Analysis of the Influencing Factors on the Extraction of Residual Oil through the Gel Foam Flooding of Underground Reservoirs in the Tahe Oilfield

Abstract

:1. Introduction

2. Results and Discussion

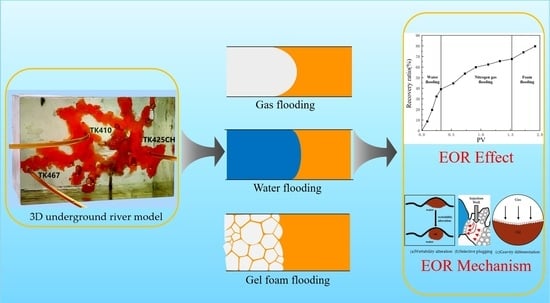

2.1. Experimental Study of Gel Foam Flooding in the 3D Visual Underground River Physical Model

2.1.1. Analysis of the Experimental Results of the 3D Visual Underground River Physical Model

- Water flooding stage

- 2.

- Gas flooding stage

- 3.

- Gel foam flooding stage

2.1.2. Impact of the Injection-Production Method on the Displacement Effect of the 3D Visual Underground River Physical Model

- Nitrogen gas flooding at different well locations

- 2.

- Gel foam flooding at different well locations

2.1.3. Impact of the Injection Rate on the Displacement Effect of the 3D Visual Underground River Physical Model

- Nitrogen flooding gas with different injection rates

- 2.

- Gel foam flooding with different injection rates

2.1.4. The Distribution of Residual Oil in Different Displacement Stages of the 3D Visual Underground River Physical Model

- The types of residual oil after gas flooding

- 2.

- The types of residual oil after gel foam flooding

2.2. Mechanical Mechanism of Gel Foam Leaving Residual Oil in the Underground River System

2.2.1. Wettability Alternation

2.2.2. Selective Plugging Effect

2.2.3. Mobility Control Ability

2.2.4. Gravity Differentiation

3. Conclusions

- Regarding the impact of injection and production methods on oil recovery in underground river fractured-vuggy reservoirs, the results showed that in the process of oil displacement, actual reservoir conditions should be considered. For the well group with good connectivity in the fractured-vuggy reservoir, the effect of gas flooding on EOR is poor, and the structure of the fractured-vuggy reservoir contains a large amount of residual oil. Gel foam flooding can be carried out for wells connecting multiple vugs, and the recovery ratio of the well group can be improved by combining multiple displacement methods. Based on gas flooding, the enhanced recovery ratio of gel foam flooding in the underground river was approximately 12%.

- The impact of injection speed on oil recovery was studied. Gel foam flooding can spread across two underground river channels; two cases of nitrogen flooding affected one underground river channel and two underground river channels with different injection rates. In underground rivers, increasing the injection rate sufficiently can improve oil recovery by increasing the injection pressure. When the gas injection rate reaches 10 mL/min, the difference in oil and gas mobility quickly causes gas channeling, shortening the gas injection time and yielding a lower final recovery ratio than that for a gas injection rate of 5 mL/min. The average recovery ratio of nitrogen flooding was 6.84% higher than that of other injection rates at 5 mL/min. In the process of gel foam injection, gel foam plugged the high-permeability channel and delayed gas channeling to a certain extent. The average recovery ratio of gel foam flooding was 1.88% higher than that of other injection rates at 5 mL/min. When the injection rate of gel foam is too high, the gas will break through the gel foam to form a channeling channel, which will lead to a decline in the oil displacement effect. Therefore, whether gas flooding or gel foam flooding, a reasonable injection rate can achieve the comprehensive oil displacement effect of delaying gas channeling and increasing swept volume.

- Through oil displacement experiments at different stages on 3D visual models, it was found that after nitrogen flooding, there were mainly four types of residual oil, and gel foam flooding mainly yielded three types of remaining oil. Research showed that, compared with 10 mL/min nitrogen gas displacement, 5 mL/min nitrogen gas displacement can displace residual oil shielded by channeling, most of the bypassed residual oil in connected fractured-vuggy structures, and most of the residual oil disturbed by bottom water. The effect of 5 mL/min nitrogen gas displacement was better. Compared with 10 mL/min gel foam flooding, 5 mL/min gel foam flooding can displace most of the residual oil disturbed by bottom water, and 5 mL/min gel foam flooding had a better displacement effect.

- The experiments demonstrated that gel foam exerts an oil displacement mechanism that changes the wettability of rock surfaces, a selective plugging effect, mobility control ability, and gravity differentiation in fractured-vuggy carbonate reservoirs.

4. Materials and Methods

4.1. Similarity Design of the Physical Model

4.2. Physical Model Design and Fabrication

4.3. Experimental Materials and Equipment

4.4. Experimental Methods and Procedures

- a.

- The 3D visual underground river fractured-vuggy reservoir physical mode was saturated with oil.

- b.

- Water flooding was carried out in an injection TK425CH well with a water injection rate of 2 mL/min (the production wells were TK410 and TK467). Water injection was stopped when the water cut at the production channel reached 98% or the water channeling was complete.

- c.

