The Polarization and Heat Generation Characteristics of Lithium-Ion Battery with Electric–Thermal Coupled Modeling

Abstract

:1. Introduction

2. Setup and Calibration for the Experiment

2.1. Details of the Battery and Apparatus

2.2. Determination of the Entropy Heat Coefficient

2.3. Convective Heat Transfer Coefficient Test

2.4. Additional Thermophysical and Physical Parameters

3. Construction of a Model of the Electric–Thermal Connection

3.1. Battery Electrical Model

Electrical Parameter Identification Method

- Determination of the open-circuit voltage in the initial shelving stage:

- 2.

- Calculation of the ohmic resistance via voltage mutation:

- 3.

- Identification of RC parameters in the shelving stage:

3.2. The Battery’s Thermal Model

3.2.1. Battery Heat Generation Model

3.2.2. Battery Heat Transfer Model

3.3. Electric–Thermal Coupling Model

COMSOL Model Building

3.4. Verification of the Electrical and Thermal Performance of Batteries

3.4.1. Verification of Electrical Properties

3.4.2. Validation of Thermal Properties

4. Results and Discussion

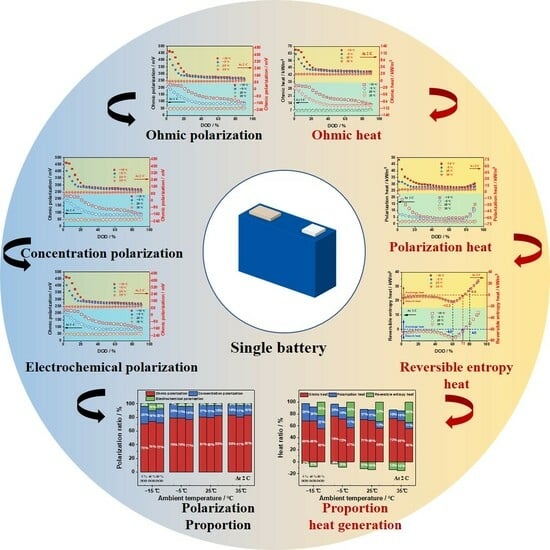

4.1. Polarization Characteristics of the Battery

4.1.1. Ohmic Polarization Characteristics

4.1.2. Concentration Polarization Characteristics

4.1.3. Electrochemical Polarization Characteristics

4.1.4. Proportion of Polarization Types

4.2. The Battery’s Characteristics for Producing Heat

4.2.1. Ohmic Heat Generation Characteristics

4.2.2. Polarization Heat Generation Characteristics

4.2.3. Reversible Entropy Heat Characteristics

4.2.4. Proportion of Heat Generation Types

5. Conclusions

- The electric–thermal coupling simulation model was validated by using experimental data under different discharge rates and ambient temperatures. The comparisons show how effectively the generated model simulates the electrical and thermal characteristics of the battery under various operation conditions.

- The impact of discharge rate and ambient temperature on the battery’s ohmic, electrochemical, and concentration polarizations was analyzed, revealing that these factors have a significant effect on these polarization types. Specifically, low-temperature environments and high discharge rates resulted in a significant increase in these polarization values, with the greatest changes observed during the discharge process. In contrast, these values remained stable at ambient temperature and low discharge rates. The proportion of ohmic polarization was found to be the highest among the three types, accounting for approximately 80% of the total polarization, while electrochemical polarization was the least significant at about 3%, and concentration polarization was about 17%.

