Integrated Performance Evaluation of Aerogel-Based Fibre-Enhanced Thermal Renders Applied on Building Walls

Abstract

:1. Introduction

2. Results and Discussion

3. Conclusions

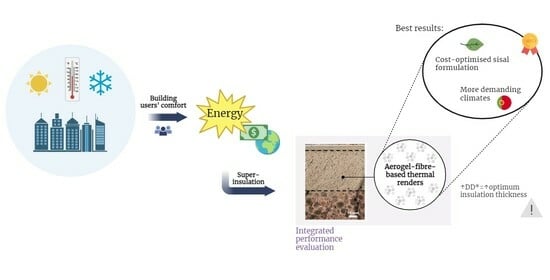

- The optimised aerogel-based renders (TRopt) showed a better performance, as expected since their acquisition costs were significantly lower (from 2477.4 to 1021.7 EUR∙m−3 for TR reference). Based on the latest findings, it is believed that this cost reduction will be possible. The sisal-enhanced formulation (TRopt sisal) showed the best integrated performance of all the considered thermal renders;

- The Portuguese region with the highest DD* (degree-days equivalent) led to higher optimum thicknesses (e.g., the Azores with 0.02 m and 0.01 m and Bragança with 0.06 m and 0.03 m for cost-optimised and non-optimised thermal renders with sisal fibre, respectively), since the use of more energy for indoor temperature regulation diluted the impacts of the thermal render;

- In the Azores, the cost-optimised formulations improved the savings during the solutions’ service life (SSL) from 8 to 10 times compared to the non-optimised, while in Bragança, although the improvement was around two-fold, it led to an additional saving of ≈60 EUR∙m−2 during the 50 years;

- There was a steeper decrease in the annual energy consumption with thermal renders up to 0.02 m thickness in the Azores and 0.04 m in Bragança, leading to absolute energy savings of ≈5 and 15 kWh∙m−2∙year−1, respectively, when compared with the uninsulated wall;

- A thickness of 0.01 m of thermal render can lead to annual operational energy savings of 7.86 kWh∙m−2 in Bragança and of 2.10 kWh∙m−2 in the Azores;

- Optimum thickness related to the ADP-ff and GWP impacts are higher than concerning economic assessment, resulting in 0.04 m for the Azores and 0.09 m for Bragança;

- The optimised formulations led to economic and environmental savings, especially from 600 DD* onwards.

