Trend of Modification by Autoclave at Low Pressure and by Natural Fermentation in Sweet Potato and Cassava Starches

Abstract

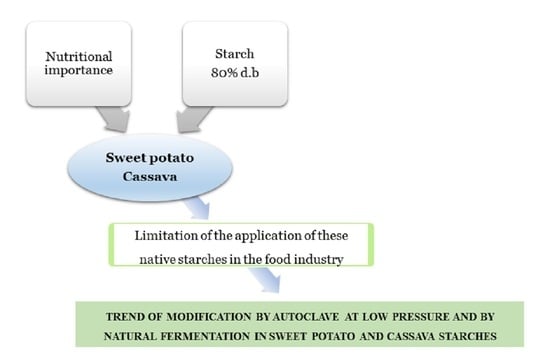

:1. Introduction

2. Sweet Potatoes (Ipomoea batatas L.)

3. Orange and Purple-Fleshed Sweet Potatoes

4. White and Beige-Fleshed Sweet Potatoes

5. Cassava (Manihot esculenta C.)

6. Starch

7. Amylose and Amylopectin

8. Solubility, Swelling, Gelatinization, and Retrogradation

9. Modification of Starch by the Physical Method of Autoclave at Low Pressure

10. Modification of Starch by Spontaneous Fermentation or “Puba” Production

11. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Zhao, L.; Bian, X.; Guo, K.; Zhou, L.; Wei, C. Characterization and comparative study of starches from seven purple sweet potatoes. Food Hydrocoll. 2018, 80, 168–176. [Google Scholar] [CrossRef]

- Bovell-Benjamin, A.C. Sweet Potato: A Review of its Past, Present, and Future Role in Human Nutrition. In Marine Medicinal Foods—Implications and Applications, Macro and Microalgae; Elsevier B.V.: Amsterdam, The Netherlands, 2007; Volume 52, pp. 1–59. [Google Scholar]

- Wang, S.; Nie, S.; Zhu, F. Chemical constituents and health effects of sweet potato. Food Res. Int. 2016, 89, 90–116. [Google Scholar] [CrossRef] [PubMed]

- Truong, V.D.; Avula, R.Y.; Pecota, K.; Yencho, C.G. Sweetpotatoes. In Handbook of Vegetables and Vegetable Processing; Wiley: Hoboken, NJ, USA, 2011; pp. 717–737. [Google Scholar]

- Silva, G.D.L.P.E.; Bento, J.A.C.; Ribeiro, G.O.; Lião, L.M.; Júnior, M.S.S.; Caliari, M. Application Potential and Technological Properties of Colored Sweet Potato Starches. Starch Stärke 2021, 73. [Google Scholar] [CrossRef]

- Abegunde, O.K.; Mu, T.-H.; Chen, J.-W.; Deng, F.-M. Physicochemical characterization of sweet potato starches popularly used in Chinese starch industry. Food Hydrocoll. 2013, 33, 169–177. [Google Scholar] [CrossRef]

- Guo, K.; Liu, T.; Xu, A.; Zhang, L.; Bian, X.; Wei, C. Structural and functional properties of starches from root tubers of white, yellow, and purple sweet potatoes. Food Hydrocoll. 2019, 89, 829–836. [Google Scholar] [CrossRef]

- Tong, C.; Ru, W.; Wu, L.; Wu, W.; Bao, J. Fine structure and relationships with functional properties of pigmented sweet potato starches. Food Chem. 2020, 311, 126011. [Google Scholar] [CrossRef]

- Setiawati, T.; Sudewi, S.; Mahmudatussa’Adah, A. Influence of sweet potato types on physical and sensory characteristics pure of sweet potato soup (ipomoea batatas L). IOP Conf. Ser. Mater. Sci. Eng. 2018, 434, 012297. [Google Scholar] [CrossRef]

- Sánchez, T.; Salcedo, E.; Ceballos, H.; Dufour, D.; Mafla, G.; Morante, N.; Calle, F.; Pérez, J.C.; Debouck, D.; Jaramillo, G.; et al. Screening of Starch Quality Traits in Cassava (Manihot esculenta Crantz). Starch Stärke 2009, 61, 12–19. [Google Scholar] [CrossRef]

- Chisenga, S.M.; Workneh, T.S.; Bultosa, G.; Alimi, B.A. Progress in research and applications of cassava flour and starch: A review. J. Food Sci. Technol. 2019, 56, 2799–2813. [Google Scholar] [CrossRef]

- Hu, A.; Li, Y.; Zheng, J. Dual-frequency ultrasonic effect on the structure and properties of starch with different size. LWT 2019, 106, 254–262. [Google Scholar] [CrossRef]

- Zhu, F.; Wang, S. Physicochemical properties, molecular structure, and uses of sweetpotato starch. Trends Food Sci. Technol. 2014, 36, 68–78. [Google Scholar] [CrossRef]

- Alonso-Gomez, L.; Niño-López, A.M.; Romero-Garzón, A.M.; Pineda-Gomez, P.; Del Real-Lopez, A.; Rodriguez-Garcia, M.E. Physicochemical transformation of cassava starch during fermentation for production of sour starch in Colombia. Starch Stärke 2016, 68, 1139–1147. [Google Scholar] [CrossRef]