- The ohmic heat generation and polarization heat generation increase significantly at high discharge rates and low ambient temperatures, while the reversible entropy heat is less affected by ambient temperatures and increases significantly with the increase in discharge rates. The ohmic heat generation and polarization heat generation contribute to the total heat generation of the battery at any ambient temperature, and the reversible entropy heat contributes to the total heat generation of the battery only at the end of the discharge period. At low discharge rates and high ambient temperatures, the entropy heat coefficient and reversible entropy heat are crucial factors in the thermal simulation of batteries.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Voskuijl, M. Cruise Range in Formation Flight. J. Aircr. 2017, 54, 2184–2191. [Google Scholar] [CrossRef]

- Xue, Q.; Li, J.; Chen, Z.; Zhang, Y.; Liu, Y.; Shen, J. Online Capacity Estimation of Lithium-Ion Batteries Based on Deep Convolutional Time Memory Network and Partial Charging Profiles. IEEE Trans. Veh. Technol. 2022, 72, 444–457. [Google Scholar] [CrossRef]

- Mathieu, R.; Briat, O.; Gyan, P.; Vinassa, J.-M. Fast charging for electric vehicles applications: Numerical optimization of a multi-stage charging protocol for lithium-ion battery and impact on cycle life. J. Energy Storage 2021, 40, 102756. [Google Scholar] [CrossRef]

- Hales, A.; Prosser, R.; Diaz, L.B.; White, G.; Patel, Y.; Offer, G. The Cell Cooling Coefficient as a design tool to optimise thermal management of lithium-ion cells in battery packs. Etransportation 2020, 6, 100089. [Google Scholar] [CrossRef]

- Hua, X.; Heckel, C.; Modrow, N.; Zhang, C.; Hales, A.; Holloway, J.; Jnawali, A.; Li, S.; Yu, Y.; Loveridge, M. The prismatic surface cell cooling coefficient: A novel cell design optimisation tool & thermal parameterization method for a 3D discretised electro-thermal equivalent-circuit model. Etransportation 2021, 7, 100099. [Google Scholar]

- Qin, P.; Sun, J.; Yang, X.; Wang, Q. Battery thermal management system based on the forced-air convection: A review. Etransportation 2021, 7, 100097. [Google Scholar] [CrossRef]

- Koch, S.; Birke, K.; Kuhn, R. Fast Thermal Runaway Detection for Lithium-Ion Cells in Large Scale Tractiones Batteri. Batteries 2018, 4, 16. [Google Scholar] [CrossRef]

- Aiello, L.; Hanzu, I.; Gstrein, G.; Ewert, E.; Ellersdorfer, C.; Sinz, W. Analysis and Investigation of Thermal Runaway Propagation for a Mechanically Constrained Lithium-Ion Pouch Cell Module. Batteries 2021, 7, 49. [Google Scholar] [CrossRef]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Guo, Y.; Bhagat, R.; Zheng, Y. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: A lifespan perspective. Etransportation 2022, 12, 100169. [Google Scholar] [CrossRef]

- Su, L.; Wu, M.; Li, Z.; Zhang, J. Cycle life prediction of lithium-ion batteries based on data-driven methods. Etransportation 2021, 10, 100137. [Google Scholar] [CrossRef]

- Du, M.; Li, Q.; Pang, H. Oxalate-derived porous prismatic nickel/nickel oxide nanocomposites toward lithium-ion battery. J. Colloid Interface Sci. 2020, 580, 614–622. [Google Scholar] [CrossRef] [PubMed]

- Xia, R.; Zhao, K.; Kuo, L.Y.; Zhang, L.; Cunha, D.M.; Wang, Y.; Huang, S.; Zheng, J.; Boukamp, B.; Kaghazchi, P.; et al. Nickel Niobate Anodes for High Rate Lithium-Ion Batteries. Adv. Energy Mater. 2021, 12, 2102972. [Google Scholar] [CrossRef]

- Zheng, W.; Bi, W.; Gao, X.; Zhang, Z.; Yuan, W.; Li, L. A nickel and cobalt bimetal organic framework with high capacity as an anode material for lithium-ion batteries. Sustain. Energy Fuels 2020, 4, 5757–5764. [Google Scholar] [CrossRef]

- Xiaomei, J.; Yanjun, C.; Xiaokai, M.; Weiguo, C.; Changcheng, L.; Que, H.; Nithesh, N.; Vignesh, M.; Mina, H.; Zhanhu, G. The impact of electrode with carbon materials on safety performance of lithium-ion batteries: A review. Carbon 2022, 191, 448–470. [Google Scholar]