4. Recommendations

5. Materials and Methods

5.1. Climate

5.2. Aerogel-Based Fibre-Enhanced Thermal Renders

5.2.1. Characterisation and Selection of Formulations

5.2.2. Sensitivity Analysis of the Silica Aerogel Cost

5.2.3. Description of the Walls

5.3. Methodology—Numerical Simulation Model

5.3.1. Materials and Processes Input

5.3.2. Calculation Parameters Input

5.3.3. Heating and Cooling Energy Consumption

5.3.4. Economic Analysis

5.3.5. Environmental Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Meaning |

| ADP-ff | Abiotic depletion potential from fossil fuels [MJ] |

| Az | The Azores |

| Br | Bragança |

| CDD | Cooling degree-days [°C∙day] |

| COP | Energy efficiency ratio of the heating system |

| Ce | Energy cost [EUR∙kW−1∙h−1] |

| Ci | Thermal insulating material cost [EUR∙m−3] |

| Cins | Thermal insulating material cost per unit area [EUR∙m−2] |

| Cuse | Annual costs of energy per surface area [EUR∙m−2] |

| Cuse,SL | Service life costs of energy per surface area [EUR∙m−2] |

| Ctotal,SL | Service life costs of the solution per surface area [EUR∙m−2] |

| DD* | Degree-days as a fraction of climate and energy efficiency [°C∙day] |

| EER | Energy efficiency ratio of the cooling system |

| EPS | Expanded polystyrene |

| ETICS | External thermal insulation composite systems |

| Econs,heat | Annual energy consumption for heating [kWh∙m−2] |

| Econs,cool | Annual energy consumption for cooling [kWh∙m−2] |

| Ecool | Annual energy requirements for cooling [J∙m−2] |

| Eheat | Annual energy requirements for heating [J∙m−2] |

| GWP | Global warming potential [kg CO2 eq] |

| g | Inflation rate |

| HDD | Heating degree-days [°C∙day] |

| Hu | Lower heating value [J∙kW−1∙h−1] |

| i | Interest rate |

| N | Lifetime [year] |

| PP | Payback period [year] |

| PWF | Present worth factor |

| q | Heat loss per unit area [W∙m−2] |

| R | Thermal resistance [m2∙K∙W−1] |

| Rin | Indoor air film thermal resistance [m2∙K∙W−1] |

| Rins | Thermal insulation material thermal resistance [m2∙K∙W−1] |

| Rout | Outdoor air film thermal resistance [m2∙K∙W−1] |

| Rw | Wall thermal resistance [m2∙K∙W−1] |

| r | Interest rate adjusted for the inflation rate |

| SES | Annual energy cost savings [EUR∙m−2∙year−1] |

| SSL | Savings achieved during the service life [EUR∙m−2] |

| TR | Thermal render |

| TRopt | Cost-optimised thermal render |

| TR cork | Thermal render with cork granules |

| Tin | Mean daily indoor temperature [°C] |

| Tout | Mean daily outdoor temperature [°C] |

| U | Thermal transmittance [W∙m−2∙°C−1] |

| Uin | Thermal transmittance of an insulated wall [W∙m−2∙°C−1] |

| Uun | Thermal transmittance of an uninsulated wall [W∙m−2∙°C−1] |

| x | Thickness [m] |

| xopt | Optimised thickness [m] |

| λ | Thermal conductivity [W∙m−1∙K−1] |

References

- European Commission. Long-Term Low Greenhouse Gas Emission Development Strategy of the European Union and Its Member States; European Union: Zagreb, Croatia, 2020.

- European Parliament. P9_TA(2020)0005 The European Green Deal—European Parliament Resolution of 15 January 2020 on the European Green Deal (2019/2956(RSP)); European Parliament: Brussels, Belgium, 2020.

- European Commission. Energy Performance of EU Buildings. 2019. Available online: https://ec.europa.eu/energy/en/topics/en-617ergy-efficiency/energy-performance-of-buildings (accessed on 15 July 2019).

- Buildings Performance Institute Europe. Europe’s Buildings under the Microscope—A Country-by-Country Review of the Energy Performance of Buildings; BPIE: Brussels, Belgium, 2011; ISBN 9789491143014. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel Insulation for Building Applications: A State-of-the-Art Review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Yu, J.; Yang, C.; Tian, L.; Liao, D. A Study on Optimum Insulation Thicknesses of External Walls in Hot Summer and Cold Winter Zone of China. Appl. Energy 2009, 86, 2520–2529. [Google Scholar] [CrossRef]

- Maia, J.; Ramos, N.M.M.; Veiga, R. Assessment of Test Methods for the Durability of Thermal Mortars Exposure to Freezing. Mater. Struct. Mater. Constr. 2019, 52, 112. [Google Scholar] [CrossRef]

- EURIMA. U-Values for Better Energy Performance of Buildings—Report Established by ECOFYS for EURIMA; EURIMA: Brussels, Belgium, 2007. [Google Scholar]

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.D.; Gomes, M.G.; Silva, L.; Ilharco, L. Physical, Mechanical, and Microstructural Characterisation of an Innovative Thermal Insulating Render Incorporating Silica Aerogel. Energy Build. 2020, 211, 109793. [Google Scholar] [CrossRef]

- Ganobjak, M.; Brunner, S.; Wernery, J. Aerogel Materials for Heritage Buildings: Materials, Properties and Case Studies. J. Cult. Herit. 2020, 42, 81–98. [Google Scholar] [CrossRef]

- Ibrahim, M.; Biwole, P.H.; Achard, P.; Wurtz, E. Aerogel-Based Materials for Improving the Building Envelope’s Thermal Behavior: A Brief Review with a Focus on a New Aerogel-Based Rendering. In Energy Sustainability Through Green Energy; Sharma, A., Kar, S., Eds.; Springer: New Delhi, India, 2015; pp. 163–188. [Google Scholar]

- Stahl, T.; Brunner, S.; Zimmermann, M.; Ghazi Wakili, K. Thermo-Hygric Properties of a Newly Developed Aerogel Based Insulation Rendering for Both Exterior and Interior Applications. Energy Build 2012, 44, 114–117. [Google Scholar] [CrossRef]

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.D.; da Glória Gomes, M. Nanomaterials’ Influence on the Performance of Thermal Insulating Mortars-A Statistical Analysis. Appl. Sci. 2020, 10, 2219. [Google Scholar] [CrossRef]

- Koebel, M.; Rigacci, A.; Achard, P. Aerogel-Based Thermal Superinsulation: An Overview. J. Solgel. Sci. Technol. 2012, 63, 315–339. [Google Scholar] [CrossRef]

- Hipin. Hipin Project—High Performance Insulation Based on Nanostructure Encapsulation of Air. 2019. Available online: http://www.hipin.eu/ (accessed on 29 December 2019).

- Nanorender. Nanorender: Performance of Nanoaerogel Silica-Based Renders. 2019. Available online: http://www.florescolen.com/Documentacao/Executive_Summary(inEnglish).pdf (accessed on 5 December 2019). (In Portuguese).

