In Situ Tests of the Monitoring and Diagnostic System for Individual Photovoltaic Panels

Abstract

:1. Introduction

1.1. Photovoltaics in the World and in Poland

1.2. Monitoring of PV Installations

1.3. Pollution of PV Installations

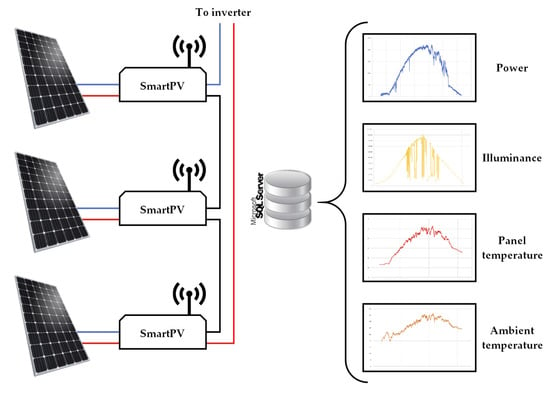

1.4. SmartPV—PV Monitoring System at a Fair Price

- Absorption of solar radiation (absorption of photons, which does not generate charge pairs);

- Ambient temperature;

- Heat generated as a result of current flow through the p-n junction.

- Continuous measurement of photovoltaic system operation parameters (voltage and current, panel temperature and solar radiation intensity, ambient temperature and humidity);

- Transparency of the system and effective maintenance,

- Accurate information on panel performance;

- Automatic data analysis;

- Reduction of operating costs (service planning, cleaning, etc.) and minimisation of the return period;

- Quick installation, using MC4 (Multi Contact 4 mm), connectors, which are standard in photovoltaics;

2. Materials and Methods

2.1. Description of SmartPV Functionality

2.2. Test Methods

3. Results and Discussion

3.1. Detection of the Installation Pollution

3.2. Impact of Temperature and Illuminance on Panel Performance

3.3. PV Panel Shading (or Damage)

3.4. Temperature Power Factor

- Pobl—calculated power (W);

- Pm—measured power (W);

- Tm—measured temperature (°C).

3.5. Sensor Failure

3.6. Wheather Anomalies

3.7. Results in Relation to International Literature

4. Conclusions

- SmartPV modules closely monitor the panel operation (whose parameters depend on the intensity of solar radiation), recording the voltage and current generated individually by each panel.

- A strong dependence of the generated electrical power on the intensity of solar radiation was confirmed, including a significant adverse effect of temperature. Excessive heating of the panels causes a decrease in efficiency of 0.5% for each 1 °C.

- Coefficients were determined to allow estimation of the expected electric power, depending on the period and weather conditions. The coefficients make it possible to increase the accuracy of the prediction of the expected power at a given period and weather conditions.

- The SmartPV system can detect the degree of pollution on the surface of the photovoltaic panels (pollution of the panels can cause up to 20% decrease in the efficiency of the installation) by comparing the currently generated power of the whole installation (or string) with the calculated theoretical value (based on current sensor data and archive data). In economically justified cases (when the loss due to pollution reaches the value of the installation cleaning costs), the system can inform the user about the need to clean the installation.

- By analysing data from each panel, it is possible to detect their damage (e.g., mechanical, e.g., caused by hail, delamination, hot spots, etc.) Damage to a single panel affects the operation of the entire installation, causing a significant loss of power in the string to which it is connected.

- Based on the analysis of sensor data, historical data and a comparison of the current panel output with the nominal output, it is possible to track the panel’s ageing trend and inform the user about the need for replacement.

- A horizontal arrangement of the photovoltaic panels is definitely more beneficial, mainly due to the effect of snowfall on the efficiency of the installation. Snow accumulated on the operating system melts slowly (under the influence of the higher surface temperature of the panels), slowly sliding off the panels, exposing successive rows of cells. In a horizontal arrangement, a PV panel starts operating at 33% efficiency when the top 2 rows of cells are uncovered and will gradually increase in efficiency. Vertically stacked panels will start operating after the snow has completely melted or slid off.

- The system can locally detect panel shading that was not considered or did not exist at the installation designing stage (e.g., trees, new buildings).

- In several cases, breaks in communication were detected, manifesting as missing data in the database. The target solution will use external Wi-Fi aerials, thus increasing the reliability of wireless communication.

