Techno-Economic Analysis of State-of-the-Art Carbon Capture Technologies and Their Applications: Scient Metric Review

Abstract

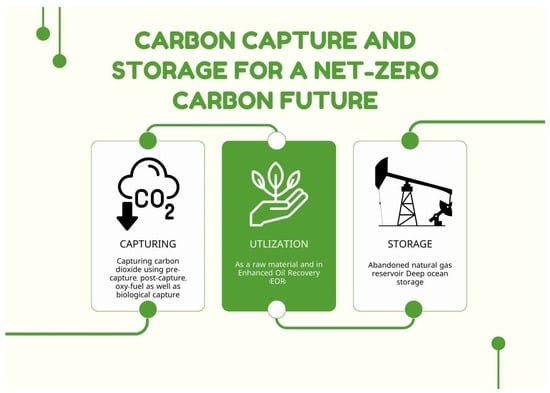

:1. Introduction

2. Literature Review

2.1. Causes and Effects of Carbon Dioxide in the Atmosphere

2.2. IPCC Regulations’ Impact on the CCS Development

2.3. Carbon Capture and Storage

2.4. Oxy-Fuel Combustion

2.5. Reviewing Carbon Capture Technologies

2.6. Waste-to-Energy Technology

Biomass Utilization in W2E Applications

2.7. Carbon Dioxide Separation Technologies

2.8. Carbon Sequestration and Utilization

- Criteria for Selecting CO2 Storage Sites:

- CO2 storage sites are chosen after careful evaluation of various factors:

- -

- Capacity of the Site: Adequate capacity is crucial to accommodating significant CO2 emissions.

- -

- Porosity: High porosity facilitates effective CO2 storage within the geological formations.

- -

- Thickness: A thick geological formation provides a larger volume for CO2 storage.

- -

- Accessibility: Easy access to the site is essential for practical implementation.

- -

- Sealing Capability: The site’s ability to prevent CO2 leakage is critical to avoiding environmental risks.

- -

- Geological Stability: A stable geological formation ensures long-term containment of CO2, ensuring safety.

- Adaptation from Enhanced Oil Recovery (EOR) Projects:

- Limited Practical Experience and Environmental Impacts:

- Different Geological Storage Sites:

- -

- Abandoned Oil and Gas Reservoirs: Empty or near-empty reservoirs are considered potential CO2 storage sites.

- -

- Unmendable Coal Beds: Certain coal beds that are unsuitable for mining may serve as storage sites.

- -

- Saline Aquifers: Underground saline water formations offer another option for CO2 storage.

- -

- Deep Ocean Storage: While a potential storage solution, it raises environmental concerns related to ocean acidification and eutrophication, making it less encouraged [62].

- Enhanced Oil Recovery (EOR): CO2 can be used to enhance oil recovery from oil fields. The injected CO2 helps to mobilize oil, making it easier to extract. While this method captures and stores some CO2, it also increases oil production and, consequently, carbon emissions from burning the additional oil [63].

- Mineralization: CO2 can be converted into mineral forms by reacting with certain rocks or minerals. This process, called mineral carbonation, results in the stable, long-term storage of CO2 in solid carbonate minerals [64].

- Afforestation and Reforestation

- Forest Management

- Agroforestry

- Soil Carbon Sequestration

- Wetland Restoration

- Blue Carbon Ecosystems

- Biochar

- Carbon Farming

- Marine Algae and Phytoplankton

3. Methodology

3.1. Conceptual Framework

3.2. Effect of Technology Costs on Mitigation Factors

3.3. Energy Generation Methods with CO2 Removal

4. Analysis

4.1. Overview of CCS Research Publication Trends

4.2. CCS Knowledge Structure

4.3. Modeling and Kinetic Studies

4.4. Some Tools That Are Used in CCS Analysis

- I.

- FOQUS: A structure is proposed for optimizing and measuring uncertainty and sensitivity, facilitating the integration of fundamental data sub-models like thermodynamics and kinetics into comprehensive process models. This integration allows for the swift synthesis and optimization of processes while also assessing the degree of uncertainty linked to the final outcomes.

- II.

- COPLOS, which stands for ‘communication about prospects and limitations of simulation results for policymakers’, is an exchange between simulation experts and simulation users who work in the field of carbon capture technologies. Different research articles have been developed using COPLOS as their tool of analysis. This tool is helpful and is used to bridge the gap between technical experts and policymakers. This tool has the potential, if used frequently, to speed up the development of different CCS, and its commercialization potential could be thoroughly developed.

- III.

- PIMS stands for polymers of intrinsic microporosity (PIMS), which are a unique class of polymers that are commonly used to capture CO2. Such polymers are used to assess and analyze the carbon capture potential of a post-combustion CCS technology, for example, absorption technology. This technology is still in development, but it provides a reliable measure of how efficient and applicable a certain technology is when it comes to absorbing CO2 from the atmosphere.

4.5. Economic Analysis of CCS Technologies

LCOE Analysis

5. Discussions

5.1. Significance of Carbon Capture Technologies

5.2. Risk Analysis of Different CCS Technologies

5.3. Limitations of CO2 Capture Capacity

5.4. Life Cycle Analysis for CCU

5.5. Government Policies in Connection to CCS

- -

- Effectiveness in Emission Reduction: The IPCC report recognized CCS as an effective method for reducing greenhouse gas emissions, particularly from large-scale fossil-based energy and industrial sources. It acknowledged that CCS could play a significant role in limiting global warming to the desired targets, such as the 1.5 °C warming limit outlined in the Paris Agreement [105].

- -

- Feasibility and Viability: The report underscored the technical feasibility and viability of CCS technologies. It provided evidence and modeling scenarios that demonstrated the potential for widescale deployment of CCS across various sectors to achieve emissions reductions.

