Modeling and Analysis of a Deflection Type Permanent Magnet Synchronous Wind Generator System

Abstract

:1. Introduction

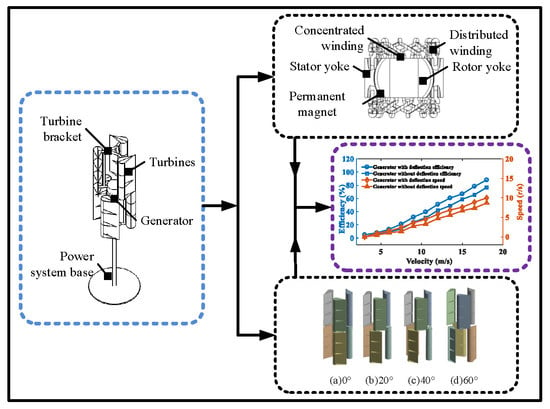

- A novel multi-DOF deflecting-type PMSG is constructed.

- The basic characteristics of the PMSG, including the structure, mechanism, electromagnetic field modeling, and torque analysis, are developed and analyzed

- The PMSG is used to operate a complete wind turbine, and the resulting aerodynamics and power generation performance of the wind turbine is analyzed.

- The generator’s operation characteristics before and after deflection are compared, and voltage variation with wind direction is demonstrated.

2. Structural Parameters and Mechanism of Multi-DOF Deflecting-Type PMSWG

2.1. Generator Structure

2.2. Determination of Main Parameters

3. Electromagnetic Field Modeling and Torque Analysis

3.1. Analytical Method Modeling

3.2. Finite Element Analysis Modeling

3.3. Torque Analysis

3.3.1. Rotation Torque

3.3.2. Deflection Torque

4. Wind Turbine Modeling

Performance Analysis

5. Multi-DOF Deflection-Type PMSWG: Transient Analysis with Deflection

5.1. Rotor Deflection Motion

5.2. Transient Analysis Post Deflection via Simulation

5.3. Experimental Transient Analysis Post Deflection

5.4. Wind Tunnel Experiment

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Blaabjerg, F.; Ma, K. Future on power electronics for wind turbine systems. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 139–152. [Google Scholar] [CrossRef]

- Du, P.; Wang, J.Z.; Yang, W.D.; Niu, T. A novel hybrid model for short-term wind power forecasting. Appl. Soft. Comput. 2019, 80, 93–106. [Google Scholar] [CrossRef]

- Davidson, M.R.; Zhang, D.; Xiong, W.; Zhang, X.; Karplus, V.J. Modeling the potential for wind energy integration on China’s coal-heavy electricity grid. Nat. Energy 2016, 1, 1–7. [Google Scholar] [CrossRef]

- Polinder, H.; Ferreira, J.A.; Jensen, B.B.; Abrahamsen, A.B.; Atallah, K.; McMahon, R.A. Trends in Wind Turbine Generator System. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 174–185. [Google Scholar] [CrossRef]

- Patil, N.S.; Bhosle, Y.N. A review on wind turbine generator topologies. In Proceedings of the 2013 International Conference on Power, Energy and Control (ICPEC), Dindigul, India, 6–8 February 2013. [Google Scholar]

- Yang, X.; Patterson, D.; Hudgins, J. Permanent magnet generator design and control for large wind turbines. In Proceedings of the 2012 IEEE Power Electronics and Machines in Wind Applications, Denver, CO, USA, 16–18 July 2012. [Google Scholar]

- Bhutto, D.K.; Ansari, J.A.S.; Bukhari, S.H.; Chachar, F.A. Wind Energy Conversion Systems (Wecs) Generators: A Review. In Proceedings of the 2019 2nd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 30–31 January 2019. [Google Scholar]

- Zhang, L.; Zhou, B.; Cheng, F.S.; Zhang, Y.S. Modeling and Dynamic Simulation of a Novel Doubly Salient Electro-Magnetic Wind Power Generator System. In Proceedings of the 2009 World Non-Grid-Connected Wind Power and Energy Conference, Nanjing, China, 24–26 September 2009. [Google Scholar]