- Saint-Gobain Weber. PEP—Efficient Plus Wall. 2019. Available online: https://www.pt.weber/pep-parede-eficiente-plus (accessed on 26 December 2019). (In Portuguese).

- Ebert, H.-P. Thermal Properties of Aerogels. In Aerogels Handbook; Aegerter, M., Leventis, N., Koebel, M.M., Eds.; Springer: New York, NY, USA, 2011; pp. 537–564. [Google Scholar]

- Bisson, A.; Rigacci, A.; Lecomte, D.; Achard, P. Effective Thermal Conductivity of Divided Silica Xerogel Beds. J. Non. Cryst. Solids 2004, 350, 379–384. [Google Scholar] [CrossRef]

- Jia, G.; Guo, J.; Li, Z. Controllable Preparation of Aerogel/Expanded Perlite Composite and Its Application in Thermal Insulation Mortar. Constr. Build Mater 2023, 394, 132257. [Google Scholar] [CrossRef]

- Kueh, A.B.H.; Razali, A.W.; Lee, Y.Y.; Hamdan, S.; Yakub, I.; Suhaili, N. Acoustical and Mechanical Characteristics of Mortars with Pineapple Leaf Fiber and Silica Aerogel Infills—Measurement and Modeling. Mater. Today Commun. 2023, 35, 105540. [Google Scholar] [CrossRef]

- Soares, A.; de Fátima Júlio, M.; Flores-Colen, I.; Ilharco, L.M.; de Brito, J. EN 998-1 Performance Requirements for Thermal Aerogel-Based Renders. Constr. Build. Mater. 2018, 179, 453–460. [Google Scholar] [CrossRef]

- de Fátima Júlio, M.; Ilharco, L.M.; Soares, A.; Flores-Colen, I.; de Brito, J. Silica-Based Aerogels as Aggregates for Cement-Based Thermal Renders. Cem. Concr. Compos. 2016, 72, 309–318. [Google Scholar] [CrossRef]

- Dams, B.; Amornrattanasereegul, N.; Shepherd, P.; Ball, R.J. Cement-Fibre Composites for Additive Building Manufacturing. In Proceedings of the 39th Cement and Concrete Science Conference; Ball, R.J., Dams, B., Ferrandiz-Mas, V., Ke, X., Paine, K., Tyrer, M., Walker, P., Eds.; University of Bath: Bath, UK, 2019; pp. 14–18. [Google Scholar]

- Pedroso, M.; Flores-Colen, I. The Influence of Dimension and Content of Natural Organic Fibrous Materials on the Multi-Performance of Cement-Based Composites: A Statistical Approach. Constr. Build. Mater. 2020, 231, 117175. [Google Scholar] [CrossRef]

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.D.; Gomes, M.G.; Hawreen, A.; Ball, R.J. Synergistic Effect of Fibres on the Physical, Mechanical, and Microstructural Properties of Aerogel-Based Thermal Insulating Renders. Cem. Concr. Compos. 2023, 139, 105045. [Google Scholar] [CrossRef]

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.D.; Gomes, M.G.; Silva, L.; Sequeira, P.; de Brito, J. Characterisation of a Multilayer External Wall Thermal Insulation System. Application in a Mediterranean Climate. J. Build. Eng. 2020, 30, 101265. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. External Thermal Insulation Composite Systems (ETICS); SpringerBriefs in Applied Sciences and Technology; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-20381-2. [Google Scholar]

- Pedroso, M.; da Gomes, M.G.; Silvestre, J.D.; Hawreen, A.; Flores-Colen, I. Thermophysical Parameters and Hygrothermal Simulation of Aerogel-Based Fibre-Enhanced Thermal Insulating Renders Applied on Exterior Walls. Energies 2023, 16, 3048. [Google Scholar] [CrossRef]

- Pedroso, M.; Silvestre, J.D.; Flores-Colen, I.; Gomes, M.G. Environmental Impact of Wall Multilayer Coating Systems Containing Aerogel-Based Fibre-Enhanced Thermal Renders. J. Build. Eng. 2023, 76, 107322. [Google Scholar] [CrossRef]

- Garrido, R.; Silvestre, J.D.; Flores-Colen, I.; de Júlio, M.F.; Pedroso, M. Economic Assessment of the Production of Subcritically Dried Silica-Based Aerogels. J. Non. Cryst. Solids 2019, 516, 26–34. [Google Scholar] [CrossRef]

- Silvestre, J.D.; Castelo, A.M.P.; Silva, J.J.B.C.; De Brito, J.M.C.L.; Pinheiro, M.D. Energy Retrofitting of a Buildings’ Envelope: Assessment of the Environmental, Economic and Energy (3E) Performance of a Cork-Based Thermal Insulating Rendering Mortar. Energies 2019, 13, 143. [Google Scholar] [CrossRef]

