Gels, Aerogels and Hydrogels: A Challenge for the Cellulose-Based Product Industries

Abstract

:1. Introduction

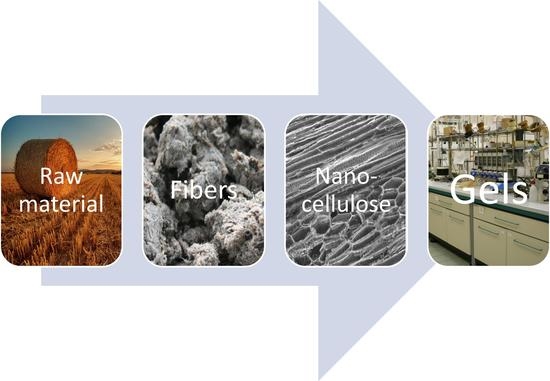

2. Preparation of Cellulose-Based Gels

3. Properties of Cellulose-Based Gels

4. Applications

5. Research, Development and Innovation in Cellulose-Based Gels

6. Concluding Remarks and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- (a)

- a covalent polymer network, e.g., a network formed by crosslinking polymer chains or by non-linear polymerization;

- (b)

- a polymer network formed through the physical aggregation of polymer chains, caused by hydrogen bonds, crystallization, helix formation, complexation, etc., that results in regions of local order acting as the network junction points. The resulting swollen network may be termed a thermoreversible gel if the regions of local order are thermally reversible;

- (c)

- a polymer network formed through glassy junction points, e.g., one based on block copolymers. If the junction points are thermally reversible glassy domains, the resulting swollen network may also be termed a thermoreversible gel;

- (d)

- lamellar structures including mesophases, e.g., soap gels, phospholipids and clays;

- (e)

- particulate disordered structures, e.g., a flocculent precipitate usually consisting of particles with large geometrical anisotropy, such as in V2O5 gels and globular or fibrillar protein gels.

References

- IUPAC. Compendium of Chemical Terminology, 2nd ed.; The “Gold Book”; McNaught, A.D., Wilkinson, A., Eds.; Blackwell Scientific Publications: Oxford, UK, 1997; Online Version (2019-) Created by S. J. Chalk. 2022. [Google Scholar] [CrossRef]

- Alger, M. Polymer Science Dictionary, 3rd ed.; Springer Science+Business Media: Dordrecht, The Netherlands, 2017; p. 346. [Google Scholar]

- Yamauchi, A. Gels: Introduction. In Gels Handbook, 4 Volume Set; Osada, Y., Kajiwara, K., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2000; Volume 1, pp. 4–12. [Google Scholar]

- DeFrance, K.J.; Hoare, T.; Cranston, E.D. Review of Hydrogels and Aerogels Containing Nanocellulose. Chem. Mater. 2017, 29, 4609–4631. [Google Scholar] [CrossRef]

- Cai, J.; Zhang, L. Unique gelation behavior of cellulose in NaOH/Urea aqueous solution. Biomacromolecules 2006, 7, 183–189. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Kimura, S.; Wada, M.; Kuga, S.; Zhang, L. Cellulose aerogels from aqueous alkali hydroxide-urea solution. Chemsuschem 2008, 1, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Gavillon, R.; Budtova, T. Aerocellulose: New highly porous cellulose prepared from cellulose-NaOH aqueous solutions. Biomacromolecules 2008, 9, 269–277. [Google Scholar] [CrossRef] [PubMed]

- Liebner, F.; Haimer, E.; Wendland, M.; Neouze, M.A.; Schlufter, K.; Miethe, P.; Heinze, T.; Potthast, A.; Rosenau, T. Aerogels from unaltered bacterial cellulose: Application of scCO2 drying for the preparation of shaped, ultra-lightweight cellulosic aerogels. Macromol. Biosci. 2010, 10, 349–352. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Thomas, S.; Pothan, L.A.; Mavelil-Sam, R. Cellulose Based Aerogels: Processing and Morphology. In Biobased Aerogels: Polysaccharide and Protein-Based Materials; Sabu, T., Laly, A.P., Rubie, M.-S., Eds.; The Royal Society of Chemistry: London, UK, 2018; pp. 25–41. [Google Scholar]

- Ratke, L.; Gurikov, P. Chemical Synthesis of Aerogels from Polymeric Precursors. In The Chemistry and Physics of Aerogels: Synthesis, Processing, and Properties; Ratke, L., Gurikov, P., Eds.; Cambridge University Press: Cambridge, UK, 2021; pp. 60–91. [Google Scholar]

- Budtova, T.; Navard, P. Cellulose in NaOH-water based solvents: A review. Cellulose 2016, 23, 5–55. [Google Scholar] [CrossRef] [Green Version]