- Astuti, R.M.; Asiah, N.; Setyowati, A.; Fitriawati, R. Effect of physical modification on granule morphology, pasting behavior, and functional properties of arrowroot (Marantha arundinacea L) starch. Food Hydrocoll. 2018, 81, 23–30. [Google Scholar] [CrossRef]

- Batista, R.D.; Mendes, D.D.C.S.; Morais, C.C.; Thomaz, D.V.; Ascheri, D.P.R.; Damiani, C.; Asquieri, E.R. Physicochemical, functional and rheological properties of fermented and non-fermented starch from canary seed (Phalaris canariensis). Food Hydrocoll. 2020, 99, 105346. [Google Scholar] [CrossRef]

- European Union. Commission Regulation (EU) 1129/2011. (11 November 2011). In UE: Official Journal of the European Union; European Union: Brussels, Belgium, 2011. [Google Scholar]

- Shah, A.; Masoodi, F.A.; Gani, A.; Ashwar, B.A. In-vitro digestibility, rheology, structure, and functionality of RS3 from oat starch. Food Chem. 2016, 212, 749–758. [Google Scholar] [CrossRef]

- Li, H.; Yu, L.; Yu, W.; Li, H.; Gilbert, R. Autoclaved rice: The textural property and its relation to starch leaching and the molecular structure of leached starch. Food Chem. 2019, 283, 199–205. [Google Scholar] [CrossRef]

- Babu, A.S.; Parimalavalli, R. Effect of Autoclaving on Functional, Chemical, Pasting and Morphological Properties of Sweet Potato Starch. J. Root Crops 2013, 39, 78–83. [Google Scholar]

- Díaz, A.; Dini, C.; Viña, S.Z.; García, M.A. Technological properties of sour cassava starches: Effect of fermentation and drying processes. LWT 2018, 93, 116–123. [Google Scholar] [CrossRef]

- Crispim, S.; Nascimento, A.; Costa, P.; Moreira, J.; Nunes, A.; Nicoli, J.; Lima, F.; Mota, V.; Nardi, R. Molecular identification of Lactobacillus spp. associated with puba, a Brazilian fermented cassava food. Braz. J. Microbiol. 2013, 44, 15–21. [Google Scholar] [CrossRef] [Green Version]

- Deng, F.-M.; Mu, T.-H.; Zhang, M.; Abegunde, O.K. Composition, structure, and physicochemical properties of sweet potato starches isolated by sour liquid processing and centrifugation. Starch Stärke 2012, 65, 162–171. [Google Scholar] [CrossRef]

- Yuliana, N.; Nurdjanah, S.; Sugiharto, R.; Amethy, D. Effect of Spontaneous Lactic Acid Fermentation on Physico-Chemical Properties of Sweet Potato Flour. Microbiol. Indones. 2014, 8, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Liu, L.; Lian, X.; Li, L.; Wu, H. The properties of different cultivars of Jinhai sweet potato starches in China. Int. J. Biol. Macromol. 2014, 67, 1–6. [Google Scholar] [CrossRef]

- Wu, X.; Sun, C.; Yang, L.; Zeng, G.; Liu, Z.; Li, Y. β-carotene content in sweet potato varieties from China and the effect of preparation on β-carotene retention in the Yanshu No. 5. Innov. Food Sci. Emerg. Technol. 2008, 9, 581–586. [Google Scholar] [CrossRef]

- Lai, Y.C.; Wang, S.Y.; Gao, H.Y.; Nguyen, K.M.; Nguyen, C.H.; Shih, M.C.; Lin, K.H. Physicochemical properties of starches and expression and activity of starch biosynthesis-related genes in sweet potatoes. Food Chem. 2016, 199, 556–564. [Google Scholar] [CrossRef]

- Zhu, F.; Yang, X.; Cai, Y.-Z.; Bertoft, E.; Corke, H. Physicochemical properties of sweetpotato starch. Starch Stärke 2011, 63, 249–259. [Google Scholar] [CrossRef]

- Sajeev, M.; Sreekumar, J.; Vimala, B.; Moorthy, S.; Jyothi, A. Textural and Gelatinization Characteristics of White, Cream, and Orange Fleshed Sweet Potato Tubers (Ipomoea BatatasL.). Int. J. Food Prop. 2012, 15, 912–931. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.J.; Park, W.S.; Bae, J.-Y.; Kang, S.Y.; Yang, M.H.; Lee, S.; Lee, H.-S.; Kwak, S.-S.; Ahn, M.-J. Variations in the carotenoid and anthocyanin contents of Korean cultural varieties and home-processed sweet potatoes. J. Food Compos. Anal. 2015, 41, 188–193. [Google Scholar] [CrossRef]

- Silva, M.L.C.; Costa, R.S.; Santana, A.D.S.; Koblitz, M.G.B. Compostos fenólicos, carotenóides e atividade antioxidante em produtos vegetais. Semina: Ciências Agrárias 2010, 31, 669. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Jin, L.; Xiao, P.; Lu, Y.; Bao, J. Total phenolics, flavonoids, antioxidant capacity in rice grain and their relations to grain color, size and weight. J. Cereal Sci. 2009, 49, 106–111. [Google Scholar] [CrossRef]

- Carmona, P.A.O. Caracterização Morfoagronômica, Físico-Química e Tolerância ao Nematoide-das-Galhas de Genótipos de Batata-Doce Avaliados No Distrito Federal. 2017. Available online: https://repositorio.unb.br/handle/10482/18170 (accessed on 14 May 2021).