- Silvestre, J.D.; De Brito, J.; Pinheiro, M.D. From the New European Standards to an Environmental, Energy and Economic Assessment of Building Assemblies from Cradle-to-Cradle (3E-C2C). Energy Build. 2013, 64, 199–208. [Google Scholar] [CrossRef]

- Kaynakli, O. A Review of the Economical and Optimum Thermal Insulation Thickness for Building Applications. Renew. Sustain. Energy Rev. 2012, 16, 415–425. [Google Scholar] [CrossRef]

- Dombayci, Ö.A. The Environmental Impact of Optimum Insulation Thickness for External Walls of Buildings. Build. Environ. 2007, 42, 3855–3859. [Google Scholar] [CrossRef]

- Mahlia, T.M.I.; Iqbal, A. Cost Benefits Analysis and Emission Reductions of Optimum Thickness and Air Gaps for Selected Insulation Materials for Building Walls in Maldives. Energy 2010, 35, 2242–2250. [Google Scholar] [CrossRef]

- Hasan, A. Optimizing Insulation Thickness for Buildings Using Life Cycle Cost. Appl. Energy 1999, 63, 115–124. [Google Scholar] [CrossRef]

- Çomaklı, K.; Yüksel, B. Optimum Insulation Thickness of External Walls for Energy Saving. Appl. Therm. Eng. 2003, 23, 473–479. [Google Scholar] [CrossRef]

- Sisman, N.; Kahya, E.; Aras, N.; Aras, H. Determination of Optimum Insulation Thicknesses of the External Walls and Roof (Ceiling) for Turkey’s Different Degree-Day Regions. Energy Policy 2007, 35, 5151–5155. [Google Scholar] [CrossRef]

- Ozel, M. Cost Analysis for Optimum Thicknesses and Environmental Impacts of Different Insulation Materials. Energy Build. 2012, 49, 552–559. [Google Scholar] [CrossRef]

- Ozel, M. Determination of Optimum Insulation Thickness Based on Cooling Transmission Load for Building Walls in a Hot Climate. Energy Convers. Manag. 2013, 66, 106–114. [Google Scholar] [CrossRef]

- Ozel, M. Thermal, Economical and Environmental Analysis of Insulated Building Walls in a Cold Climate. Energy Convers. Manag. 2013, 76, 674–684. [Google Scholar] [CrossRef]

- Sagbansua, L.; Balo, F. Ecological Impact & Financial Feasibility of Energy Recovery (EIFFER) Model for Natural Insulation Material Optimization. Energy Build. 2017, 148, 1–14. [Google Scholar] [CrossRef]

- Çomakli, K.; Yüksel, B. Environmental Impact of Thermal Insulation Thickness in Buildings. Appl. Therm. Eng. 2004, 24, 933–940. [Google Scholar] [CrossRef]

- Ucar, A.; Balo, F. Determination of Environmental Impact and Optimum Thickness of Insulation for Building Walls. Environ. Prog. Sustain. Energy 2011, 30, 113–122. [Google Scholar] [CrossRef]

- Dombayci, Ö.A.; Gölcü, M.; Pancar, Y. Optimization of Insulation Thickness for External Walls Using Different Energy-Sources. Appl. Energy 2006, 83, 921–928. [Google Scholar] [CrossRef]

- Ucar, A.; Balo, F. Effect of Fuel Type on the Optimum Thickness of Selected Insulation Materials for the Four Different Climatic Regions of Turkey. Appl. Energy 2009, 86, 730–736. [Google Scholar] [CrossRef]

- Bolattürk, A. Determination of Optimum Insulation Thickness for Building Walls with Respect to Various Fuels and Climate Zones in Turkey. Appl. Therm. Eng. 2006, 26, 1301–1309. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward Aerogel Based Thermal Superinsulation in Buildings: A Comprehensive Review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Optimizing Insulation Thickness and Analysing Environmental Impacts of Aerogel-Based Thermal Superinsulation in Buildings. Energy Build. 2014, 77, 28–39. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, Y.; Huang, R.; Wu, H.; Sun, Y.; Huang, G.; Xu, T. Optimum Insulation Thicknesses and Energy Conservation of Building Thermal Insulation Materials in Chinese Zone of Humid Subtropical Climate. Sustain. Cities Soc. 2020, 52, 101840. [Google Scholar] [CrossRef]

- Ibrahim, M.; Biwole, P.H.; Achard, P.; Wurtz, E.; Ansart, G. Building Envelope with a New Aerogel-Based Insulating Rendering: Experimental and Numerical Study, Cost Analysis, and Thickness Optimization. Appl. Energy 2015, 159, 490–501. [Google Scholar] [CrossRef]