- Liebner, F.; Potthast, A.; Rosenau, T.; Haimer, E.; Loidl, D.; Teschegg, S.; Neouze, M.A.; Maitz, M.; Seib, P.; Werner, C.; et al. Ultra lightweight cellulosic aerogels: Preparation and properties. In Proceedings of the 237th ACS National Meeting, Salt Lake City, UT, USA, 22–26 March 2009. [Google Scholar]

- Liebner, F.; Haimer, E.; Potthast, A.; Loidl, D.; Tschegg, S.; Neouze, M.A.; Wendland, M.; Rosenau, T. Cellulosic aerogels as ultra-lightweight materials. Part 2: Synthesis and properties. 2nd ICC 2007, Tokyo, Japan, October 25–29, 2007. Holzforschung 2009, 63, 3–11. [Google Scholar] [CrossRef]

- Sen, S.; Martin, J.D.; Argyropoulos, D.S. Review of cellulose non-derivatizing solvent interactions with emphasis on activity in inorganic molten salt hydrates. ACS Sustain. Chem. Eng. 2013, 1, 858–870. [Google Scholar] [CrossRef]

- Zainal, S.H.; Mohd, N.H.; Suhaili, N.; Anuar, F.H.; Lazim, A.M.; Othaman, R. Preparation of cellulose-based hydrogel: A review. J. Mater. Res. Technol. 2021, 10, 935–952. [Google Scholar] [CrossRef]

- Ratke, L. Monoliths and Fibrous Cellulose Aerogels. In Aerogels Handbook. Advances in Sol-Gel Derived Materials and Technologies; Aegerter, M., Leventis, N., Koebel, M., Eds.; Springer: New York, NY, USA, 2011; pp. 173–190. [Google Scholar]

- Chang, C.; Zhang, L. Cellulose-based hydrogels: Present status and application prospects. Carbohyd. Polym. 2011, 84, 40–53. [Google Scholar] [CrossRef]

- Ciolacu, D.E.; Suflet, D.M. Cellulose-Based Hydrogels for Medical/Pharmaceutical Applications. In Biomass as Renewable Raw Material to Obtain Bioproducts of High-Tech Value; Popa, V.I., Volf, I.I., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 401–439. [Google Scholar]

- Rusu, D.; Ciolacu, D.E.; Simionescu, B.C. Cellulose-based hydrogels in tissue engineering applications. Cellul. Chem. Technol. 2019, 53, 907–923. [Google Scholar] [CrossRef]

- Ciolacu, D.E. Structure-Property Relationships in Cellulose-Based Hydrogels. In Cellulose-Based Superabsorbent Hydrogels. Polymers and Polymeric Composites: A Reference Series; Mondal, M., Ed.; Springer: Cham, Switzerland, 2019; pp. 65–96. [Google Scholar]

- Budtova, T. Cellulose II aerogels: A review. Cellulose 2019, 26, 81–121. [Google Scholar] [CrossRef]

- Wan, C.; Jiao, Y.; Wei, S.; Zhang, L.; Wu, Y.; Li, J. Functional nanocomposites from sustainable regenerated cellulose aerogels: A review. Chem. Eng. J. 2019, 359, 459–475. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Adnan, A.S.; Yahya, E.B.; Olaiya, N.G.; Safrida, S.; Hossain, M.S.; Pasquini, D. A Review on Plant Cellulose Nanofibre-Based Aerogels for Biomedical Applications. Polymers 2020, 12, 1759. [Google Scholar] [CrossRef]

- Varghese, S.A.; Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J. Natural polymers and the hydrogels prepared from them. In Hydrogels Based on Natural Polymers; Chen, Y.Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 17–47. [Google Scholar]

- Ambrosio, L.; Demitri, C.; Sannino, A. Superabsorbent cellulose-based hydrogels for biomedical applications. In Woodhead Publishing Series in Biomaterials, Biomedical Hydrogels; Rimmer, S., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 25–50. [Google Scholar]

- Belosinschi, D.; Tofanica, B.M. A new bio-material with 3D lightweight network for energy and advanced applications. Cellulose 2018, 25, 897–902. [Google Scholar] [CrossRef]

- Palencia, M.; Espinosa-Duque, A.; Otálora, A.; García-Quintero, A. Cellulose-based stimuli-responsive hydrogels. In Woodhead Publishing Series in Biomaterials, Plant and Algal Hydrogels for Drug Delivery and Regenerative Medicine; Giri, T.K., Ghosh, B., Eds.; Woodhead Publishing: Cambridge, UK, 2021; pp. 423–470. [Google Scholar]

- Mondal, I.H. Cellulose-Based Superabsorbent Hydrogels; Springer: Berlin/Heidelberg, Germany, 2019; p. 1859. [Google Scholar]