- Zamani, M.H.; Riahy, G.H.; Abedi, M. Rotor-Speed Stability Improvement of Dual Stator-Winding Induction Generator-Based Wind Farms by Control-Windings Voltage Oriented Control. IEEE Trans. Power Electron. 2016, 31, 5538–5546. [Google Scholar] [CrossRef]

- Bai, Y.R.; Kou, B.Q.; Chan, C.C. A Simple Structure Passive MPPT Standalone Wind Turbine Generator System. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Cui, Y.; Song, P.; Wang, X.S.; Yang, W.X.; Liu, H. Wind Power Virtual Synchronous Generator Frequency Regulation Characteristics Field Test and Analysis. In Proceedings of the 2018 2nd International Conference on Green Energy and Applications (ICGEA), Singapore, 24–26 March 2018. [Google Scholar]

- Li, X.M.; Xiao, Z.; Song, D.L. A Novel Outer Rotor Axial Primary Magnetic Circuit Permanent Magnet Generator. In Proceedings of the 2015 International Conference on Advanced Mechatronic Systems (ICAMechS), Beijing, China, 22–24 August 2015. [Google Scholar]

- Li, Z.; Wang, Q.J. The present research and development situation of permanent magnet spherical motor of multi-dimensions. Small Spec. Electr. Mach. 2006, 34, 7–11. [Google Scholar]

- Li, Z.; Lun, Q.Q.; Xue, Z.T.; Wang, Q.J. Calculation and analysis of magnetic field and torque characteristics for 3-DOF deflection type PM motor. Trans. China Electrotech. Soc. 2017, 32, 81–90. [Google Scholar]

- Li, Z.; YU, X.X.; Zhang, L.W.; Xue, Z.T.; Wang, Q.J. Design and Analysis of PM Deflection Type Synchronous Wind Generator. Small Spec. Electr. Mach. 2017, 45, 14–21. [Google Scholar]

- Li, Z.; Chen, Q.M.; Wang, Q.J. Rotor dynamics characteristic analysis of Multi-degree-of-freedom permanent magnet synchronous motor. Trans. China Electrotech. Soc. 2019, 34, 2269–2276. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Liu, L.Q.; Guo, P. Modeling and Dynamics Analysis of Permanent Magnet Three-DOF Motor. Electr. Appl. 2018, 11, 37–42. [Google Scholar]

- Li, Z.; Chen, Q.; Wang, Q.J. Analysis of Magnetic-Thermal-Solid Coupling Fields of Multi-Degree of Freedom Permanent magnet motor. Small Spec. Electr. Mach. 2018, 46, 40–44. [Google Scholar]

- Meng, H.M.; Li, P.F.; Lin, Z.W.; Hu, Y. Multi-degree of freedom optimization control for large inertia wind energy conversion system using model predictive approach. In Proceedings of the 2017 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017. [Google Scholar]

- Zhang, M.H.; Li, M.T.; Sun, L.N. A Multi-DOF Ultrasonic Motor Using In-plane Deformation of PZT Elements and Its Driving Circuit. In Proceedings of the 2007 International Conference on Mechatronics and Automation, Harbin, China, 5–8 August 2007. [Google Scholar]

- Xiao, S.C.; Qin, M. Electromagnetic design and simulation for large-scale double-stator direct driving permanent magnet wind generator. Motor Control Appl. 2013, 40, 45–50. [Google Scholar]

- Lv, Y.N.; Peng, X.; Wang, B.Y. Electromagnetic design of 2MW direct drive permanent magnet synchronous wind generator. J. Hunan Inst. Eng. 2016, 206, 15–18. [Google Scholar]