- A self-diagnostics algorithm, built into the system software, enables real-time self-monitoring to detect erroneous values from the sensors or damage.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Michalski, M. Wykład: Energetyka Słoneczna—Fotowoltaika., Systemy Energetyki Odnawialnej B.22; VIESSMAN Academy: Telford, UK, 2016; Available online: https://www.viessmann.ovh/wp-content/uploads/T3_SEO-B22_Fotowoltaika_M_Michalski_29_11_2016.pdf (accessed on 6 December 2020).

- Institute for Renewable Energy. In Photovoltaic Market in Poland 2020; IEO: Warsaw, Poland, 2020; Available online: https://ieo.pl/en/pv-report (accessed on 20 January 2021).

- KGHM Is Preparing Further PV Projects. Available online: https://www.gramwzielone.pl/energia-sloneczna/104137/kghm-szykuje-kolejne-projekty-pv (accessed on 30 January 2021).

- Olczak, P.; Matuszewska, D.; Kryzia, D. “Mój Prąd” as an example of the photovoltaic one off grant program in Poland. Polityka Energetyczna 2020, 23, 123–137. [Google Scholar] [CrossRef]

- Choi, J.; Choi, M.; Shin, Y.; Lee, I.W. Design of Web-based Monitoring System for Solar Photovoltaic Power Plants. In Proceedings of the International Conference on Information Networking, Barcelona, Spain, 7–10 January 2020; pp. 784–786. [Google Scholar]

- Guerriero, P.; Catalano, A.P.; Matacena, I.; Codecasa, L.; D’Alessandro, V.; Daliento, S. Experimental Assessment of Malfunction Events in Photovoltaic Modules from IR Thermal Maps. In Proceedings of the THERMINIC 2019—2019 25th International Workshop Thermal Investigations of ICs and Systems, Lecco, Italy, 25–27 September 2019. [Google Scholar]

- Chao, K.H.; Tsai, J.H.; Chen, Y.H. Development of a low-cost fault detector for photovoltaic module array. Electronics 2019, 8, 255. [Google Scholar] [CrossRef] [Green Version]

- Samara, S.; Natsheh, E. Intelligent Real-Time Photovoltaic Panel Monitoring System Using Artificial Neural Networks. IEEE Access 2019, 7, 50287–50299. [Google Scholar] [CrossRef]

- Skomedal, Å.F.; Aarseth, B.L.; Haug, H.; Selj, J.; Marstein, E.S. How much power is lost in a hot-spot? A case study quantifying the effect of thermal anomalies in two utility scale PV power plants. Sol. Energy 2020, 211, 1255–1262. [Google Scholar] [CrossRef]

- Bayrak, F.; Oztop, H.F. Effects of static and dynamic shading on thermodynamic and electrical performance for photovoltaic panels. Appl. Therm. Eng. 2020, 169, 114900. [Google Scholar] [CrossRef]

- Kunz, O.; Evans, R.J.; Juhl, M.K.; Trupke, T. Understanding partial shading effects in shingled PV modules. Sol. Energy 2020, 202, 420–428. [Google Scholar] [CrossRef]

- Dhimish, M.; Alrashidi, A. Photovoltaic degradation rate affected by different weather conditions: A case study based on PV systems in the UK and Australia. Electronics 2020, 9, 650. [Google Scholar] [CrossRef] [Green Version]

- PN-EN 61724: 2002—Monitorowanie Własności Systemu Fotowoltaicznego—Wytyczne Pomiarów, Wymiany Danych i Analizy (Photovoltaic System Performance Monitoring—Guidelines for Measurement, Data Exchange and Analysis); Polski Komitet Normalizacyjny: Warszawa, Poland, 2002.

- Jaszczur, M.; Koshti, A.; Nawrot, W.; Sędor, P. An investigation of the dust accumulation on photovoltaic panels. Environ. Sci. Pollut. Res. 2020, 27, 2001–2014. [Google Scholar] [CrossRef] [PubMed]

- Styszko, K.; Jaszczur, M.; Teneta, J.; Hassan, Q.; Burzyńska, P.; Marcinek, E.; Łopian, N.; Samek, L. An analysis of the dust deposition on solar photovoltaic modules. Environ. Sci. Pollut. Res. 2019, 26, 8393–8401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kasim, N.K.; Obaid, N.M.; Abood, H.G.; Mahdi, R.A.; Humada, A.M. Experimental study for the effect of dust cleaning on the performance of grid-tied photovoltaic solar systems. Int. J. Electr. Comput. Eng. 2021, 11, 74–83. [Google Scholar]