- Long, L.-Y.; Weng, Y.-X.; Wang, Y.-Z. Cellulose Aerogels: Synthesis, Applications, and Prospects. Polymers 2018, 10, 623. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, E.S.; Rezende, C.A.; Cranston, E.D. Fundamentals of cellulose lightweight materials: Bio-based assemblies with tailored properties. Green Chem. 2021, 23, 3542–3568. [Google Scholar] [CrossRef]

- Ferreira-Gonçalves, T.; Constantin, C.; Neagu, M.; Reis, C.P.; Simón-Vázquez, R.S.R. Safety and efficacy assessment of aerogels for biomedical applications. Biomed. Pharmacother. 2021, 144, 112356. [Google Scholar] [CrossRef]

- Shojaeiarani, J.; Bajwa, D.; Shirzadifar, A. A review on cellulose nanocrystals as promising biocompounds for the synthesis of nanocomposite hydrogels. Carbohydr. Polym. 2019, 216, 247–259. [Google Scholar] [CrossRef]

- Zou, P.; Yao, J.; Cui, Y.-N.; Zhao, T.; Che, J.; Yang, M.; Li, Z.; Gao, C. Advances in Cellulose-Based Hydrogels for Biomedical Engineering: A Review Summary. Gels 2022, 8, 364. [Google Scholar] [CrossRef]

- Mirtaghavi, A.; Luo, J.; Muthuraj, R. Recent Advances in Porous 3D Cellulose Aerogels for Tissue Engineering Applications: A Review. J. Compos. Sci. 2020, 4, 152. [Google Scholar] [CrossRef]

- Liu, H.; Geng, B.; Chen, Y.; Wang, H. Review on the Aerogel-Type Oil Sorbents Derived from Nanocellulose. ACS Sustain. Chem. Eng. 2017, 5, 49–66. [Google Scholar] [CrossRef]

- Akter, M.; Bhattacharjee, M.; Dhar, A.K.; Rahman, F.B.A.; Haque, S.; Rashid, T.U.; Kabir, S.M.F. Cellulose-Based Hydrogels for Wastewater Treatment: A Concise Review. Gels 2021, 7, 30. [Google Scholar] [CrossRef] [PubMed]

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/FMBI972354 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/EV5V0077 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/505888 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/260141 (accessed on 25 June 2022).

- The European Cooperation in Science and Technology (COST) Action. Available online: https://www.cost.eu/actions/CA18125 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/814496 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/692373 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/788489 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/642687/ (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/735760 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/101032227 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/742829 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/760876 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/608893 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/714429 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/685648 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/760601 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/640598 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/798455 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/798917 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/891084 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/952169 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/101031327 (accessed on 25 June 2022).

- The Community Research and Development Information Service (CORDIS)—Innovate with EU Research Results. Available online: https://cordis.europa.eu/project/id/742733 (accessed on 25 June 2022).

- Yu, J.; Ma, S.; Mi, Q.; Zhang, J. A Kind of Preparation Method of Cellulose Aerogels and Its Hybrid Aerogel. CN105017555B, 12 October 2018. Available online: https://patents.google.com/patent/CN105017555B (accessed on 25 June 2022).

- Li, J.; Chao, W.; Sun, Q.; Lu, Y.; Gao, L.; Kun, G. A Kind of Preparation Method of Nanofibrils Cellulose Aerogel of Ultralight, Hydrophobic, High Oil Absorbency. CN103756006B, 20 January 2016. Available online: https://patents.google.com/patent/CN103756006B (accessed on 25 June 2022).

- Zhang, J.; Li, L.; Li, B. A Kind of Preparation Method of the Elastic Aerogel of Multifunctional Fiber element. CN105566673B, 2 November 2018. Available online: https://patents.google.com/patent/CN105566673B (accessed on 25 June 2022).

- Marie, E.; Vitali, P. Biodegradable Single-Phase Cohesive Hydrogel. CN101925348B, 4 December 2013. Available online: https://patents.google.com/patent/CN101925348B (accessed on 25 June 2022).

- Thielemans, W.A.W.I.; Davies, R. Cellulose Nanoparticle Aerogels, Hydrogels and Organogels. US20130018112A1, 17 January 2013. Available online: https://patents.google.com/patent/US20130018112A1 (accessed on 25 June 2022).

- Zhang, H.; Xing, C.; Chen, S. Cellulose/Black Phosphorus Nanosheet Composite Hydrogel and Preparation Method Thereof. CN107936266B, 26 October 2021. Available online: https://patents.google.com/patent/CN107936266B (accessed on 25 June 2022).