- Li, Z.; Zhang, L.W.; YU, X.X.; Wang, Q.J. Electromagnetic Modeling and Transient Analysis of a Deflection Type Permanent Magnet Synchronous Wind Generator. Mach. Des. Manuf. 2019, 5, 217–221. [Google Scholar]

- Li, Z.; Gao, P.F.; Sun, T.T.; Xue, Z.T.; Wang, Q.J. Numerical simulation and analysis of characteristics of drag type vertical axis wind turbine for distributed energy system. Trans. China Electrotech. Soc. 2017, 32, 155–163. [Google Scholar]

- Kong, L.; Cai, G.; Chen, C.; Xing, L. Modeling and grid-connected control of proactive permanent magnet direct-driven wind turbine based on energy storage of hydrogen. Trans. China Electrotech. Soc. 2017, 18, 276–285. [Google Scholar]

- Brain, H.; Andrew, C.; Ger, K. Alow-order model for offshore floating vertical axis wind turbine aerodynamics. IEEE Trans. Ind. Appl. 2017, 53, 512–520. [Google Scholar]

| Parameter | Values |

|---|---|

| Rate power/kW | 10 |

| Rate current/A | 13.5 |

| Efficiency at rated operating point | 88 |

| Geometric dimension | 3 |

| Mass of generator/kg | 15 |

| Outer diameter of rotor/mm | 43 |

| Inner diameter of rotor/mm | 36 |

| Outer diameter of stator/mm | 100 |

| Inner diameter of stator/mm | 56 |

| Rated voltage/V | 120 |

| Rated speed/r/min | 600 |

| Number of magnetic pole pairs | 4 |

| Permanent magnet material | NdFeB |

| Number of parallel branches Residual magnetic flux density/T | 1 1.4 |

| Air gap width/mm | 1 |

| Step Size | Step Number | Operation Time | Nonlinear Residual |

|---|---|---|---|

| 0.0005 s | 100 | 0.05 s | 1.0 × |

| Angle | X-Axis Deflection Torque Value (N*m) | Y-Axis Deflection Torque Value (N*m) |

|---|---|---|

| 0.019923 | 0.011817 | |

| 1.1979 | 1.2316 | |

| 1.0811 | 1.0864 | |

| 0.94953 | 0.97457 | |

| 0.85378 | 0.85074 | |

| 0.7826 | 0.78247 | |

| 0.74123 | 0.71937 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Height of the blade | 0.3 m | Rated power | 10 kW |

| Radius of the blade | 0.65 m | Radius of shaft | 0.2 m |

| Height of shaft | 5 m | Starting wind speed | 2–3 m/s |

| Reynolds Number | Turbulence Model | No. of Meshes | Residual Target | Iterations |

|---|---|---|---|---|

| 6.0 × 105 | Standard k-e model | 240,000 | 1.0 × 10−4 | 200 |

| Low Speed Experimental Section | High Speed Experimental Section | |

|---|---|---|

| Model size | Width: 4 m; Long: 24 m; Height: 3 m | |

| Maximum wind velocity | ≥30.0 m/s | ≥80.0 m/s |

| Velocity instability | ≤0.6% | ≤0.2% |

| Velocity field inhomogeneity | ≤0.4% | ≤0.2% |

| Turbulivity | ≤0.4% | ≤0.2% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, W.; Li, Z.; Sun, H.; Zhang, J. Modeling and Analysis of a Deflection Type Permanent Magnet Synchronous Wind Generator System. Energies 2020, 13, 1524. https://doi.org/10.3390/en13061524

Dong W, Li Z, Sun H, Zhang J. Modeling and Analysis of a Deflection Type Permanent Magnet Synchronous Wind Generator System. Energies. 2020; 13(6):1524. https://doi.org/10.3390/en13061524

Chicago/Turabian StyleDong, Weichao, Zheng Li, Hexu Sun, and Jingxuan Zhang. 2020. "Modeling and Analysis of a Deflection Type Permanent Magnet Synchronous Wind Generator System" Energies 13, no. 6: 1524. https://doi.org/10.3390/en13061524