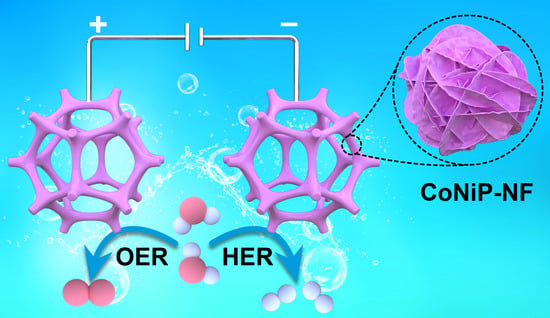

Surface Modulation of 3D Porous CoNiP Nanoarrays In Situ Grown on Nickel Foams for Robust Overall Water Splitting

Abstract

:1. Introduction

2. Results and Discussion

2.1. Structural Characterization of Catalysts

2.2. Electrochemical Characterization for HER and OER

2.3. Theoretical Calculation

3. Materials and Methods

3.1. Preparation of Cobalt/Nickel-Hydroxide Nanoarray Precursor Grown on Nickel Foam (CoNi-Hydroxides NA/NF)

3.2. Preparation of Cobalt/Nickel Nanoarrays Grown on Nickel Foam (CoNiP NA/NF-2)

3.3. Characterization

3.4. Electrochemical Measurement

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ratso, S.; Walke, P.R.; Mikli, V.; Ločs, J.; Šmits, K.; Vītola, V.; Kruusenberg, I. CO2 turned into a nitrogen doped carbon catalyst for fuel cells and metal–air battery applications. Green Chem. 2021, 23, 4435–4445. [Google Scholar] [CrossRef]

- Peng, Z.K.; Wang, H.Y.; Zhou, L.L.; Wang, Y.B.; Gao, J.; Liu, G.J.; Redfern, S.A.T.; Feng, X.L.; Lu, S.Y.; Li, B.J.; et al. Hollow carbon shells enhanced by confined ruthenium as cost-efficient and superior catalysts for the alkaline hydrogen evolution reaction. J. Mate. Chem. A 2019, 7, 6676–6685. [Google Scholar] [CrossRef]

- Jaeeun, J.; Kyoung, R.P.; Kang, M.K.; Daehyeon, K.; HyukSu, H.; Nuri, O.; Sunghwan, Y.; Chisung, A.; Sungwook, M. CoFeS2@CoS2 Nanocubes Entangled with CNT for efficient bifunctional performance for oxygen evolution and oxygen reduction reactions. Nanomaterials 2022, 12, 983. [Google Scholar]

- Sun, Y.; Xue, Z.; Liu, Q.; Jia, Y.; Li, Y.; Liu, K.; Lin, Y.; Liu, M.; Li, G.; Su, C.Y. Modulating electronic structure of metal-organic frameworks by introducing atomically dispersed Ru for efficient hydrogen evolution. Nat. Commun. 2021, 12, 1369. [Google Scholar] [CrossRef]

- Wang, C.; Qi, L. Heterostructured inter-doped ruthenium-cobalt oxide hollow nanosheet arrays for highly efficient overall water splitting. Angew. Chem. Int. Ed. Eng. 2020, 59, 17219–17224. [Google Scholar] [CrossRef]

- Li, K.; Li, Y.; Wang, Y.M.; Ge, J.J.; Liu, C.P.; Xing, W. Enhanced electrocatalytic performance for the hydrogen evolution reaction through surface enrichment of platinum nanoclusters alloying with ruthenium in situ embedded in carbon. Energy Environ. Sci. 2018, 11, 1232–1239. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, Q.; Wang, X.; Zheng, J.; Li, X. MOF-derived surface modified Ni nanoparticles as an efficient catalyst for the hydrogen evolution reaction. J. Mater. Chem. A 2015, 32, 16435–16439. [Google Scholar] [CrossRef]

- Wang, T.; Wang, X.; Liu, Y.; Zheng, J.; Li, X. A highly efficient and stable biphasic nanocrystalline Ni–Mo–N catalyst for hydrogen evolution in both acidic and alkaline electrolytes. Nano Energ. 2016, 22, 111–119. [Google Scholar] [CrossRef]

- Li, R.; Zang, J.; Li, W.; Li, J.; Zou, Q.; Zhou, S.; Wang, Y. Three-Dimensional Transition Metal Phosphide Heteronanorods for Efficient Overall Water Splitting. ChemSusChem 2020, 13, 3718–3725. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zhang, M.; Zhou, Y.; Rao, D.; Zhong, C.; Zhang, J.; Han, X.; Hu, W.; Zhang, Y.; et al. Lattice-strain engineering of homogeneous NiS0.5Se0.5 core-shell nanostructure as a highly efficient and robust electrocatalyst for overall water splitting. Adv. Mater. 2020, 32, e2000231. [Google Scholar]