- Zhang, H.; Xing, C.; Chen, S. Cellulose/Two-Dimensional Layered Material Composite Hydrogel and Preparation Method Therefor. WO2019095751A1, 23 May 2019. Available online: https://patents.google.com/patent/WO2019095751A1 (accessed on 25 June 2022).

- Abidi, N.; Hu, Y. Cotton Fiber Dissolution and Regeneration and 3D Printing of Cellulose-Based Conductive Composites. US10311993B2, 4 June 2019. Available online: https://patents.google.com/patent/US10311993B2 (accessed on 25 June 2022).

- Cai, J.; Li, K.; Zhao, D.; Zhang, L. It Is a Kind of Based on the Dual Network Cellulose Gel-Based Material Being Chemically and Physically Crosslinked. CN104448396B, 16 June 2017. Available online: https://patents.google.com/patent/CN104448396B (accessed on 25 June 2022).

- Yano, S.; Sawaguchi, T.; Hagihara, S.; Maeda, H.; Nakajima, E.; Sasaki, I. Lithium-Ion Conductive Material Using Bacterial Cellulose Organic Gel, Lithium-Ion Battery and Bacterial Cellulose Airgel Using the Same. JP5110462B2, 26 December 2012. Available online: https://patents.google.com/patent/JP5110462B2 (accessed on 25 June 2022).

- Kim, C.-y.; Go, E.-b. Manufacturing Method of Cellulose Aerogel Membrane. KR101494641B1, 24 February 2015. Available online: https://patents.google.com/patent/KR101494641B1 (accessed on 25 June 2022).

- Luko, K.; Nopening, M. Medical Hydrogel. CN110072567B, 12 April 2022. Available online: https://patents.google.com/patent/CN110072567B (accessed on 25 June 2022).

- Laukkanen, A.; Nuopponen, M. Method and Apparatus for Processing Fibril Cellulose and Fibril Cellulose Product. EP2815026B1, 16 June 2021. Available online: https://patents.google.com/patent/EP2815026B1 (accessed on 25 June 2022).

- Lu, Y.; Sun, Q.; Liu, Y.; Yu, H.; Yang, D. Method for Preparing Amorphous Cellulose Aerogel with Ionic Liquid. CN102443188B, 13 March 2013. Available online: https://patents.google.com/patent/CN102443188B (accessed on 25 June 2022).

- Laukkanen, A.; Teirfolk, J.; Nuopponen, M. Method for Processing Nanofibrillar Cellulose. CA2824125C, 7 May 2019. Available online: https://patents.google.com/patent/CA2824125C (accessed on 25 June 2022).

- Sea, P.A.; Michelle, G.; Lambsey, C.; Joachim, S.M.; Kotup, C. Method for Producing a Gel-Based Composite Material. JP6224175B2, 1 November 2017. Available online: https://patents.google.com/patent/JP6224175B2 (accessed on 25 June 2022).

- Sea, P.A.; Joachim, G.; Daniel, C.K.; Cienker, G.M. Method for Producing Nanofibril Cellulose Gel. JP6698236B1, 27 May 2020. Available online: https://patents.google.com/patent/JP6698236B1 (accessed on 25 June 2022).

- Nuopponen, M.; Tamper, J.; Kajanto, I. Method for Producing Nanofibrillar Cellulose and Nanofibrillar Cellulose Product. US11274396B2, 15 March 2022. Available online: https://patents.google.com/patent/US11274396B2 (accessed on 25 June 2022).

- Sea, P.A.; Michelle, G.; Lambsey, C.; Joachim, S.M.; Kotup, C. Methods for Making Structured Materials Using Nanofibril Cellulose Gel. JP7033105B2, 9 March 2022. Available online: https://patents.google.com/patent/JP7033105B2 (accessed on 25 June 2022).

- Yliperttula, M.; Lauren, P.; Somersalo, P.; Lou, Y. Nanofibrillar Cellulose Composition. US10729804B2, 4 August 2020. Available online: https://patents.google.com/patent/US10729804B2 (accessed on 25 June 2022).

- Laukkanen, A.; Kankuri, E.; Nuuutila, K. Nanofibrillar Polysaccharide for Use in the Control and Prevention of Contraction and Scarring. EP2958599B1, 16 November 2016. Available online: https://patents.google.com/patent/EP2958599B1 (accessed on 25 June 2022).

- Umeda, Y.; Matsumoto, Y.; Shiina, M.; Todokoro, M.; Matsumoto, Y. Porous Cellulose Gel, Method for Producing the Same, and Use Thereof. US9446382B2, 20 September 2016. Available online: https://patents.google.com/patent/US9446382B2 (accessed on 25 June 2022).