- -

- Complementary Role with Carbon Dioxide Removal (CDR): The IPCC report highlighted the complementary relationship between CCS and technology-based carbon dioxide removal (CDR) methods. It recognized that while emissions reduction efforts are crucial, there will still be residual emissions that need to be counterbalanced with CDR and CCS to achieve net-zero emissions.

- -

- Role in Specific Sectors: The report emphasized the importance of CCS in certain sectors, such as heavy industry and power generation. It identified CCS as a key tool for decarbonizing these sectors, which are particularly challenging to address through other means.

- -

- Integration with Sustainable Development Goals (SDGs): The report analyzed the relationship between CCS and the Sustainable Development Goals (SDGs). It identified synergies between CCS deployment and specific SDGs, demonstrating how CCS can contribute to broader sustainable development objectives.

- -

- Policy Support and Investment: The IPCC report called for increased policy support and investment in CCS technologies. It encouraged governments and stakeholders to create favorable regulatory frameworks and financial incentives to promote the development and deployment of CCS projects.

- -

- Financial Incentives and Subsidies: Governments may offer financial incentives, grants, or subsidies to support the development and deployment of CCS technologies. These incentives can help reduce the high upfront costs associated with building and operating CCS facilities and encourage private investment in such projects.

- -

- Carbon Pricing: Many countries implement carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, to put a price on carbon emissions. By valuing CO2 reductions, these policies create economic incentives for industries to invest in CCS technologies as a means to lower their carbon liabilities and comply with emissions reduction targets.

- -

- Regulatory Requirements and Emission Standards: Governments may establish regulations or emission standards that require certain industries or large emitters to reduce their greenhouse gas emissions. CCS can be considered a compliance option, providing companies with an alternative way to meet their emission reduction obligations.

- -

- Research and Development Funding: Governments often invest in research and development (R&D) programs focused on advancing CCS technologies. These funding initiatives aim to improve the efficiency, cost-effectiveness, and safety of CCS systems, making them more viable for widespread deployment.

- -

- Supportive Policy Frameworks: Governments can create comprehensive policy frameworks that prioritize low-carbon technologies, including CCS, within national energy and climate strategies. This involves setting clear long-term goals and targets for emissions reductions and providing a roadmap for CCS integration into the energy sector.

- -

- Carbon Capture Utilization and Storage (CCUS) Deployment Roadmaps: Governments may develop deployment roadmaps outlining the steps and timelines for the large-scale adoption of CCUS technologies. These roadmaps facilitate coordination among stakeholders and provide a clear vision for the development and deployment of CCS projects.

- -

- Public–Private Partnerships: Governments may establish partnerships with private companies and research institutions to accelerate the development and deployment of CCS technologies. Such collaborations can leverage expertise, resources, and funding to overcome technical and financial challenges.

- -

- International Collaboration and Agreements: Many governments participate in international agreements and initiatives to cooperate on CCS research, development, and deployment. Sharing knowledge and experiences with other countries can help accelerate the global deployment of CCS technologies.

- -

- Support for CCS Infrastructure: Governments may provide support for the development of CCS infrastructure, such as CO2 transport and storage networks, to encourage the growth of a viable CCS industry.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| COP21 | 21st Conference of The Parties |

| GHG | Greenhouse gases |

| IPCC | Intergovernmental Panel on Climate Change |

| UNFCC | United Nations Framework Convention on Climate Change |

| CCS | Carbon capture and storage |

| CDR | Carbon dioxide removal |

| LCA | Life cycle assessment |

| ASU | Air separation unit |

| IGCC | integra |

| OFC | Oxy-fuel combustion |

| NCS | Natural climate solutions |

| BECCS | Bioenergy With carbon capture and storage |

| DACS | Direct air capture and storage |

| OFC | Oxy-fuel combustion |

| CHP | Combined heat and power |

| LCOE | Levelized cost of energy |

| NPV | Net present value |

| PV | Present value |

| SBC | Sodium bicarbonate slurry |

| CSP | Concentrated solar power |

| TGA | Thermogravimetric analysis |

| FTIR | Fourier transform infrared |

| GC | Gas chromatography |

| MS | Mass spectrometry |

| CD | Carbon emissions |

| GPD | Economic development |

| P | Population |

| E | Energy production |

| C | Carbon-based fuel |

| Carbon dioxide sinks | |

| CFD | Computational fluid dynamics |

| FOQUS | Framework for optimization, quantification of uncertainty and surrogates |

| COPLOS | Communication about prospects and limitations of simulation results for policymakers |

| PIMS | Polymers of intrinsic microporosity |

| YCN | Year of carbon neutrality |

References

- Chen, X.; Wu, X. The roles of carbon capture, utilization and storage in the transition to a low-carbon energy system using a stochastic optimal scheduling approach. J. Clean. Prod. 2022, 366, 132860. [Google Scholar] [CrossRef]

- Gowd, S.C.; Ganeshan, P.; Vigneswaran, V.S.; Hossain, M.S.; Kumar, D.; Rajendran, K.; Ngo, H.H.; Pugazhendhi, A. Economic perspectives and policy insights on carbon capture, storage, and utilization for sustainable development. Sci. Total. Environ. 2023, 883, 163656. [Google Scholar] [CrossRef] [PubMed]

- Henry, A.; McCallum, C.; McStay, D.; Rooney, D.; Robertson, P.; Foley, A. Analysis of wind to hydrogen production and carbon capture utilisation and storage systems for novel production of chemical energy carriers. J. Clean. Prod. 2022, 354, 131695. [Google Scholar] [CrossRef]

- Kim, Y.J.; Cho, S.H.; Sharma, B.P. Constructing efficient portfolios of low-carbon technologies. Renew. Sustain. Energy Rev. 2021, 150, 111515. [Google Scholar] [CrossRef]

- Masson-Delmotte, V.; Zhai, P.; Pörtner, H.-O.; Roberts, D.; Skea, J.; Shukla, P.R.; Pirani, A.; Moufouma-Okia, W.; Péan, C.; Pidcock, R.; et al. Global Warming of 1.5 °C an IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty Edited by Science Officer Science Assistant Graphics Officer Working Group I Technical Support Unit. 2019. Available online: www.environmentalgraphiti.org (accessed on 16 November 2022).