- Lopes, T.; Xavier, M.; Quadri, M.G.; Quadri, M. Antocianinas: Uma breve revisão das características estruturais e da estabilidade. J. Curr. Agric. Sci. Technol. 2007, 13. [Google Scholar] [CrossRef]

- Lee, Y.-T.; Lee, B.-H. Physicochemical and structural properties of different colored sweet potato starches. Starch Stärke 2016, 69, 1600001. [Google Scholar] [CrossRef]

- Park, S.-Y.; Lee, S.Y.; Yang, J.W.; Lee, J.-S.; Oh, S.-D.; Oh, S.; Lee, S.M.; Lim, M.-H.; Park, S.K.; Jang, J.-S.; et al. Comparative analysis of phytochemicals and polar metabolites from colored sweet potato (Ipomoea batatas L.) tubers. Food Sci. Biotechnol. 2016, 25, 283–291. [Google Scholar] [CrossRef] [PubMed]

- Grace, M.H.; Yousef, G.G.; Gustafson, S.J.; Truong, V.-D.; Yencho, G.C.; Lila, M.A. Phytochemical changes in phenolics, anthocyanins, ascorbic acid, and carotenoids associated with sweetpotato storage and impacts on bioactive properties. Food Chem. 2014, 145, 717–724. [Google Scholar] [CrossRef] [PubMed]

- De Albuquerque, T.M.R.; Sampaio, K.B.; de Souza, E.L. Sweet potato roots: Unrevealing an old food as a source of health promoting bioactive compounds—A review. Trends Food Sci. Technol. 2019, 85, 277–286. [Google Scholar] [CrossRef]

- Tang, Y.; Cai, W.; Xu, B. Profiles of phenolics, carotenoids and antioxidative capacities of thermal processed white, yellow, orange and purple sweet potatoes grown in Guilin, China. Food Sci. Hum. Wellness 2015, 4, 123–132. [Google Scholar] [CrossRef] [Green Version]

- Trancoso-Reyes, N.; Ochoa-Martínez, L.A.; Bello-Pérez, L.A.; Morales-Castro, J.; Estévez-Santiago, R.; Olmedilla-Alonso, B. Effect of pre-treatment on physicochemical and structural properties, and the bioaccessibility of β-carotene in sweet potato flour. Food Chem. 2016, 200, 199–205. [Google Scholar] [CrossRef] [Green Version]

- Sasaki, K.; Han, J.; Shimozono, H.; Villareal, M.O.; Isoda, H. Caffeoylquinic Acid-Rich Purple Sweet Potato Extract, with or without Anthocyanin, Imparts Neuroprotection and Contributes to the Improvement of Spatial Learning and Memory of SAMP8 Mouse. J. Agric. Food Chem. 2013, 61, 5037–5045. [Google Scholar] [CrossRef]

- Maoka, T.; Akimoto, N.; Ishiguro, K.; Yoshinaga, M.; Yoshimoto, M. Carotenoids with a 5,6-dihydro-5,6-dihydroxy-β-end group, from yellow sweet potato “Benimasari”, Ipomoea batatas Lam. Phytochemistry 2007, 68, 1740–1745. [Google Scholar] [CrossRef]

- Drapal, M.; Fraser, P.D. Determination of carotenoids in sweet potato (Ipomoea batatas L., Lam) tubers: Implications for accurate provitamin A determination in staple sturdy tuber crops. Phytochemistry 2019, 167, 112102. [Google Scholar] [CrossRef]

- Teow, C.C.; Truong, V.-D.; McFeeters, R.F.; Thompson, R.L.; Pecota, K.V.; Yencho, G.C. Antioxidant activities, phenolic and β-carotene contents of sweet potato genotypes with varying flesh colours. Food Chem. 2007, 103, 829–838. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Q.; Gao, L.; Gong, X.; Qu, Y.; Feng, B. Functional and physicochemical properties of flours and starches from different tuber crops. Int. J. Biol. Macromol. 2020, 148, 324–332. [Google Scholar] [CrossRef]

- Amajor, J.; Oti, E.; Ekeledo, N.; Omodamiro, R.; Amajor, E.; Aniedu, C. Studies on the Characteristic Properties of Fermented, Sun-Dried Orange-Fleshed Sweet Potato Flour. Niger. Food J. 2014, 32, 45–53. [Google Scholar] [CrossRef] [Green Version]

- Yong, H.; Wang, X.; Sun, J.; Fang, Y.; Liu, J.; Jin, C. Comparison of the structural characterization and physicochemical properties of starches from seven purple sweet potato varieties cultivated in China. Int. J. Biol. Macromol. 2018, 120, 1632–1638. [Google Scholar] [CrossRef]