- Zhang, J.; Zhang, X.; Yu, J.; Li, R.; Wu, J.; Gao, Y.; Zhang, J.; Qiu, J. Regenerated Cellulose Film, Functional Film and Preparation Method thereof. EP3064534B1, 20 October 2021. Available online: https://patents.google.com/patent/EP3064534B1 (accessed on 25 June 2022).

- Saga, H.; Saito, H. Transparent Cellulose Hydrogel and Production Process Thereof. US5962005A, 10 May 1999. Available online: https://patents.google.com/patent/US5962005A (accessed on 25 June 2022).

- Trexler, M.M.; Elisseeff, J.H.; Mulreany, D.; Guo, Q.; Jennifer; Breidenich, L.; Jeffrey; Maranchi, P.; Jenna; Graham, L.; et al. Wound healing Compositions Comprising Biocompatible Cellulose Hydrogel Membranes and Methods of Use Thereof. US9314531B2, 19 April 2016. Available online: https://patents.google.com/patent/US9314531B2 (accessed on 25 June 2022).

- Belosinschi, D.; Tofanica, B.M. Application of nanocellulose in agriculture. Reversing the hydrophobic behavior of peat moss. In Proceedings of the 6th EPNOE International Polysaccharide Conference, Aveiro, Portugal, 21–25 October 2019; Book of Abstracts, European Polysaccharide Network of Excellence (EPNOE). p. 155. [Google Scholar]

| Category | Property | Characteristics |

|---|---|---|

| Cellulose-based gels | Chemical | Radiation resistance, sunlight and UV resistance, weather (temperature, humidity, atmospheric pressure) resistance, recyclability |

| Physical | Surface topology, texture, specific heat, density/porosity, thermal expansion, surface roughness, electrical conductivity, dielectric constant, thermal stability, color and esthetic | |

| Biological | Toxicity, biodegradability, biostability | |

| Mechanical/structural | Mechanical strength, Shear modulus, elastic modulus, fatigue strength, impact strength, creep resistance, yield strength, elongation to break, | |

| Technical | Fabrication costs, packaging, reproducibility, product quality, safety, life-cycle analysis |

| Acronym | Project Name | Cellulose-Based Molecule | Implementation Dates | Coordinator | Funding Programme | References |

|---|---|---|---|---|---|---|

| -- | Polysaccharide upgrading via chemical and enzymatic modifications | Cellulose | 1 December 1997–30 November 1999 | University of Rome “La Sapienza”, Italy | FP4-TMR-Specific research and technological development programme in the field of the training and mobility of researchers, 1994–1998 | [37] |

| -- | The development of micro-biosensors for monitoring hazardous gases in the environment | Hydroxyethyl cellulose gel | 1 November 1992–31 July 1995 | University of Ioannina, Greece | FP3-ENV 1C-Specific research and technological development programme (EEC) in the field of the environment, 1990–1994 | [38] |

| -- | Aerocellulose and its carbon counterparts—porous, multifunctional nanomaterials from renewable resources | Cellulose | 1 January 2004–31 December 2006 | Lenzing Aktiengesellschaft, Austria | FP6-NMP-Nanotechnologies and nanosciences NMP-2002-3.4.2.3-2-New knowledge-based higher performance materials for macro-scale applications | [39] |

| AEROCOINS | Aerogel-Based Composite/Hybrid Nanomaterials for Cost-Effective Building Super-Insulation Systems | Nanofibrillated cellulose | 16 June 2011–15 June 2015 | Fundacion Tecnalia Research & Innovation, Spain | FP7-NMP-EeB.NMP.2010-1-New nanotechnology-based high-performance insulation systems for energy efficiency | [40] |

| AERoGELS | COST CA18125-Advanced Engineering and Research of aeroGels for Environment and Life Sciences | Cellulose | 30 April 2019–26 February 2023 | Universidad de Santiago de Compostela, Spain | COST (European Cooperation in Science and Technology) Action 2018 | [41] |

| APACHE | Active & intelligent Packaging materials and display cases as a tool for preventive conservation of Cultural Heritage | Nanocellulose | 1 January 2019–30 June 2022 | Consorzio Interuniversitario Perlo Sviluppo Dei Sistemi A Grande Interfase, Italy | H2020-EU.2.1.3.-INDUSTRIAL LEADERSHIP-NMBP-33-2018-Innovative and affordable solutions for the preventive conservation of cultural heritage | [42] |

| BET-EU | Materials Synergy Integration for a Better Europe | Nanocellulose | 1 January 2016–31 December 2018 | Uninova-Instituto De Desenvolvimento De Novas Tecnologias–Associacao, Portugal | H2020-TWINN-2015-Twinning | [43] |

