

- Demenko, A.; Stachowiak, D. Finite Element and Experimental Analysis of an Axisymmetric Electromechanical Converter with a Magnetostrictive Rod. Energies 2020, 13, 1230. [Google Scholar] [CrossRef] [Green Version]

- Zhai, J.-J.; Kong, X.-X.; Wang, L.-C. Thermo-Viscoelastic Response of 3D Braided Composites Based on a Novel FsMsFE Method. Materials 2021, 14, 271. [Google Scholar] [CrossRef]

- Chávez, O.; Godínez, F.; Méndez, F.; Aguilar, A. Prediction of temperature profiles and ampacity for a monometallic conductor considering the skin effect and temperature-dependent resistivity. Appl. Therm. Eng. 2016, 109, 401–412. [Google Scholar] [CrossRef]

- Karahan, M.; Kalenderli, Ö. Coupled electrical and thermal analysis of power cables using Finite Element Method. In Heat Transfer-Engineering Applications; Vikhrenko, V., Ed.; InTech: London, UK, 2009; Available online: http://www.intechopen.com/books/heat-transfer-engineering-applications/coupled-electrical-and-thermal-analysis-of-power-cables-using-finite-element-method (accessed on 7 February 2021).

- Enescu, D.; Colella, P.; Russo, A. Thermal Assessment of Power Cables and Impacts on Cable Current Rating: An Overview. Energies 2020, 13, 5319. [Google Scholar] [CrossRef]

- De León, F. Major factors affecting the cable ampacity. In Proceedings of the IEEE Power Engineering Society General Meeting, Montreal, QC, Canada, 18–22 June 2006. [Google Scholar] [CrossRef]

- Sedaghat, A.; de León, F. Thermal Analysis of Power Cables in Free Air: Evaluation and Improvement of the IEC Standard Ampacity Calculations. IEEE Trans. Power Deliv. 2014, 29, 2306–2314. [Google Scholar] [CrossRef]

- IEC Standard-Electric Cables–Calculation of the Current Rating–Part 2: Thermal Resistance–Section 1: Calculation of the Thermal Resistance; IEC Standard: Geneva, Switzerland, 1994.

- Anders, G.J. Rating of Electric Power Cables: Ampacity Computations for Transmission, Distribution, and Industrial Applications; IEEE Press: New York, NY, USA, 1997. [Google Scholar]

- Thue, W.A. (Ed.) Electrical Power Cable Engineering; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Goga, V.; Paulech, J.; Váry, M. Cooling of Electrical Cu Conductor with PVC Insulation–Analytical, Numerical and Fluid Flow Solution. J. Electr. Eng. 2013, 64, 92–99. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Liang, Y.; Li, W.; Si, W.; Yuan, P.; Li, J. Coupled Electromagnetic-Thermal Modeling the Temperature Distribution of XLPE Cable. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 27–31 March 2009. [Google Scholar] [CrossRef]

- Cirino, A.W.; de Paula, H.; Mesquita, R.C.; Saraiva, E. Cable Parameter Variation due to Skin and Proximity Effects: Determination by means of Finite Element Analysis. In Proceedings of the 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009. [Google Scholar] [CrossRef]

- Korovkin, N.; Greshnyakov, G.; Dubitsky, S. Multiphysics Approach to the Boundary Problems of Power Engineering and Their Application to the Analysis of Load-Carrying Capacity of Power Cable Line. In Proceedings of the Electric Power Quality and Supply Reliability Conference (PQ), Rakvere, Estonia, 11–13 June 2014. [Google Scholar] [CrossRef]

- Hameyer, K.; Driesen, J.; De Gersem, H.; Belmans, R. The classification of coupled field problems. IEEE Trans. Magn. 1999, 35, 1618–1621. [Google Scholar] [CrossRef]

- Ocłoń, P.; Cisek, P.; Pilarczyk, M.; Taler, D. Numerical simulation of heat dissipation processes in underground power cable system situated in thermal backfill and buried in a multilayered soil. Energy Convers. Manag. 2015, 95, 352–370. [Google Scholar] [CrossRef]

- Maximov, S.; Venegas, V.; Guardado, J.L.; Moreno, E.L.; López, R. Analysis of underground cable ampacity considering non-uniform soil temperature distributions. Electr. Power Syst. Res. 2016, 132, 22–29. [Google Scholar] [CrossRef]

- Sedaghat, A.; Lu, H.; Bokhari, A.; de León, F. Enhanced Thermal Model of Power Cables Installed in Ducts for Ampacity Calculations. IEEE Trans. Power Deliv. 2018, 33, 2404–2411. [Google Scholar] [CrossRef]

- Czapp, S.; Ratkowski, F. Optimization of Thermal Backfill Configurations for Desired High-Voltage Power Cables Ampacity. Energies 2021, 14, 1452. [Google Scholar] [CrossRef]

- Ghoneim, S.S.M.; Ahmed, M.; Sabiha, N.A. Transient Thermal Performance of Power Cable Ascertained Using Finite Element Analysis. Processes 2021, 9, 438. [Google Scholar] [CrossRef]

- Meng, X.; Han, P.; Liu, Y.; Lu, Z.; Jin, T. Working temperature calculation of single-core cable by nonlinear finite element method. Arch. Electr. Eng. 2019, 68, 643–656. [Google Scholar]

- Ansys Engineering Simulation–3D Design Software. Available online: http://www.ansys.com (accessed on 7 January 2021).