- Ullah, N.; Zhao, W.; Lu, X.; Oluigbo, C.J.; Shah, S.A.; Zhang, M.; Xu, Y. In situ growth of M-MO (M= Ni, Co) in 3D graphene as a competent bifunctional electrocatalyst for OER and HER. Electrochim. Acta 2019, 298, 163–171. [Google Scholar] [CrossRef]

- Du, X.; Fu, J.; Zhang, X. NiCo2O4@ NiMoO4 supported on nickel foam for electrocatalytic water splitting. ChemCatChem 2018, 10, 5533–5540. [Google Scholar] [CrossRef]

- Pan, Y.; Sun, K.A.; Liu, S.J.; Cao, X.; Wu, K.L.; Cheong, W.C.; Chen, Z.; Wang, Y.; Li, Y.; Liu, Y.Q.; et al. Core-Shell ZIF-8@ZIF-67-Derived CoP nanoparticle-embedded N-doped carbon nanotube hollow polyhedron for efficient overall water splitting. J. Am. Chem. Soc. 2018, 140, 2610–2618. [Google Scholar] [CrossRef] [PubMed]

- Remmel, A.L.; Ratso, S.; Divitini, G.; Danilson, M.; Mikli, V.; Uibu, M.; Kruusenberg, I. Nickel and Nitrogen-Doped Bifunctional ORR and HER Electrocatalysts Derived from CO2. ACS Sus. Chem. Eng. 2022, 10, 134–145. [Google Scholar] [CrossRef]

- Wang, K.W.; She, X.L.; Chen, S.; Liu, H.L.; Li, D.H.; Wang, Y.; Zhang, H.W.; Yang, D.J.; Yao, X.D. Boosting hydrogen evolution via optimized hydrogen adsorption at the interface of CoP3 and Ni2P. J. Mate. Chem. A 2018, 6, 5560–5565. [Google Scholar] [CrossRef]

- Wang, L.; Fan, J.; Liu, Y.; Chen, M.; Lin, Y.; Bi, H.; Han, M. Phase-Modulation of Iron/Nickel Phosphides Nanocrystals “Armored” with Porous P-Doped Carbon and Anchored on P-Doped Graphene Nanohybrids for Enhanced Overall Water Splitting. Adv. Funct. Mater. 2021, 31, 2010912. [Google Scholar] [CrossRef]

- Wu, Z.; Feng, Y.H.; Qin, Z.B.; Han, X.P.; Zheng, X.R.; Deng, Y.D.; Hu, W.B. Bimetallic Multi-level layered Co-NiOOH/Ni3S2@NF nanosheet for hydrogen evolution reaction in alkaline medium. Small 2022, 2106904. [Google Scholar] [CrossRef]

- Li, G.F.; Cui, X.; Song, B.; Ouyang, H.; Wang, K.L.; Sun, Y.M.; Wang, Y.Y. One-pot synthesis of Cu-doped Ni3S2 nano-sheet/rod nanoarray for high performance supercapacitors. Chem. Eng. J. 2020, 388, 124319. [Google Scholar] [CrossRef]

- Callejas, J.F.; Read, C.G.; Popczun, E.J.; McEnaney, J.M.; Schaak, R.E. Nanostructured Co2P electrocatalyst for the hydrogen evolution reaction and direct comparison with morphologically equivalent CoP. Chem. Mater. 2015, 27, 3769–3774. [Google Scholar] [CrossRef]

- Zhou, Y.; Xi, S.Q.; Yang, X.G.; Wu, H.J. In situ hydrothermal growth of metallic Co9S8-Ni3S2 nanoarrays on nickel foam as bifunctional electrocatalysts for hydrogen and oxygen evolution reactions. J. Solid State Chem. 2019, 270, 398–406. [Google Scholar] [CrossRef]

- Yan, G.; Tan, H.Q.; Wang, Y.H.; Li, Y.G. Amorphous quaternary alloy phosphide hierarchical nanoarrays with pagoda-like structure grown on Ni foam as pH-universal electrocatalyst for hydrogen evolution reaction. Appl. Surf. Sci. 2019, 489, 519–527. [Google Scholar] [CrossRef]

- Bao, J.H.; Zhou, Y.M.; Zhang, Y.W.; Sheng, X.L.; Wang, Y.Y.; Liang, S.; Guo, C.; Yang, W.; Zhuang, T.; Hu, Y.J. Engineering water splitting sites in three-dimensional flower-like Co-Ni-P/MoS2 heterostructural hybrid spheres for accelerating electrocatalytic oxygen and hydrogen evolution. J. Mate. Chem. A 2020, 8, 22181–22190. [Google Scholar] [CrossRef]