- D’Amore, F.; Romano, M.C.; Bezzo, F. Carbon capture and storage from energy and industrial emission sources: A Europe-wide supply chain optimisation. J. Clean. Prod. 2021, 290, 125202. [Google Scholar] [CrossRef]

- Olabi, A.G.; Obaideen, K.; Elsaid, K.; Wilberforce, T.; Sayed, E.T.; Maghrabie, H.M.; Abdelkareem, M.A. Assessment of the pre-combustion carbon capture contribution into sustainable development goals SDGs using novel indicators. Renew. Sustain. Energy Rev. 2022, 153, 111710. [Google Scholar] [CrossRef]

- Du, K.; Li, P.; Yan, Z. Do green technology innovations contribute to carbon dioxide emission reduction? Empirical evidence from patent data. Technol. Forecast. Soc. Chang. 2019, 146, 297–303. [Google Scholar] [CrossRef]

- Giannousakis, A.; Hilaire, J.; Nemet, G.F.; Luderer, G.; Pietzcker, R.C.; Rodrigues, R.; Baumstark, L.; Kriegler, E. How uncertainty in technology costs and carbon dioxide removal availability affect climate mitigation pathways. Energy 2021, 216, 119253. [Google Scholar] [CrossRef]

- Heubaum, H.; Biermann, F. Integrating global energy and climate governance: The changing role of the International Energy Agency. Energy Policy 2015, 87, 229–239. [Google Scholar] [CrossRef]

- Ghiat, I.; Al-Ansari, T. A review of carbon capture and utilisation as a CO2 abatement opportunity within the EWF nexus. J. CO2 Util. 2021, 45, 101432. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, Y.; Li, Y.; Teng, Y.; Yue, W. Can bioenergy carbon capture and storage aggravate global water crisis? Sci. Total Environ. 2020, 714, 136856. [Google Scholar] [CrossRef] [PubMed]

- Dindi, A.; Quang, D.V.; Vega, L.F.; Nashef, E.; Abu-Zahra, M.R.M. Applications of fly ash for CO2 capture, utilization, and storage. J. CO2 Util. 2019, 29, 82–102. [Google Scholar] [CrossRef]

- Dash, S.K.; Samanta, A.N.; Bandyopadhyay, S.S. Simulation and parametric study of post combustion CO2 capture process using (AMP + PZ) blended solvent. Int. J. Greenh. Gas Control 2014, 21, 130–139. [Google Scholar] [CrossRef]

- Khan, F.M.; Krishnamoorthi, V.; Mahmud, T. Modelling reactive absorption of CO2 in packed columns for post-combustion carbon capture applications. Chem. Eng. Res. Des. 2011, 89, 1600–1608. [Google Scholar] [CrossRef]

- Hussin, F.; Aroua, M.K. Recent trends in the development of adsorption technologies for carbon dioxide capture: A brief literature and patent reviews (2014–2018). J. Clean. Prod. 2020, 253, 119707. [Google Scholar] [CrossRef]

- Jung, S.; Park, Y.K.; Kwon, E.E. Strategic use of biochar for CO2 capture and sequestration. J. CO2 Util. 2019, 32, 128–139. [Google Scholar] [CrossRef]

- Ahmed, R.; Liu, G.; Yousaf, B.; Abbas, Q.; Ullah, H.; Ali, M.U. Recent advances in carbon-based renewable adsorbent for selective carbon dioxide capture and separation—A review. J. Clean. Prod. 2020, 242, 118409. [Google Scholar] [CrossRef]

- Pokhrel, S.R.; Hewage, K.; Chhipi-Shrestha, G.; Karunathilake, H.; Li, E.; Sadiq, R. Carbon capturing for emissions reduction at building level: A market assessment from a building management perspective. J. Clean. Prod. 2021, 294, 126323. [Google Scholar] [CrossRef]

- Shu, D.Y.; Deutz, S.; Winter, B.A.; Baumgärtner, N.; Leenders, L.; Bardow, A. The role of carbon capture and storage to achieve net-zero energy systems: Trade-offs between economics and the environment. Renew. Sustain. Energy Rev. 2023, 178, 113246. [Google Scholar] [CrossRef]

- Wennersten, R.; Sun, Q.; Li, H. The future potential for Carbon Capture and Storage in climate change mitigation—An overview from perspectives of technology, economy and risk. J. Clean. Prod. 2015, 103, 724–736. [Google Scholar] [CrossRef]

- Van Alphen, K.; Noothout, P.M.; Hekkert, M.P.; Turkenburg, W.C. Evaluating the development of carbon capture and storage technologies in the United States. Renew. Sustain. Energy Rev. 2010, 14, 971–986. [Google Scholar] [CrossRef]

- Nocito, F.; Dibenedetto, A. Atmospheric CO2 mitigation technologies: Carbon capture utilization and storage. Curr. Opin. Green Sustain. Chem. 2020, 21, 34–43. [Google Scholar] [CrossRef]