- Oyeyinka, S.A.; Adeloye, A.A.; Olaomo, O.O.; Kayitesi, E. Effect of fermentation time on physicochemical properties of starch extracted from cassava root. Food Biosci. 2020, 33, 100485. [Google Scholar] [CrossRef]

- Moorthy, S.N. Tropical sources of starch. In Starch in Food: Structure, Function and Applications; Eliasson, A.-C., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2004; pp. 321–359. [Google Scholar]

- El-Sharkawy, M.A. Global warming: Causes and impacts on agroecosystems productivity and food security with emphasis on cassava comparative advantage in the tropics/subtropics. Photosynth 2014, 52, 161–178. [Google Scholar] [CrossRef]

- Fukuda, W.M.G.; Guevara, C.L. Descritores morfológicos e agronômicos para a caracterização de mandioca (Manihot esculenta Crantz) Embrapa Mandioca e Fruficuftura. 1998. Available online: http://www.infoteca.cnptia.embrapa.br/infoteca/handle/doc/638631 (accessed on 14 May 2021).

- Montagnac, J.A.; Davis, C.R.; Tanumihardjo, S.A. Nutritional Value of Cassava for Use as a Staple Food and Recent Advances for Improvement. Compr. Rev. Food Sci. Food Saf. 2009, 8, 181–194. [Google Scholar] [CrossRef]

- Tappiban, P.; Smith, D.R.; Triwitayakorn, K.; Bao, J. Recent understanding of starch biosynthesis in cassava for quality improvement: A review. Trends Food Sci. Technol. 2019, 83, 167–180. [Google Scholar] [CrossRef]

- Nabeshima, E.H.; Moro, T.M.A.; Campelo, P.H.; Sant’Ana, A.S.; Clerici, M.T.P.S. Chapter Seven-Tubers and roots as a source of prebiotic fibers. In Advances in Food and Nutrition Research; da Cruz, A.G., Prudencio, E.S., Esmerino, E.A., da Silva, M.C., Eds.; Academic Press: Cambridge, MA, USA, 2020; Volume 94, pp. 267–293. [Google Scholar]

- Feniman, C.M. Caracterização de Raízes de Mandioca (Manihot esculenta Crantz) do Cultivar IAC 576-70 Quanto à Cocção, Composição Química e Propriedades do Amido em Duas Épocas de Colheita; Universidade de São Paulo: Butanta, Brazil, 2004. [Google Scholar]

- Eriksson, E.; Koch, K.; Tortoe, C.; Akonor, P.; Oduro-Yeboah, C. Evaluation of the physical and sensory characteristics of bread produced from three varieties of cassava and wheat composite flours. Food Public Health 2014, 4, 214–222. [Google Scholar] [CrossRef]

- Obadi, M.; Xu, B. Review on the physicochemical properties, modifications, and applications of starches and its common modified forms used in noodle products. Food Hydrocoll. 2021, 112, 106286. [Google Scholar] [CrossRef]

- Adejumo, O.; Okoruwa, V.; Abass, A.; Salman, K. Post-harvest technology change in cassava processing: A choice paradigm. Sci. Afr. 2020, 7, e00276. [Google Scholar] [CrossRef]

- Tappiban, P.; Ying, Y.; Pang, Y.; Sraphet, S.; Srisawad, N.; Smith, D.R.; Wu, P.; Triwitayakorn, K.; Bao, J. Gelatinization, pasting and retrogradation properties and molecular fine structure of starches from seven cassava cultivars. Int. J. Biol. Macromol. 2020, 150, 831–838. [Google Scholar] [CrossRef] [PubMed]

- Tester, R.F.; Karkalas, J.; Qi, X. Starch—Composition, fine structure and architecture. J. Cereal Sci. 2004, 39, 151–165. [Google Scholar] [CrossRef]

- Xijun, L.; Lin, L.; Kunsheng, Z.; Ying, X.; Jiaxin, L. A new proposed sweet potato starch granule structure—Pomegranate concept. Int. J. Biol. Macromol. 2012, 50, 471–475. [Google Scholar] [CrossRef] [PubMed]

- Amagliani, L.; O’Regan, J.; Kelly, A.L.; O’Mahony, J.A. Chemistry, structure, functionality and applications of rice starch. J. Cereal Sci. 2016, 70, 291–300. [Google Scholar] [CrossRef]

- Narpinder, S.; Amritpal, K.; Khetan, S.; Rajarathnam, E. Potato: Production, Composition and Starch Processing; Scrivener Publishing LLC: Beverly, MA, USA, 2013; pp. 23–48. [Google Scholar]

- Le Corre, D.; Bras, J.; Dufresne, A. Starch Nanoparticles: A Review. Biomacromolecules 2010, 11, 1139–1153. [Google Scholar] [CrossRef] [PubMed]

- Gallant, D.J.; Bouchet, B.; Baldwin, P.M. Microscopy of starch: Evidence of a new level of granule organization. Carbohydr. Polym. 1997, 32, 177–191. [Google Scholar] [CrossRef]

- Fan, Y.; Picchioni, F. Modification of starch: A review on the application of “green” solvents and controlled functionalization. Carbohydr. Polym. 2020, 241, 116350. [Google Scholar] [CrossRef]