- Gas flooding was carried out in the TK425CH well with a gas injection rate of 5 mL/min. The gas injection was stopped until gas channeling occurred at the production channel.

- d.

- Gel foam flooding was carried out in a TK425CH well with an injection rate of 2 mL/min. Gel foam flooding was stopped until no oil was produced at the production channel.

- e.

- The experimental process was recorded using an HD camera. The experimental schemes are shown in Table 4.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, W.; Fu, S.; Li, A.; Xie, H.; Cui, S.; Nangendo, J. Experimental research on the mechanisms of improving water flooding in fractured-vuggy reservoirs. J. Pet. Sci. Eng. 2022, 213, 110383. [Google Scholar] [CrossRef]

- Li, Y. The theory and method for the development of carbonate fractured-cavity reservoirs in Tahe oilfield. Acta Petrol. Sin. 2013, 34, 115–121. [Google Scholar]

- Yu, Z.; Wang, Z.; Wei, H.; Xiao, F.; Li, Y. Characterization of fracture-cave karst reservoirs with different genesis in Tahe Oilfield. Pet. Geol. Recovery Effic. 2019, 26, 53–61. [Google Scholar]

- Tian, F.; Di, Q.; Jin, Q.; Cheng, F.; Zhang, W.; Lin, L.; Wang, Y.; Yang, D.; Niu, C.; Li, Y. Multiscale geological-geophysical characterization of the epigenic origin and deeply buried paleokarst system in Tahe Oilfield, Tarim Basin. Mar. Pet. Geol. 2019, 102, 16–32. [Google Scholar] [CrossRef]

- Li, Y.; Fan, Z. Developmental pattern and distribution rule of the fracture-cavity system of Ordovician carbonate reservoirs in the Tahe Oilfield. Acta Petrol. Sin. 2011, 32, 101–106. [Google Scholar]

- Lu, G.; Zhang, L.; Liu, Q.; Xu, Q.; Zhao, Y.; Li, X.; Deng, G.; Wang, Y. Experiment analysis of remaining oil distribution and potential tapping for fractured-vuggy reservoir. J. Pet. Sci. Eng. 2022, 208, 109544. [Google Scholar] [CrossRef]

- Zheng, S.; Yang, M.; Kang, Z.; Liu, Z.; Long, X.; Liu, K.; Li, X. Controlling factors of remaining oil distribution after water flooding and enhanced oil recovery methods for fracture-cavity carbonate reservoirs in Tahe Oilfield. Pet. Explor. Dev. 2019, 46, 746–754. [Google Scholar] [CrossRef]

- Liu, Z. Enhanced oil recovery in Tahe karstic/fractured carbonate reservoir. Pet. Geol. Recovery Effic. 2012, 19, 66–68. [Google Scholar]

- Rong, Y.; Tu, X.; Liu, X. Single well water injection production in Tahe fracture-vuggy reservoir, Tahe oilfield. Pet. Geol. Recovery Effic. 2010, 17, 97–100. [Google Scholar]

- Ren, Y.; Li, J.; Huang, X. Study on developmental technologic strategies in Tahe carbonate oilfield. Pet. Geol. Recovery Effic. 2004, 5, 57–59. [Google Scholar]

- Khormali, A. Effect of water cut on the performance of an asphaltene inhibitor package: Experimental and modeling analysis. Pet Sci Technol. 2022, 40, 2890–2906. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, W.; Liu, H.; Liu, F.; Zhang, T.; Dou, L.; Yang, X.; Li, B. Inter-well interferences and their influencing factors during water flooding in fractured-vuggy carbonate reservoirs. Petrol. Explor. Dev. 2020, 47, 1062–1073. [Google Scholar] [CrossRef]

- Zeng, S.; Liu, Z.; Qiu, L. Evaluation of Injected Water Utilization for Fractured–Vuggy Reservoirs in Tahe Oilfield. Xinjiang Pet. Geol. 2017, 38, 452–454. [Google Scholar]

- Karimaie, H.; Darvish, G.; Lindeberg, E.; Torsæter, O. Secondary and tertiary gas injection in fractured carbonate rock: Experimental study. J. Pet. Sci. Eng. 2008, 62, 45–51. [Google Scholar] [CrossRef]

- Hui, J.; Liu, X.; Wang, Y.; Yang, Z.; Chen, Y. Mechanism and Practice of Nitrogen lnjection for EOR in Fractured-Vuggy Carbonate Reservoir in Tahe Oilfield, Tarim Basin. Mar. Pet. Geol. 2015, 36, 75–77. [Google Scholar]

- Wang, J.; Ji, Z.; Liu, H.; Huang, Y.; Wang, Y.; Pu, Y. Experiments on nitrogen assisted gravity drainage in fractured-vuggy reservoirs. Pet. Explor. Dev. 2019, 46, 355–366. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Z.; Li, S.; Lv, Q.; Wang, P.; Liu, J.; Liu, J. Enhancing Sodium Bis(2-ethylhexyl) Sulfosuccinate Injectivity for CO2 Foam Formation in Low-Permeability Cores: Dissolving in CO2 with Ethanol. Energy Fuels. 2018, 32, 5846–5856. [Google Scholar] [CrossRef]