- Norouzi, M.; Haddad, A.N.; Jiménez, L.; Hoseinzadeh, S.; Boer, D. Carbon footprint of low-energy buildings in the United Kingdom: Effects of mitigating technological pathways and decarbonization strategies. Sci. Total Environ. 2023, 882, 163490. [Google Scholar] [CrossRef]

- Rahman, F.A.; Aziz, M.M.A.; Saidur, R.; Bakar, W.A.W.A.; Hainin, M.R.; Putrajaya, R.; Hassan, N.A. Pollution to solution: Capture and sequestration of carbon dioxide (CO2) and its utilization as a renewable energy source for a sustainable future. Renew. Sustain. Energy Rev. 2017, 71, 112–126. [Google Scholar] [CrossRef]

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- Agaton, C.B. Application of real options in carbon capture and storage literature: Valuation techniques and research hotspots. Sci. Total. Environ. 2021, 795, 148683. [Google Scholar] [CrossRef] [PubMed]

- Chao, C.; Deng, Y.; Dewil, R.; Baeyens, J.; Fan, X. Post-combustion carbon capture. Renew. Sustain. Energy Rev. 2021, 138, 110490. [Google Scholar] [CrossRef]

- Talapaneni, S.N.; Singh, G.; Kim, I.Y.; AlBahily, K.; Al-Muhtaseb, A.H.; Karakoti, A.S.; Tavakkoli, E.; Vinu, A. Nanostructured Carbon Nitrides for CO2 Capture and Conversion. Adv. Mater. 2020, 32, e1904635. [Google Scholar] [CrossRef]

- Zhang, Z.; Pan, S.Y.; Li, H.; Cai, J.; Olabi, A.G.; Anthony, E.J.; Manovic, V. Recent advances in carbon dioxide utilization. Renew. Sustain. Energy Rev. 2020, 125, 109799. [Google Scholar] [CrossRef]

- Wei, N.; Liu, S.; Jiao, Z.; Li, X.C. A possible contribution of carbon capture, geological utilization, and storage in the Chinese crude steel industry for carbon neutrality. J. Clean. Prod. 2022, 374, 133793. [Google Scholar] [CrossRef]

- Zhou, N.; Price, L.; Yande, D.; Creyts, J.; Khanna, N.; Fridley, D.; Lu, H.; Feng, W.; Liu, X.; Hasanbeigi, A.; et al. A roadmap for China to peak carbon dioxide emissions and achieve a 20% share of non-fossil fuels in primary energy by 2030. Appl. Energy 2019, 239, 793–819. [Google Scholar] [CrossRef]

- Yao, X.; Yuan, X.; Yu, S.; Lei, M. Economic feasibility analysis of carbon capture technology in steelworks based on system dynamics. J. Clean. Prod. 2021, 322, 129046. [Google Scholar] [CrossRef]

- Porter, R.T.J.; Fairweather, M.; Kolster, C.; Mac Dowell, N.; Shah, N.; Woolley, R.M. Cost and performance of some carbon capture technology options for producing different quality CO2 product streams. Int. J. Greenh. Gas Control 2017, 57, 185–195. [Google Scholar] [CrossRef]

- Wilberforce, T.; Olabi, A.G.; Sayed, E.T.; Elsaid, K.; Abdelkareem, M.A. Progress in carbon capture technologies. Sci. Total Environ. 2021, 761. [Google Scholar] [CrossRef] [PubMed]

- Williams, J.H.; Jones, R.A.; Haley, B.; Kwok, G.; Hargreaves, J.; Farbes, J.; Torn, M.S. Carbon-Neutral Pathways for the United States. AGU Adv. 2021, 2, e2020AV000284. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Lootah, M.A.; Sayed, E.T.; Wilberforce, T.; Alawadhi, H.; Yousef, B.A.A.; Olabi, A.G. Fuel cells for carbon capture applications. Sci. Total Environ. 2021, 769, 144243. [Google Scholar] [CrossRef]

- Baena-Moreno, F.M.; Rodríguez-Galán, M.; Vega, F.; Alonso-Fariñas, B.; Vilches Arenas, L.F.; Navarrete, B. Carbon capture and utilization technologies: A literature review and recent advances. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 1403–1433. [Google Scholar] [CrossRef]

- Jiang, K.; Ashworth, P.; Zhang, S.; Liang, X.; Sun, Y.; Angus, D. China’s carbon capture, utilization and storage (CCUS) policy: A critical review. Renew. Sustain. Energy Rev. 2020, 119, 109601. [Google Scholar] [CrossRef]

- Khudhur, F.W.K.; MacDonald, J.M.; Macente, A.; Daly, L. The utilization of alkaline wastes in passive carbon capture and sequestration: Promises, challenges and environmental aspects. Sci. Total. Environ. 2022, 823, 153553. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Ma, X.; Cai, W.; Cai, W. Carbon-dioxide mitigation in the residential building sector: A household scale-based assessment. Energy Convers. Manag. 2019, 198, 111915. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Elsaid, K.; Sayed, E.T.; Maghrabie, H.M.; Abdelkareem, M.A. Large scale application of carbon capture to process industries—A review. J. Clean. Prod. 2022, 362, 132300. [Google Scholar] [CrossRef]

- Lin, B.; Ma, R. Towards carbon neutrality: The role of different paths of technological progress in mitigating China’s CO2 emissions. Sci. Total Environ. 2022, 813, 152588. [Google Scholar] [CrossRef]

- Wienchol, P.; Szlęk, A.; Ditaranto, M. Waste-to-energy technology integrated with carbon capture—Challenges and opportunities. Energy 2020, 198, 117352. [Google Scholar] [CrossRef]