- Garrido, R.; Silvestre, J.D.; Flores-Colen, I. Economic and Energy Life Cycle Assessment of Aerogel-Based Thermal Renders. J. Clean. Prod. 2017, 151, 537–545. [Google Scholar] [CrossRef]

- Karatum, O.; Bhuiya, M.M.H.; Carroll, M.K.; Anderson, A.M.; Plata, D.L. Life Cycle Assessment of Aerogel Manufacture on Small and Large Scales: Weighing the Use of Advanced Materials in Oil Spill Remediation. J. Ind. Ecol. 2018, 22, 1365–1377. [Google Scholar] [CrossRef]

- Pinto, I.; Silvestre, J.D.; de Brito, J.; Júlio, M.F. Environmental Impact of the Subcritical Production of Silica Aerogels. J. Clean. Prod. 2020, 252, 119696. [Google Scholar] [CrossRef]

- Boccia, A.C.; Pulvirenti, A.; García-González, C.A.; Grisi, F.; Neagu, M. Compendium of Safety Regulatory for Safe Applications of Aerogels. Gels 2023, 9, 842. [Google Scholar] [CrossRef]

- Göswein, V.; Rodrigues, C.; Silvestre, J.D.; Freire, F.; Habert, G.; König, J. Using Anticipatory Life Cycle Assessment to Enable Future Sustainable Construction. J. Ind. Ecol. 2020, 24, 178–192. [Google Scholar] [CrossRef]

- Meex, E.; Hollberg, A.; Knapen, E.; Hildebrand, L.; Verbeeck, G. Requirements for Applying LCA-Based Environmental Impact Assessment Tools in the Early Stages of Building Design. Build. Environ. 2018, 133, 228–236. [Google Scholar] [CrossRef]

- Bolattürk, A. Optimum Insulation Thicknesses for Building Walls with Respect to Cooling and Heating Degree-Hours in the Warmest Zone of Turkey. Build. Environ. 2008, 43, 1055–1064. [Google Scholar] [CrossRef]

- Assembleia da República. Statute n.o 379-A/2015 of October 22—Requirements for the Energy Performance of Housing Buildings (REH)—Requirements; Diário da República: Lisbon, Portugal, 2015. (In Portuguese)

- Ibrahim, M. Improving the Buildings Envelopes Energy Performance Using Aerogel-Based Insulating Mineral Rendering. Ph.D. Thesis, École Nationale Supérieure des Mines de Paris, Paris, France, 2014. [Google Scholar]

- Beccali, M.; Cellura, M.; Fontana, M.; Longo, S.; Mistretta, M. Energy Retrofit of a Single-Family House: Life Cycle Net Energy Saving and Environmental Benefits. Renew. Sustain. Energy Rev. 2013, 27, 283–293. [Google Scholar] [CrossRef]

- Nan, X.; Yan, H.; Wu, R.; Shi, Y.; Bao, Z. Assessing the Thermal Performance of Living Wall Systems in Wet and Cold Climates during the Winter. Energy Build. 2020, 208, 109680. [Google Scholar] [CrossRef]

- Eurostat. Cooling and Heating Degree Days by Country—Annual Data. Available online: https://ec.europa.eu/eurostat/web/products-datasets/-/nrg_chdd_a (accessed on 3 July 2020).

- Dylewski, R.; Adamczyk, J. Economic and Environmental Benefits of Thermal Insulation of Building External Walls. Build. Environ. 2011, 46, 2615–2623. [Google Scholar] [CrossRef]

- Arslan, O.; Kose, R. Thermoeconomic Optimization of Insulation Thickness Considering Condensed Vapor in Buildings. Energy Build. 2006, 38, 1400–1408. [Google Scholar] [CrossRef]

- Nosrati, R.H.; Berardi, U. Hygrothermal Characteristics of Aerogel-Enhanced Insulating Materials under Different Humidity and Temperature Conditions. Energy Build. 2018, 158, 698–711. [Google Scholar] [CrossRef]

- Naman Karim, A.; Sasic Kalagasidis, A.; Johansson, P. Moisture Absorption of an Aerogel-Based Coating System under Different Wetting Scenarios. Build. Environ. 2023, 245, 110905. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F. Optimum Insulation Thickness for Building Walls in a Hot-Dry Climate. Int. J. Ambient. Energy 2002, 23, 115–126. [Google Scholar] [CrossRef]

- Kaynakli, O. Parametric Investigation of Optimum Thermal Insulation Thickness for External Walls. Energies 2011, 4, 913–927. [Google Scholar] [CrossRef]

- Ganobjak, M.; Brunner, S.; Hofmann, J.; Klar, V.; Ledermann, M.; Herzog, V.; Kämpfen, B.; Kilian, R.; Wehdorn, M.; Wernery, J. Current Trends in Aerogel Use in Heritage Buildings: Case Studies from the Aerogel Architecture Award 2021. Gels 2023, 9, 814. [Google Scholar] [CrossRef]

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and Future Köppen-Geiger Climate Classification Maps at 1-Km Resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated World Map of the Köppen-Geiger Climate Classification. Hydrol. Earth Syst. Sci. 2007, 11, 1633–1644. [Google Scholar] [CrossRef]

- Assembleia da Republica. Dispatch 15793-F/2013—Establishing the Parameters for the Climatic Zoning of Portugal; Diário da República: Lisbon, Portugal, 2013. (In Portuguese)

- BizEE. Degree Days: Weather Data for Energy Saving. 2020. Available online: https://www.degreedays.net/ (accessed on 23 July 2020).

