An Optimal Slip Ratio-Based Revised Regenerative Braking Control Strategy of Range-Extended Electric Vehicle

Abstract

:1. Introduction

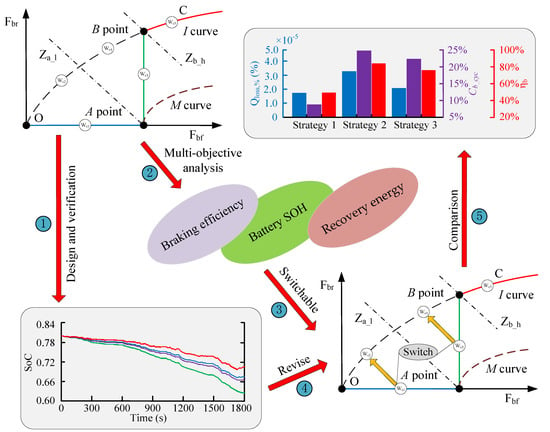

2. IRBCS Based on OSR

2.1. Control Principle Overview of IRBCS

2.2. Tire–Road Adhesion Coefficient Recognition Module (TACRM)

2.3. Distribution of Front and Rear Slip Ratio

- (1)

- OA stage: full regenerative braking

- (2)

- AB stage: hydraulic braking compensation

- (3)

- BC stage: coordination braking on the I curve

2.4. Allocation of Braking Work-Point

3. Verification and Discussion of IRBCS in Simulation Environment

3.1. Simulation Model of R-EEV

3.2. Verification of TACRM

3.3. OSR Control Method By DFLC

3.4. Simulation Analysis of IRBCS

3.4.1. High Tire–Road Adhesion Condition

3.4.2. Medium Tire–Road Adhesion Condition

3.4.3. Low Tire–road Adhesion Condition

4. Revised Regenerative Braking Control Strategy (RRBCS)

4.1. Battery Capacity Loss Model (BCLM)

4.2. Regenerative Braking Work-Point Switching

5. Comparison and Analysis of Three Control Strategies

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Du, J.; Ouyang, D. Progress of Chinese electric vehicles industrialization in 2015: A review. Appl. Energy 2016, 188, 529–546. [Google Scholar] [CrossRef]

- Ma, H.; Balthasar, F.; Tait, N.; Riera-Palou, X.; Harrison, A. A new comparison between the life cycle greenhouse gas emissions of battery electric vehicles and internal combustion vehicles. Energy Policy 2012, 44, 160–173. [Google Scholar] [CrossRef]

- Chen, B.; Wu, Y.; Tsai, H. Design and analysis of power management strategy for range extended electric vehicle using dynamic programming. Appl. Energy 2014, 113, 1764–1774. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, G. New evaluation methodology of regenerative braking contribution to energy efficiency improvement of electric vehicles. Energy Convers. Manag. 2016, 119, 389–398. [Google Scholar] [CrossRef]

- Shi, Q.; Zhang, X.; Chen, F. Multi-lookup table based regenerative braking strategy of plug-in hybrid electric vehicle. Appl. Mech. Mater. 2010, 44, 1509–1513. [Google Scholar] [CrossRef]

- Ko, J.; Ko, S.; Kim, I.; Hyun, D.; Kim, H. Cooperative control for regenerative braking and friction braking to increase energy recovery without wheel lock. Int. J. Autom. Technol. 2014, 15, 253–262. [Google Scholar] [CrossRef]

- Guo, J.; Jian, X.; Lin, G. Performance evaluation of an anti-lock braking system for electric vehicle with a fuzzy sliding mode controller. Energies 2014, 7, 6459–6476. [Google Scholar] [CrossRef] [Green Version]

- Kumar, C.N.; Subramanian, S.C. Cooperative control of regenerative braking and friction braking for a hybrid electric vehicle. Proc. Inst. Mech. Eng. J. Automob. Eng. 2015, 230, 103–116. [Google Scholar] [CrossRef]

- Zhang, J.; Lv, C.; Gou, J.; Kong, D. Cooperative control of regenerative braking and hydraulic braking of an electrified passenger car. J. Automob. Eng. 2012, 226, 1289–1302. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, G.; Meng, M.; Shen, Y. A novel control strategy of regenerative braking system for electric vehicles under safety critical driving situations. Energy 2018, 149, 329–340. [Google Scholar] [CrossRef]

- Yin, G.; Jin, X. Cooperative Control of Regenerative Braking and Antilock Braking for a Hybrid Electric Vehicle. Math. Probl. Eng. 2013, 4, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Wei, Z.; Xu, J.; Halim, D. Braking force control strategy for electric vehicles with load variation and wheel slip considerations. IET Electr. Syst. Transp. 2017, 7, 41–47. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Yang, C. Model predictive control-based efficient energy recovery control strategy for regenerative braking system of hybrid electric bus. Energy Convers. Manag. 2016, 111, 299–314. [Google Scholar] [CrossRef]