- Kontou, V.; Grimekis, D.; Braimakis, K.; Karellas, S. Techno-economic assessment of dimethyl carbonate production based on carbon capture and utilization and power-to-fuel technology. Renew. Sustain. Energy Rev. 2022, 157, 112006. [Google Scholar] [CrossRef]

- Kemper, J. Biomass and carbon dioxide capture and storage: A review. Int. J. Greenh. Gas Control 2015, 40, 401–430. [Google Scholar] [CrossRef]

- Poblete, I.B.S.; Araujo, O.d.Q.F.; De Medeiros, J.L. Dynamic analysis of sustainable biogas-combined-cycle plant: Time-varying demand and bioenergy with carbon capture and storage. Renew. Sustain. Energy Rev. 2020, 131, 109997. [Google Scholar] [CrossRef]

- Martín, C.F.; Plaza, M.G.; Pis, J.J.; Rubiera, F.; Pevida, C.; Centeno, T.A. On the limits of CO2 capture capacity of carbons. Sep. Purif. Technol. 2010, 74, 225–229. [Google Scholar] [CrossRef]

- Scheer, D. Computer simulation at the science-policy interface: Assessing the policy relevance of Carbon Capture & Storage simulations. Energy Procedia 2011, 4, 5770–5777. [Google Scholar] [CrossRef]

- Mukherjee, A.; Okolie, J.A.; Abdelrasoul, A.; Niu, C.; Dalai, A.K. Review of post-combustion carbon dioxide capture technologies using activated carbon. J. Environ. Sci. 2019, 83, 46–63. [Google Scholar] [CrossRef] [PubMed]

- Luan, B.; Huang, J.; Zou, H. Domestic R&D, technology acquisition, technology assimilation and China’s industrial carbon intensity: Evidence from a dynamic panel threshold model. Sci. Total Environ. 2019, 693, 133436. [Google Scholar] [CrossRef] [PubMed]

- Lei, L.; Pan, F.; Lindbrathen, A.; Zhang, X.; Hillestad, M. Carbon hollow fiber membranes for a molecular sieve with precise-cutoff ultramicropores for superior hydrogen separation. Nat. Commun. 2021, 12, 268. [Google Scholar] [CrossRef] [PubMed]

- Sreenivasulu, B.; Gayatri, D.V.; Sreedhar, I.; Raghavan, K.V. A journey into the process and engineering aspects of carbon capture technologies. Renew. Sustain. Energy Rev. 2015, 41, 1324–1350. [Google Scholar] [CrossRef]

- Kikuchi, R. CO2 Recovery and Reuse in the Energy Sector, Energy Resource Development and Others: Economic and Technical Evaluation of Large-Scale Co2 Recycling. Energy Environ. 2003, 14, 383–395. [Google Scholar] [CrossRef]

- Dooley, J.; Davidson, C. Carbon Dioxide Capture and Geologic Storage: A Key Component of a Global Energy Technology Strategy to Address Climate Change; Joint Global Change Research Institute: Riverdale Park, MD, USA, 2006. [Google Scholar]

- Aresta, M.; Angela, D. Carbon Recycling Through CO2-Conversion for Stepping Toward a Cyclic-C Economy. A Perspective. Frontiers 2020, 8, 159. [Google Scholar] [CrossRef]

- Oldenburg, C. Migration Mechanisms and Potential Impacts of CO2 Leakage and Seepage; Lawrence National Lab: Livermore, CA, USA, 2013. [Google Scholar]

- Reichle, D.; Houghton, J.; Kane, B.; Ekmann, J. Carbon Sequestration Research and Development; Depeartment of Energy: Washington, DC, USA, 1999. [Google Scholar]

- Leung, D.; Caramanna, G.; Maroto-Valer, M. An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 2014, 39, 426–443. [Google Scholar] [CrossRef]

- Bachu, S. Sequestration of CO2 in geological media: Criteria and approach for site selection in response to climate change. Energy Convers. Manag. 1999, 41, 953–970. [Google Scholar] [CrossRef]

- Spek, M.; Fernandez, E.; Eldrup, N.; Skagested, R.; Ramirez, A.; Faaij, A. Unravelling uncertainty and variability in early stage techno-economic assessments of carbon capture technologies. Int. J. Greenh. Gas Control 2016, 56, 221–236. [Google Scholar] [CrossRef]

- Langie, K.; Tak, K.; Kim, C. Toward economical application of carbon capture and utilization technology with near-zero carbon emission. Nat. Commun. 2022, 13, 7482. [Google Scholar] [CrossRef] [PubMed]

- Alshargabi, M.; Davoodi, S.; Wood, D. Carbon Dioxide Applications for Enhanced Oil Recovery Assisted by Nanoparticles: Recent Developments. ACS Omega 2022, 7, 9984–9994. [Google Scholar] [CrossRef] [PubMed]

- Almutairi, H.; Pierru, A. Assessing Climate Mitigation Benefits of Public Support to CCS-EOR: An Economic Analysis; King Abdullah Petroleum Studies and Research Center (“KAPSARC”): Riyadh, Saudi Arabia, 2023; p. 24. [Google Scholar]

- Ghayathri, R.; Mahboob, S.; Govindarajan, M.; Alghanim, K.; Ahmed, Z.; Almulhum, N.; Vodovnik, M.; Vijayalakshmi, S. A review on biological carbon sequestration: A sustainable solution for a cleaner air environment, less pollution and lower health risks. J. King Saud Univ. Sci. 2021, 33, 101282. [Google Scholar] [CrossRef]

- Alami, A.H.; Abu Hawili, A.; Tawalbeh, M.; Hasan, R.; Al Mahmoud, L.; Chibib, S.; Mahmood, A.; Aokal, K.; Rattanapanya, P. Materials and logistics for carbon dioxide capture, storage and utilization. Sci. Total Environ. 2020, 717, 137221. [Google Scholar] [CrossRef]