- IPMA Portuguese Institute for Sea and Atmosphere. Climate Normals. 2020. Available online: https://www.ipma.pt/en/oclima/normais.clima/ (accessed on 25 June 2020).

- Zhang, D.; Yu, J.; Wu, H.; Jaworska, B.; Ellis, B.R.; Li, V.C. Discontinuous Micro-Fibers as Intrinsic Reinforcement for Ductile Engineered Cementitious Composites (ECC). Compos. B Eng. 2020, 184, 107741. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- INE Statistical Data of Portugal. 2020. Available online: https://www.ine.pt/xportal/xmain?xpgid=ine_main&xpid=INE&xlang=en (accessed on 20 June 2020).

- Gomes, M.G.; Flores-Colen, I.; da Silva, F.; Pedroso, M. Thermal Conductivity Measurement of Thermal Insulating Mortars with EPS and Silica Aerogel by Steady-State and Transient Methods. Constr. Build. Mater. 2018, 172, 696–705. [Google Scholar] [CrossRef]

- Enersens. Product Data Sheet: Aerogel Kwark. 2020. Available online: http://enersens.fr/en/home/ (accessed on 7 January 2020).

- Huber, L.; Zhao, S.; Malfait, W.J.; Vares, S.; Koebel, M.M. Fast and Minimal-Solvent Production of Superinsulating Silica Aerogel Granulate. Angew. Chem. 2017, 129, 4831–4834. [Google Scholar] [CrossRef]

- Stojanovic, A.; Zhao, S.; Angelica, E.; Malfait, W.J.; Koebel, M.M. Three Routes to Superinsulating Silica Aerogel Powder. J. Solgel. Sci. Technol. 2019, 90, 57–66. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, State-of-the-Art and Future Thermal Building Insulation Materials and Solutions—Properties, Requirements and Possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Daouas, N. A Study on Optimum Insulation Thickness in Walls and Energy Savings in Tunisian Buildings Based on Analytical Calculation of Cooling and Heating Transmission Loads. Appl. Energy 2011, 88, 156–164. [Google Scholar] [CrossRef]

- Kurekci, N.A. Determination of Optimum Insulation Thickness for Building Walls by Using Heating and Cooling Degree-Day Values of All Turkey’s Provincial Centers. Energy Build. 2016, 118, 197–213. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Dos Santos, C.P.; Matias, L. ITE50—Thermal Transmittance of Building Envelope Elements, 1st ed.; LNEC: Lisbon, Portugal, 2006. (In Portuguese) [Google Scholar]

- Gomes, M.G.; Flores-Colen, I.; Melo, H.; Soares, A. Physical Performance of Industrial and EPS and Cork Experimental Thermal Insulation Renders. Constr. Build. Mater. 2019, 198, 786–795. [Google Scholar] [CrossRef]

- de Freitas, V.P. Support Manual for the Rehabilitation Project of Old Buildings, 1st ed.; Ordem dos Engenheiros da Região Norte: Porto, Portugal, 2012. (In Portuguese) [Google Scholar]

- PORDATA. Accomodations and Their Characteristics. 2019. Available online: https://www.pordata.pt/Subtema/Portugal/Alojamentos-53 (accessed on 5 September 2019). (In Portuguese).

- Assembleia da República. Decree-Law No. 80/2006 Regulation of the Thermal Behaviour of Buildings; Diário da República: Lisbon, Portugal, 2006. (In Portuguese)

- Assembleia da Republica. Ordinance 17-A/2016; Diário da República: Lisbon, Portugal, 2016.

- ISO 9869-1: 2014; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance—Part 1: Heat Flow Meter Method. ISO: Geneva, Switzerland, 2014.