- Hoover, R. Composition, molecular structure, and physicochemical properties of tuber and root starches: A review. Carbohydr. Polym. 2001, 45, 253–267. [Google Scholar] [CrossRef]

- Bertoft, E. Understanding Starch Structure: Recent Progress. Agronomy 2017, 7, 56. [Google Scholar] [CrossRef]

- Eliasson, A.-C. Starch in Food: Structure, Function and Applications; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Castro, L.M.; Alexandre, E.M.; Saraiva, J.A.; Pintado, M. Impact of high pressure on starch properties: A review. Food Hydrocoll. 2020, 106, 105877. [Google Scholar] [CrossRef]

- Leyva, J.D.H.; Alonso-Gomez, L.; Rueda-Enciso, J.; Yee-Madeira, H.; Bello-Perez, L.; Alvarez-Ramirez, J. Morphological, physicochemical and functional characteristics of starch from Marantha ruiziana Koern. LWT 2017, 83, 150–156. [Google Scholar] [CrossRef]

- Kong, L.; Ziegler, G.R. Molecular encapsulation of ascorbyl palmitate in preformed V-type starch and amylose. Carbohydr. Polym. 2014, 111, 256–263. [Google Scholar] [CrossRef]

- Zhu, F. Relationships between amylopectin internal molecular structure and physicochemical properties of starch. Trends Food Sci. Technol. 2018, 78, 234–242. [Google Scholar] [CrossRef]

- Ojogbo, E.; Ogunsona, E.O.; Mekonnen, T.H. Chemical and physical modifications of starch for renewable polymeric materials. Mater. Today Sustain. 2020, 7–8, 100028. [Google Scholar] [CrossRef]

- Pascoal, A.M.; Di-Medeiros, M.C.B.; Batista, K.A.; Leles, M.I.G.; Lião, L.M.; Fernandes, K.F. Extraction and chemical characterization of starch from S. lycocarpum fruits. Carbohydr. Polym. 2013, 98, 1304–1310. [Google Scholar] [CrossRef]

- Bento, J.A.C.; Ferreira, K.C.; Bassinello, P.Z.; Neto, M.A.D.S. Methodologies for the Study of Morphological and Thermal Properties of Starch. Científic@ Multidisc. J. 2018, 5, 187–195. [Google Scholar] [CrossRef]

- Liu, H.; Xie, F.; Yu, L.; Chen, L.; Li, L. Thermal processing of starch-based polymers. Prog. Polym. Sci. 2009, 34, 1348–1368. [Google Scholar] [CrossRef]

- Tharanathan, R.N. Food-Derived Carbohydrates—Structural Complexity and Functional Diversity. Crit. Rev. Biotechnol. 2002, 22, 65–84. [Google Scholar] [CrossRef]

- Cozzolino, D.; Roumeliotis, S.; Eglinton, J. Relationships between starch pasting properties, free fatty acids and amylose content in barley. Food Res. Int. 2013, 51, 444–449. [Google Scholar] [CrossRef]

- Deka, D.; Sit, N. Dual modification of taro starch by microwave and other heat moisture treatments. Int. J. Biol. Macromol. 2016, 92, 416–422. [Google Scholar] [CrossRef]

- Masina, N.; Choonara, Y.E.; Kumar, P.; du Toit, L.C.; Govender, M.; Indermun, S.; Pillay, V. A review of the chemical modification techniques of starch. Carbohydr. Polym. 2017, 157, 1226–1236. [Google Scholar] [CrossRef] [PubMed]

- Yadav, B.S.; Guleria, P.; Yadav, R.B. Hydrothermal modification of Indian water chestnut starch: Influence of heat-moisture treatment and annealing on the physicochemical, gelatinization and pasting characteristics. LWT 2013, 53, 211–217. [Google Scholar] [CrossRef]

- Alay, S.C.A.; Meireles, M.A.A. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci. Technol. 2015, 35, 215–236. [Google Scholar] [CrossRef] [Green Version]

- Jyothi, A.N.; Sajeev, M.S.; Sreekumar, J.N. Hydrothermal Modifications of Tropical Tuber Starches. 1. Effect of Heat-Moisture Treatment on the Physicochemical, Rheological and Gelatinization Characteristics. Starch Stärke 2010, 62, 28–40. [Google Scholar] [CrossRef]

- Trung, P.T.B.; Ngoc, L.B.B.; Hoa, P.N.; Tien, N.N.T.; Van Hung, P. Impact of heat-moisture and annealing treatments on physicochemical properties and digestibility of starches from different colored sweet potato varieties. Int. J. Biol. Macromol. 2017, 105, 1071–1078. [Google Scholar] [CrossRef]

- Huang, T.-T.; Zhou, D.-N.; Jin, Z.-Y.; Xu, X.-M.; Chen, H.-Q. Effect of repeated heat-moisture treatments on digestibility, physicochemical and structural properties of sweet potato starch. Food Hydrocoll. 2016, 54, 202–210. [Google Scholar] [CrossRef]

- Pérez, I.C.; Mu, T.-H.; Zhang, M.; Ji, L.-L. Effect of high hydrostatic pressure to sweet potato flour on dough properties and characteristics of sweet potato-wheat bread. Int. J. Food Sci. Technol. 2017, 53, 1087–1094. [Google Scholar] [CrossRef]