- Onishchenko, D.V.; Popovich, A.A.; Boiko, Y.N. Carbon-silicon anode composites for lithium-ion (polymer) rechargeable batteries. Russ. J. Non-Ferr. Met. 2010, 51, 169–172. [Google Scholar] [CrossRef]

- Wang, L.; Ding, C.X.; Zhang, L.C.; Xu, H.W.; Zhang, D.W.; Cheng, T.; Chen, C.H. A novel carbon–silicon composite nanofiber prepared via electrospinning as anode material for high energy-density lithium ion batteries. J. Power Sources 2010, 195, 5052–5056. [Google Scholar] [CrossRef]

- Wenjie, T.; Shuai, L.; Sandile, F.; Jiangang, H.; Jiaxin, W.; Chen, W.; Jianqiang, C. Ionic liquid-induced interfacially bonding of bio-based RH-Si/SiOx@C anodes for enhanced ultra-long cycling of Li-ion batteries. Mater. Chem. Phys. 2022, 291, 126671. [Google Scholar]

- Yang, X.-G.; Liu, T.; Wang, C.-Y. Thermally modulated lithium iron phosphate batteries for mass-market electric vehicles. Nat. Energy 2021, 6, 176–185. [Google Scholar] [CrossRef]

- Yue, M.; Lv, Z.; Zheng, Q.; Li, X.; Zhang, H. Battery assembly optimization: Tailoring the electrode compression ratio based on the polarization analysis in vanadium flow batteries. Appl. Energy 2018, 235, 495–508. [Google Scholar] [CrossRef]

- Haber, S.; Leskes, M. Dynamic Nuclear Polarization in battery materials. Solid State Nucl. Magn. Reson. 2021, 117, 101763. [Google Scholar] [CrossRef]

- Qiu, C.; He, G.; Shi, W.; Zou, M.; Liu, C. The polarization characteristics of lithium-ion batteries under cyclic charge and discharge. J. Solid State Electrochem. 2019, 23, 1887–1902. [Google Scholar] [CrossRef]

- Luyao, Z.; Minxue, Z.; Junming, Z.; Hong, L.; Wei, L.; Mingyi, C. Numerical modeling of thermal runaway for low temperature cycling lithium-ion batteries. J. Energy Storage 2023, 63, 107053. [Google Scholar]

- Zhizuan, Z.; Xiaodong, Z.; Bei, C.; Lizhong, Y.; Liew, K.M. Investigating the relationship between heating temperature and thermal runaway of prismatic lithium-ion battery with LiFePO4 as cathode. Energy 2022, 256, 124714. [Google Scholar]

- Kalaf, O.; Solyali, D.; Asmael, M.; Zeeshan, Q.; Safaei, B.; Askir, A. Experimental and simulation study of liquid coolant battery thermal management system for electric vehicles: A review. Int. J. Energy Res. 2021, 45, 6495–6517. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, H.; Qu, Z.; Zhang, J. Recent progress in lithium-ion battery thermal management for a wide range of temperature and abuse conditions. Int. J. Hydrogen Energy 2022, 47, 9428–9459. [Google Scholar] [CrossRef]

- Ji, H.; Luo, T.; Dai, L.; He, Z.; Wang, Q. Numerical investigation on the polarization and thermal characteristics of LiFePO4-based batteries during charging process. Appl. Therm. Eng. 2022, 214, 118709. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, J.; Yuan, Y.; Zhang, H.; Tian, S.; Lu, X.; Zhang, X.; Jiang, F.; Liu, Z.; Zhang, J.; et al. Distributed Measurement of Polarization Characteristics for a Multifunctional Integrated Optical Chip: A Review. IEEE Trans. Instrum. Meas. 2018, 68, 1543–1553. [Google Scholar] [CrossRef]

- He, X.; Sun, B.; Zhang, W.; Fan, X.; Su, X.; Ruan, H. Multi-time scale variable-order equivalent circuit model for virtual battery considering initial polarization condition of lithium-ion battery. Energy 2022, 244, 123084. [Google Scholar] [CrossRef]