- Bermeo, M.; Vega, L.F.; Abu-Zahra, M.R.M.; Khaleel, M. Critical assessment of the performance of next-generation carbon-based adsorbents for CO2 capture focused on their structural properties. Sci. Total. Environ. 2022, 810, 151720. [Google Scholar] [CrossRef]

- Ko, K.; Lee, J.Y.; Chung, H. Highly efficient colorimetric CO2 sensors for monitoring CO2 leakage from carbon capture and storage sites. Sci. Total Environ. 2020, 729, 138786. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Jiang, H.D.; Yang, B.; Liao, H. An analysis of research hotspots and modeling techniques on carbon capture and storage. Sci. Total. Environ. 2019, 687, 687–701. [Google Scholar] [CrossRef]

- Sarkar, A.; Pan, W.; Suh, D.M.; Huckaby, E.D.; Sun, X. Multiphase flow simulations of a moving fluidized bed regenerator in a carbon capture unit. Powder Technol. 2014, 265, 35–46. [Google Scholar] [CrossRef]

- Zhai, M.; Jia, H.; Yin, D. An interval chance-constrained programming-based optimization model for carbon capture, utilization, and storage system planning. Sci. Total Environ. 2021, 772, 145560. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Guo, Y. Rate based modeling of absorption and regeneration for CO2 capture by aqueous ammonia solution. Appl. Energy 2013, 111, 142–152. [Google Scholar] [CrossRef]

- Borgonovo, E. A methodology for determining interactions in probabilistic safety assessment models by varying one parameter at a time. Risk Anal. 2010, 30, 385–399. [Google Scholar] [CrossRef] [PubMed]

- Gardarsdottir, S.O.; De Lena, E.; Romano, M.; Roussanaly, S.; Voldsund, M.; Pérez-Calvo, J.F.; Berstad, D.; Fu, C.; Anantharaman, R.; Sutter, D.; et al. Comparison of technologies for CO2 capture from cement production—Part 2: Cost analysis. Energies 2019, 12, 542. [Google Scholar] [CrossRef]

- Hepburn, C.; Adlen, E.; Beddington, J.; Carter, E.A.; Fuss, S.; Mac Dowell, N.; Minx, J.C.; Smith, P.; Williams, C.K. The technological and economic prospects for CO2 utilization and removal. Nature 2019, 575, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Fikru, M.G. The impact of policies on profit-maximizing rates of reliance on carbon capture for storage versus cleaner production. J. Clean. Prod. 2022, 379, 134659. [Google Scholar] [CrossRef]

- Yong, W.T.L.; Thien, V.Y.; Rupert, R.; Rodrigues, K.F. Seaweed: A potential climate change solution. Renew. Sustain. Energy Rev. 2022, 159, 112222. [Google Scholar] [CrossRef]

- Guo, Z.-L.; Bian, X.-L.; DU, Y.-B.; Zhang, W.-C.; Yao, D.-D.; Yang, H.-P. Recent advances in integrated carbon dioxide capture and methanation technology. J. Fuel Chem. Technol. 2023, 51, 293–302. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Wilberforce, T.; Baroutaji, A.; Soudan, B.; Al-Alami, A.H.; Olabi, A.G. Outlook of carbon capture technology and challenges. Sci. Total Environ. 2019, 657, 56–72. [Google Scholar] [CrossRef]

- Bolan, N.; Hoang, S.A.; Beiyuan, J.; Gupta, S.; Hou, D.; Karakoti, A.; Joseph, S.; Jung, S.; Kim, K.H.; Kirkham, M.B.; et al. Multifunctional applications of biochar beyond carbon storage. Int. Mater. Rev. 2022, 67, 150–200. [Google Scholar] [CrossRef]

- Rosa, L.; Sanchez, D.L.; Realmonte, G.; Baldocchi, D.; D’Odorico, P. The water footprint of carbon capture and storage technologies. Renew. Sustain. Energy Rev. 2021, 138, 110511. [Google Scholar] [CrossRef]

- Zheng, C.; Wu, X.; Chen, X. Low-carbon transformation of ethylene production system through deployment of carbon capture, utilization, storage and renewable energy technologies. J. Clean. Prod. 2023, 413, 137475. [Google Scholar] [CrossRef]

- Cao, M.; Shu, Y.; Bai, Q.; Li, C.; Chen, B.; Shen, Y.; Uyama, H. Design of biomass-based N, S co-doped porous carbon via a straightforward post-treatment strategy for enhanced CO2 capture performance. Sci. Total Environ. 2023, 884, 163750. [Google Scholar] [CrossRef]

- Dabral, S.; Schaub, T. The Use of Carbon Dioxide (CO2) as a Building Block in Organic Synthesis from an Industrial Perspective. Adv. Synth. Catal. 2019, 361, 223–246. [Google Scholar] [CrossRef]

- Balaguer, M.; Puig, S.; Bolognesi, S.; Baneras, L.; Peona-vico, E.; Capodagio, A. Carbon dioxide to bio-oil in a bioelectrochemical system-assisted microalgae biorefinery process. Sustain. Energy Fuels 2022, 6, 150–161. [Google Scholar]

- Singh, G.; Lakhi, K.S.; Sil, S.; Bhosale, S.V.; Kim, I.Y.; Albahily, K.; Vinu, A. Biomass derived porous carbon for CO2 capture. In Carbon; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; Volume 148, pp. 164–186. [Google Scholar] [CrossRef]