| BioELCell | Bioproducts Engineered from Lignocelluloses: from plants and upcycling to next-generation materials | Cellulose nanofibers | 1 August 2018–31 July 2023 | Aalto Korkeakoulusaatio SR, Finland | H2020-EU.1.1.-EXCELLENT SCIENCE- ERC-2017-ADG-ERC Advanced Grant | [44] |

| BIOGEL | Engineering responsive and biomimetic hydrogels for biomedical therapeutic and diagnostic applications | Nanocellulose | 1 January 2015–31 December 2018 | DWI Leibniz-Institut Fur Interaktive Materialien Ev, Germany | H2020-EU.1.3.1.-MSCA-ITN-2014-ETN-Marie Skłodowska-Curie Innovative Training Networks | [45] |

| BioMicroGels | Innovative environmentally-benign wastewater treatment reagents offering a step change in efficiency in the cleaning of water from oils and metal ions and in liquidation of emergency oil spills | Cellulose | 1 August 2016–31 December 2016 | BMG Intepco LTD, United Kingdom | H2020–MEInst-02- 2016-2017-Accelerating the uptake of nanotechnologies advanced materials or advanced manufacturing and processing technologies by SMEs | [46] |

| BIOSIC | Biopolymer-based Single-Ion Conducting Gel Polymer Electrolytes for Highly Performant and more Sustainable Batteries | Cellulose | 1 September 2021–1 October 2023 | Max–Planck-Gesellschaft Zur Forderung Der Wissenschaften EvGermany | H2020-EU.1.3.-EXCELLENT SCIENCE-Marie Skłodowska-Curie Actions | [47] |

| DRIVEN | Field-driven materials for functions, dissipation, and mimicking Pavlovian adaptation | Methylcellulose/Cellulose Nanocrystal | 1 October 2017–30 September 2022 | Aalto Korkeakoulusaatio SR Finland | H2020-EU.1.1.-EXCELLENT SCIENCE - ERC-2016-ADG-ERC Advanced Grant | [48] |

| INNPAPER | Innovative and Smart Printed Electronics based on Multifunctionalized Paper: from Smart Labelling to Point of Care Bioplatforms | Nanofibrillated Cellulose | 1 January 2018–31 December 2021 | Fundacion CIDETEC, Spain | H2020-EU.2.1.2.-INDUSTRIAL LEADERSHIP-PILOTS-05-2017-Paper-based electronics | [49] |

| H-House | Healthier Life with Eco-innovative Components for Housing Constructions | Cellulose | 1 September 2013–31 August 2017 | RISE CBI Betonginstitutet AB, Sweden | FP7-NMP-EeB.NMP.2013-2-Safe, energy-efficient and affordable new eco-innovative materials for building envelopes and/or partitions to provide a healthier indoor environment | [50] |

| MAEROSTRUC | Multicomponent Aerogels with Tailored Nano-, Micro- Macrostructure | Microcrystalline cellulose | 1 March 2017–28 February 2022 | Gottfried Wilhelm Leibniz Universitaet Hannover, Germany | H2020-EU.1.1.-EXCELLENT SCIENCE- ERC-2016-STG-ERC Starting Grant | [51] |

| NanoHybrids | New generation of nanoporous organic and hybrid aerogels for industrial applications: from the lab to pilot scale production | Cellulose | 1 November 2015–30 April 2019 | Technische Universitat Hamburg, Germany | H2020–NMP–PILOTS-2015-Manufacturing and control of nanoporous materials | [52] |

| NanoTextSurf | Nanotextured surfaces for membranes, protective textiles, friction pads and abrasive materials | Cellulose nanofibrils | 1 November 2017–30 November 2020 | Teknologian Tutkimuskeskus Vtt OY, Finland | H2020-EU.2.1.2.-INDUSTRIAL LEADERSHIP-PILOTS-03-2017-Pilot lines for manufacturing of nanotextured surfaces with mechanically enhanced properties | [53] |

| NewFUN | New era of printed paper electronics based on advanced functional cellulose | Cellulose nanocrystals | 1 September 2015–31 May 2021 | NOVA ID FCT-Associacao Para A Inovacao E Desenvolvimento Da FCT, Portugal | H2020-EU.1.1.-EXCELLENT SCIENCE-ERC-StG-2014-ERC Starting Grant | [54] |

| PlantEmulGel | Emulsions in Plant-based Edible Cellulose Microfibril Gels: Structure, Texture and Stability | Cellulose microfibril Gel | 1 December 2018–30 November 2020 | Unilever Innovation Centre Wageningen, Netherlands | H2020-EU.1.3-EXCELLENT SCIENCE-Marie Skłodowska-Curie Actions | [55] |