- Lin, P.; Jin, P.; Hong, J.; Wang, Z. Battery voltage and state of power prediction based on an improved novel polarization voltage model. Energy Rep. 2020, 6, 2299–2308. [Google Scholar] [CrossRef]

- Fan, Y.; Yanlong, Q.; Degang, G. Lithium-ion battery polarization characteristics at different charging modes. Trans. China Electrotech. Soc. 2017, 32, 171. [Google Scholar]

- Lv, S.; Wang, X.; Lu, W.; Zhang, J.; Ni, H. The influence of temperature on the capacity of lithium ion batteries with different anodes. Energies 2021, 15, 60. [Google Scholar] [CrossRef]

- Sherfey, J.; Brenner, A. Electrochemical calorimetry. J. Electrochem. Soc. 1958, 105, 665. [Google Scholar] [CrossRef]

- Bernardi, D.; Pawlikowski, E.; Newman, J. A General Energy Balance for Battery Systems. J. Electrochem. Soc. 1985, 132, 5. [Google Scholar] [CrossRef]

- Renfeng, C.; Xingjuan, Z.; Han, Y.; Chao, W. Experimental study on heat generation characteristics of lithium-ion batteries using a forced convection calorimetry method. Appl. Therm. Eng. 2022, 219, 119559. [Google Scholar]

- Rui, H.; Yidan, X.; Qichao, W.; Junxuan, C.; Fenfang, C.; Xiaoli, Y. Simulation Study on Heat Generation Characteristics of Lithium-Ion Battery Aging Process. Electronics 2023, 12, 1444. [Google Scholar]

- Xie, Y.; Shi, S.; Tang, J.; Wu, H.; Yu, J. Experimental and analytical study on heat generation characteristics of a lithium-ion power battery. Int. J. Heat Mass Transf. 2018, 122, 884–894. [Google Scholar] [CrossRef]

- Hu, G.; Huang, P.; Bai, Z.; Wang, Q.; Qi, K. Comprehensively analysis the failure evolution and safety evaluation of automotive lithium ion battery. Etransportation 2021, 10, 100140. [Google Scholar] [CrossRef]

- Kong, D.; Wang, G.; Ping, P.; Wen, J. A coupled conjugate heat transfer and CFD model for the thermal runaway evolution and jet fire of 18650 lithium-ion battery under thermal abuse. Etransportation 2022, 12, 100157. [Google Scholar] [CrossRef]

- Peiyan, Q.; Jie, Z.M.; Da, J.; Kai, Y.; Jianling, L.; Yilin, L.; Fei, G.; Hao, L. Combustion characteristics of lithium–iron–phosphate batteries with different combustion states. Etransportation 2022, 11, 100148. [Google Scholar] [CrossRef]

- Piao, N.; Gao, X.; Yang, H.; Guo, Z.; Hu, G.; Cheng, H.-M.; Li, F. Challenges and development of lithium-ion batteries for low temperature environments. Etransportation 2022, 11, 100145. [Google Scholar] [CrossRef]

- Wang, H.; Xu, H.; Zhang, Z.; Wang, Q.; Jin, C.; Wu, C.; Xu, C.; Hao, J.; Sun, L.; Du, Z. Fire and explosion characteristics of vent gas from lithium-ion batteries after thermal runaway: A comparative study. Etransportation 2022, 13, 100190. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z.; Yang, X.; Gong, J.; Zhang, J. Thermal management of parallel cells—Methodology based on non-linear dynamics. Etransportation 2022, 13, 100187. [Google Scholar] [CrossRef]

- Joula, M.; Dilibal, S.; Owusu-Danquah, J. Smart adaptronic thermal management system designs for the Li-ion battery packs. In Proceedings of the 2021 IEEE International Conference on Mechatronics (ICM), Kashiwa, Japan, 7–9 March 2021; IEEE: New York, NY, USA, 2021; pp. 1–6. [Google Scholar]