- Jadoon, U.K.; Ahmad, I.; Noor, T.; Kano, M.; Caliskan, H.; Ahsan, M. An intelligent sensing system for estimation of efficiency of carbon-capturing unit in a cement plant. J. Clean. Prod. 2022, 377, 134359. [Google Scholar] [CrossRef]

- Dubey, A.; Arora, A. Advancements in carbon capture technologies: A review. J. Clean. Prod. 2022, 373, 133932. [Google Scholar] [CrossRef]

- Ryu, K.H.; Kim, B.; Heo, S. Sustainability analysis framework based on global market dynamics: A carbon capture and utilization industry case. Renew. Sustain. Energy Rev. 2022, 166, 112639. [Google Scholar] [CrossRef]

- Li, J.R.; Ma, Y.; McCarthy, M.C.; Sculley, J.; Yu, J.; Jeong, H.K.; Balbuena, P.B.; Zhou, H.C. Carbon dioxide capture-related gas adsorption and separation in metal-organic frameworks. Coord. Chem. Rev. 2011, 255, 1791–1823. [Google Scholar] [CrossRef]

- Martin, E.; Scott, V.; Flude, S.; Johnson, G.; Stuart, R. Carbon capture and storage at the end of a lost decade. One Earth 2021, 4, 1569–1584. [Google Scholar] [CrossRef]

- Wang, N.; Akimoto, K.; Nemet, G. What went wrong? Learning from three decades of carbon capture, utilization and sequestration (CCUS) pilot and demonstration projects. Energy Policy 2021, 158, 112546. [Google Scholar] [CrossRef]

- Rubin, E.S.; Short, C.; Booras, G.; Davison, J.; Ekstrom, C.; Matuszewski, M.; McCoy, S. A proposed methodology for CO2 Capture and Storage Cost Estimates. Int. J. Greenh. Gas Control 2013, 17, 488–503. [Google Scholar] [CrossRef]

- Kheirinik, M.; Ahmed, S.; Rahmanian, N. Comparative Techno-Economic Analysis of Carbon Capture Processes: Pre-Combustion, Post-Combustion, and Oxy-Fuel Combustion Operations. Sustainability 2021, 13, 13567. [Google Scholar] [CrossRef]

- Taylor, J.H. The ‘process step scoring’ method for making quick capital estimates. Eng. Process Ecom. 1977, 2, 259–267. [Google Scholar] [CrossRef]

- Retail Prices Index: Long Run Series. Census. 2021. Available online: https://www.ons.gov.uk/economy/inflationandpriceindices/timeseries/cdko/mm23 (accessed on 11 August 2023).

- Petley, G.J. A Method for Estimating the Capital Cost of Chemical Process Plants: Fuzzy Matching; Loughborough University: Loughborough, UK, 1997. [Google Scholar]

- Bai, C.; Feng, C.; Yan, H.; Yi, X.; Chen, Z.; Wei, W. Will income inequality influence the abatement effect of renewable energy technological innovation on carbon dioxide emissions? J. Environ. Manag. 2020, 264, 110482. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, J.; Deng, S.; Suvarna, M.; Wang, X.; Zhang, W.; Hamilton, S.T.; Alahmed, A.; Jamal, A.; Park, A.H.A.; et al. Recent advancements in sustainable upcycling of solid waste into porous carbons for carbon dioxide capture. Sustain. Energy Rev. 2022, 162, 112413. [Google Scholar] [CrossRef]

- Khosroabadi, F.; Aslani, A.; Bekhrad, K.; Zolfaghari, Z. Analysis of Carbon Dioxide Capturing Technologies and their technology developments. Clean. Eng. Technol. 2021, 5, 100279. [Google Scholar] [CrossRef]

- Mikulčić, H.; Skov, I.R.; Dominković, D.F.; Wan Alwi, S.R.; Manan, Z.A.; Tan, R.; Duić, N.; Hidayah Mohamad, S.N.; Wang, X. Flexible Carbon Capture and Utilization technologies in future energy systems and the utilization pathways of captured CO2. Renew. Sustain. Energy Rev. 2019, 114, 109338. [Google Scholar] [CrossRef]

- López, L.R.; Dessì, P.; Cabrera-Codony, A.; Rocha-Melogno, L.; Kraakman, B.; Naddeo, V.; Balaguer, M.D.; Puig, S. CO2 in indoor environments: From environmental and health risk to potential renewable carbon source. Sci. Total. Environ. 2023, 856, 159088. [Google Scholar] [CrossRef]

- Steyn, M.; Oglesby, J.; Turan, G.; Zapantis, A.; Gebremedhin, R. Global Status of CCS 2022; Global CCS Institute: Washington, DC, USA, 2022. [Google Scholar]

- Jones, A.; Lawson, A. Carbon Capture and Sequestration (CCS) in the United Sates; Congressional Research Service: Washington, DC, USA, 2022. [Google Scholar]

- Birol, F. World Energy Outlook; IEA: Paris, France, 2020. [Google Scholar]

- Rassool, D.; Consoli, C.; Townsend, A.; Liu, H. Overview of Organisations and Policies Supporting the Deployment of Large-Scale Ccs Facilities; Global CCS Institute: Melbourne, Australia, 2020. [Google Scholar]

- Golombek, R.; Greaker, M.; Kverndokk, S.; Ma, L. Policies to promotes carbon capture and storage technologies. Environ. Resour. Econ. 2023, 85, 267–302. [Google Scholar] [CrossRef]

- Meckling, J.; Biber, E. A policy roadmap for negative emissions using direct air capture. Nat. Commun. 2021, 12, 2051. [Google Scholar] [CrossRef] [PubMed]

- National Rice Research Institute. The Economics of Carbon Capture and Sequestration; NRRI: Cuttack, India, 2022. [Google Scholar]