- Di Noia, L.P.; Rizzo, R. Thermal Analysis of Battery Cables for Electric Vehicles. In Proceedings of the 2nd IEEE International Conference on Industrial Electronics for Sustainable Energy Systems (IESES), Cagliari, Italy, 1–3 September 2020. [Google Scholar] [CrossRef]

- Rasoulpoor, M.; Mirzaie, M.; Mirimani, S.M. Effects of non-sinusoidal current on current division, ampacity and magnetic field of parallel power cables. IET Sci. Meas. Technol. 2017, 11, 553–562. [Google Scholar] [CrossRef]

- Kasaš-Lažetić, K.; Mijatović, G.; Herceg, D.; Kljajić, D.; Krstajić, M.; Prša, M. Heating of Current Conducting Aluminum Wire. In Proceedings of the 20th International Symposium on Power Electronics, Novi Sad, Serbia, 23–26 October 2019. [Google Scholar]

- Neher, J.H.; McGrath, M.H. The calculation of the temperature rise and load capability of cable systems. AIEE Trans. 1957, 76, 752–772. [Google Scholar] [CrossRef]

- Al-Ohaly, A.A.; Ali, K.F.; El-Kady, M.A. An Improved Algorithm for Efficient Computation of Current Distribution in Power Cables. King Saud Univ. Eng. Sci. 2002, 14, 251–259. [Google Scholar] [CrossRef]

- Cywiński, A.; Chwastek, K. Modeling of skin and proximity effects in multi-bundle cable lines. In Proceedings of the Progress in Applied Electrical Engineering (PAEE), Kościelisko, Poland, 17–21 June 2019. [Google Scholar] [CrossRef]

| YAKXS 1 × 240 | YAKXS 1 × 70 | |

|---|---|---|

| Working aluminum strand—RMC | 240 mm2 | 70 mm2 |

| Insulation—cross-linked polyethylene | 1.7 mm | 1.1 mm |

| Coating—polyvinyl chloride | 1.7 mm | 1.4 mm |

| Outer diameter | 24.8 mm | 14.7 mm |

| Maximum resistance at 20 °C | 0.125 Ω/km | 0.443 Ω/km |

| Maximum working temperature | 90 °C | 90 °C |

| A1B1C1A2B2C2 | A1B1C1/C2B2A2 | A1B1C1/A2B2C2 | ||||

|---|---|---|---|---|---|---|

| P (W) | Tmax (°C) | P (W) | Tmax (°C) | P (W) | Tmax (°C) | |

| A1 | 22.91 | 24.73 | 24.48 | |||

| B1 | 24.61 | 25.19 | 90.85 | 26.87 | 93.3 | |

| C1 | 24.27 | 74.1 | 24.40 | 24.52 | ||

| A2 | 22.91 | - | 24.37 | 24.53 | ||

| B2 | 24.61 | - | 25.21 | 90.85 | 26.89 | 93.3 |

| C2 | 24.26 | 74.1 | 24.40 | 24.49 | ||

| ΣP [W] | - | 143.57 | - | 148.3 | - | 151.78 |

| Strand No. | RMS Current after the First Iteration (A) | Final RMS Current (A) |

|---|---|---|

| 1 | 722 | 687 |

| 2 | 411 | 437 |

| 3 | 329 | 348 |

| 4 | 329 | 348 |

| 5 | 411 | 437 |

| 6 | 722 | 687 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cywiński, A.; Chwastek, K. A Multiphysics Analysis of Coupled Electromagnetic-Thermal Phenomena in Cable Lines. Energies 2021, 14, 2008. https://doi.org/10.3390/en14072008

Cywiński A, Chwastek K. A Multiphysics Analysis of Coupled Electromagnetic-Thermal Phenomena in Cable Lines. Energies. 2021; 14(7):2008. https://doi.org/10.3390/en14072008

Chicago/Turabian StyleCywiński, Artur, and Krzysztof Chwastek. 2021. "A Multiphysics Analysis of Coupled Electromagnetic-Thermal Phenomena in Cable Lines" Energies 14, no. 7: 2008. https://doi.org/10.3390/en14072008