- Li, H.; Hou, J.; Li, W.; Yuan, D.; Zhang, L.; Jiang, Y.; Yuan, W. Laboratory research on nitrogen foam injection in fracture-vuggy reservoir for enhanced oil recovery. Pet. Geol. Recovery Effic. 2014, 21, 93–96. [Google Scholar]

- Yang, J.; Hou, J.; Qu, M.; Liang, T.; Wen, Y. Experimental study the flow behaviors and mechanisms of nitrogen and foam assisted nitrogen gas flooding in 2-D visualized fractured-vuggy model. J. Pet. Sci. Eng. 2020, 94, 107501. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Z.; Cui, S.; Li, B.; Chen, D.; Zhang, Q.; Zheng, L.; Husein, M. Flow characteristics and EOR mechanism of foam flooding in fractured vuggy reservoirs. J. Pet. Sci. Eng. 2022, 211, 110170. [Google Scholar] [CrossRef]

- Qu, M.; Hou, J.; Liang, T.; Raj, I.; Yang, Y.; Qi, P. Synthesis of α-starch based nanogel particles and its application for long-term stabilizing foam in high-salinity, high-temperature and crude oil environment. J. Pet. Sci. Eng. 2020, 191, 107185. [Google Scholar] [CrossRef]

| Similarity Conditions | Similarity Criteria | Physical Significance | Similarity Index |

|---|---|---|---|

| Dynamic similarity | FG = ΔP/(ρogd) | Ratio of the injected pressure to gravity | 1.01–1.04 |

| Re = ρul/μ | Ratio of the moving inertial force to the viscous force | 1 | |

| Kinematic similarity | FQ = Q/(r2 u) | Ratio of the recovery volume to the injection volume | 1.01–1.04 |

| Characteristic similarity | π2 = ξ | Coordination number | 1 |

| π3 = η | Filling degree | 1 |

| Parameters | Reservoir Model | Physical Model | Similarity Coefficient |

|---|---|---|---|

| Cavity diameter (d)/cm | 500–2500 | 3–12 | 166.667–200 |

| Pressure difference (Δp)/kPa | 2000–14,000 | 10–60 | 200–233.333 |

| Viscosity of crude oil (μ)/(mPa·s) | 19.7–28.5 | 65 | 0.3038–0.4377 |

| Density of crude oil (ρo)/(g·cm−3) | 0.92 | 0.8 | 1.15 |

| Gravity acceleration (g)/(m·s−2) | 9.8 | 9.8 | 1 |

| Seepage velocity (u)/(m·s−1) | 0.0147–0.147 | 0.007–0.049 | 2.103–2.993 |

| Injection velocity (Q)/(m3·d−1) | 20–60 | 0.006–0.015 | 3334–4000 |

| Well diameter (r)/mm | 120 | 3 | 40 |

| Fracture aperture(B)/mm | 0.5–5 | 0.2–4.5 | 0.25–1.11 |

| Filling degree | 0–100% | 0–100% | 1 |

| Total Salinity/mg·L−1 | Ionic Concentration/mg·L−1 | |||||

|---|---|---|---|---|---|---|

| Na+ | Ca2+ | Mg2+ | Cl− | HCO3− | SO42− | |

| 253,225 | 82,023 | 14,849 | 905 | 154,748 | 418 | 282 |

| Injection Well | Water Flooding | Nitrogen Gas Flooding | Foam Flooding | |

|---|---|---|---|---|

| 1 | TK425CH | 2 mL/min | 5 mL/min | 2 mL/min |

| TK410 | ||||

| TK467 | ||||

| 2 | TK425CH | 2 mL/min | ||

| TK410 | 5 mL/min | 2 mL/min | ||

| TK467 | ||||

| 3 | TK425CH | |||

| TK410 | 5 mL/min | 1, 3, 5, 7, 9, 10 mL/min | ||

| TK467 | 5 mL/min | |||

| 4 | TK425CH | |||

| TK410 | 1, 3, 5, 7, 9, 10 mL/min | 10 mL/min | ||

| TK467 | 5 mL/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.-M.; Hou, J.-R.; Wen, Y.-C.; Liang, T. Analysis of the Influencing Factors on the Extraction of Residual Oil through the Gel Foam Flooding of Underground Reservoirs in the Tahe Oilfield. Gels 2023, 9, 804. https://doi.org/10.3390/gels9100804

Li C-M, Hou J-R, Wen Y-C, Liang T. Analysis of the Influencing Factors on the Extraction of Residual Oil through the Gel Foam Flooding of Underground Reservoirs in the Tahe Oilfield. Gels. 2023; 9(10):804. https://doi.org/10.3390/gels9100804

Chicago/Turabian StyleLi, Chang-Ming, Ji-Rui Hou, Yu-Chen Wen, and Tuo Liang. 2023. "Analysis of the Influencing Factors on the Extraction of Residual Oil through the Gel Foam Flooding of Underground Reservoirs in the Tahe Oilfield" Gels 9, no. 10: 804. https://doi.org/10.3390/gels9100804