| PlantOleogels | Plant Particle-based Hybrid Bicontinuous Oleogels | Micro fibrillated cellulose | 1 November 2018–31 October 2020 | Unilever Innovation Centre Wageningen, Netherlands | H2020-EU.1.3-EXCELLENT SCIENCE-Marie Skłodowska-Curie Actions | [56] |

| SAM | Soft Artificial Muscles | Cellulose nanocrystals | 1 March 2021–28 February 2023 | Universite de Fribourg, Switzerland | H2020-EU.1.3.-EXCELLENT SCIENCE-Marie Skłodowska-Curie Actions | [57] |

| SYNERGY | Symbiosis for energy harvesting concepts for smart platforms on foils | Microcrystalline cellulose | 1 October 2020–30 September 2023 | UNINOVA-Instituto De Desenvolvimento De Novas Tecnologias-Associacao, Portugal | H2020-EU.4.b.-WIDESPREAD-05-2020-Twinning | [58] |

| WEARSENSNANO | Continuous monitoring of hypothermia in elderly people by the novel integrated wearable sensor system based on cellulose hydrogel and metallic nanowires | Cellulose | 1 June 2021–31 May 2023 | Aalto Korkeakoulusaatio SR, Finland | H2020-EU.1.3.2.-MSCA-IF-2020-Individual Fellowships | [59] |

| WoodNanoTech | Wood Nanotechnology for Multifunctional Structures | Nanocellulose | 1 September 2017–31 August 2022 | Kungliga Tekniska Hoegskolan, Sweden | H2020-EU.1.1.-EXCELLENT SCIENCE-ERC-2016-ADG-ERC Advanced Grant | [60] |

| Reference Title | Publication Number | Raw Material | Inventors | Publication Date | References |

|---|---|---|---|---|---|

| A kind of preparation method of cellulose aerogels and its hybrid aerogel | CN105017555B China | Cellulose | Yu Jian, Ma Shurong, Mi Qinyong, Zhang Jun (Institute of Chemistry of CAS) | 12 October 2018 | [61] |

| A kind of preparation method of nanofibrils cellulose aerogel of ultralight, hydrophobic, high oil absorbency | CN103756006B China | Nanofibrils cellulose | Li Jian, Wancai Chao, Sun Qingfeng, Lu Yun, Gao Li, Kun Gan Wentao (Northeast Forestry University) | 20 January 2016 | [62] |

| A kind of preparation method of the elastic aerogel of multifunctional fiber element | CN105566673B China | Cellulose | Zhang Junping, Li Lingxiao, Li Bucheng (Lanzhou Institute of Chemical Physics LICP of CAS) | 2 November 2018 | [63] |

| Biodegradable single-phase cohesive hydrogel | CN101925348B China | Cellulose and cellulose derivative | Estelle Marie, Pirongueil Vitali (Laboratoires Vivacy SAS) | 4 December 2013 | [64] |

| Cellulose nanoparticle aerogels, hydrogels and organogels | US20130018112A1 United States | Cellulose nanoparticle | Wim Albert Wilfried Irene Thielemans, Rebecca Davies (University of Nottingham) | 17 January 2013 | [65] |

| Cellulose/black phosphorus nanosheet composite hydrogel and preparation method thereof | CN107936266B China | Cellulose | Zhang Han, Xing Chenyang, Chen Shiyou (Shenzhen University) | 26 October 2021 | [66] |

| Cellulose/two-dimensional layered material composite hydrogel and preparation method therefor | WO2019095751A1 WIPO | Cellulose | Zhang Han, Xing Chenyang, Chen Shiyou | 23 May 2019 | [67] |

| Cotton fiber dissolution and regeneration and 3D printing of cellulose-based conductive composites | US10311993B2 United States | Microcrystalline cellulose. | Noureddine Abidi, Yang Hu (Texas Tech University System) | 4 June 2019 | [68] |

| It is a kind of based on the dual network cellulose gel-based material being chemically and physically crosslinked | CN104448396B, China | Cellulose | Cai Jie, Li Kai, Zhao Dan, Zhang Lina | 16 June 2017 | [69] |

| Lithium-ion conductive material using bacterial cellulose organic gel, lithium-ion battery and bacterial cellulose airgel using the same | JP5110462B2, Japan | Bacterial cellulose | Shoichiro Yano, Takashi Sawaguchi, Shunki Hagihara, Hideaki Maeda, Ei Nakajima, Ichihiro Sasaki | 26 December 2012 | [70] |

| Manufacturing method of cellulose aerogel membrane | KR101494641B1 South Korea | Cellulose | Kim Chang-yeol, Go Eun-byeol | 24 February 2015 | [71] |

| Medical hydrogel | CN110072567B, China | Nanofibrillar cellulose | K. Luko M. Nopening (UPM Kymmene Oy) | 12 April 2022 | [72] |