- Song, M.-R.; Choi, S.-H.; Kim, H.-S.; Kim, B.-Y.; Baik, M.-Y. Efficiency of high hydrostatic pressure in preparing amorphous granular starches. Starch Stärke 2015, 67, 790–801. [Google Scholar] [CrossRef]

- Zavareze, E.D.R.; Dias, A.R.G. Impact of heat-moisture treatment and annealing in starches: A review. Carbohydr. Polym. 2011, 83, 317–328. [Google Scholar] [CrossRef]

- Alvarado, P.M.; Grosmaire, L.; Dufour, D.; Toro, A.G.; Sánchez, T.; Calle, F.; Santander, M.A.M.; Ceballos, H.; Delarbre, J.L.; Tran, T. Combined effect of fermentation, sun-drying and genotype on breadmaking ability of sour cassava starch. Carbohydr. Polym. 2013, 98, 1137–1146. [Google Scholar] [CrossRef] [Green Version]

- Ye, F.; Xiao, L.; Liang, Y.; Zhou, Y.; Zhao, G. Spontaneous fermentation tunes the physicochemical properties of sweet potato starch by modifying the structure of starch molecules. Carbohydr. Polym. 2019, 213, 79–88. [Google Scholar] [CrossRef]

- Putri, W.D.R.; Haryadi; Marseno, D.W.; Cahyanto, M.N. Role of Lactic Acid Bacteria on Structural and Physicochemical Properties of Sour Cassava Starch. APCBEE Procedia 2012, 2, 104–109. [Google Scholar] [CrossRef] [Green Version]

- Silva, G.D.L.P.E.; Bento, J.A.C.; Oliveira, A.R.; Garcia, M.C.; Júnior, M.S.S.; Caliari, M. Pasting and thermal properties of fermented cassava (Manihotesculenta Crantz). J. Food Sci. Technol. 2021, 58, 1441–1448. [Google Scholar] [CrossRef]

- Silva, G.D.L.P.E.; Bento, J.A.C.; Bataus, L.A.M.; Júnior, M.S.S.; Caliari, M. Purple and Beige-Fleshed Sweet Potato Starches Modified by Autoclaving. Starch Stärke 2021, 73. [Google Scholar] [CrossRef]

- Silva, G.D.L.P.E.; Bento, J.A.C.; Bataus, L.A.M.; Júnior, M.S.S.; Caliari, M.; Neto, M.A.D.S.; Ferreira, K.C.; De Oliveira, A.L.M.; Andrade, J.R. White and orange fleshed-sweet potato starches modified by autoclave. Res. Soc. Dev. 2021, 10. [Google Scholar] [CrossRef]

- Qi, Q.; Hong, Y.; Zhang, Y.; Gu, Z.; Cheng, L.; Li, Z.; Li, C. Combinatorial effect of fermentation and drying on the relationship between the structure and expansion properties of tapioca starch and potato starch. Int. J. Biol. Macromol. 2020, 145, 965–973. [Google Scholar] [CrossRef]

- Liao, L.; Wu, W. Fermentation Effect on the Properties of Sweet Potato Starch and its Noodle’s Quality byLactobacillus plantarum. J. Food Process. Eng. 2016, 40, e12460. [Google Scholar] [CrossRef]

- Akanbi, C.T.; Kadiri, O.; Gbadamosi, S.O. Kinetics of starch digestion in native and modified sweetpotato starches from an orange fleshed cultivar. Int. J. Biol. Macromol. 2019, 134, 946–953. [Google Scholar] [CrossRef]

- Mendes, M.; Vasques, C.; Silva, D.; Monteiro, C.; Demiate, I.; Monteiro, A.J.C.E.T. Influence of Acidity in Paste Properties of Modified Corn Starch Through Natural Fermentation. Chem. Eng. Trans. 2019, 75, 463–468. [Google Scholar] [CrossRef]

| Starch Source | Modification | Mean Diameter (µm) | Amylose (%) | pH | Reference | ||

|---|---|---|---|---|---|---|---|

| Native/Modified Starch | % ** | Native/Modified Starch | % ** | ||||

| Sweet potato | HPP (100, 200, 300 and 400 MPa; 20 min, 25 °C) | 34.86–14.95 * | 56.80 | - | - | - | Carballo Pérez, Mu [87] |

| Sweet potato | Autoclave (1.1 Kgf.cm−2, 1 h, 121 °C | - | - | 18.17–24.98 | 37.50 | - | Babu and Parimalavalli [20] |

| Sweet potato | Fermentation (natural of sour liquid) (24 h, 25 °C) | 12.81–11.44 | 10.69 | 25.61–24.27 | 5,23 | - | Deng, Mu [23] |

| Cassava | Fermentation (natural in a tank) (30 days, 35 °C) | 15.30–13.90 | 9.15 | - | - | Alvarado, Grosmaire [90] | |

| Sweet potato | Fermentation (natural in a tank) (3.8 and 12 months; 30 °C) | - | - | 29.40–6.10 | 79.25 | - | Ye, Xiao [91] |