- White, J.A.; Case, K.E.; Pratt, D.B. Principles of Engineering Economic Analysis, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Akyüz, M.K.; Altuntaş, Ö.; Söğüt, M.Z. Economic and Environmental Optimization of an Airport Terminal Building’s Wall and Roof Insulation. Sustainability 2017, 9, 1849. [Google Scholar] [CrossRef]

| Region (DD*) | Render Designation | U [W∙m−2∙°C−1] | xopt [m] | Cins [EUR∙m−2] | SSL [EUR∙m−2] | PP [Year] | SL ADP-ff Savings [MJ∙m−2] | PP ADP-ff [Year] | SL GWP Savings [kgCO2 eq∙m−2] | PP GWP [Year] |

|---|---|---|---|---|---|---|---|---|---|---|

| Azores (188.8) | TR aramid | 0.99 | 0.01 | 25.96 | 0.05 | >50 | 313.80 | 11.4 | 36.61 | 8.2 |

| TR sisal | 0.98 | 0.01 | 24.77 | 2.42 | >50 | 340.78 | 9.9 | 39.08 | 7.3 | |

| TRopt aramid | 0.75 | 0.02 | 22.93 | 16.60 | >50 | 432.20 | 15.1 | 52.17 | 10.8 | |

| TRopt sisal | 0.73 | 0.02 | 20.43 | 20.45 | 49.8 | 470.31 | 13.2 | 55.41 | 9.8 | |

| Bragança (680.1) | TR aramid | 0.61 | 0.03 | 77.88 | 94.41 | 41.2 | 2415.23 | 5.2 | 268.56 | 3.7 |

| TR sisal | 0.59 | 0.03 | 74.32 | 102.67 | 36.1 | 2514.39 | 4.6 | 277.92 | 3.4 | |

| TRopt aramid | 0.44 | 0.05 | 57.33 | 149.65 | 19.1 | 2771.74 | 7.2 | 312.57 | 5.2 | |

| TRopt sisal | 0.36 | 0.06 | 61.30 | 160.42 | 19.1 | 2959.73 | 7.3 | 333.03 | 5.4 |

| Location | City | Alt. [m] [76] | Long. [°] [76] | Lat. [°] [76] | Köppen Class [76] | HDD [°C∙Day] Base 18 °C [74] | CDD [°C∙Day] Base 25 °C [64,75] |

|---|---|---|---|---|---|---|---|

| Islands | Azores—Ponta Delgada | 48 | 25W40 | 37N43 | Cfb | 604 | 0 |

| Madeira—Funchal | 380 | 16W54 | 32N37 | Csa | 618 | 18 | |

| Mainland | Faro | 9 | 7W55 | 37N1 | Csa | 987 | 98 |

| Lisboa | 4 | 9W7 | 38N43 | Csa | 1071 | 105 | |

| Évora | 240 | 7W54 | 38N34 | Csa | 1150 | 289 | |

| Porto | 94 | 8W36 | 41N8 | Csb | 1250 | 27 | |

| Castelo Branco | 348 | 7W29 | 39N49 | Csa | 1274 | 278 | |

| Coimbra | 151 | 8W25 | 40N12 | Csb | 1304 | 32 | |

| Vila Real | 450 | 7W44 | 41N18 | Csb | 1764 | 121 | |

| Guarda | 1056 | 7W15 | 40N32 | Csb | 1924 | 16 | |

| Bragança | 674 | 6W45 | 41N48 | Csb | 2015 | 136 |

| Group of Tests | Parameter | Render Designation | |||

|---|---|---|---|---|---|

| TR Reference | TR Aramid | TR Sisal | TR Biomass | ||

| Fresh state [26] | Water powder ratio | 1.3 | 1.3 | 1.3 | 1.3 |

| Workability | Excellent | Good | Excellent | Excellent | |

| Consistency [mm] | 143.5 | 121.1 | 139.7 | 139.1 | |

| Bulk density [kg∙m−3] | 293 | 310 | 297 | 299 | |

| Air content [%] | 21.5 | 19.5 | 22 | 22.5 | |

| Mechanical [26] | Bulk density [kg∙m−3] | 159 | 165 | 160 | 162 |

| Compressive strength, peak [MPa] | 0.185 | 0.208 | 0.193 | 0.19 | |

| Flexural strength, peak [MPa] | 0.092 | 0.165 | 0.093 | 0.092 | |

| Cracks during curing (visual evaluation) | No | No | No | No | |

| Dynamic modulus of elasticity [MPa] | 51.3 | 77.4 | 49.2 | 48.3 | |

| Impact [26] | Adhesive strength to block [MPa] | 0.066:B | 0.075:B | 0.067:B | 0.066:B |

| Adhesive strength to basecoat [MPa] | 0.065:B | 0.073:B | 0.065:B | 0.066:B | |

| Diameter impact 3 J [mm] | 31.5 | 29.9 | 31 | 31.2 | |

| Cracks (number of impacts with cracks in 5 impacts) | 3 in 5 | 0 in 5 | 1 in 5 | 2 in 5 | |

| Pendulum hammer index | 59.3 | 62.4 | 59.5 | 59.4 | |

| Physical [26,29] | Water absorption coefficient [kg∙m−2∙s−1/2] | 0.109 | 0.0286 | 0.0325 | 0.031 |