- Hoa, V.H.; Tran, D.T.; Le, H.T.; Kim, N.H.; Lee, J.H. Hierarchically porous nickel-cobalt phosphide nanoneedle arrays loaded micro-carbon spheres as an advanced electrocatalyst for overall water splitting application. Appl. Catal. B Environ. 2019, 253, 235–245. [Google Scholar] [CrossRef]

- He, P.; Yu, X.Y.; Lou, X.W. Carbon-incorporated nickel-cobalt mixed metal phosphide nanoboxes with enhanced electrocatalytic activity for oxygen evolution. Angew. Chem. Int. Ed. 2017, 56, 3897–3900. [Google Scholar] [CrossRef]

- Ramadoss, M.; Chen, Y.; Chen, X.; Su, Z.; Karpuraranjith, M.; Yang, D.; Muralidharan, K. Iron-Modulated Three-Dimensional CoNiP Vertical Nanoarrays: An Exploratory Binder-Free Bifunctional Electrocatalyst for Efficient Overall Water Splitting. J. Phy. Chem. C 2021, 125, 20972–20979. [Google Scholar] [CrossRef]

- Liu, D.; Ai, H.; Chen, M.; Zhou, P.; Li, B.; Liu, D.; Pan, H. Multi-Phase Heterostructure of CoNiP/CoxP for Enhanced Hydrogen Evolution Under Alkaline and Seawater Conditions by Promoting H2O Dissociation. Small 2021, 17, 2007557. [Google Scholar] [CrossRef]

- Qu, M.J.; Jiang, Y.M.; Yang, M.; Liu, S.; Guo, Q.F.; Shen, W.; Li, M.; He, R.X. Regulating electron density of NiFe-P nanosheets electrocatalysts by a trifle of Ru for high-efficient overall water splitting. Appl. Catal. B Environ. 2020, 263, 118324. [Google Scholar] [CrossRef]

- Liu, Q.; Tian, J.; Cui, W.; Jiang, P.; Cheng, N.; Asiri, A.M.; Sun, X. Carbon nanotubes decorated with CoP nanocrystals: A highly active non-noble-metal nanohybrid electrocatalyst for hydrogen evolution. Angew. Chem. Int. Ed. 2014, 53, 6710–6714. [Google Scholar] [CrossRef]

- Wang, H.Y.; Niu, Z.L.; Peng, Z.K.; Wu, X.L.; Gao, C.Y.; Zhao, S.F.; Young, D.K.; Wu, H.; Du, X.; Liu, Z.Y.; et al. Engineering interface on 3D CoxNi1-x(OH)2@MoS2 hollow heterostructure for robust electrocatalytic hydrogen evolution. ACS Appl. Mater. Inter. 2022, 14, 9116–9125. [Google Scholar] [CrossRef]

- Zhang, G.X.; Li, Y.L.; Xiao, X.; Shan, Y.; Bai, Y.; Xue, H.G.; Pang, H.; Tian, Z.Q.; Xu, Q. In situ anchoring polymetallic phosphide nanoparticles within porous prussian blue analogue nanocages for boosting oxygen evolution catalysis. Nano Lett. 2021, 21, 3016–3025. [Google Scholar] [CrossRef]

- Ji, L.L.; Wei, Y.J.; Wu, P.R.; Xu, M.Z.; Wang, T.; Wang, S.; Liang, Q.F.; Meyer, T.J.; Chen, Z.F. Heterointerface engineering of Ni2P-Co2P nanoframes for efficient water splitting. Chem. Mater. 2021, 33, 9165–9173. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Gao, C.; Wang, H.; Li, B.; Zhao, S.; Kim, Y.D.; Liu, Z.; Du, X.; Peng, Z. Surface Modulation of 3D Porous CoNiP Nanoarrays In Situ Grown on Nickel Foams for Robust Overall Water Splitting. Int. J. Mol. Sci. 2022, 23, 5290. https://doi.org/10.3390/ijms23105290

Li J, Gao C, Wang H, Li B, Zhao S, Kim YD, Liu Z, Du X, Peng Z. Surface Modulation of 3D Porous CoNiP Nanoarrays In Situ Grown on Nickel Foams for Robust Overall Water Splitting. International Journal of Molecular Sciences. 2022; 23(10):5290. https://doi.org/10.3390/ijms23105290

Chicago/Turabian StyleLi, Jianpeng, Caiyan Gao, Haiyang Wang, Baojun Li, Shufang Zhao, Young Dok Kim, Zhongyi Liu, Xin Du, and Zhikun Peng. 2022. "Surface Modulation of 3D Porous CoNiP Nanoarrays In Situ Grown on Nickel Foams for Robust Overall Water Splitting" International Journal of Molecular Sciences 23, no. 10: 5290. https://doi.org/10.3390/ijms23105290