| Cassava | Fermentation (natural) (20 days, 20 °C) | - | - | 20.00–17.00 | 15.00 | - | Díaz, Dini [21] |

| Sweet potato | Fermentation (natural) (120 h, 30 °C) | - | - | - | - | 6.49–4.50 | Yuliana, Nurdjanah [24] |

| Cassava | Fermentation (artificial: L. amylophyllus) 48 h, 30 °C) | - | - | - | - | 6.16–6.95 | Putri, Haryadi [92] |

| Cassava | Fermentation (natural) (7 days, 40 °C) | - | - | - | - | 6.42–4.95 | Paixão e Silva, Bento [93] |

| Cassava | Fermentation (natural) (72 h, 25 °C) | - | - | - | - | 5.40–4.60 | Oyeyinka, Adeloye [48] |

| Starch Source | Modification | WAI (g/g) | WSI (%) | Reference | ||

|---|---|---|---|---|---|---|

| Native/Modified Starch | % 1 | Native/Modified Starch | % 1 | |||

| Sweet potato | HTM (6, 10 and 14 h, 80, 100 and 120 °C; 15.20 e 25% of moisture) | 25.10–15.30 **** | 39.04 | 15.70–31.90 **** | 103.19 | Jyothi, Sajeev [84] |

| Cassava | HTM (6, 10 and 14 h, 80, 100 and 120 °C; 15.20 e 25% of moisture) | 36.60–19.70 **** | 46.17 | 22.30–48.20 **** | 116.14 | Jyothi, Sajeev [84] |

| Sweet potato | HTM (6 h, 100 °C; 35% of moisture) | 12.00–10.0 **** | 16.66 | 8.00–4.00 **** | 50.00 | Trung, Ngoc [85] |

| Sweet potato | HTM (2 h, 100 °C; 30% of moisture) | 21.01–6.71 *** | 68.08 | 11.44–2.69 *** | 76.48 | Huang, Zhou [86] |

| Sweet potato | Autoclave (1.1 Kgf.cm−2, 15 to 60 min, 121 °C | 5.00–10.00 * | 50.00 | 2.00–8.00 * | 300.00 | Paixão e Silva, Bento [94] |

| Sweet potato | Autoclave (1.1 Kgf.cm−2, 15 to 60 min, 121 °C | 6.70–14.80 * | 120.90 | 1.00–9.00 * | 800.00 | Silva, Bento [95] |

| Sweet potato | Fermentation (natural) (120 h, 30 °C) | 4.50–6.00 ** | 33.33 | 21.00–13.00 ** | 38.09 | Yuliana, Nurdjanah [24] |

| Cassava | Fermentation (natural) (72 h, 25 °C) | 24.00–12.00 ** | 50.00 | - | - | Oyeyinka, Adeloye [48] |

| Starch Source | Modification | Pasting Temperature (°C) | Peak Viscosity (cP) | Final Viscosity (cP) | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Native/Modified Starch | % * | Native/Modified Starch | % * | Native/Modified Starch | % * | ||||

| Sweet potato | Autoclave (1.1 Kgf.cm−2, 1 h, 121 °C | 70.68–50.07 | 29.15 | 4906.66–381.00 | 92.23 | 3558.33–581.50 | 83.65 | Babu and Parimalavalli [20] | |

| Sweet potato | Autoclave (1.1 Kgf.cm−2, 15 to 60 min, 121 °C | 74.60–82.00 | 9.92 | - | - | 2682.00–450.00 | 83.22 | Paixão e Silva, Bento [94] | |

| Sweet potato | HTM (6, 10 and 14 h, 80, 100 and 120 °C; 15.20 e 25% of moisture) | - | - | 2723.00–873.50 | 67.92 | - | - | Jyothi, Sajeev [84] | |

| Cassava | HTM (6, 10 and 14 h, 80, 100 and 120 °C; 15.20 e 25% of moisture) | - | - | 2826.50–872.00 | 69.14 | - | - | Jyothi, Sajeev [84] | |

| Sweet potato | HTM (6 h, 100 °C; 35% of moisture) | 71.50–81.50 | 13.98 | 1778.00–1074.00 | 30.60 | 1592.00–1942.00 | 21.98 | Trung, Ngoc [85] | |

| Sweet potato | Fermentation (natural of sour liquid) (24 h, 25 °C) | 79.50–82.70 | 4.02 | 178.00–189.00 | 6.18 | - | - | Deng, Mu [23] | |

| Cassava | Fermentation (natural in a tank) (30 days, 35 °C) | 61.60–62.00 | 0.65 | 835.00–777.00 | 6.95 | 844.00–522.00 | 38.15 | Alvarado, Grosmaire [90] | |

| Sweet potato | Fermentation (natural in a tank) (3.8 and 12 months; 30 °C) | 78.60–78.80 | 0.25 | 5346.00–2246.00 | 58.00 | 3737.00–1237.00 | 66.89 | Ye, Xiao [91] | |

| Sweet potato | Fermentation (natural) (120 h, 30 °C) | 93.87–84.30 | 10.20 | 430.00–947.00 | 120.00 | - | - | Yuliana, Nurdjanah [24] | |