| Open porosity [%] | 86.3 | 85.1 | 86.9 | 87 | |

| Thermal conductivity at 10 °C and dry-state [W∙m−1∙K−1] | 0.029 | 0.032 | 0.030 | 0.031 | |

| Thermal conductivity at 10 °C and saturated [W∙m−1∙K−1] | 0.1401 | 0.1311 | 0.123 | 0.1285 | |

| Water content at 80%RH [kg∙m−3] | 7.8 | 7.12 | 7.56 | 7.28 | |

| Water content saturation by capillary action [kg∙m−3] | 281.04 | 246.08 | 260.2 | 274.82 | |

| Water vapour diffusion resistance factor | 13.7 | 13.3 | 12.7 | 12.4 | |

| LCA [30] | ADP-ff [MJ], per cubic meter | 8494.9 | 9303.2 | 8452.3 | 8459.3 |

| GWP [kg CO2 eq], per cubic meter | 675.1 | 720.4 | 672.2 | 672.8 | |

| Economic | Cost [EUR∙m−3] | 2478.76 | 2596.37 | 2477.35 | 2480.12 |

—Improved performance over reference;

—Improved performance over reference;  —Similar performance to reference or non-significant;

—Similar performance to reference or non-significant;  —Worse performance over reference.

—Worse performance over reference.| Material | Density [kg∙m−3] | Thickness [m] | Λ [W∙m−1∙K−1] | R [m2∙K∙W−1] | Cost [EUR∙m−3] | ADP-ff [MJ∙m−3] | GWP [kg CO2 eq∙m−3] |

|---|---|---|---|---|---|---|---|

| Internal plaster [88] | 0.020 | 0.011 | |||||

| Lightweight concrete block [88] | 0.200 | 0.520 | |||||

| Multilayer coating system [27] | 0.0055 | 0.007 | |||||

| TR cork [89] | 825 | 0.095 | 566.0 * | 2739.0 | 333.3 | ||

| TR aramid | 165 | 0.032 | 2596.3 | 9303.2 | 720.4 | ||

| TR sisal | 160 | 0.030 | 2477.3 | 8452.3 | 672.2 | ||

| TRopt aramid | 165 | 0.032 | 1146.5 | 9303.2 | 720.4 | ||

| TRopt sisal | 160 | 0.030 | 1021.6 | 8452.3 | 672.2 |

| Material | Ecoinvent Process and Literature References |

|---|---|

| TR cork | [32] |

| TR aramid | [84] |

| TR sisal | [84] |

| Ecoinvent Process | Cost [EUR∙kWh−1] | ADP-ff [MJ∙kWh−1] | GWP [kg CO2 eq∙kWh−1] | Lower Heating Value (Hu) [J∙kW∙h−1] |

|---|---|---|---|---|

| Electricity, low voltage {PT}|market for|Cut-off, S | 0.22 | 3.90 | 0.42 | 3.60 × 106 |

| Parameter | Value |

|---|---|

| Locations | Table 2 |

| CDD [°C∙day] | Table 2 |

| HDD [°C∙day] | Table 2 |

| TR/TRopt aramid and sisal | Table 4 |

| Other materials’ characteristics | Table 4 |

| Rin [m²∙K∙W−1] | 0.13 [92] |

| Rout [m²∙K∙W−1] | 0.04 [92] |

| Electricity | Table 6 |

| COP (multisplit) | 3.40 [93] |

| EER (multisplit) | 3.00 [93] |

| Interest rate (i) | 3.0% [79] |

| Inflation rate (g) | 2.0% [79] |

| Service life new wall, Nnew [year] | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pedroso, M.; Silvestre, J.D.; Gomes, M.d.G.; Hawreen, A.; Bersch, J.D.; Flores-Colen, I. Integrated Performance Evaluation of Aerogel-Based Fibre-Enhanced Thermal Renders Applied on Building Walls. Gels 2023, 9, 898. https://doi.org/10.3390/gels9110898

Pedroso M, Silvestre JD, Gomes MdG, Hawreen A, Bersch JD, Flores-Colen I. Integrated Performance Evaluation of Aerogel-Based Fibre-Enhanced Thermal Renders Applied on Building Walls. Gels. 2023; 9(11):898. https://doi.org/10.3390/gels9110898

Chicago/Turabian StylePedroso, Marco, José Dinis Silvestre, Maria da Glória Gomes, Ahmed Hawreen, Jéssica D. Bersch, and Inês Flores-Colen. 2023. "Integrated Performance Evaluation of Aerogel-Based Fibre-Enhanced Thermal Renders Applied on Building Walls" Gels 9, no. 11: 898. https://doi.org/10.3390/gels9110898