- Guo, H.; He, H.; Sun, F. A Combined Cooperative Braking Model with a Predictive Control Strategy in an Electric Vehicle. Energies 2013, 6, 6455–6475. [Google Scholar] [CrossRef]

- Kunagone, K.; Werachet, K.N. Performance Evaluation of Regenerative Braking System Based on a HESS in Extended Range BEV. J. Electr. Eng. Technol. 2018, 13, 1965–1977. [Google Scholar]

- Hoseinnezhad, R.; Bab-Hadiashar, A. Efficient antilock braking by direct maximization of tire–road frictions. IEEE Trans. Ind. Electron. 2011, 58, 3593–3600. [Google Scholar] [CrossRef]

- Deepak, P.; Efstathios, V.; Cao, D.P.; Tamas, D. Optimal μ-Estimation-Based Regenerative Braking Strategy for an AWD HEV. IEEE Trans. Transp. Electrif. 2017, 3, 249–258. [Google Scholar]

- Zhu, Q.; Wang, Q.F.; Chen, Q.H. Component sizing for compound hybrid excavators. Proc. Inst. Mech. Eng. J. Automob. Eng. 2015, 230, 969–982. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Li, L.; Qin, C.; Du, Y. Hierarchical control strategy with battery aging consideration for hybrid electric vehicle regenerative braking control. Energy 2018, 145, 301–312. [Google Scholar] [CrossRef]

- Maia, R.; Silva, M.; Araújo, R.; Nunes, U. Electrical vehicle modeling: A fuzzy logic model for regenerative braking. Expert Syst. Appl. 2015, 42, 8504–8519. [Google Scholar] [CrossRef]

- Topalov, A.V.; Oniz, Y.; Kayacan, E.; Kaynak, O. Neuro-fuzzy control of antilock braking system using sliding mode incremental learning algorithm. Neurocomputing 2011, 74, 1883–1893. [Google Scholar] [CrossRef]

- Roumila, Z.; Rekioua, D.; Rekioua, T. Energy management based fuzzy logic controller of hybrid system wind/photovoltaic/diesel with storage battery. Int. J. Hydrog. Energy 2017, 42, 19525–19535. [Google Scholar] [CrossRef]

- Abdel-Monem, M.; Trad, K.; Omar, N.; Hegazy, O.; Peter, V.D.B.; Van Mierlo, J. Influence analysis of static and dynamic fast-charging current profiles on ageing performance of commercial lithium-ion batteries. Energy 2017, 120, 179–191. [Google Scholar] [CrossRef]

- Kevin, L.; Gering, A.; Sergiy, V.; Sazhin, A. Investigation of path dependence in commercial lithium-ion cells chosen for plug-in hybrid vehicle duty cycle protocols. J. Power Sources 2011, 196, 3395–3403. [Google Scholar]

- Aksjonov, A.; Vodovozov, V.; Augsburg, K.; Petlenkov, E. Design of regenerative anti-lock braking system controller for 4 in-wheel-motor drive electric vehicle with road surface estimation. Int. J. Automot. Technol. 2018, 19, 727–742. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Jin, X.; Xiong, R. Multi-objective optimization study of energy management strategy and economic analysis for a range-extended electric bus. Energy Policy 2017, 194, 798–807. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Gao, Y.; Guo, Q. Recognition of battery aging variations for LiFePO4 batteries in 2nd use applications combining incremental capacity analysis and statistical approaches. J. Power Sources 2017, 360, 180–188. [Google Scholar] [CrossRef]

- Wang, J.; Purewal, J.; Liu, P.; Hicks-Garner, J.; Soukazian, S.; Sherman, E. Degradation of lithium ion batteries employing graphite negatives and nickel–cobalt–manganese oxide+ spinel manganese oxide positives: Part 1, aging mechanisms and life estimation. J. Power Sources 2014, 269, 937–948. [Google Scholar] [CrossRef]

| Road | C1 | C2 | C3 |

|---|---|---|---|

| Dry asphalt | 1.28 | 23.99 | 0.52 |

| Wet asphalt | 1.197 | 25.17 | 0.54 |

| Dry cement | 0.857 | 33.82 | 0.35 |

| Wet cobblestone | 0.4 | 33.71 | 0.12 |

| Ice | 0.05 | 306.39 | 0.001 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Full load weight (kg) | 1700 | Brake pedal leverage ratio | 3.5 |