| Method and apparatus for processing fibril cellulose and fibril cellulose product | EP2815026B1, European Patent Office | Nanofibrillar cellulose | Antti Laukkanen, Markus Nuopponen (UPM Kymmene Oy) | 16 June 2021 | [73] |

| Method for preparing amorphous cellulose aerogel with ionic liquid | CN102443188B China | Cellulose | Lu Yun Sun Qingfeng Liu Yixing Yu Haipeng Yang Dongjiang (Northeast Forestry University) | 13 March 2013 | [74] |

| Method for processing nanofibrillar cellulose | CA2824125C, Canada | Nanofibrillar cellulose | Antti Laukkanen, Jan-Erik Teirfolk, Markus Nuopponen (UPM Kymmene Oy) | 7 May 2019 | [75] |

| Method for producing a gel-based composite material | JP6224175B2, Japan | Cellulose fibers | Patrick A, Sea, Gain Michelle, Cienkar Lambsey, Subra Manian Joachim, Ciel Kotup | 1 November 2017 | [76] |

| Method for producing nanofibril cellulose gel | JP6698236B1, Japan | Nanofibril Cellulosic fibers | Patrick, A, Sea, Gain Joachim, Ciel Kotup Daniel, Gantenbain Michel Cienker | 27 May 2020 | [77] |

| Method for producing nanofibrillar cellulose and nanofibrillar cellulose product | US11274396B2 United States | Nanofibrillar cellulose | Markus Nuopponen, Juha Tamper, Isko Kajanto (UPM Kymmene Oy) | 15 March 2022 | [78] |

| Methods for Making Structured Materials Using Nanofibril Cellulose Gel | JP7033105B2, Japan | Cellulose fibers | Patrick A, Sea, Gain Michelle, Cienkar Lambsey, Subra Manian Joachim, Ciel Kotup | 9 March 2022 | [79] |

| Nanofibrillar cellulose composition | US10729804B2 United States | Nanofibrillar cellulose | Marjo Yliperttula, Patrick Lauren, Petter Somersalo, Yanru Lou (UPM Kymmene Oy) | 4 August 2020 | [80] |

| Nanofibrillar polysaccharide for use in the control and prevention of contraction and scarring | EP2958599B1 European Patent Office | Nanofibrillar cellulose | Antti Laukkanen, Esko Kankuri, Kristo Nuuutila (UPM Kymmene Oy) | 16 November 2016 | [81] |

| Porous cellulose gel, method for producing the same, and use thereof | US9446382B2, United States | Crosslinked spherical crystalline cellulose particles | Yasuto Umeda, Yasuo Matsumoto, Masami Shiina, Masami Todokoro, Yoshihiro Matsumoto (JNC Corp) | 20 September 2016 | [82] |

| Regenerated cellulose film, functional film and preparation method thereof | EP3064534B1 European Patent Office | Regenerated cellulose | Jun Zhang, Xiaoyu Zhang, Jian Yu, Ruifeng Li, Jin Wu, Yugang GAO, Jinming Zhang, Jinjiang QIU (Inst of Chemistry Chinese Academic of Sciences, Institute of Chemistry of CAS) | 20 October 2021 | [83] |

| Transparent cellulose hydrogel and production process thereof | US5962005A United States | Regenerated cellulose | Hiroshi Saga, Hidenao Saito (Rengo Co Ltd.) | 10 May 1999 | [84] |

| Wound healing compositions comprising biocompatible cellulose hydrogel membranes and methods of use thereof | US9314531B2 United States | Microcrystalline cellulose and bacterial cellulose, | Morgana M. Trexler, Jennifer H. Elisseeff, Daniel Mulreany, Qiongyu Guo, Jennifer L. Breidenich, Jeffrey P. Maranchi, Jenna L. Graham, Julia B. Patrone, Marcia W. Patchan, Xiomara Calderon-Colon (Johns Hopkins University) | 19 April 2016 | [85] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tofanica, B.-M.; Belosinschi, D.; Volf, I. Gels, Aerogels and Hydrogels: A Challenge for the Cellulose-Based Product Industries. Gels 2022, 8, 497. https://doi.org/10.3390/gels8080497

Tofanica B-M, Belosinschi D, Volf I. Gels, Aerogels and Hydrogels: A Challenge for the Cellulose-Based Product Industries. Gels. 2022; 8(8):497. https://doi.org/10.3390/gels8080497

Chicago/Turabian StyleTofanica, Bogdan-Marian, Dan Belosinschi, and Irina Volf. 2022. "Gels, Aerogels and Hydrogels: A Challenge for the Cellulose-Based Product Industries" Gels 8, no. 8: 497. https://doi.org/10.3390/gels8080497