- Wang, X.; Wei, X.; Zhu, J.; Dai, H.; Zheng, Y.; Xu, X.; Chen, Q. A review of modeling, acquisition, and application of lithium-ion battery impedance for onboard battery management. Etransportation 2021, 7, 100093. [Google Scholar] [CrossRef]

- Zhu, L.; Xiong, F.; Chen, H.; Wei, D.; Li, G.; Ouyang, C. Thermal analysis and optimization of an EV battery pack for real applications. Int. J. Heat Mass Transf. 2020, 163, 120384. [Google Scholar] [CrossRef]

- Chen, Z.; Qin, Y.; Dong, Z.; Zheng, J.; Liu, Y. Numerical study on the heat generation and thermal control of lithium-ion battery. Appl. Therm. Eng. 2023, 221, 119852. [Google Scholar] [CrossRef]

- Ren, H.; Jia, L.; Dang, C.; Qi, Z. An electrochemical-thermal coupling model for heat generation analysis of prismatic lithium battery. J. Energy Storage 2022, 50, 104277. [Google Scholar] [CrossRef]

- Mei, W.; Li, H.; Zhao, C.; Sun, J.; Wang, Q. Numerical study on thermal characteristics comparison between charge and discharge process for lithium ion battery. Int. J. Heat Mass Transf. 2020, 162, 120319. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, H.; Cao, L.; Yi, Z.; Li, P.; Guo, H. Heat generation and surrogate model for large-capacity nickel-rich prismatic lithium-ion battery as against 18650 battery. J. Loss Prev. Process Ind. 2022, 77, 104783. [Google Scholar] [CrossRef]

- Joula, M.; Dilibal, S.; Mafratoglu, G.; Danquah, J.O.; Alipour, M. Hybrid Battery Thermal Management System with NiTi SMA and Phase Change Material (PCM) for Li-ion Batteries. Energies 2022, 15, 4403. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Nominal capacity | Ah | 104 |

| Nominal voltage | V | 3.66 |

| Working voltage | V | 2.8~4.2 |

| Size | mm | 52 ∗ 148 ∗ 95 |

| Weight | kg | 1.7 |

| Energy density | Wh/kg | 220 |

| State of charge window | % | 5~100 |

| Equipment | Type | Manufacturer | Range | Accuracy |

|---|---|---|---|---|

| Battery charge/discharge test system | CT-8008-5 V 300 A-NTFA | Shenzhen Xinwei Electronics Co., Ltd., Shenzhen, China | 0 V~5 V −200 A~+200 A | ±0.05% FSR |

| High- and low-temperature humidity test chamber | SC2-400-SD-3 | Guangdong Sanmu Technology Co., Ltd., Guangdong, China | −70 °C~180 °C | ±1 °C |

| Thermocouple | −200~260 °C | ±1 °C |

| Parameter | Unit | Value |

|---|---|---|

| Average specific heat capacity of the battery | J/(kg·K) | 1020 |

| Thermal conductivity | 17.8 (X direction) | |

| W/(m·K) | 4.9 (Y direction) | |

| 8.8 (Z direction) | ||

| Density | kg/m3 | 2353 |

| Surface convective heat transfer coefficient | W/(m2·K) | 20.6 |

| Positive terminal material | - | Al |

| Negative terminal material | - | Cu |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Guo, Q.; Liu, J.; Wang, H. The Polarization and Heat Generation Characteristics of Lithium-Ion Battery with Electric–Thermal Coupled Modeling. Batteries 2023, 9, 529. https://doi.org/10.3390/batteries9110529

Guo J, Guo Q, Liu J, Wang H. The Polarization and Heat Generation Characteristics of Lithium-Ion Battery with Electric–Thermal Coupled Modeling. Batteries. 2023; 9(11):529. https://doi.org/10.3390/batteries9110529

Chicago/Turabian StyleGuo, Jiayong, Qiang Guo, Jie Liu, and Hewu Wang. 2023. "The Polarization and Heat Generation Characteristics of Lithium-Ion Battery with Electric–Thermal Coupled Modeling" Batteries 9, no. 11: 529. https://doi.org/10.3390/batteries9110529