| Cassava | Fermentation (artificial: L. amylophyllus) 48 h, 30 °C) | 85.10–91.40 | 7.4 | 2169.60–1209.60 | 44.25 | 1984.00–1561.00 | 21.32 | Putri, Haryadi [92] | |

| Cassava | Fermentation (natural) (7 days, 40 °C) | 63.37–61.22 | 3.40 | 3035.88–5540.76 | 82.50 | 2088.84–2529.36 | 21.10 | Paixão e Silva, Bento [93] | |

| Cassava | Fermentation (natural) (72 h, 25 °C) | 74.00–75.00 | 1.35 | 5930.00–5210 | 12.15 | 3450.00–5260.00 | 62.89 | Oyeyinka, Adeloye [48] | |

| Cassava | Fermentation (natural in a tank) (15 to 90 days; 25 °C) | 63.48–64.52 | 1.64 | 24,000.00–10,000.00 | 58.33 | - | - | Alonso-Gomez, Niño-López [14] | |

| Cassava (tapioca) | Fermentation (artificial: L. plantarum) 24 h, 37 °C) | 65.00–65.80 | 1.23 | 1650.00–1218.30 | 26.16 | 1304.00–901.70 | 30.85 | Qi, Hong [96] | |

| Sweet potato | Fermentation (artificial: L. plantarum) 3 days, 37 °C) | 79.25–79.90 | 0.82 | 5227.20–4722.00 | 9.67 | 3219.60–3417.60 | 6.15 | Liao and Wu [97] | |

| Starch Source | Modification | Peak Temperature (°C) | Gelatinization Enthalpy/∆H (J/g) | Reference | ||

|---|---|---|---|---|---|---|

| Native/Modified Starch | % 1 | Native/Modified Starch | % 1 | |||

| Sweet potato | HPP (100, 200, 300 and 400 Mpa; 20 min, 25 °C) | 78.59–77.32 | 1.62 | 0.79–0.76 | 3.80 | Carballo Pérez, Mu [87] |

| Sweet potato | Autoclave (1.1 Kgf.cm−2, 15 to 60 min, 121 °C | - | - | 11.24–22.00 | 95.73 | Silva, Bento [95] |

| Sweet potato | Autoclave (1.1 Kgf.cm−2, 15 to 60 min, 121 °C | 73.35–86.00 | 17.24 | - | - | Paixão e Silva, Bento [93] |

| Sweet potato | HTM (6, 10 and 14 h, 80, 100 and 120 °C; 15.20 e 25% of moisture) | - | - | 10.70–9.60 | 10.28 | Jyothi, Sajeev [84] |

| Cassava | HTM (6, 10 and 14 h, 80, 100 and 120 °C; 15.20 e 25% of moisture) | - | - | 11.80–7.30 | 38.13 | Jyothi, Sajeev [84] |

| Sweet potato | HTM (6 h, 100 °C; 35% of moisture) | 71.88–86.65 | 20.59 | 12.36–4.69 | 62.05 | Huang, Zhou [86] |

| Sweet potato | Fermentation (natural of sour liquid) (24 h, 25 °C) | 77.77–78.66 | 1.14 | 8.22–4.49 | 45.37 | Deng, Mu [23] |

| Sweet potato | Fermentation (natural in a tank) (3.8 and 12 months; 30 °C) | 73.90–74.40 | 0.67 | 12.30–12.70 | 3.25 | Ye, Xiao [91] |

| Cassava | Fermentation (natural) (20 days, 20 °C) | 68.50–67.20 | 1.89 | 15.40–13.85 | 10.06 | Díaz, Dini [21] |

| Cassava | Fermentation (natural) (7 days, 40 °C) | 68.87–67.69 | 1.71 | 10.43–11.96 | 14.67 | Paixão e Silva, Bento [93] |

| Cassava | Fermentation (natural) (72 h, 25 °C) | 72.00–80.00 | 11.11 | 4.00–3.00 | 25.00 | Oyeyinka, Adeloye [48] |

| Cassava | Fermentation (natural in a tank) (15 to 90 days; 25 °C) | - | - | 2.18–3.47 | 59.17 | Alonso-Gomez, Niño-López [14] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paixão e Silva, G.d.L.; Bento, J.A.C.; Soares Júnior, M.S.; Caliari, M. Trend of Modification by Autoclave at Low Pressure and by Natural Fermentation in Sweet Potato and Cassava Starches. Polysaccharides 2021, 2, 354-372. https://doi.org/10.3390/polysaccharides2020023

Paixão e Silva GdL, Bento JAC, Soares Júnior MS, Caliari M. Trend of Modification by Autoclave at Low Pressure and by Natural Fermentation in Sweet Potato and Cassava Starches. Polysaccharides. 2021; 2(2):354-372. https://doi.org/10.3390/polysaccharides2020023

Chicago/Turabian StylePaixão e Silva, Giselle de Lima, Juliana Aparecida Correia Bento, Manoel Soares Soares Júnior, and Márcio Caliari. 2021. "Trend of Modification by Autoclave at Low Pressure and by Natural Fermentation in Sweet Potato and Cassava Starches" Polysaccharides 2, no. 2: 354-372. https://doi.org/10.3390/polysaccharides2020023