| Wheelbase (mm) | 2865 | Diameter of pedal travel simulator (mm) | 15 |

| Battery capacity (kWh) | 20 | Distance from front axle to centroid (mm) | 1352 |

| Initial SoC (state of charge) | 0.8 | Distance from rear axle to centroid (mm) | 1513 |

| Centroid height (mm) | 500 | Diameter of front wheel cylinder (mm) | 56.95 |

| Drag area (m2) | 1.66 | Diameter of rear wheel cylinder (mm) | 33.82 |

| Correction coefficient of rotating mass | 1.1 | Diameter of master cylinder (mm) | 18 |

| Mechanical efficiency | 0.96 | Effective radius of front brake rotor (mm) | 0.235 |

| Transmission reduction ratio | 4.2 | Effective radius of rear brake rotor (mm) | 0.227 |

| s′f (t) | NB | NS | ZO | PS | PB | |

|---|---|---|---|---|---|---|

| ef (t) | NB | PB | PM | PS | ZO | ZO |

| NS | PB | PS | ZO | ZO | NS | |

| ZO | PM | PS | ZO | NS | NM | |

| PS | PS | ZO | NS | NM | NB | |

| PB | ZO | ZO | NM | NB | NB | |

| s′r (t) | NB | NS | ZO | PS | PB | |

|---|---|---|---|---|---|---|

| er (t) | NB | PM | PM | PS | ZO | ZO |

| NS | PM | PS | ZO | ZO | NS | |

| ZO | PS | ZO | ZO | NS | NM | |

| PS | PS | ZO | NS | NM | NM | |

| PB | ZO | ZO | NS | NM | NB | |

| Electrical Parameters | Value | Electrical Parameters | Value |

|---|---|---|---|

| Typical capacity (Ah) | 3.65 | End-of-charge voltage (V) | 4.20±0.05 |

| Minimum capacity (Ah) | 3.60 | End-of-discharge voltage (V) | 3.00 |

| Nominal voltage (V) | 3.7 | Energy density (Wh/kg) | 150 |

| Cn = 1C | Id (A) | Td (s) | Ich (A) | Tch (s) | I *d (A) | I *ch (A) | ΔId (A) | ΔIch (A) | Ts (s) | fp |

|---|---|---|---|---|---|---|---|---|---|---|

| Case 1 | 28 | 12 | 14 | 2 | − | − | − | − | 0.5 | 21 |

| Case 2 | − | 12 | − | 2 | 30 | 15 | 0.2 | 0.1 | 0.5 | 21 |

| Case 3 | − | 12 | − | 2 | 32 | 16 | 0.4 | 0.2 | 0.5 | 21 |

| Case 4 | − | 12 | − | 2 | 34 | 17 | 0.6 | 0.3 | 0.5 | 21 |

| Case 5 | − | 12 | − | 2 | 36 | 18 | 0.8 | 0.4 | 0.5 | 21 |

| Case 6 | − | 12 | − | 2 | 38 | 19 | 1.0 | 0.5 | 0.5 | 21 |

| Control Strategy | Cb_cyc (%) | ηb (%) | Qloss,% (%) | ΔCb_cyc (%) | ΔQloss,% (%) |

|---|---|---|---|---|---|

| Strategy 1 | 8.5 | 49.59 | 0.00176 | −100 | −100 |

| Strategy 2 | 24.8 | 84.43 | 0.00325 | 0 | 0 |

| Strategy 3 | 22.1 | 76.51 | 0.00207 | −16.6 | −79.2 |

| Cycles | 1000 | 2000 | 5000 | 10000 |

|---|---|---|---|---|

| Strategy 1 | 1.77 | 3.89 | 10.27 | 19.64 |

| Strategy 2 | 3.29 | 7.24 | 19.08 | 36.52 |

| Strategy 3 | 2.25 | 4.95 | 13.05 | 24.97 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Lei, Y.; Fu, Y.; Li, X. An Optimal Slip Ratio-Based Revised Regenerative Braking Control Strategy of Range-Extended Electric Vehicle. Energies 2020, 13, 1526. https://doi.org/10.3390/en13061526

Liu H, Lei Y, Fu Y, Li X. An Optimal Slip Ratio-Based Revised Regenerative Braking Control Strategy of Range-Extended Electric Vehicle. Energies. 2020; 13(6):1526. https://doi.org/10.3390/en13061526

Chicago/Turabian StyleLiu, Hanwu, Yulong Lei, Yao Fu, and Xingzhong Li. 2020. "An Optimal Slip Ratio-Based Revised Regenerative Braking Control Strategy of Range-Extended Electric Vehicle" Energies 13, no. 6: 1526. https://doi.org/10.3390/en13061526