- De Arquer Fernández, P.; Fernández Fernández, M.Á.; Carús Candás, J.L.; Arboleya Arboleya, P. An IoT open source platform for photovoltaic plants supervision. Int. J. Electr. Comput. Eng. 2021, 125, 106540. [Google Scholar] [CrossRef]

- Ding, W.; Liu, Y.; Aamir, M.L.; Beluch, T.; Filipski, A. The role of internet of things monitoring in photovoltaic solar energy. J. Mine Vent. Soc. S. Afr. 2020, 73, 33–37. [Google Scholar]

- Woszczyński, M.; Grabowski, J. Koncepcja Inteligentnego Systemu Monitoringu i Diagnostyki Paneli Fotowoltaicznych. KOMTECH 2016, Innowacyjne Techniki i Technologie dla Górnictwa. Bezpieczeństwo—Efektywność—Niezawodność; Instytut Techniki Górniczej KOMAG: Gliwice, Poland, 2016; pp. 110–125. ISBN 978-83-60708-97-2. [Google Scholar]

- Woszczyński, M. Model inteligentnego systemu monitoringu i diagnostyki paneli fotowoltaicznych. Napędy Sterow. 2018, 5, 70–73. [Google Scholar]

- Lu, S.; Wang, F.; Ren, L.; Zhu, W. A health diagnosis method for photovoltaic module based on neural network. In Proceedings of the 8th Renewable Power Generation Conference (RPG 2019), Shanghai, China, 24–25 October 2019. [Google Scholar]

- Ortega, E.; Aranguren, G.; Saenz, M.J.; Gutierrez, R.; Jimeno, J.C. Wireless sensor network for photovoltaic modules monitoring. In Proceedings of the IEEE 44th Photovoltaic Specialist Conference, PVSC, Portland, OR, USA, 5–10 June 2016; pp. 1–5. [Google Scholar]

- Mazurek, K.; Szygula, M.; Perutka, K.; Turczynski, K.; Stankiewicz, K. Acquiring electric energy from the transport conveyor roller movement for distributed sensors network. J. Electr. Eng. Elektrotechnicky Cas. 2020, 71, 87–95. [Google Scholar] [CrossRef]

- Hadipour, A.; Rajabi Zargarabadi, M.; Rashidi, S. An efficient pulsed- spray water cooling system for photovoltaic panels: Experimental study and cost. Renew. Energy 2021, 164, 867–875. [Google Scholar] [CrossRef]

- Kulkarni, R.S.; Talange, D.B.; Dharme, A.A.; Mate, N.V. Development and performance analysis of solar photovoltaic–thermal (PVT) systems. Sadhana Acad. Proc. Eng. Sci. 2020, 45, 208. [Google Scholar] [CrossRef]

- Baran, K.; Leśko, M.; Wachta, H. Badania pozycjonowania paneli fotowoltaicznych na terytorium Polski. PAK 2013, 59, 1097–1100. [Google Scholar]

- Rodziewicz, T.; Wacławek, M. Ogniwa słoneczne—Wpływ środowiska naturalnego na ich pracę; WNT: Warsaw, Poland, 2011; ISBN 978-83-7926-264-9. [Google Scholar]

| Month | Average Power Coefficient (W/lux) | Average Temperature (°C) |

|---|---|---|

| June | 0.0027 | 43.6 |

| July | 0.0030 | 40.1 |

| August | 0.0026 | 44.7 |

| September | 0.0035 | 34.0 |

| October | 0.0043 | 27.5 |

| November | 0.0051 | 18.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woszczyński, M.; Rogala-Rojek, J.; Bartoszek, S.; Gaiceanu, M.; Filipowicz, K.; Kotwica, K. In Situ Tests of the Monitoring and Diagnostic System for Individual Photovoltaic Panels. Energies 2021, 14, 1770. https://doi.org/10.3390/en14061770

Woszczyński M, Rogala-Rojek J, Bartoszek S, Gaiceanu M, Filipowicz K, Kotwica K. In Situ Tests of the Monitoring and Diagnostic System for Individual Photovoltaic Panels. Energies. 2021; 14(6):1770. https://doi.org/10.3390/en14061770

Chicago/Turabian StyleWoszczyński, Mariusz, Joanna Rogala-Rojek, Sławomir Bartoszek, Marian Gaiceanu, Krzysztof Filipowicz, and Krzysztof Kotwica. 2021. "In Situ Tests of the Monitoring and Diagnostic System for Individual Photovoltaic Panels" Energies 14, no. 6: 1770. https://doi.org/10.3390/en14061770