- Shell Global. Carbon Capture and Storage. Available online: https://www.shell.com/energy-and-innovation/carbon-capture-and-storage.html#iframe=L3dlYmFwcHMvQ0NTX0dsb2JlLw (accessed on 11 August 2023).

| Country | CO2 Emissions Reduction Target | Target Year |

|---|---|---|

| The EU | 40% | 2030 |

| The USA | 26–28% | 2025 |

| China | 60–65% | 2030 |

| South Korea | 37% | 2030 |

| Japan | 26% | 2030 |

| Malaysia | 45% | 2030 |

| Technology Number | CO2 Capture Technologies | Definition |

|---|---|---|

| 1 | Absorption |

|

| 2 | Adsorption |

|

| 3 | Membrane |

|

| 4 | Cryogenic |

|

| Technology Number | Technology Name | Current Challenges | Future Suggestions |

|---|---|---|---|

| 1 | Absorption |

|

|

| 2 | Adsorption |

|

|

| 3 | Membrane |

|

|

| 4 | Cryogenic |

|

|

| Advantages | Disadvantages |

|---|---|

| Has the highest efficiency of carbon capture among the other technologies | High capital investment |

| Reduction in volume of the flue gas | The air separation unit (ASU) requires a high amount of energy |

| Increase in boiler efficiency | Further research is being conducted on oxygen transport membranes, ion-transport membranes, or chemical looping |

| NOx gases elimination | |

| NOx gases elimination | |

| Potential to be used in oxy-fired and IGCC power plant |

| Country | Technology |

|---|---|

| Norway | Waste-to-energy (WtE) |

| The Netherlands | |

| France | Ethanol plants |

| Brazil | |

| Sweden | |

| Japan | Biomass combustion and co-firing |

| Sweden | Pulp and paper plants |

| The United States | Biomass gasification |

| Sweden | Biogas plant |

| Analysis Type | Criteria to Be Found |

|---|---|

| Technical aspect analysis | Inlet carbon dioxide concentration |

| Outlet carbon dioxide concentration | |

| Separation efficiency calculation | |

| Mass transfer rate | |

| Climatic condition | |

| Minimum carbon dioxide concentration required for each technology | |

| Life cycle assessment | |

| Economic analysis aspect | LCOE |

| NPV | |

| PV | |

| Whether the project is worth it economically |

| With CDR | Without CDR | Description | |

|---|---|---|---|

| No-policy baseline | 3 + 9 × 4 | 3 + 9 × 4 | No climate policy |

| NDC | 3 + 9 × 4 | 3 + 9 × 4 | No increased ambition |

| B1300 | 3 + 9 × 4 | 3 + 9 × 4 | 67% prob. of 2 °C |

| B1100 | 3 + 9 × 4 | 3 + 9 × 4 | Well below 2 °C |

| B900 | 3 + 9 × 4 | 3 + 9 × 4 | 67% prob. of 1.5 °C |

| Year | Ref | Plant with Pre-Combustion | Plant without Pre-Combustion | Plant Post-Combustion | Plant without Post-Combustion | Oxy-Fuel | Plant without Oxy-Fuel |

|---|---|---|---|---|---|---|---|

| 1977 | [95] | GBP 16,412,256.00 | GBP 14,706,549.00 | GBP 15,795,650.00 | GBP 11,719,613.00 | GBP 10,277,226.00 | GBP 5,398,367.00 |

| 2023 | Data by the authors | GBP 133,913,187.69 | GBP 119,995,743.21 | GBP 128,882,089.29 | GBP 95,624,314.86 | GBP 83,855,387.97 | GBP 44,047,115.36 |

| Technology | Calculated (GBP/MWh) |

|---|---|

| Post-combustion | 142 |

| PC (without CCS) | 107 |

| Pre-combustion | 148 |

| IGCC (without CCS) | 134 |

| Oxy-fuel combustion | 95 |

| Oxy-fuel (without CCS) | 53 |

| Technology | Techno-Economic Parameter | Ranges (2050) | ||

|---|---|---|---|---|

| Low | Medium | High | ||

| Wind | Capital cost USD 2005/kW | 4800 | 830 | 1290 |

| Solar | Capital cost USD 2005/kW | 180/1500 | 230/2350 | 420/3300 |

| Nuclear | Capital cost USD 2005/kW | 2700 | 6000 | 8750 |

| Group | Metric | Sector | Year | Aggregated |

|---|---|---|---|---|

| Carbon tax Climate policy costs | No No | 2100 2010–2100 | No |

| CO2 emissions Electricity share of final energy Fossil carbon intensity of fuels | Yes Yes Yes | 2030–2050 mean 2030–2050 mean 2030–2050 mean | No No No |

| Aggregated CDR Year Of Carbon Neutrality | No No | 2020–2100 - | Yes No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adam, R.; Ozarisoy, B. Techno-Economic Analysis of State-of-the-Art Carbon Capture Technologies and Their Applications: Scient Metric Review. Encyclopedia 2023, 3, 1270-1305. https://doi.org/10.3390/encyclopedia3040092

Adam R, Ozarisoy B. Techno-Economic Analysis of State-of-the-Art Carbon Capture Technologies and Their Applications: Scient Metric Review. Encyclopedia. 2023; 3(4):1270-1305. https://doi.org/10.3390/encyclopedia3040092

Chicago/Turabian StyleAdam, Raghad, and Bertug Ozarisoy. 2023. "Techno-Economic Analysis of State-of-the-Art Carbon Capture Technologies and Their Applications: Scient Metric Review" Encyclopedia 3, no. 4: 1270-1305. https://doi.org/10.3390/encyclopedia3040092